Patents

Literature

84results about How to "Guaranteed productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic spraying system coordinate transform method based on point cloud and image matching

ActiveCN106651894AReduce downtimeShorten the timeImage enhancementImage analysisProduction ratePoint cloud

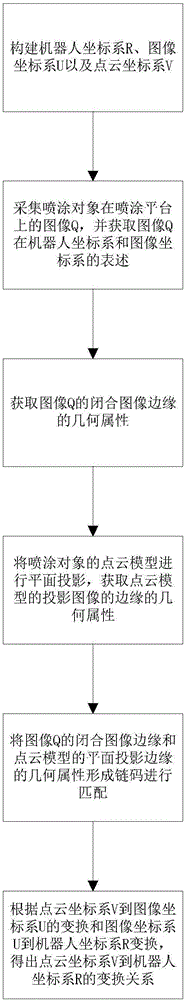

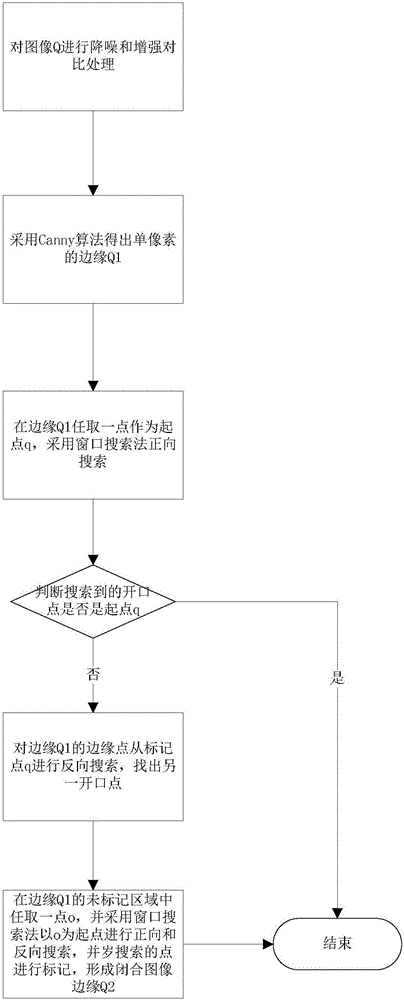

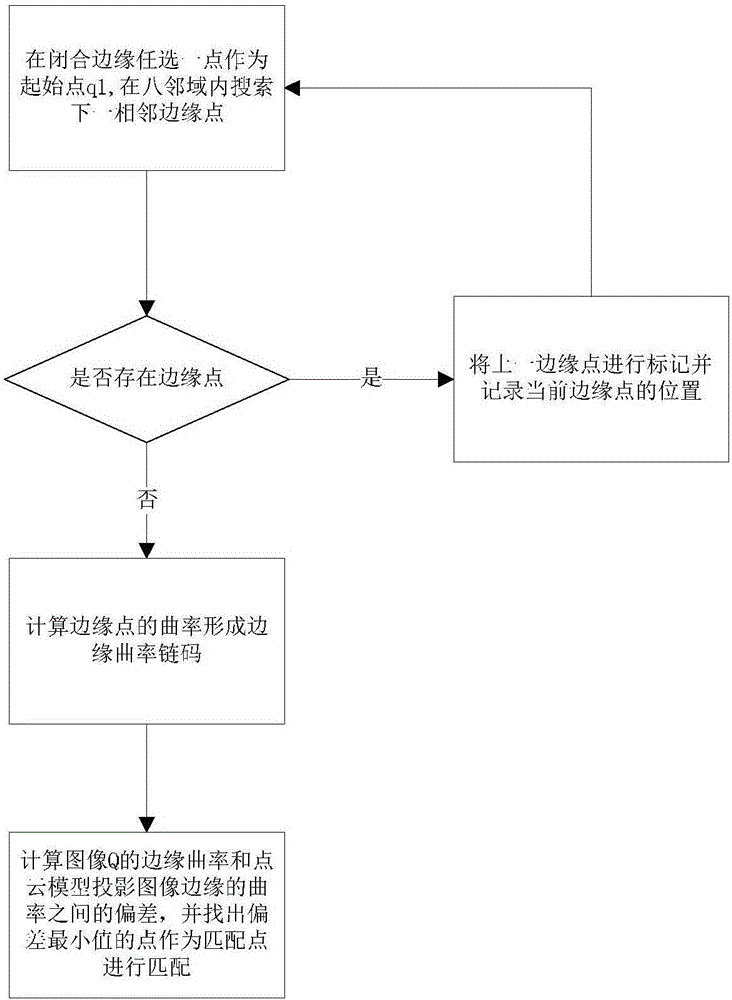

The invention provides an automatic spraying system coordinate transform method based on point cloud and image matching. The method comprises the steps of building a robot coordinate system R, an image coordinate system U and a point cloud coordinate system V; collecting an image Q of a spraying object on a spraying platform, and acquiring description of the spraying object in the robot coordinate R, wherein RQ is equal to RTUUQ; acquiring geometric attributes of the closed image edge of the image Q; acquiring geometric attributes of the edge of the projection of a point cloud model; forming the geometric attributes of the closed image edge of the image Q and the geometric attributes of the edge of the planar projection of the point cloud model into chain codes and matching with each other, and acquiring a transformation relation from the point cloud coordinate system V to the robot coordinate system R according to transformation from the point cloud coordinate system V to the image coordinate system U and transformation from the image coordinate system U to the robot coordinate system. According to the method provided by the invention, a calculation amount can be effectively reduced, time consumed during a path planning process of a spraying robot is shortened, efficiency is improved, downtime of the spraying robot is effectively reduced, and productivity is ensured.

Owner:CHONGQING UNIV

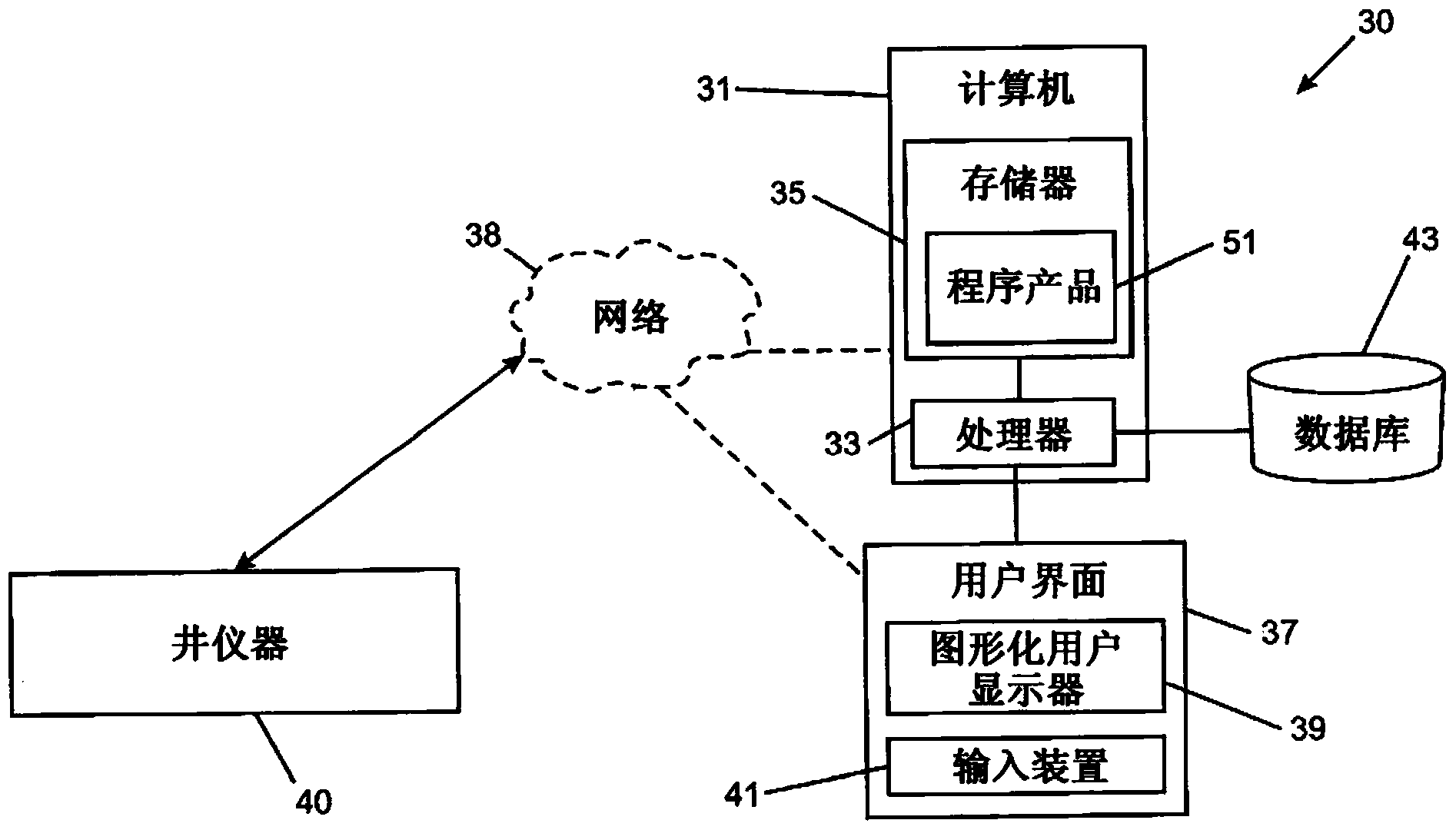

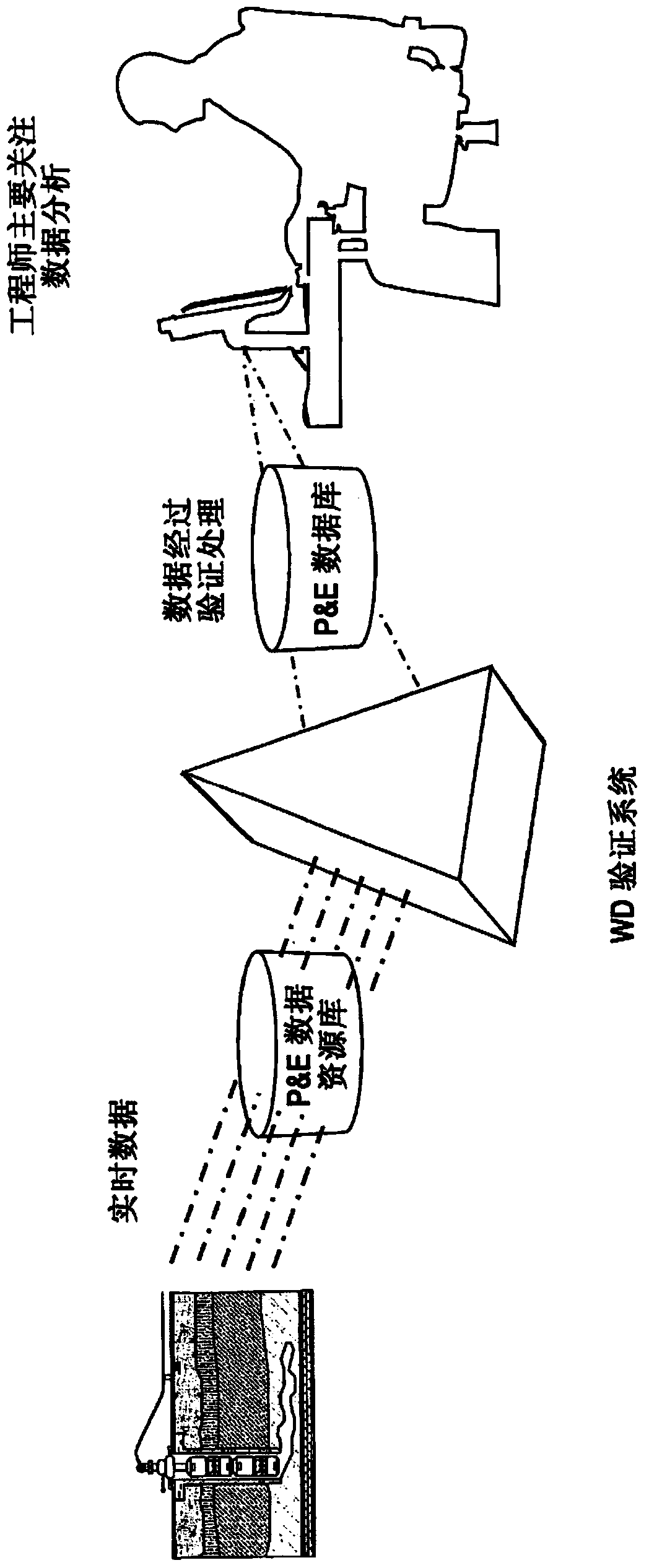

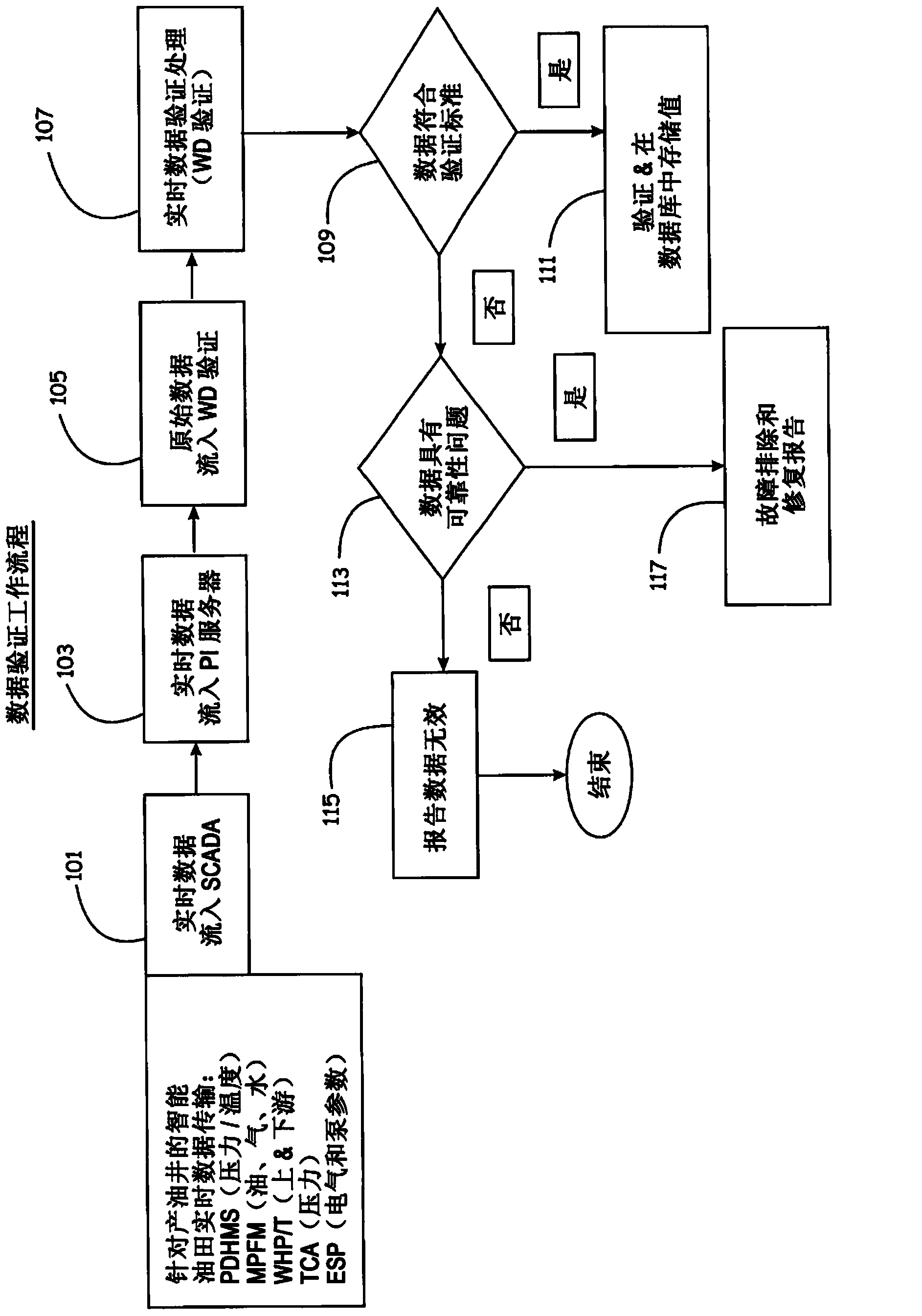

Real-time dynamic data validation apparatus, system, program code, computer readable medium, and methods for intelligent fields

ActiveCN104093931AImprove work efficiencySimple designSurveyFluid removalData validationDynamic field

Owner:SAUDI ARABIAN OIL CO

Multifunctional nanoparticles for downhole formation treatments

ActiveCN101644151AHigh viscosityEasy to removeFluid removalSealing/packingParticulatesMultifunctional nanoparticles

An aqueous, viscoelastic fluid gelled with a viscoelastic surfactant (VES) is stabilized and improved with an effective amount of an alkaline earth metal oxide alkaline earth metal hydroxide, alkali metal oxides, alkali metal hydroxides transition metal oxides, transition metal hydroxides, post-transition metal oxides, and post-transition metal hydroxides. These fluids are more stable and have a reduced or no tendency to precipitate, particularly at elevated temperatures, and may also help control fluid loss. When the particle size of the magnesium oxide or other particulate agent is a nanometer scale, for instance having a mean particle size of 100 nm or less, that scale may provide unique particle charges that use chemisorption, ''crosslinking'' and / or other chemistries to associate and stabilize the VES fluids, and also help trap or fixate formation fines when deposited into a proppant pack in a fracture.

Owner:BAKER HUGHES INC

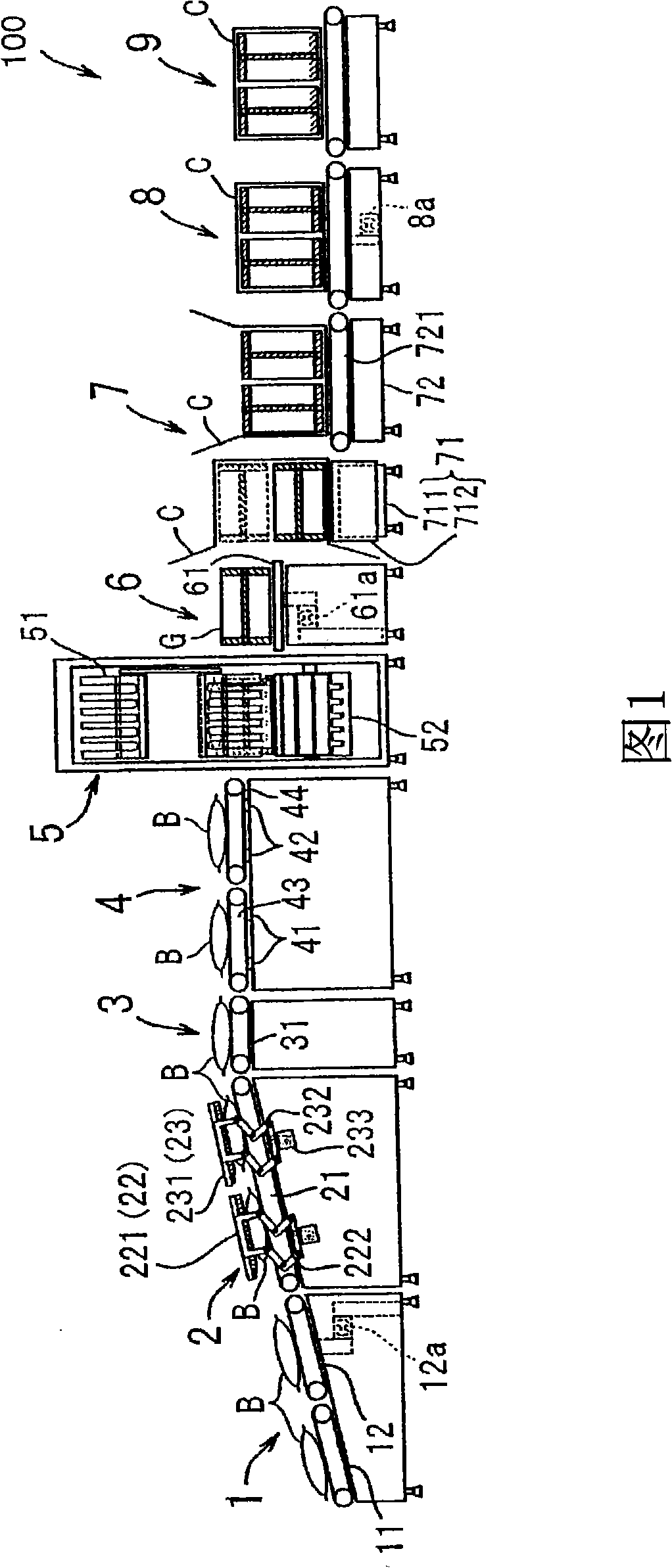

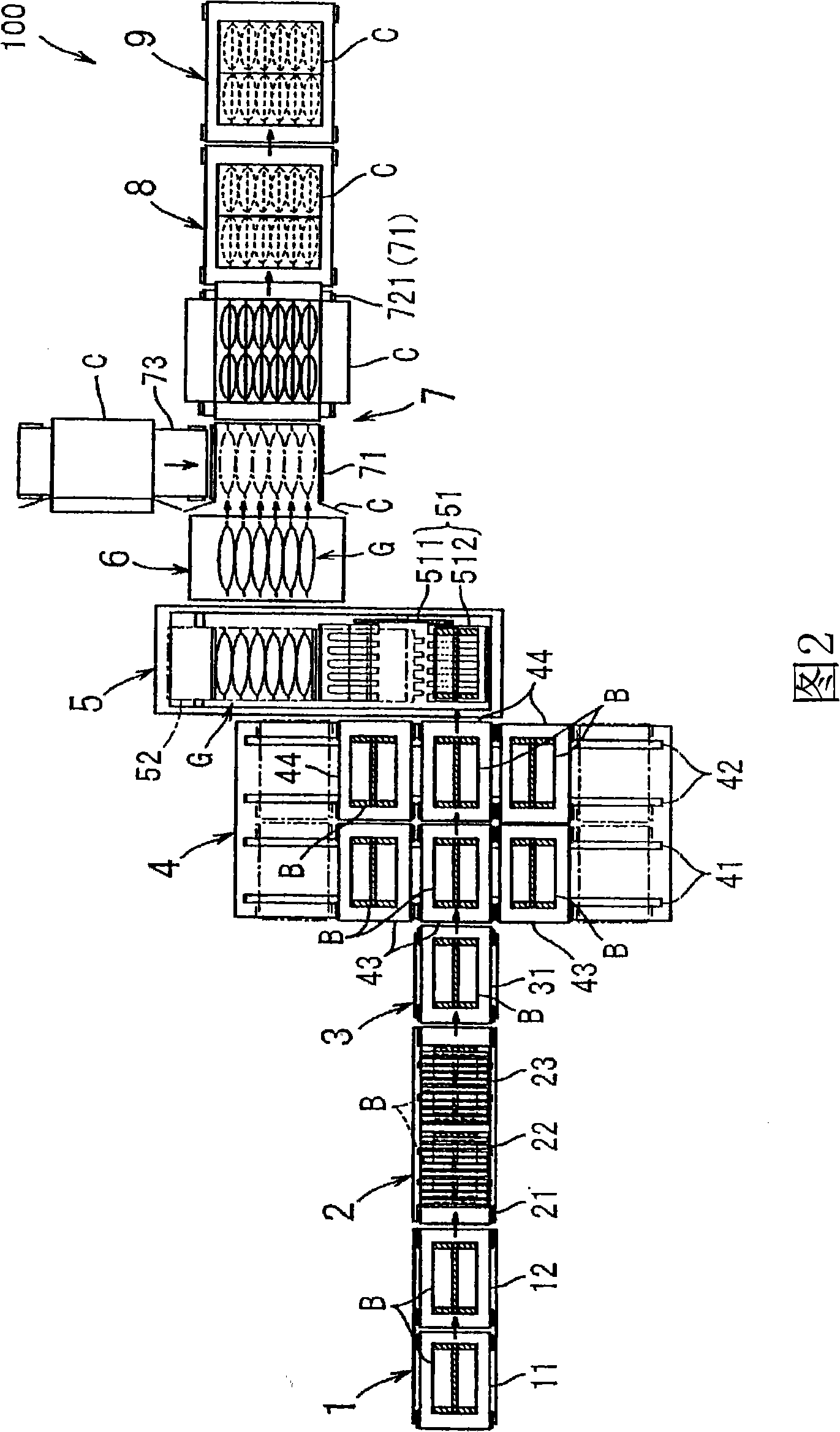

Boxing apparatus and packaging apparatus

InactiveCN101516731AReduce wasteWeight judgmentFluid-tightness measurement by detecting dimension changeMaterial check-weighingProduction lineEngineering

Owner:ISHIDA CO LTD

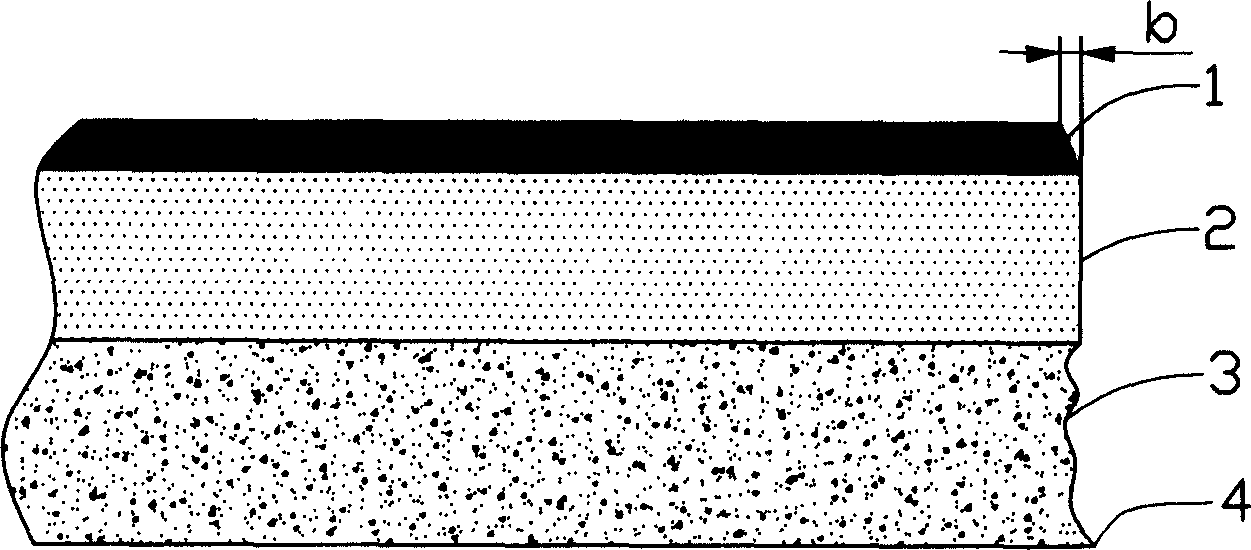

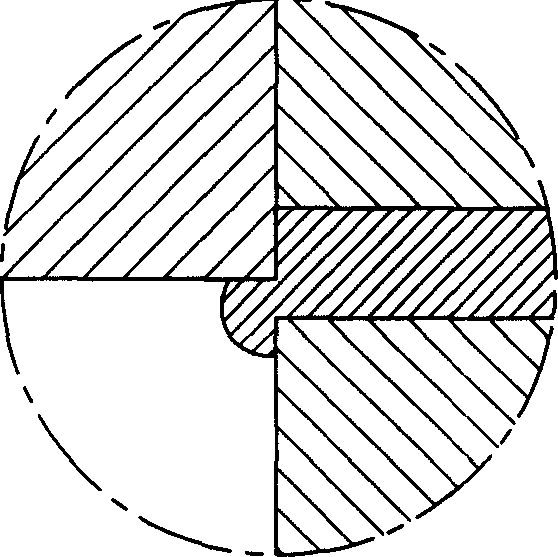

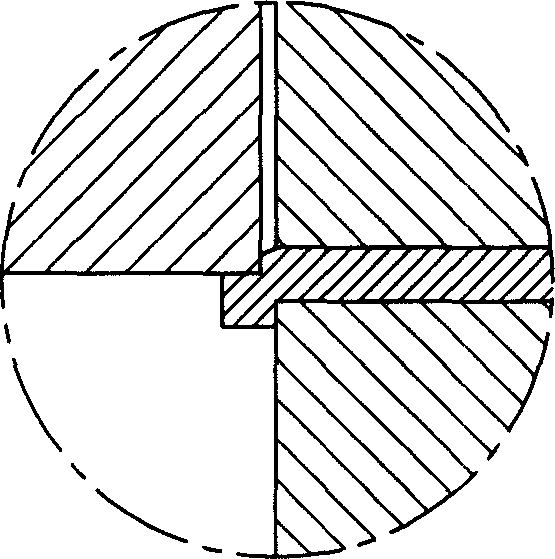

Metal plate punching process

InactiveCN1672830AReduce high costLow costShearing machinesMetal working apparatusPunchingEdge structure

The metal plate punching process has reasonable selection and design of punching interval, punching allowance, punching force and punching die edge structure to obtain high precision cross section quality of the punched part. The punching process may include once coarse punching and one or several times of finish punching, the coarse punching has parameter values similar to those of common punching process, and once finish punching has single side punching gap not greater than 0.5T%, where T is the material thickness. During several times of finish punching, the total single side punching allowance not smaller than the sunk angle width produced in the coarse punching, the punching die edge has one angle and one tangent arced notch to avoid the accumulation of cutting allowance, and the force is 10-30 MPa.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

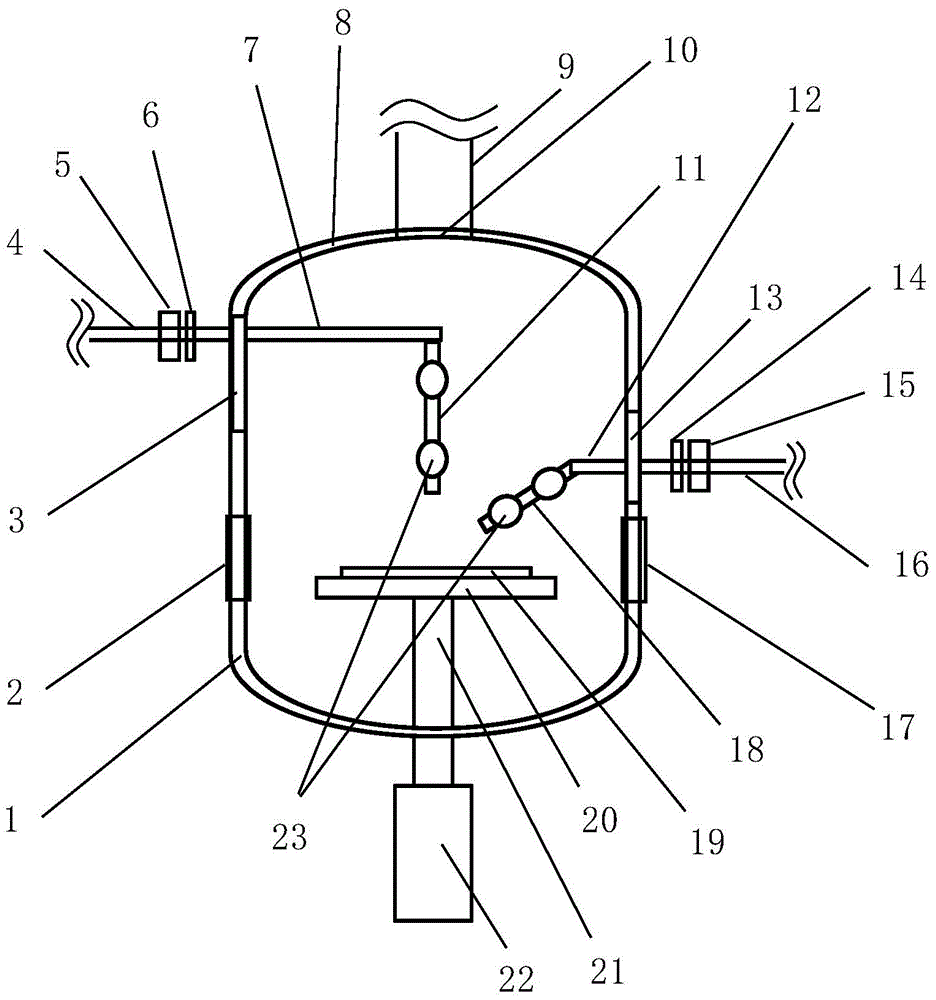

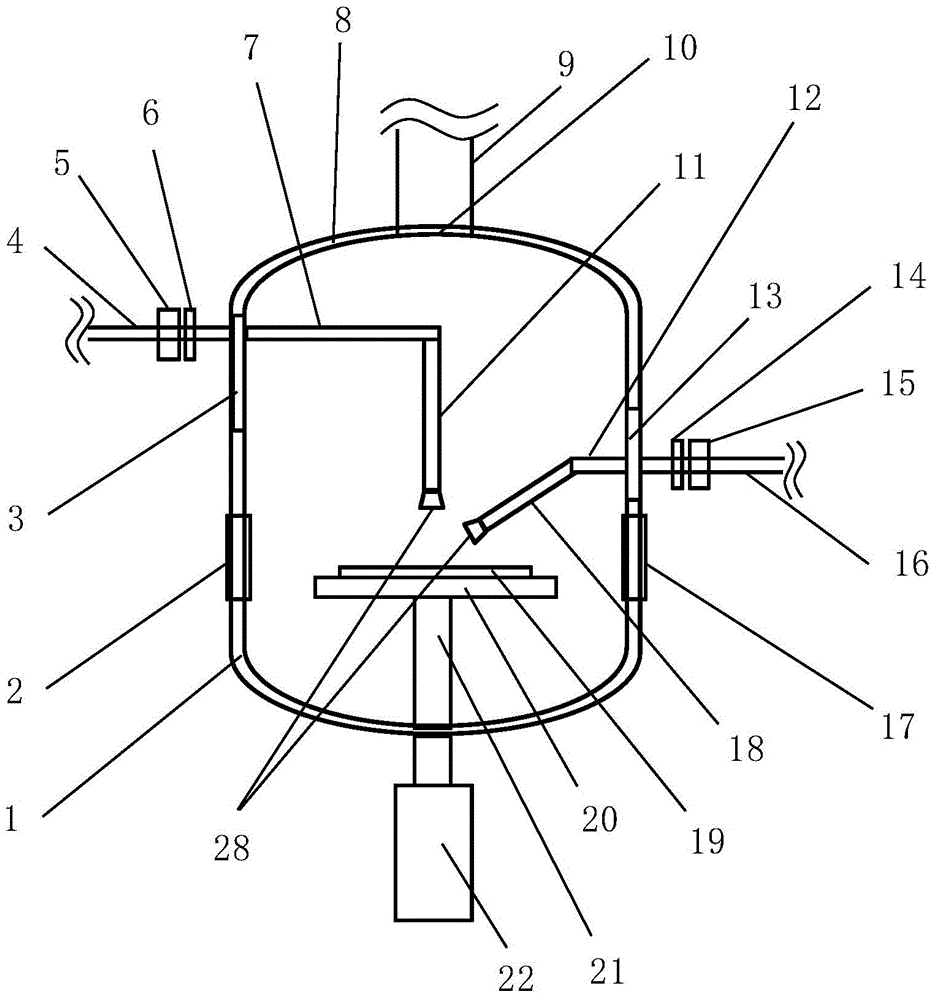

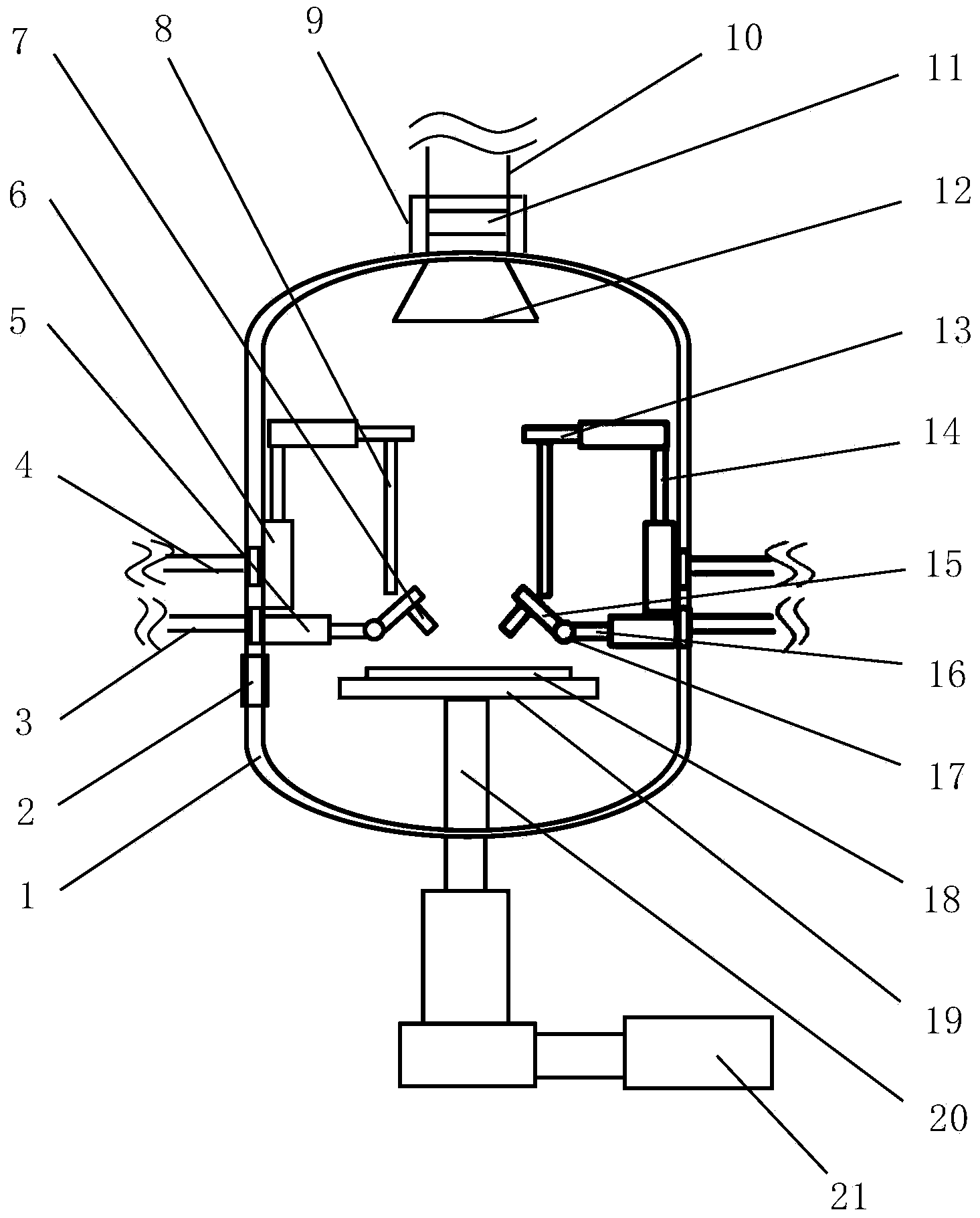

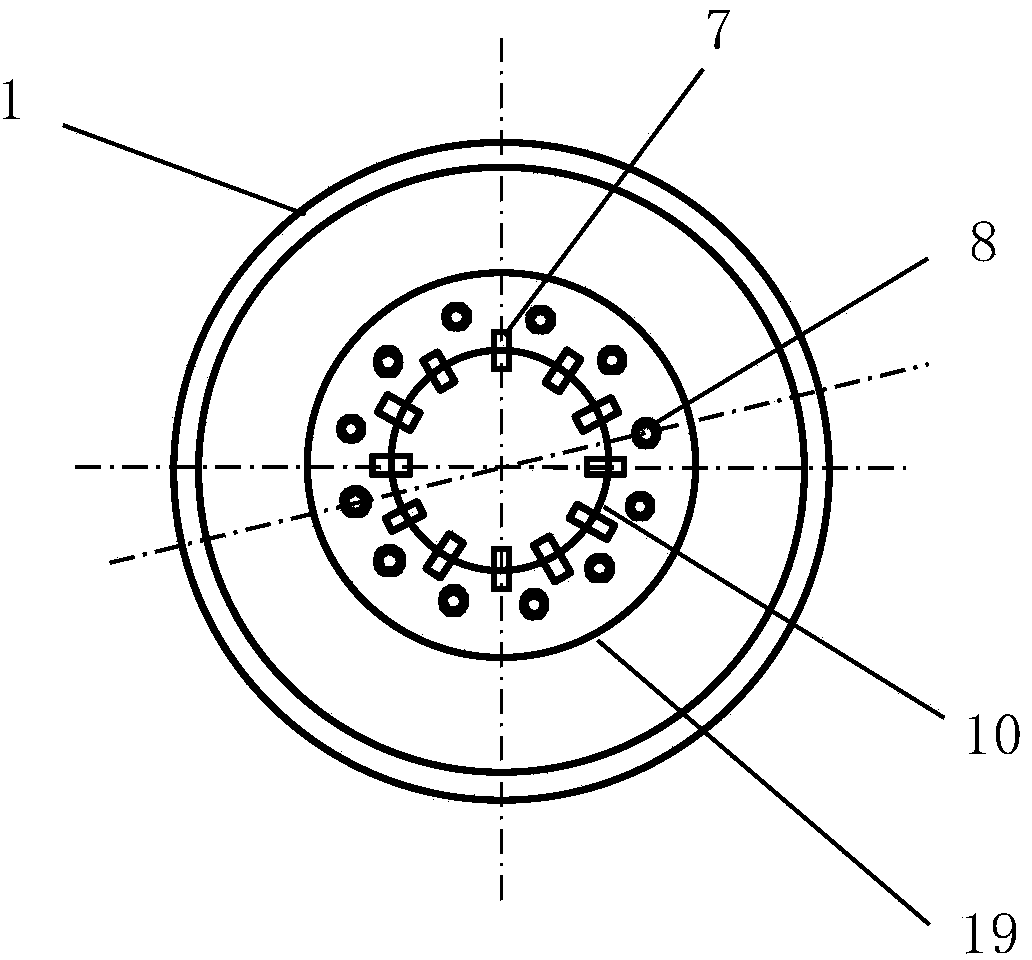

Wafer purifying equipment for eliminating etching byproduct coagulation defect of connecting hole

ActiveCN104091776AAchieve removalEfficient removalSemiconductor/solid-state device manufacturingEtchingCoagulation defects

The invention discloses wafer purifying equipment for eliminating an etching byproduct coagulation defect of a connecting hole. The wafer purifying equipment is used for purifying a wafer after connecting hole etching is carried out on the wafer and before cleaning, spraying guns are arranged in a cavity of the wafer purifying equipment in different directions, and can simultaneously spray purifying gas to the wafer on a rotating wafer supporting platform, a dome-shaped exhaust pipe above the cavity and in the center of the inner wall exhausts the purified gas and etching byproducts carried by the purified gas in the cavity, and the purifying effect can be further improved through a gas stirring device or spraying nozzle arranged on each spraying gun. The wafer purifying equipment not only avoids damage to the wafer, especially for a CD, but also can eliminate etching byproducts attached to the wafer, thereby eliminating the coagulation defect generated by reaction of the etching byproducts and water when the etching byproducts wait to be cleaned.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

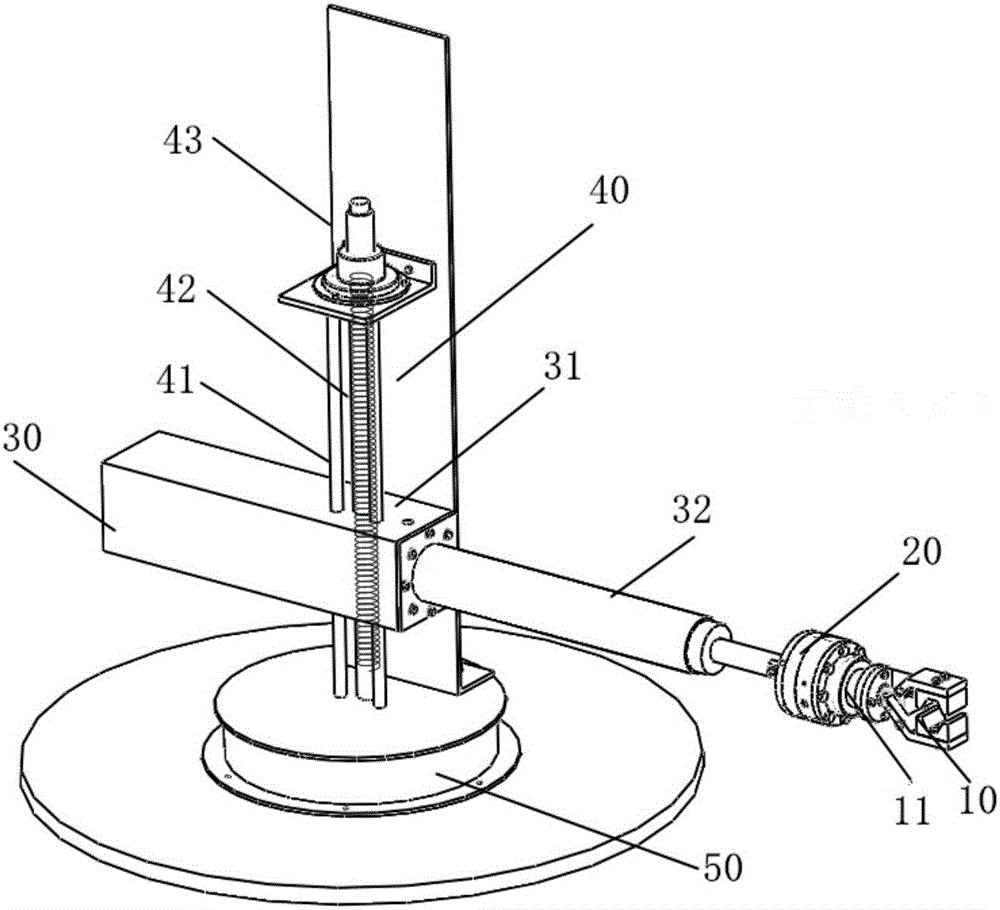

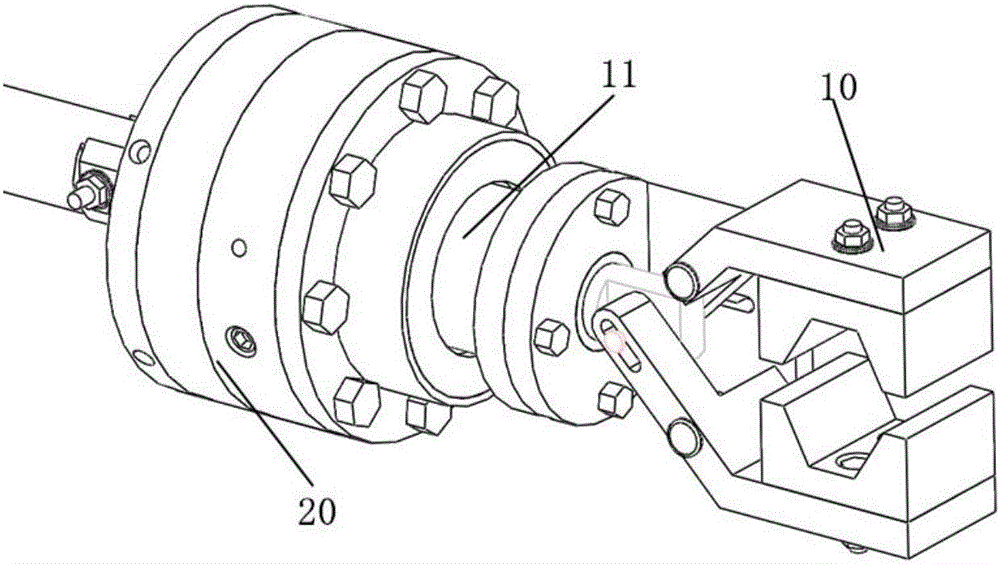

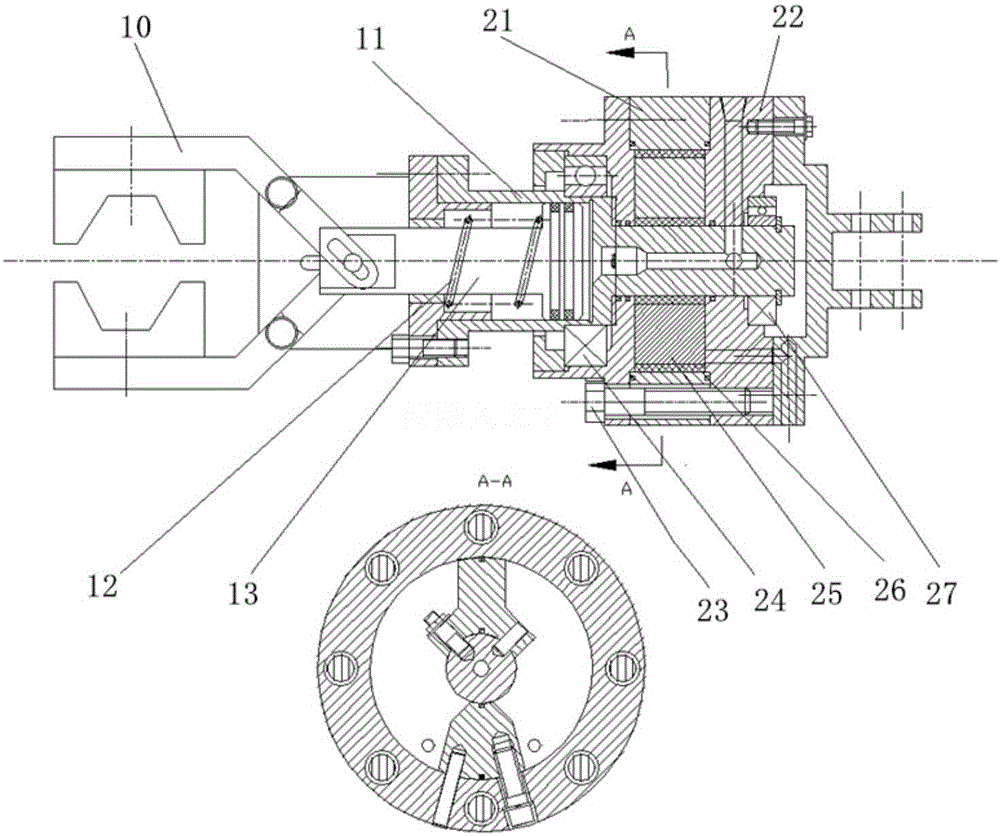

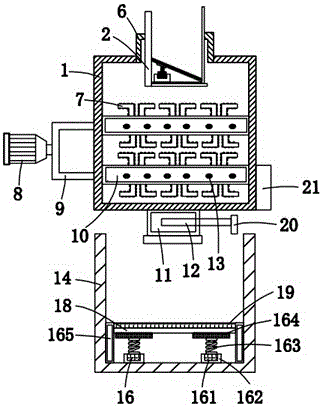

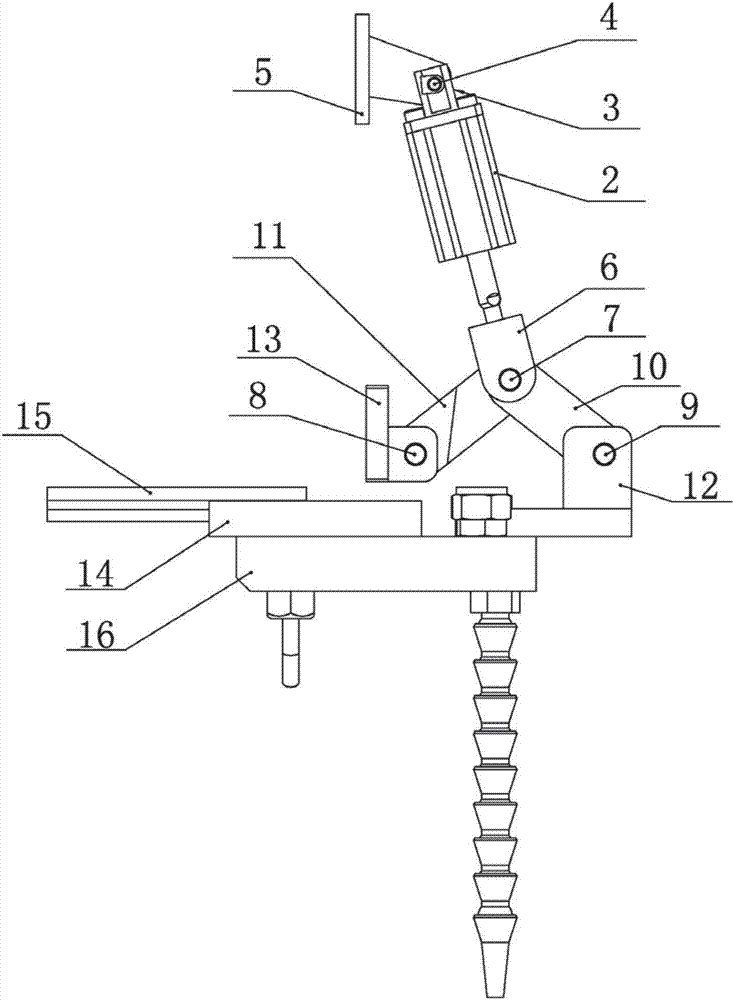

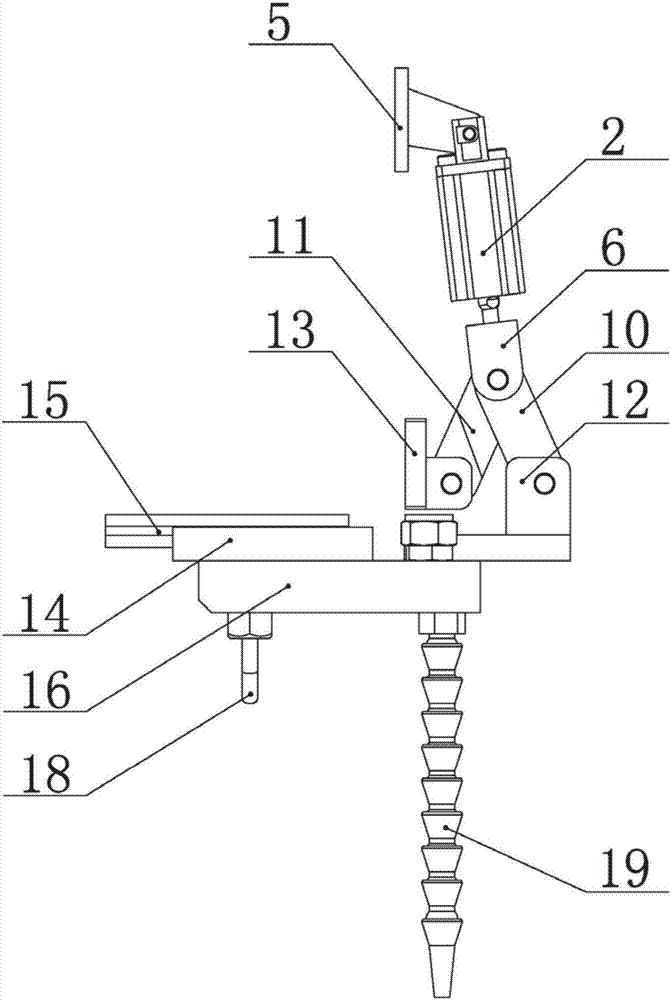

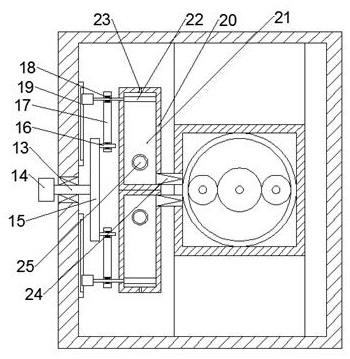

Feeding manipulator for stamping

InactiveCN106514640AGuaranteed productivitySave human effortProgramme-controlled manipulatorGripping headsManipulatorMulti degree of freedom

The invention discloses a feeding manipulator for stamping. The feeding manipulator comprises an actuating mechanism, a driving mechanism and a control system, wherein the actuating mechanism comprises a hand, a wrist, a telescopic arm, an engine body and an engine base; the hand and the telescopic arm are connected through the wrist; the telescopic arm is mounted on the engine body; the engine body is mounted on the engine base; the driving mechanism performs driving action by adopting a hydraulic driving method, and comprises a hand grasping hydraulic cylinder, a wrist rotating hydraulic cylinder and a telescopic arm extending-retracting hydraulic cylinder; and the control system is designed to control the feeding manipulator by adopting a PLC program. The feeding manipulator disclosed by the invention serves as a multi-degree-of-freedom automatic feeding manipulator; by adoption of the feeding manipulator, the mechanization and the automated production of stamping equipment can be achieved; and the advantages of lower manpower consumption, production safety and the like can be guaranteed when the productivity is guaranteed.

Owner:HOHAI UNIV CHANGZHOU

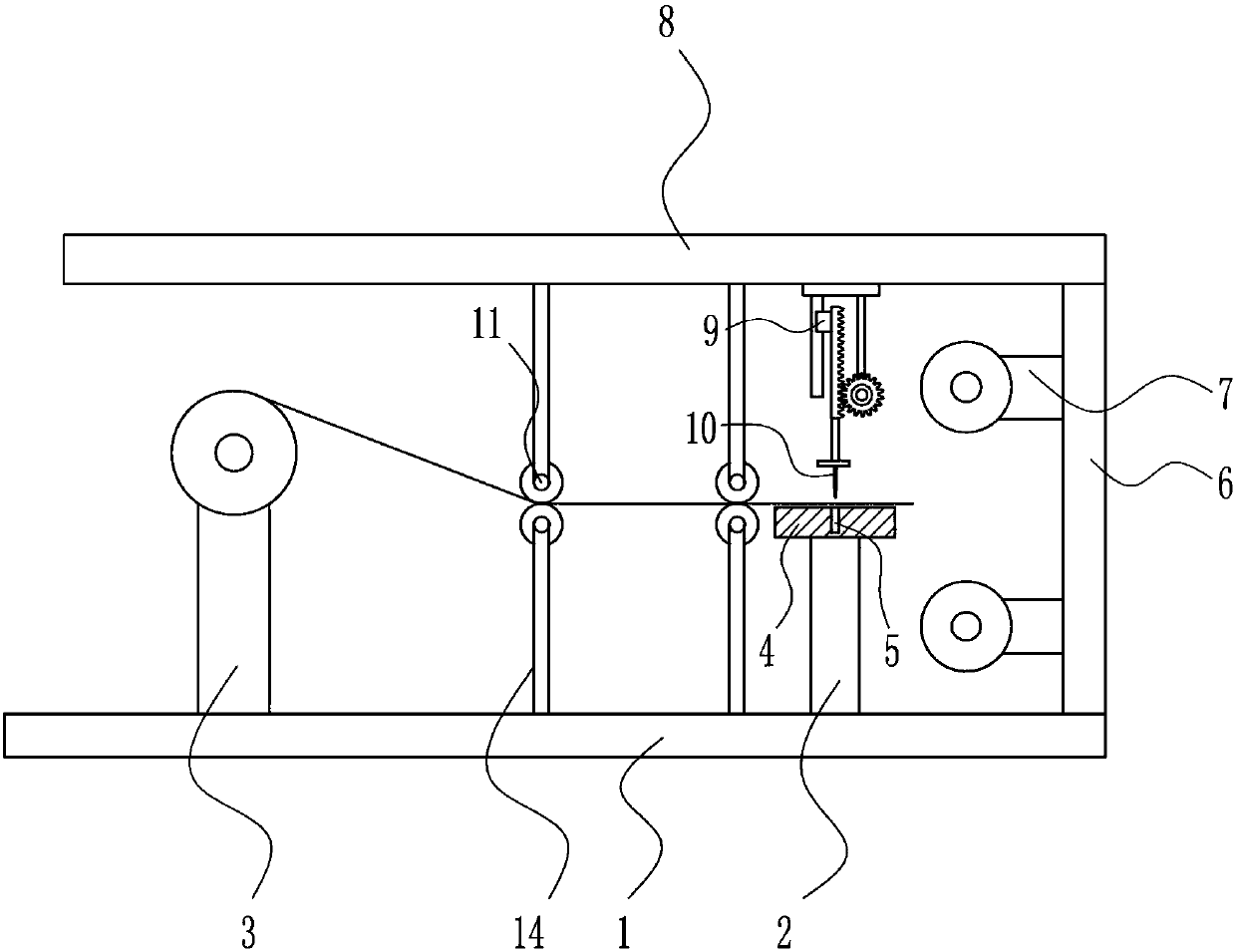

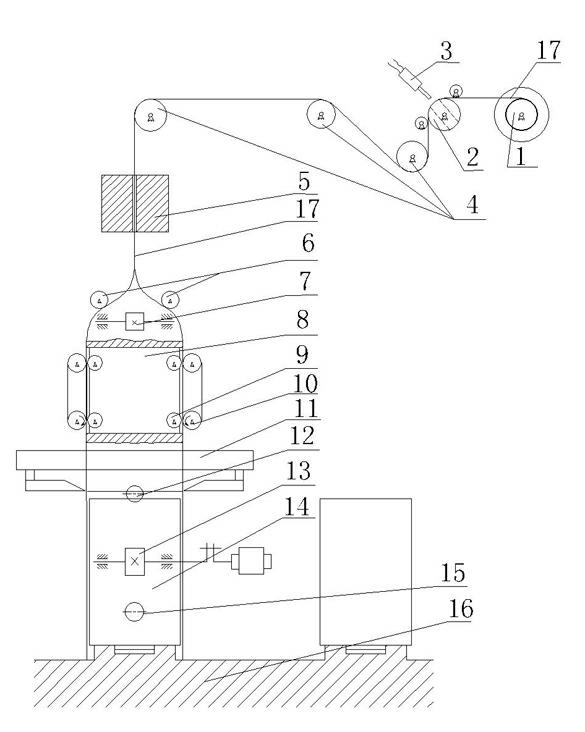

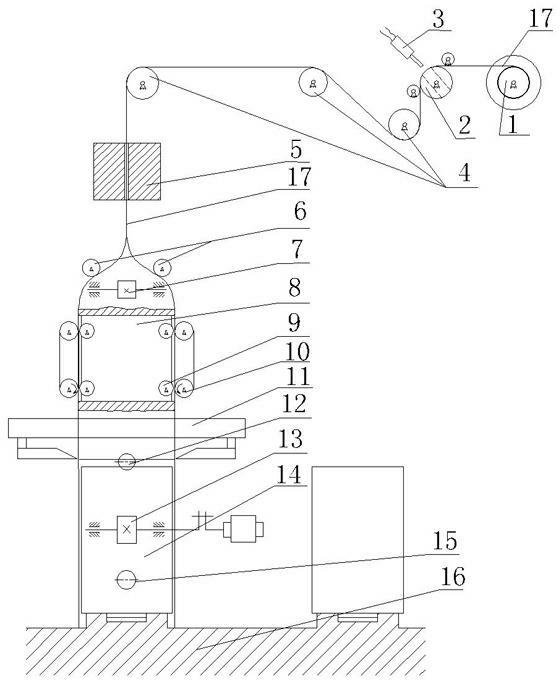

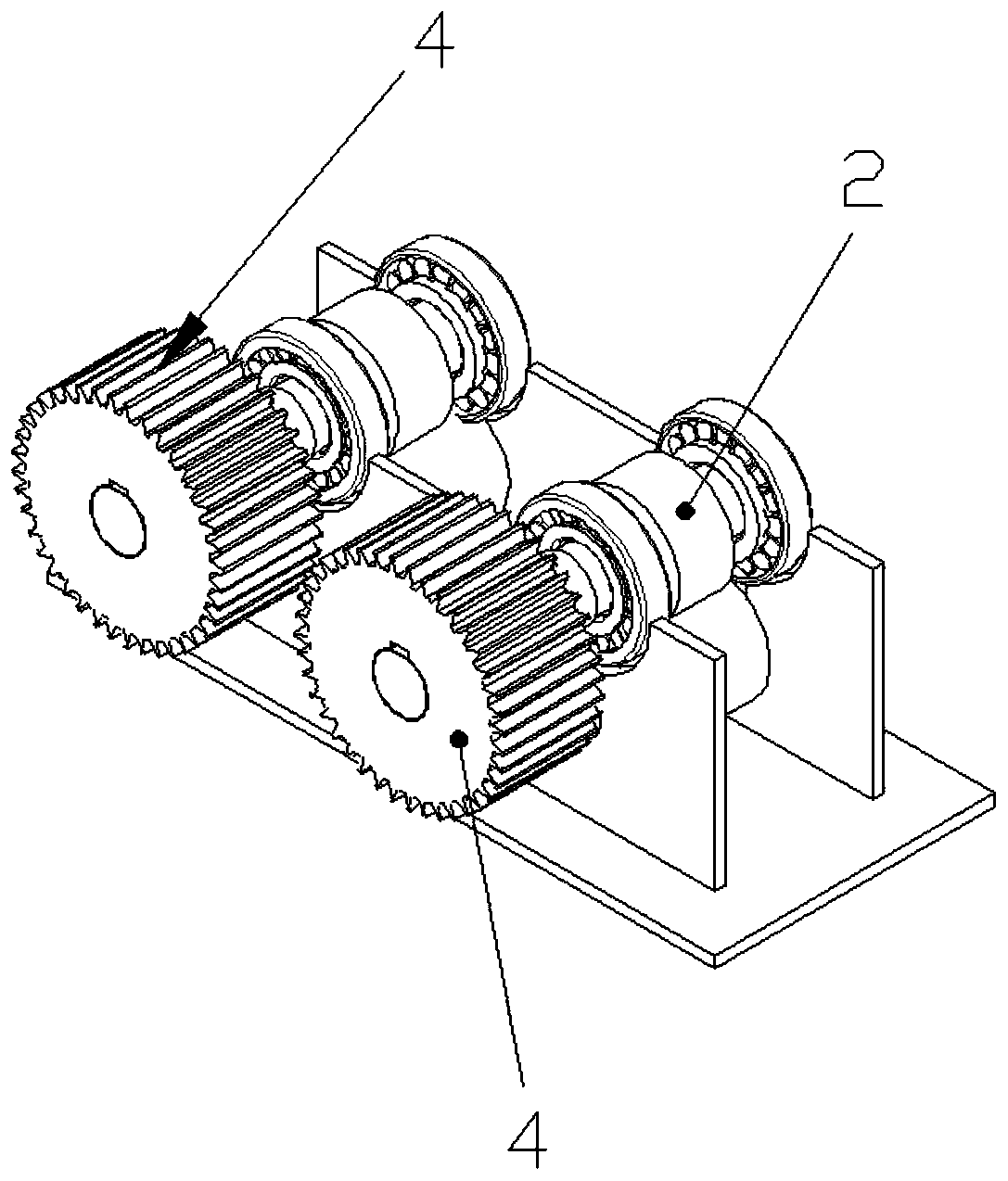

Rapid shunt winding device for copper wire of power line

The invention relates to shunt winding devices, in particular to a rapid shunt winding device for a copper wire of a power line. According to the rapid shunt winding device for the copper wire of thepower line, production is fast, the efficiency is high, and the labor cost is low. The rapid shunt winding device for the copper wire of the power line comprises a bottom plate, a supporting seat, a wire feeding mechanism, a cutting table, a side plate, wire winding mechanisms, a top plate and the like. A cutting groove is formed in the cutting table; the wire winding mechanisms are fixedly connected to the side part, close to the supporting seat, of the side plate; the top plate is fixedly connected to the top of the side plate; a lifting mechanism is fixedly connected to the bottom of the top plate and located over the cutting table; and a cutting blade is fixedly connected to the output end of the lifting mechanism. Through matching of the wire feeding mechanism, the wire winding mechanisms and the lifting mechanism, the rapid shunt winding effect is achieved; and by applying the rapid shunt winding device, the production rate is guaranteed, the labor cost is reduced, and the production quality is further improved.

Owner:刘同海

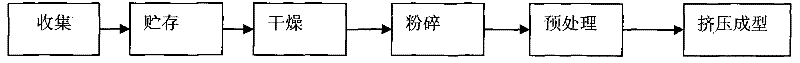

Method for producing shaped fuel from tobacco stalk biomass

The invention discloses a method for producing shaped fuel from tobacco stalk biomass, and relates to a utilization method of tobacco stalk biomass. The method comprises steps that: (1) raw materials are collected, (2) the raw materials are stored, (3) the raw materials are dried, (4) the raw materials are crushed, (5) the raw materials are pretreated, and (6) the treated material is shaped through extrusion. According to the invention, complete technology for producing tobacco stalk biomass shaped fuel is provided. According to the technology, all root part tobacco stalks, which have high heat value and relatively large soil content, are utilized as energy. The method provided by the invention is characterized in that: the fuel is tobacco stalk biomass shaped fuel, which satisfies a requirement of clean energy; collection of tobacco stalks is convenient and feasible; production technology is economic and reasonable, and the cost is low; produced biomass shaped fuel can be used in various heating apparatuses for purposes such as tobacco leaf baking.

Owner:贵州省烟草公司毕节地区公司

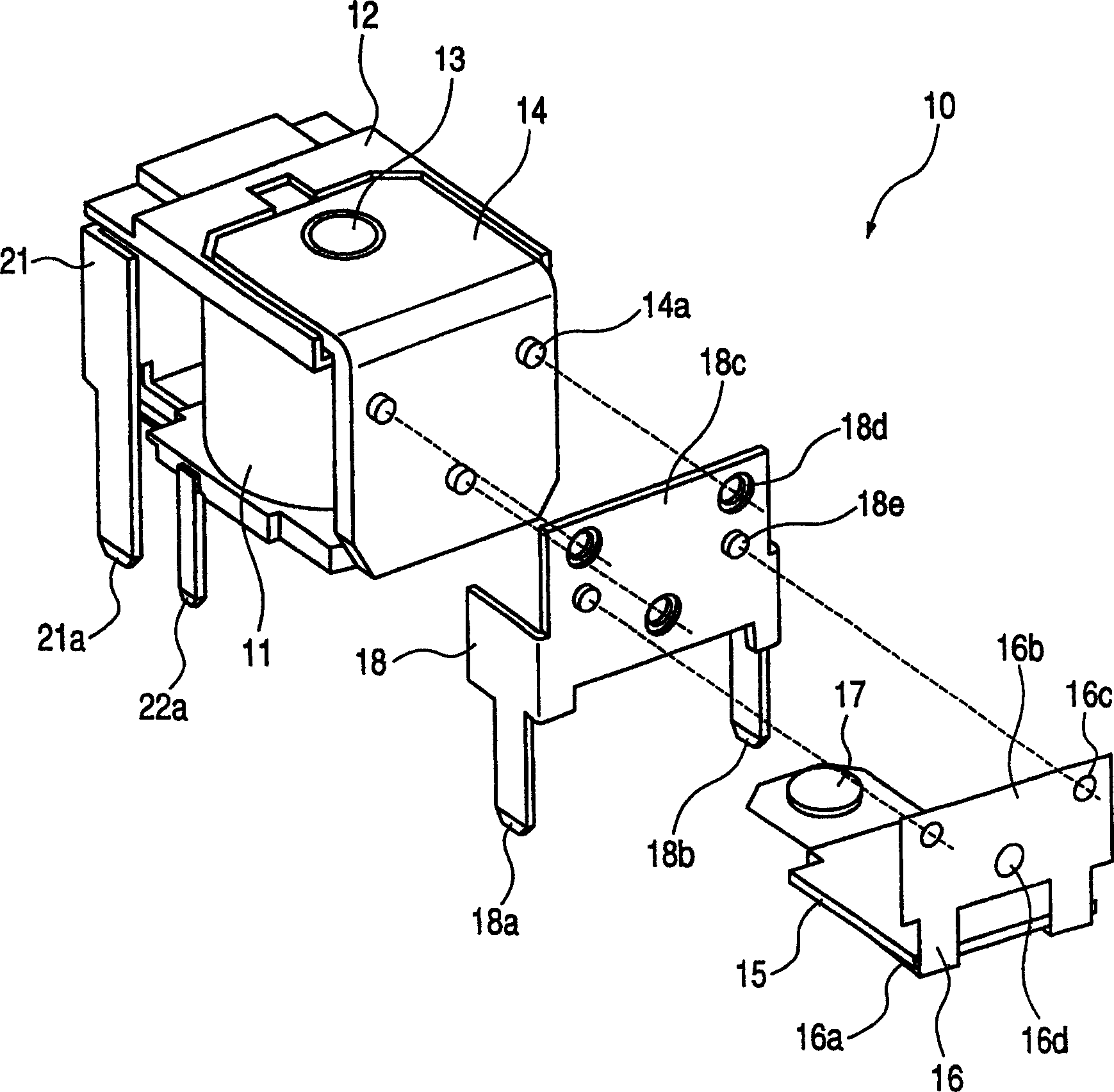

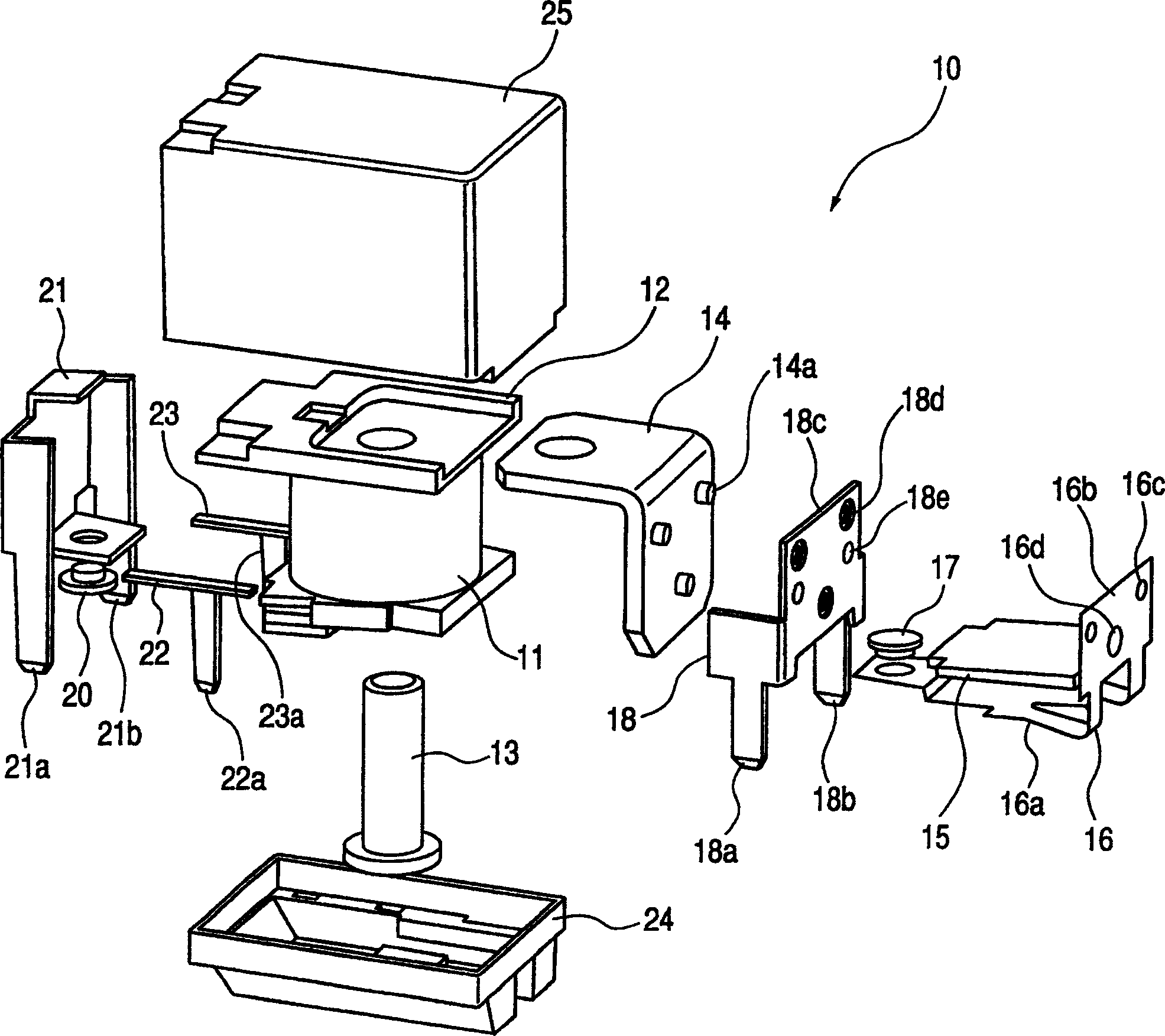

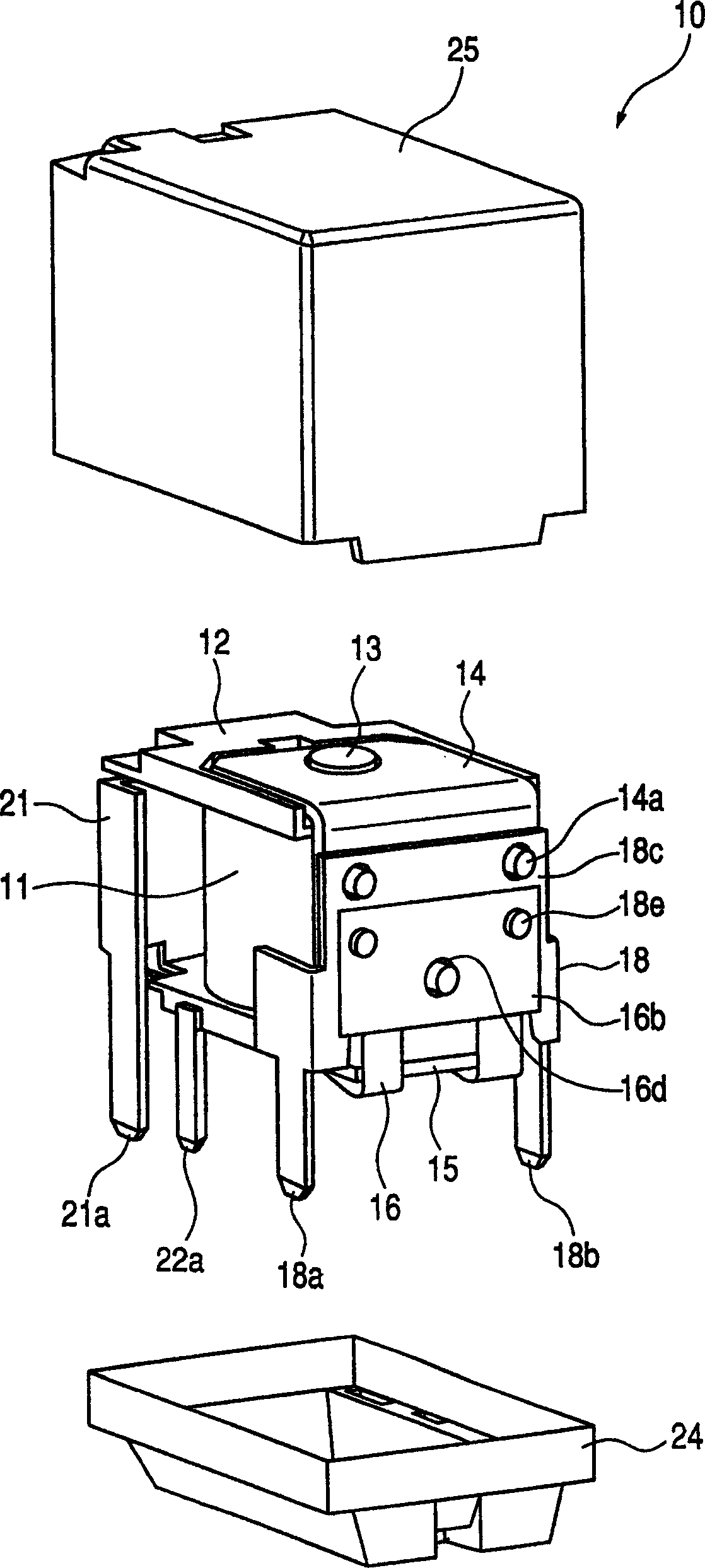

Electromagnetic relay

InactiveCN1503296AImprove thermal conductivityIncrease the cross-sectional areaElectromagnetic relay detailsEngineeringRivet

A small-sized electromagnetic relay which can afford high current and dissipate generated heat efficiently is disclosed. A plate section 18c for coupling to one side of a yoke 14 is formed on a movable contact terminal 18. Countersunk rivet features at three or more positions which are not aligned on a line on the plate section 18c couple the movable contact terminal 18 to the yoke 14. A base end 16b of a movable contact spring 16 is coupled to the surface of the plate section 18c opposite to the yoke 14 to support the movable contact spring 16. In the countersunk rivet feature, each protrusion 14a formed on the yoke 14 is inserted into the corresponding countersunk hole 18d formed on the plate section 18c, respectively, and the tops of the protrusions 14a are crushed to expand its diameter so as to sandwich the plate section 18c against the yoke 14.

Owner:ORMON CORP

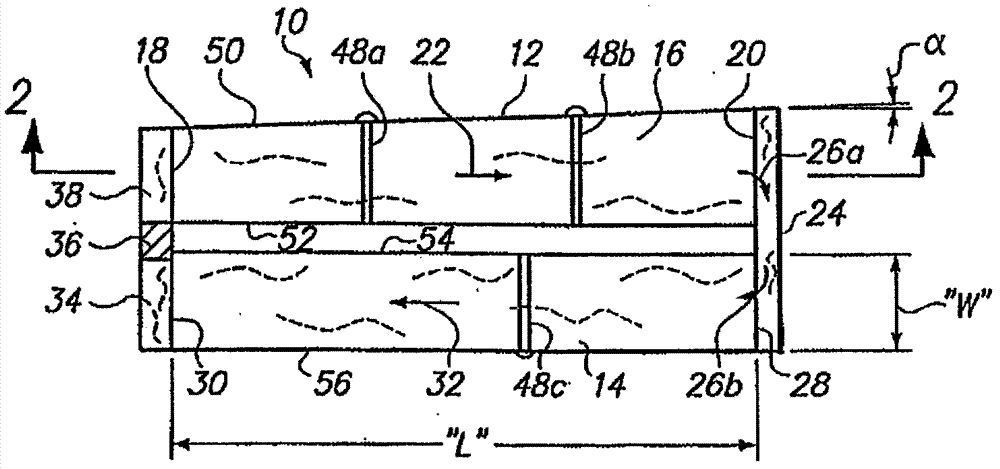

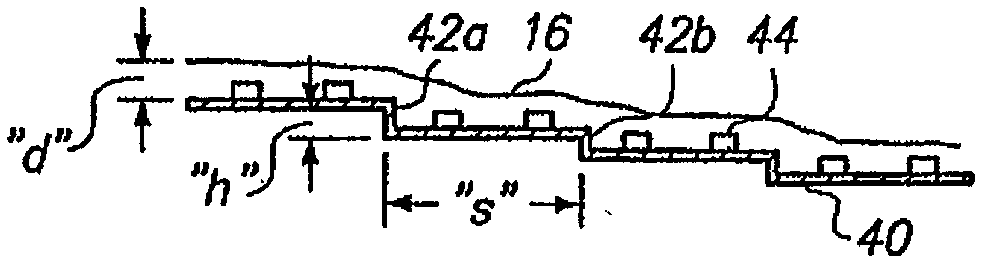

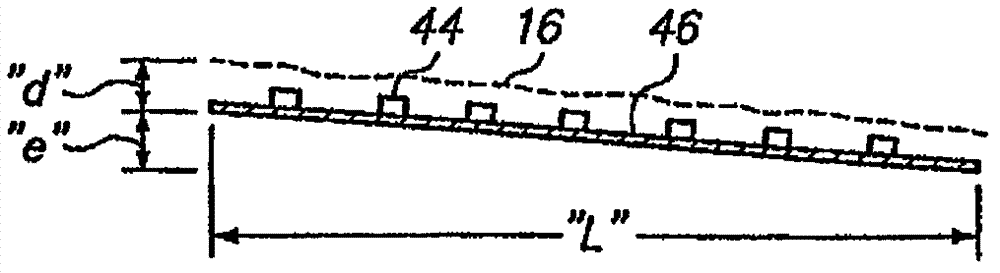

Microalgae growth pond design

InactiveCN103096708AGuaranteed productivityBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringMicroalgae growth

A raceway pond for circulating microalgae in a fluid medium includes a plurality of interconnected channels. Each channel is straight and has a structured gradient, due to tilt or terracing, that moves the fluid medium along the raceway. In operation, the concentration of microalgae in the fluid medium is maintained substantially constant, and the depth of the fluid medium in the raceway is maintained below a pre-determined level.

Owner:GENERAL ATOMICS

Wafer purifying chamber for improving defect of coagulation of etching by-products

InactiveCN104078398AAchieve removalEliminate Condensate DefectsSemiconductor/solid-state device manufacturingEtchingExhaust pipe

The invention discloses a wafer purifying chamber for improving the defect of coagulation of etching by-products. The wafer purifying chamber is used for conducting pre-purification treatment on a wafer after the wafer is etched and before the wafer is washed; purifying gas can be jetted simultaneously to the wafer in different directions at adjustable angles and distances through a plurality of top jetting guns and a plurality of side-wall jetting guns, which are arranged in the chamber body of the wafer purifying chamber and around the vertical center of the chamber body; used gas in the chamber body and etching by-products carried by the used gas are exhausted through an exhaust pipe at the top of the chamber body. Through the application of the wafer purifying chamber provided by the invention, not only can damage to the wafer, especially to a CD, be avoided, but also the etching by-products attached to the wafer can be avoided, so that the defect of coagulum produced by reaction of the etching by-products and water in a cleaning waiting process is eliminated.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

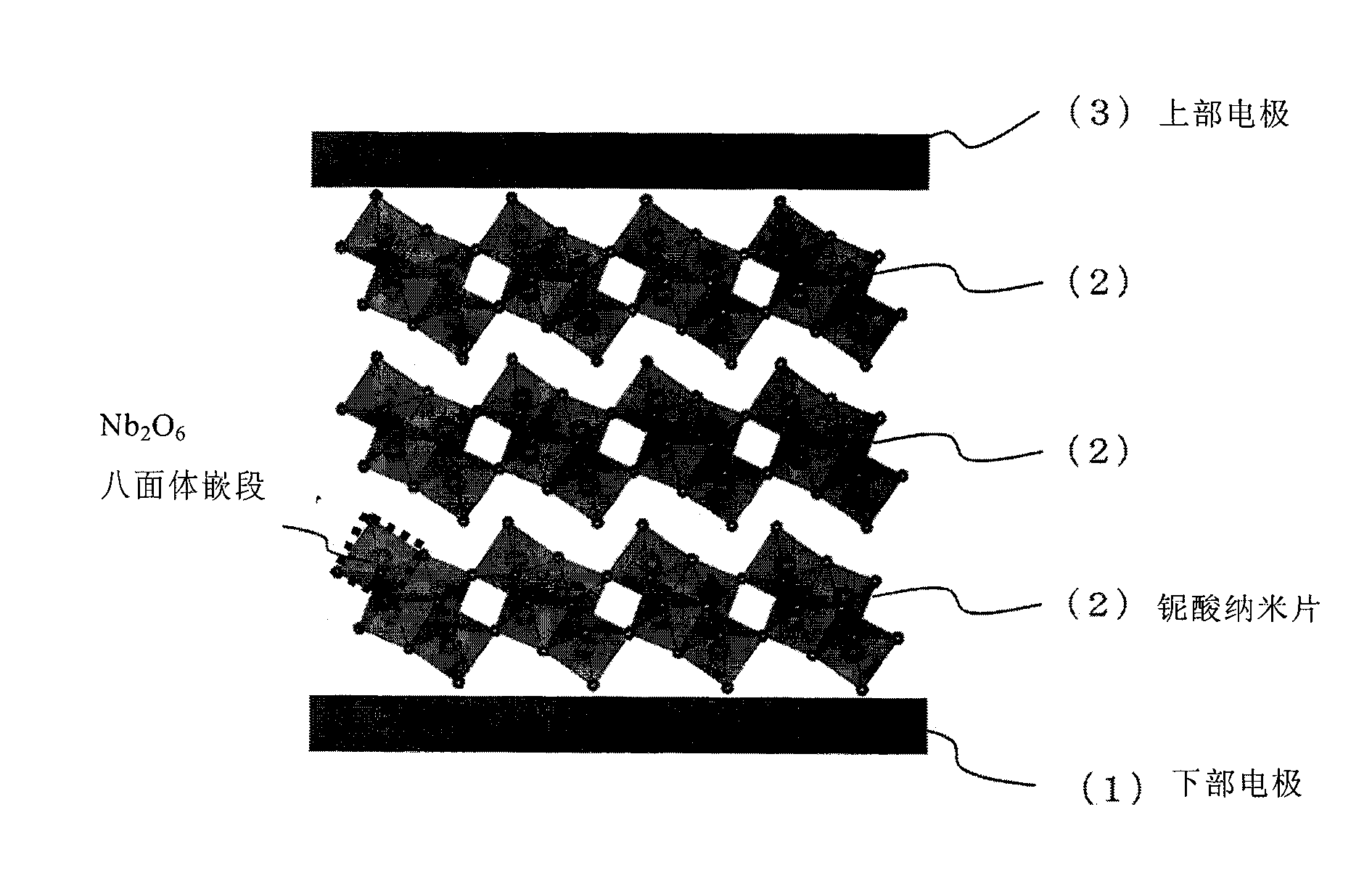

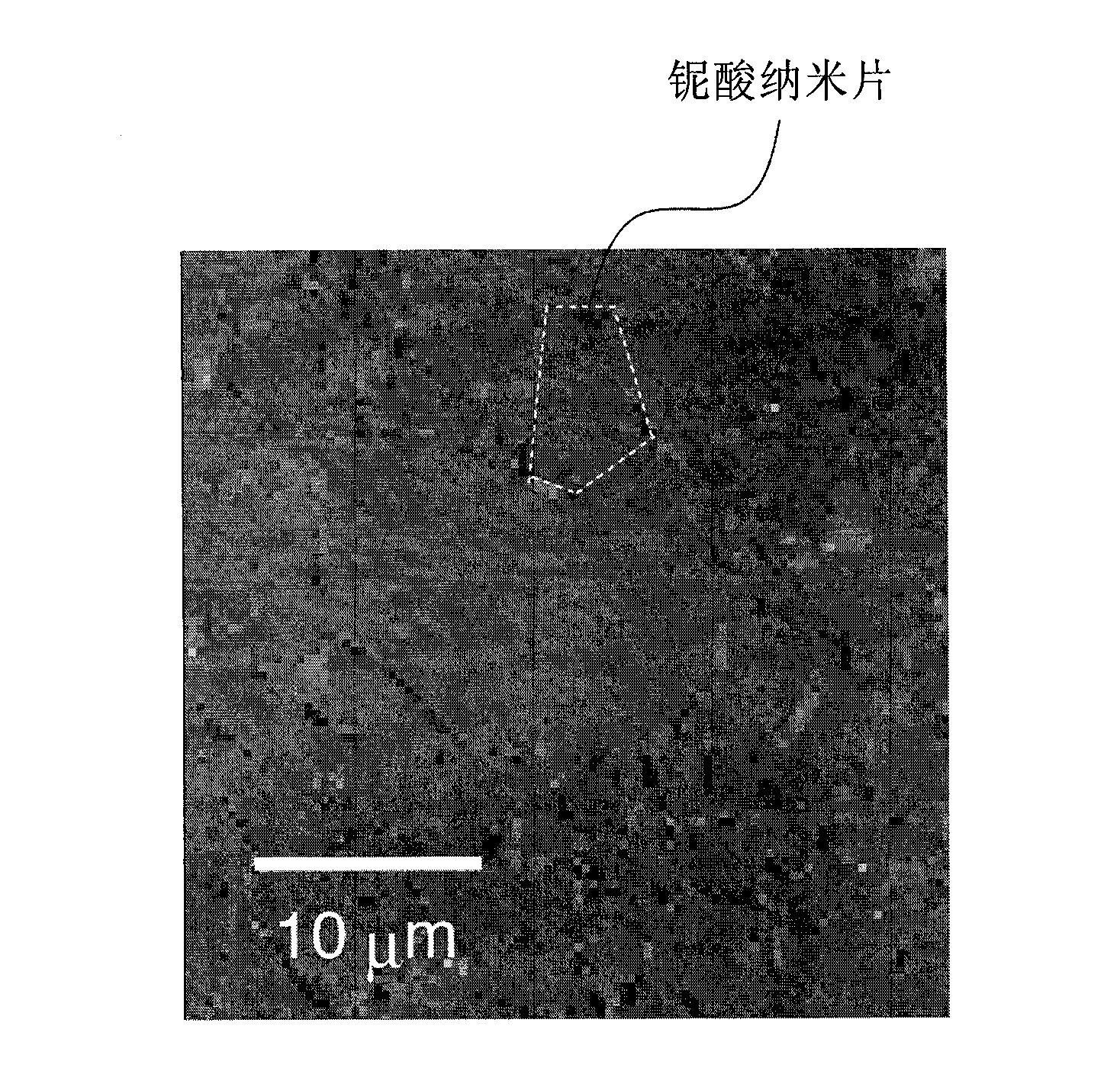

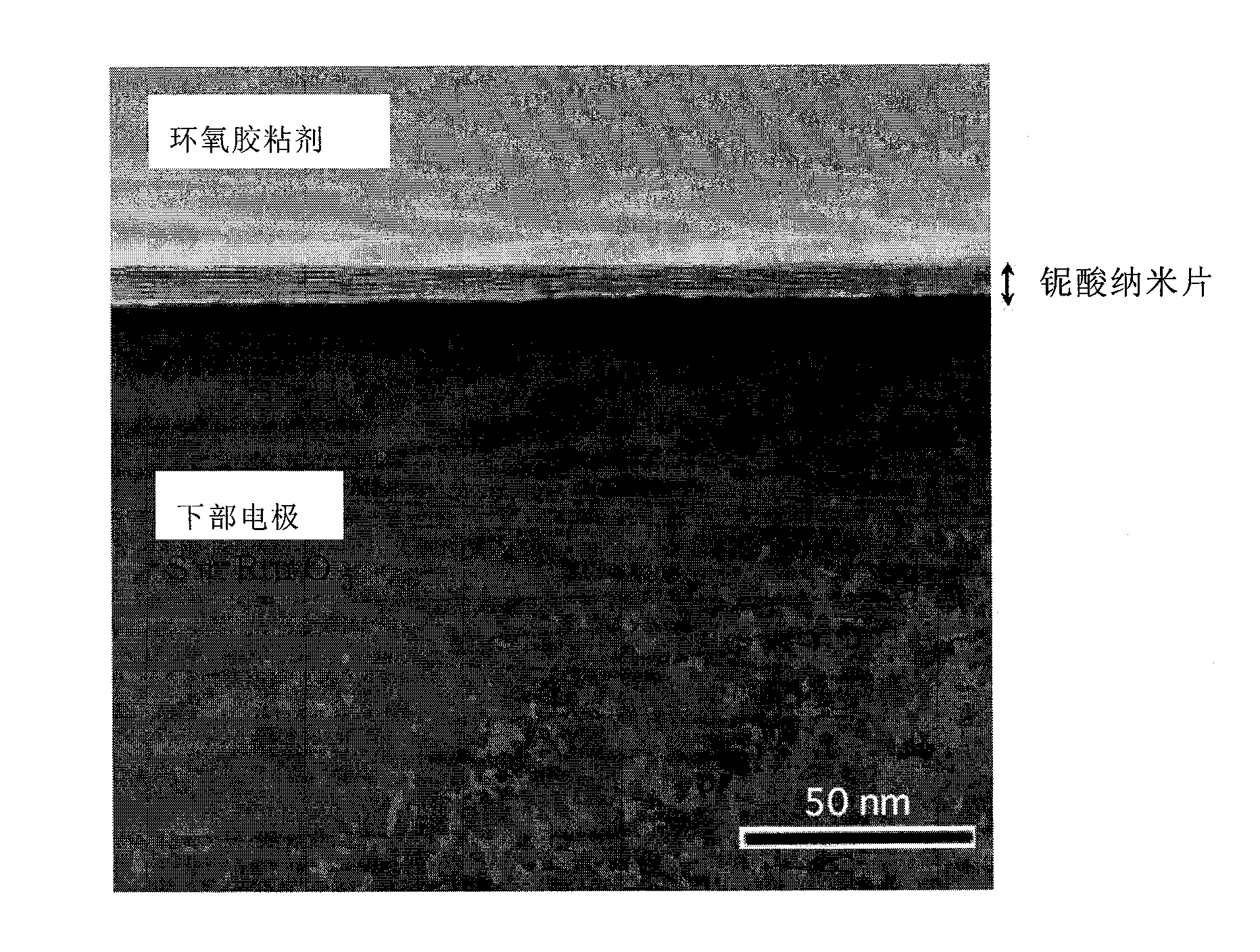

Dielectric film, dielectric element, and process for producing the dielectric element

InactiveCN102036918AImprove organizationHigh structural controlTransistorMaterial nanotechnologyElectricityDielectric permittivity

Disclosed is a dielectric film formed by attaching a single layer or a multilayer of a niobic acid nano sheet. Also disclosed is a dielectric element that can simultaneously realize a high permittivity and good insulating properties even in a nano region. The dielectric element comprises a dielectric film and other electrode disposed on the surface of the dielectric film. Further disclosed is a process for producing the dielectric element that can sweep away problems of a deterioration in a substrate interface by heat annealing in the production process, a deviation in composition from a contemplated composition caused by the deterioration in the substrate interface, and electrical mismatching, and an essential problem of a ''size effect'' that a reduction in the thickness of the film to a nano level lowers the specific permittivity and increases a leak current; can utilize unique properties and high texture and structure regulating properties possessed by the niobic acid nano sheet; and can produce the element at a low temperature free from the influence of a deterioration in substrate interface and a deviation in composition from a contemplated composition.

Owner:NAT INST FOR MATERIALS SCI

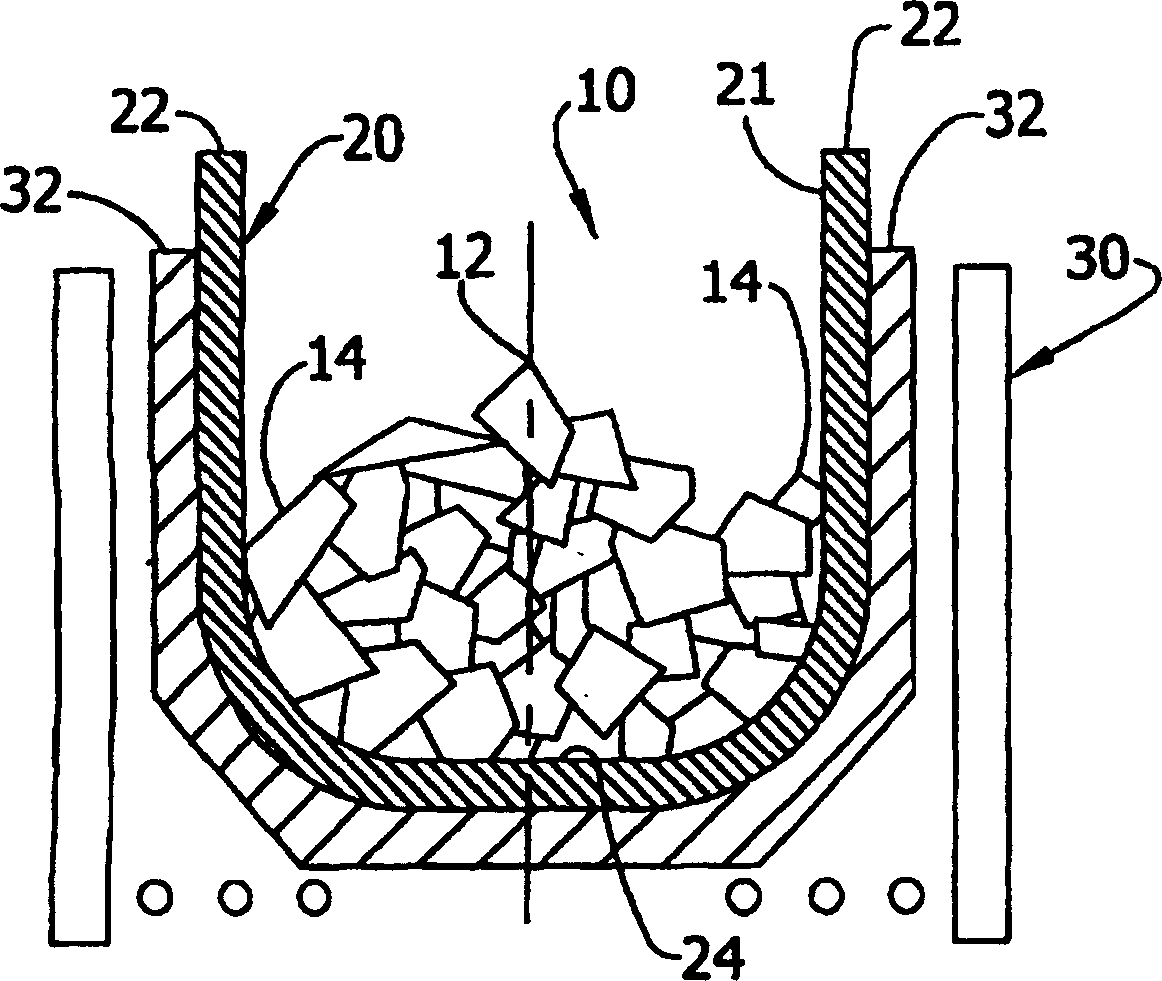

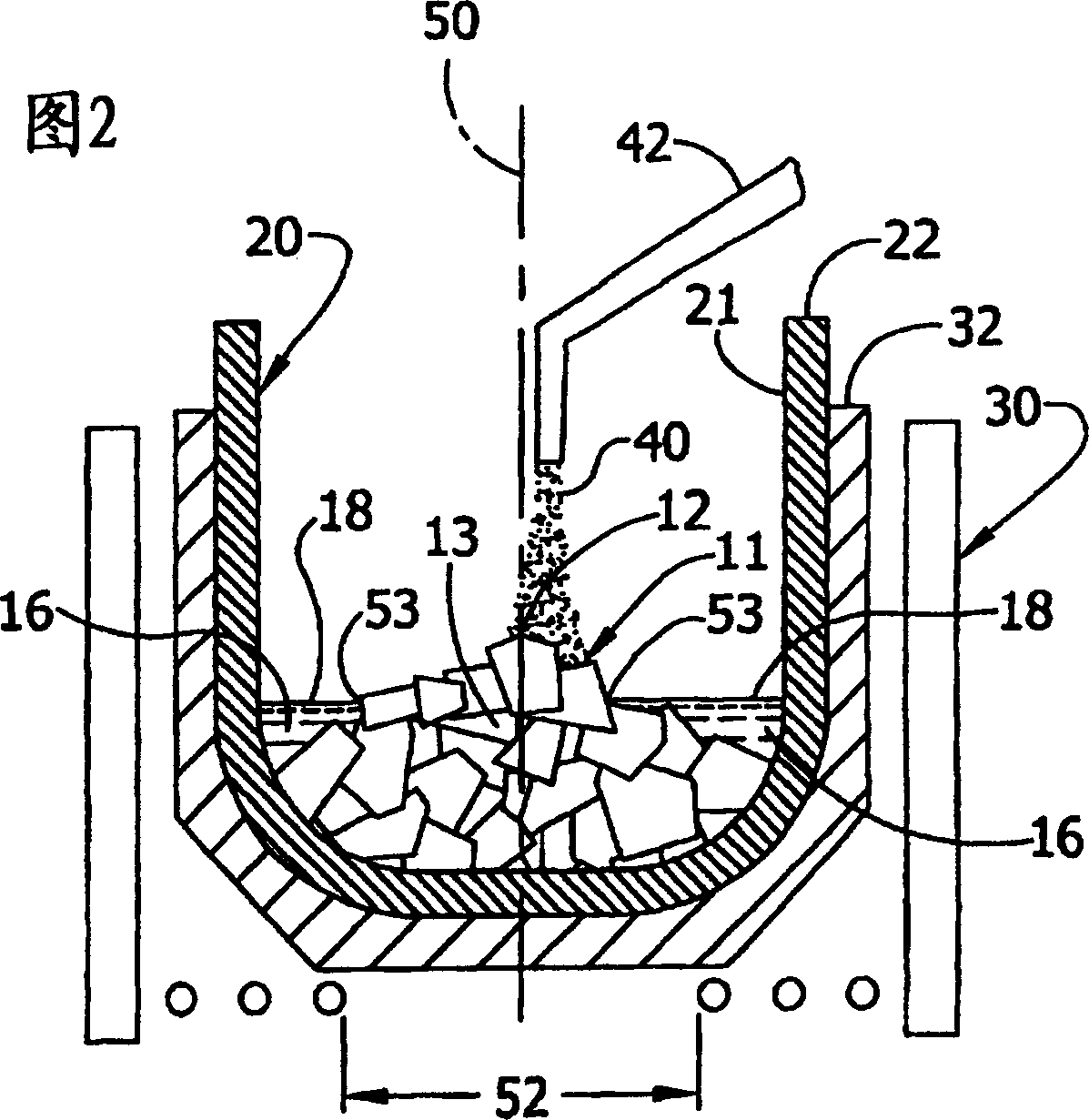

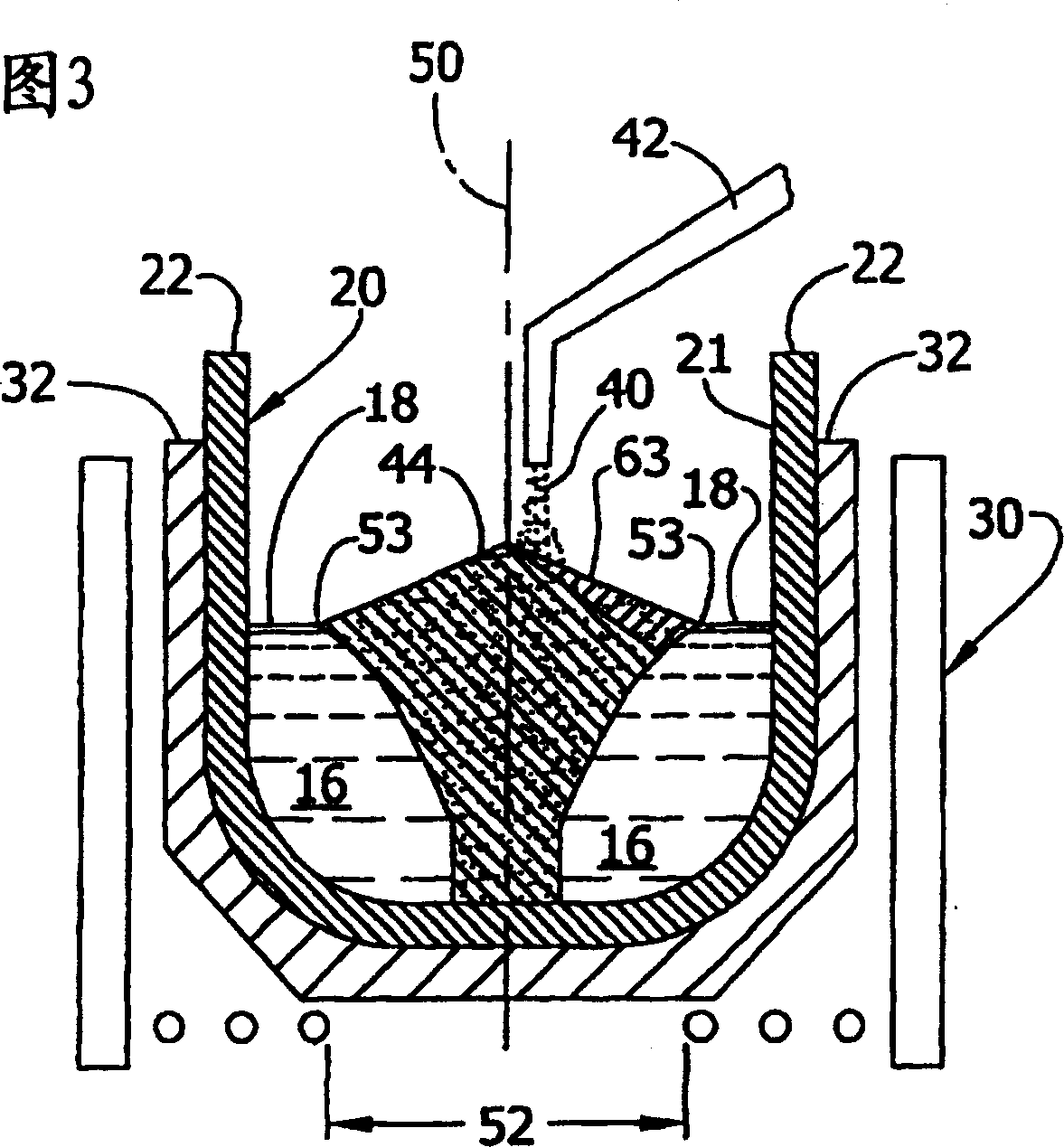

Intermittent feeding technique for increasing the melting rate of polycrystalline silicon

InactiveCN1585838AMelting fastControl the position of feedingPolycrystalline material growthBy pulling from meltFeed techniqueCzochralski method

A process for preparing a silicon melt in a crucible for use in growing a single crystal silicon ingot by the Czochralski method. The crucible is first loaded with chunk polycrystalline silicon and heated to partially melt the load. Granular polycrystalline silicon is then fed onto the exposed unmelted chunk polycrystalline silicon to complete the charge of silicon in the crucible. The granular polycrystalline silicon is intermittently delivered using a plurality of alternating on-periods and off-periods. During each on-period, granular polycrystalline silicon is flowed through a feed device that directs the granular polycrystalline silicon onto the unmelted chunk polycrystalline silicon. During each off-period, the flow of the granular polycrystalline silicon is interrupted. The loaded chunk polycrystalline silicon and the fed granular polycrystalline silicon are melted to form the silicon melt.

Owner:MEMC ELECTONIC MATERIALS INC

Mixing device for raw materials of plastic product

The invention discloses a mixing device for raw materials of a plastic product. The mixing device comprises a mixing box; a reinforcing rod is fixedly mounted at the top of the mixing box; a feeding pipeline is arranged at an inner side of the reinforcing rod; a first spring is arranged at the top of a first vibrator; an inclined plate is arranged at the top of the first spring; a weight sensor is arranged at the top of the inclined plate; a rotary shaft is arranged in an inner cavity of the mixing box. According to the mixing device for the raw materials of the plastic product, materials to be mixed can be conveyed into the feeding pipeline and the weight of the materials can be sensed through the weight sensor; after the weight reaches proper weight, the materials can be conveyed into the mixing box through pulling a pull plate; the inclined plate is continuously vibrated through the first vibrator and the materials can be rapidly conveyed into the mixing box; a double-through pipe is driven by a motor to rotate, so that the double-through pipe drives the rotary shaft to rotate and starts to stir the materials; when the materials are uniformly stirred, a mixing ratio can be strictly controlled.

Owner:安庆市东源印刷包装有限公司

Full-automatic plastic label capsulation device based on mechanical suspension

The invention discloses a full-automatic plastic label capsulation device based on mechanical suspension, which comprises a frame, wherein the frame is sequentially provided with a damping label holding plate, a label feeding plate, a label feeding rubber wheel, a guide chute, a suspension core, a label cutter, a photoelectric cutting control sensor, a label brushing wheel, a photoelectric distance measurement sensor and a workpiece conveying belt; the damping label holding plate is provided with a coiled plastic label; the frame above the label feeding plate is provided with a photoelectric material measurement sensor; the frame between the guide chute and the suspension core is also provided with two core guide wheels; the two sides of the suspension core are provided with a core suspension wheel respectively; the suspension core is provided with a label pressing wheel; and a label shooter is also mounted on the frame at the same height as the label pressing wheel. The device disclosed by the invention has the characteristics of low cost, compact structure and high productivity, and is convenient to operate.

Owner:SHAOXING UNIVERSITY

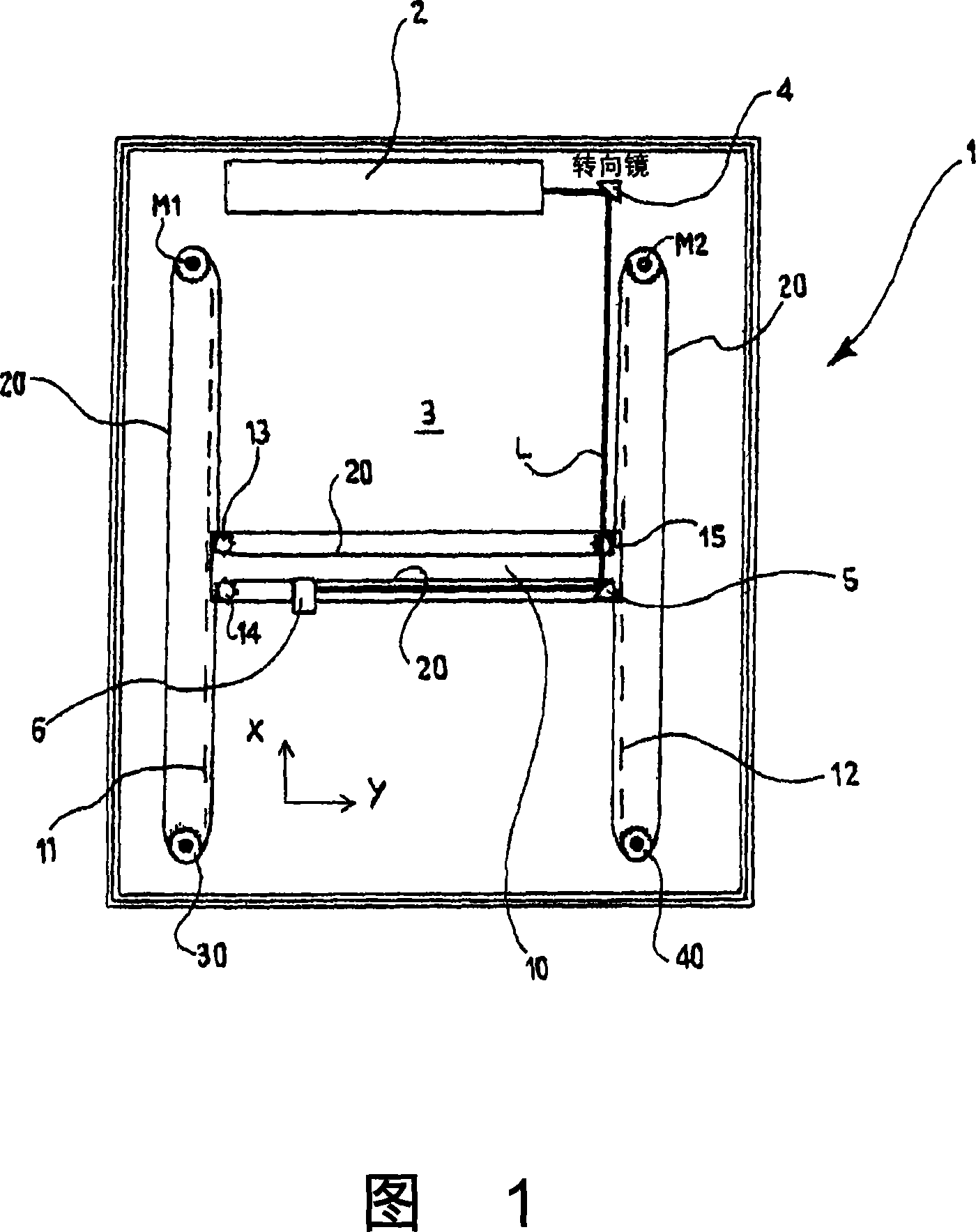

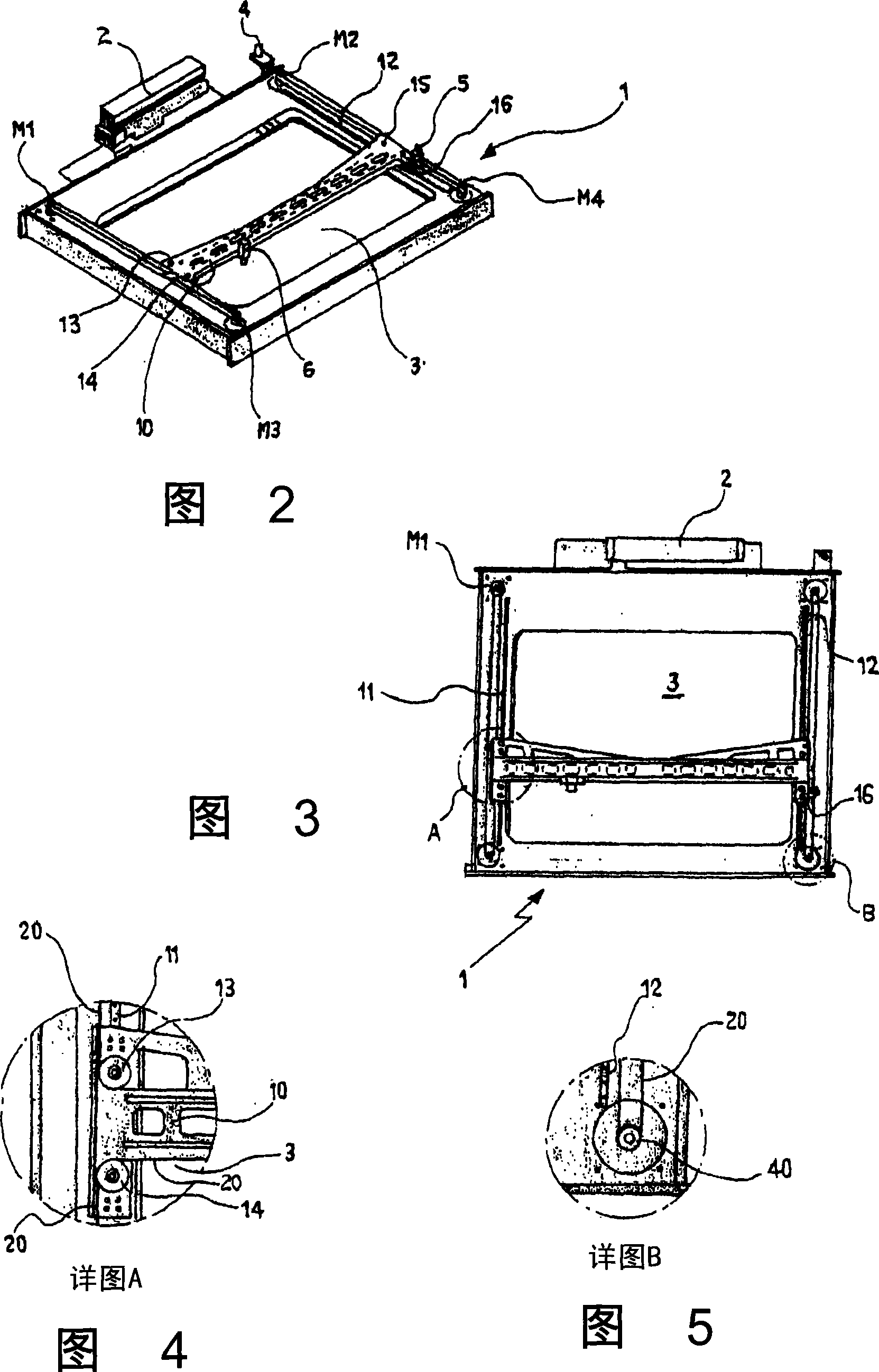

Apparatus for laser cutting and/or marking

InactiveCN101045270AEasy to replaceReduce noiseProgramme-controlled manipulatorMechanical apparatusLaser transmitterTransmission belt

The present invention relates to an apparatus for cutting and / or marking products by means of laser beams. The apparatus comprises at least one laser light emitter moveable in a first direction (X) along a cross-bar, the cross-bar being in turn moveable above a working plan in a second direction transversal to said first direction (X), and at least two motors for moving the laser light emitter and the cross-bar. The laser light source is positioned to direct a laser light beam onto said working plan. Advantageously the two motors are positioned fixed and are coupled together and both to the laser light source, and to the cross-bar, by means of a transmission belt.

Owner:赛股份有限公司

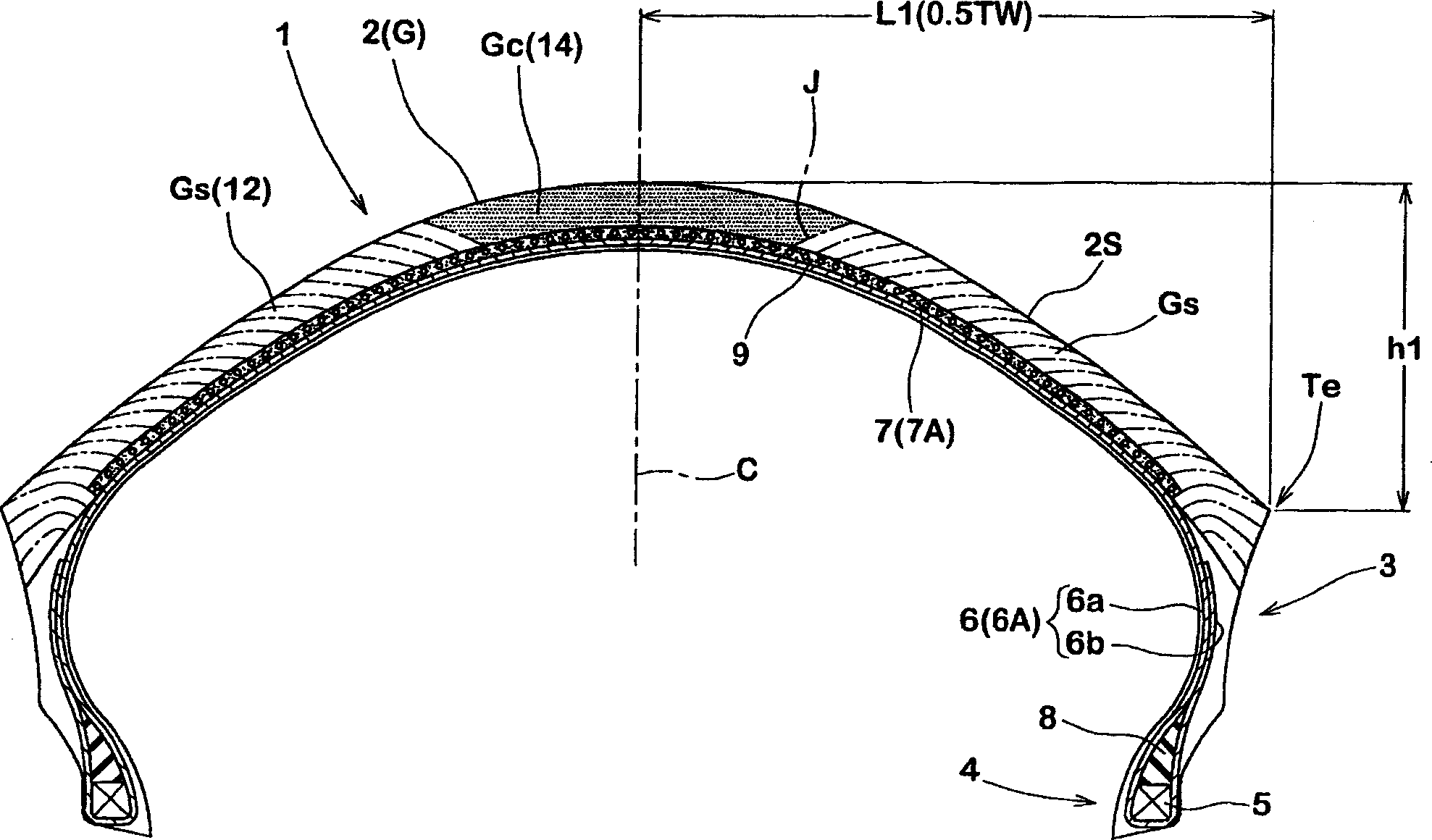

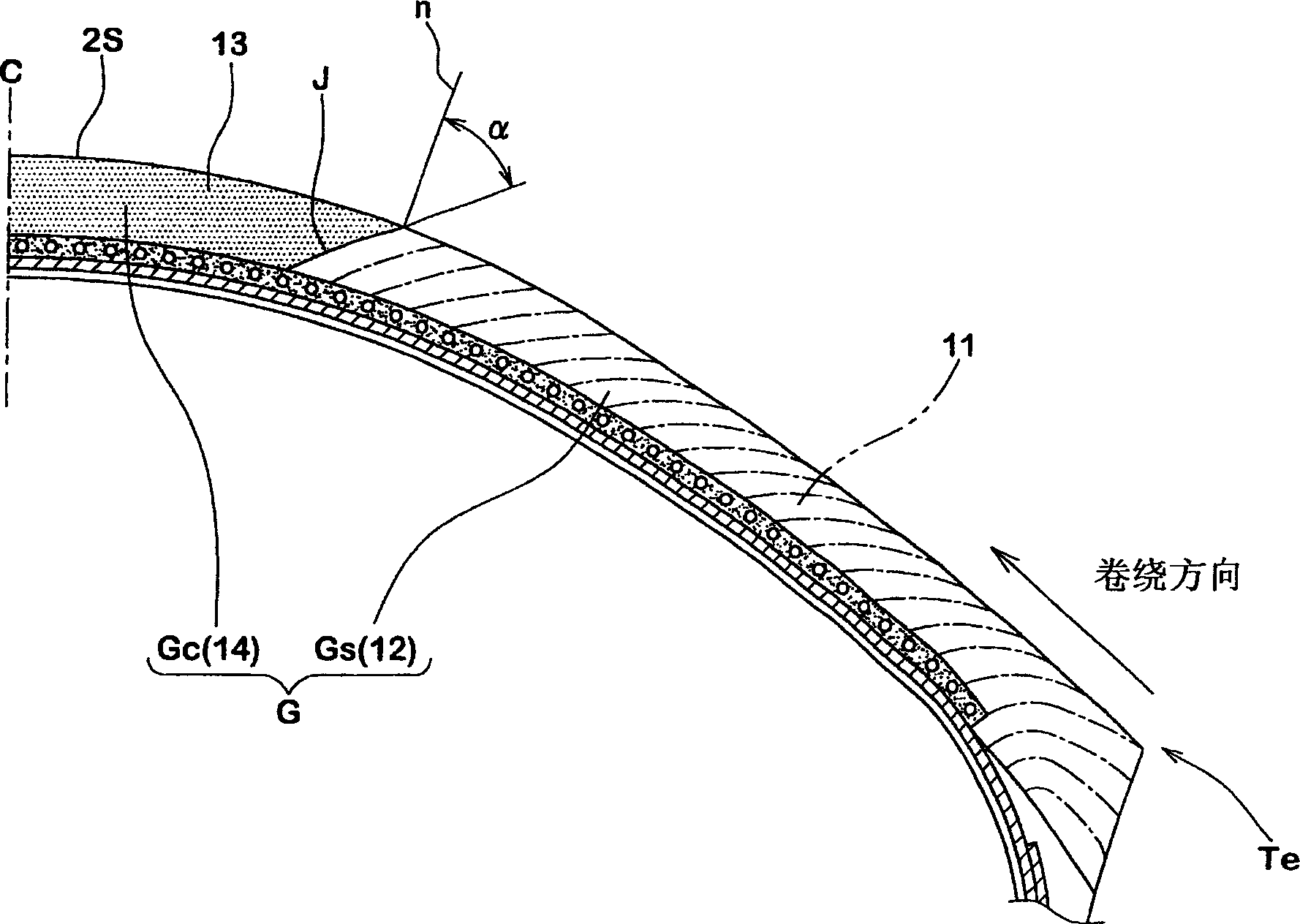

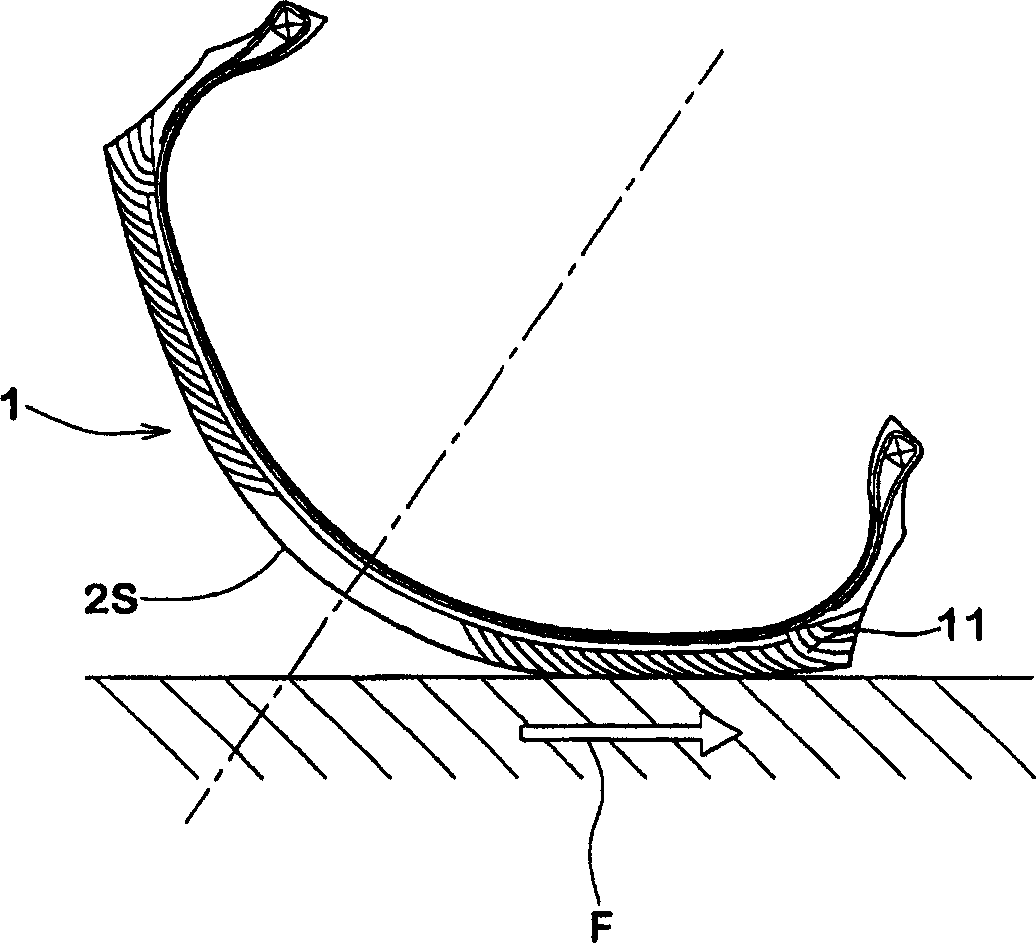

Tire for two-wheeled vehicle and manufacturing method of the same

ActiveCN1833889AAvoid wrinklesGuaranteed productivityTyresMotorcycle tyresRubber materialEngineering

The tire for a two-wheeled vehicle comprises at a tread portion thereof shoulder rubber portions on tread end sides and a central rubber portion between the shoulder rubber portions. The central rubber portion is comprised of a once-wound body in which a wide flat rubber material has been wound once in the tire circumferential direction. The shoulder rubber portions are comprised of strip wound bodies in which a narrow and long rubber strip is spirally wound in the tire circumferential direction.

Owner:SUMITOMO RUBBER IND LTD

Agent for reducing coating film overall friction coefficient for trivalent chromate treating solution, trivalent chromate treating solution and method for production thereof, and trivalent chromate co

InactiveCN1950544ALower overall coefficient of frictionImprove corrosion resistanceMetallic material coating processesChromate conversion coatingQuinoline

An agent for reducing a coating film overall friction coefficient for a trivalent chromate treating solution, characterized in that it comprises a quinoline based compound or a derivative thereof. A coating film formed by the contact of a zinc or zinc alloy plating with the trivalent chromate treating solution containing no hexavalent chromium and containing the above agent on the surface of the plating exhibits a corrosion resistance equivalent to that of a coating film formed by a chromate treatment with a treating solution having a conventional hexavalent chromium as a main component, and also exhibits an overall friction coefficient equivalent to or less than that of a coating film formed by a conventional hexavalent chromate.

Owner:DISPOL CHEMICALS CO LTD

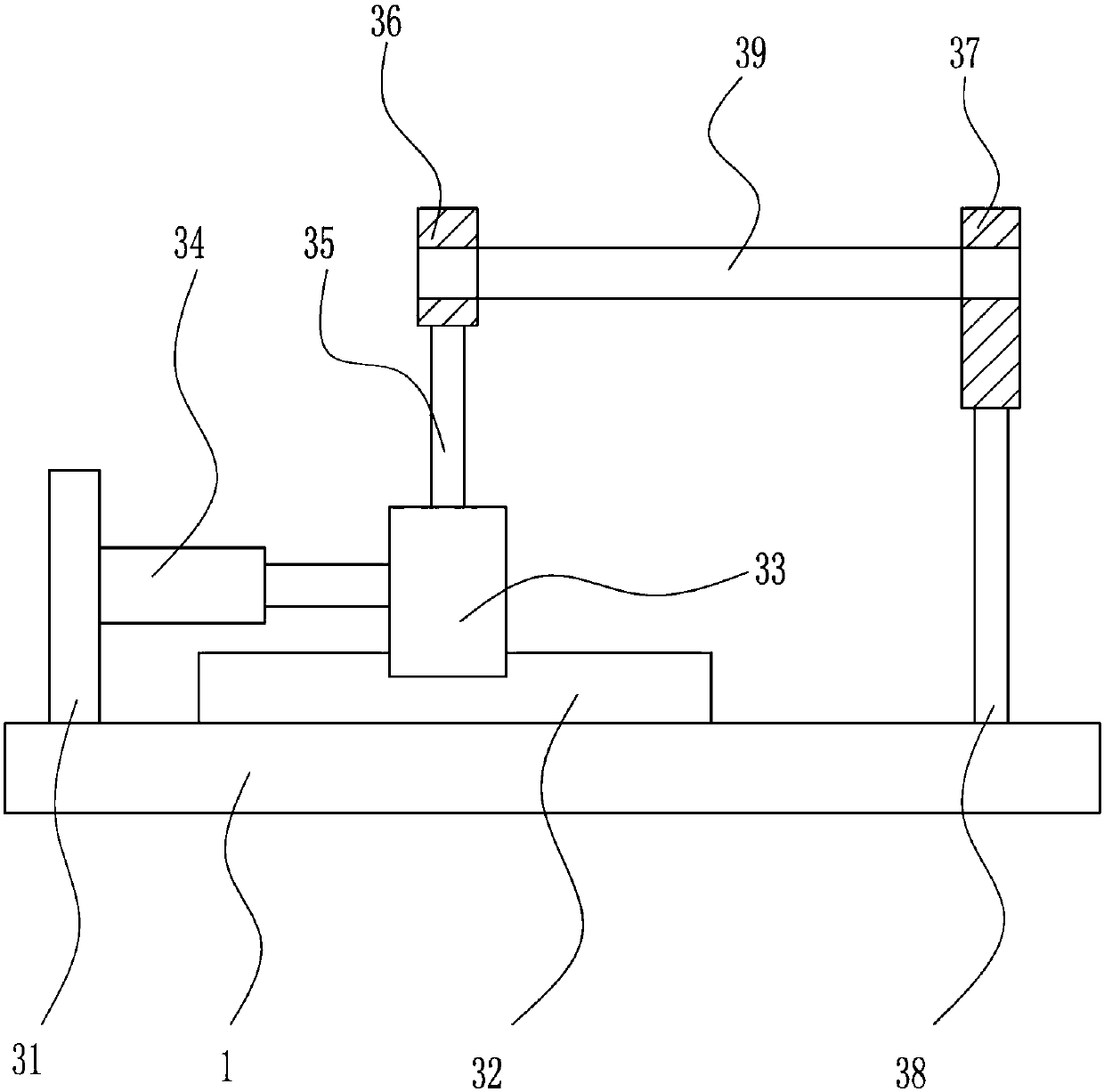

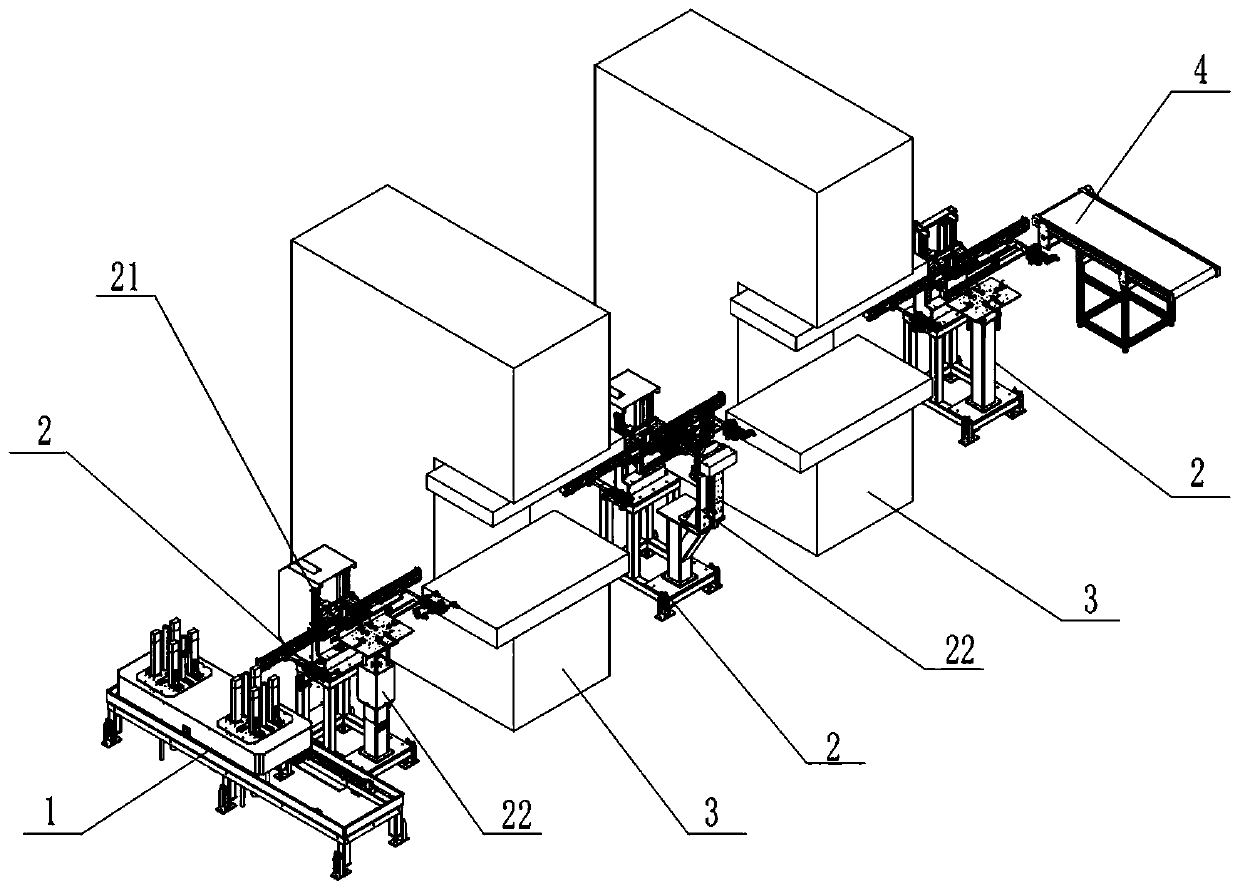

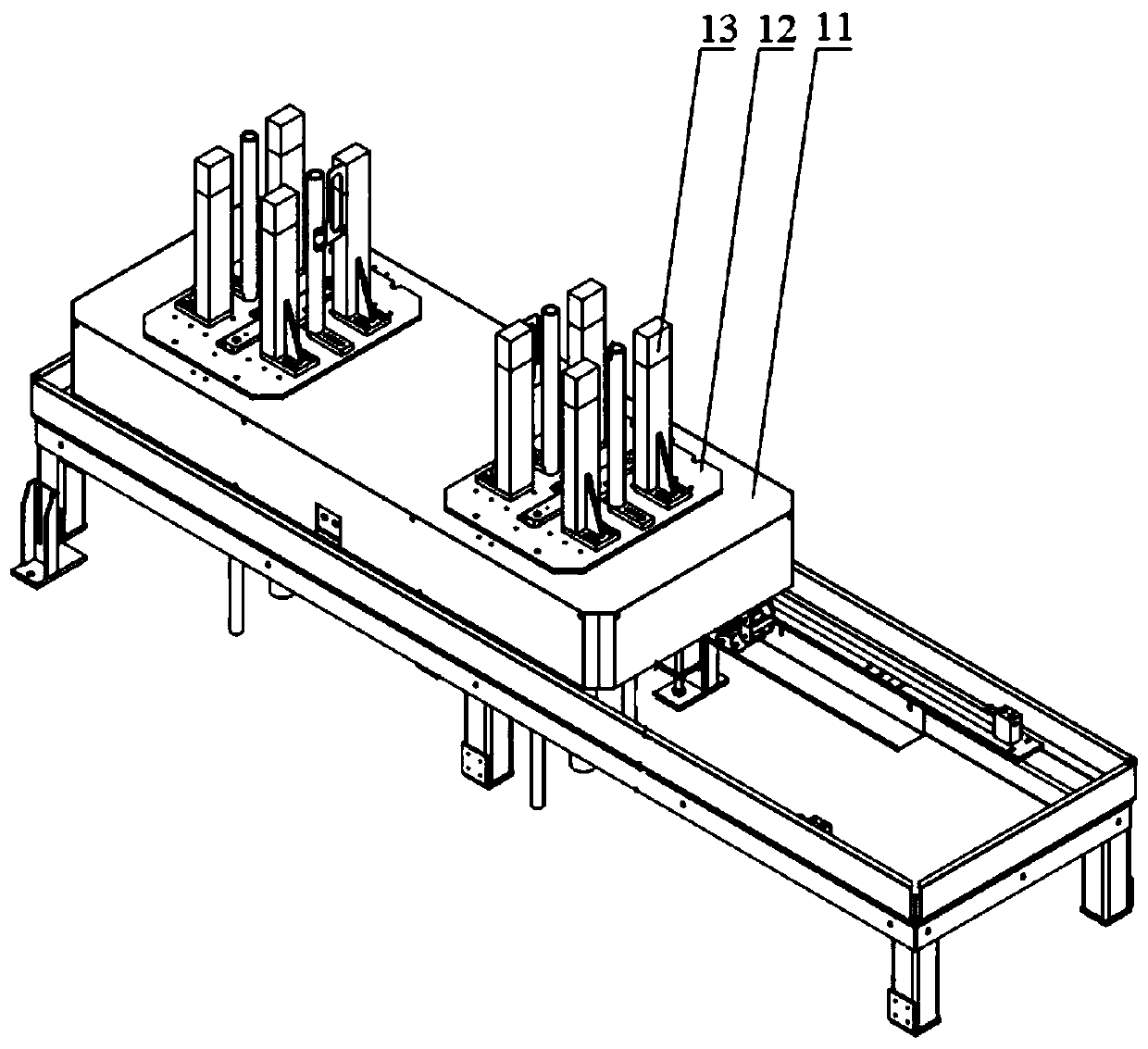

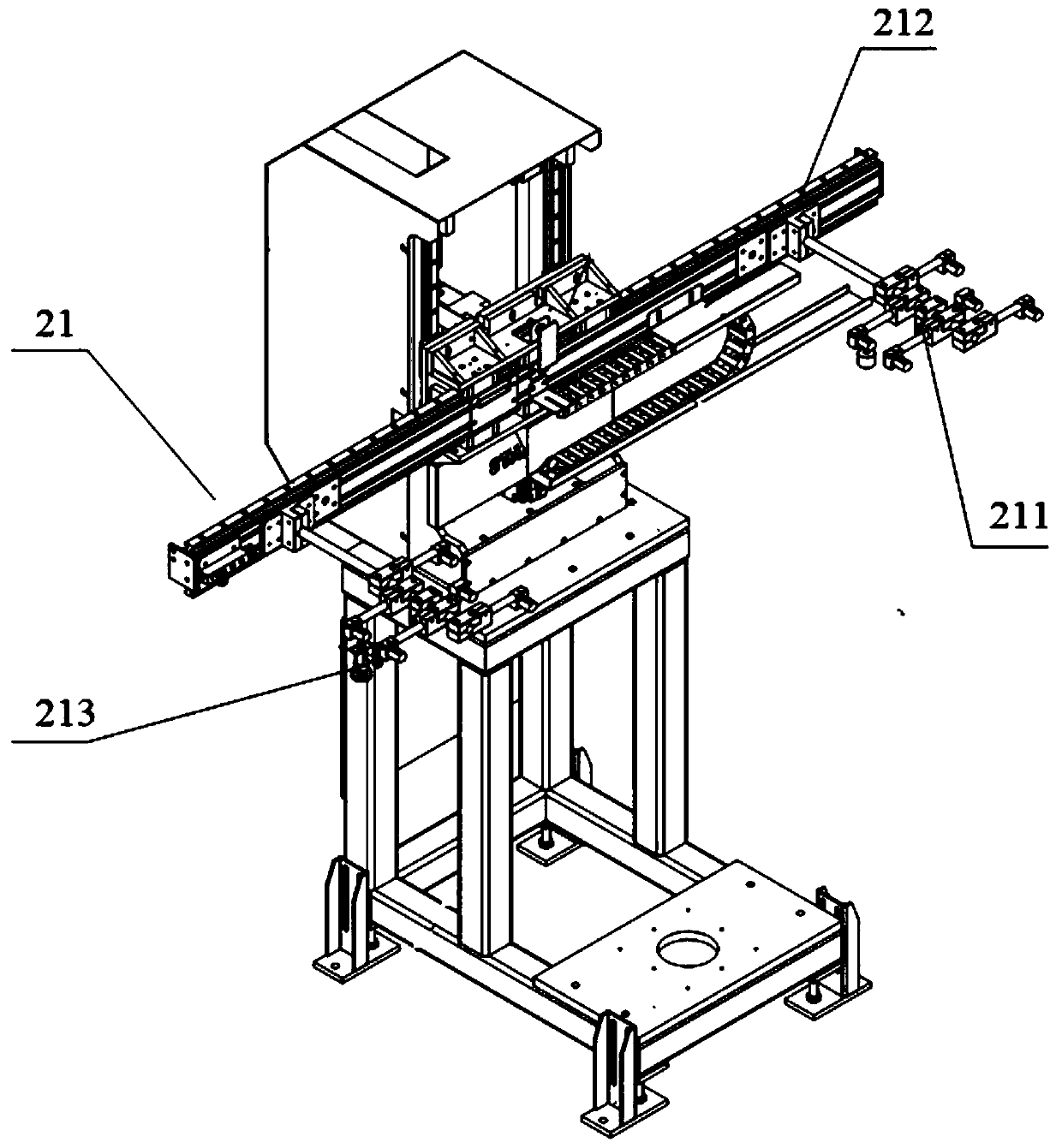

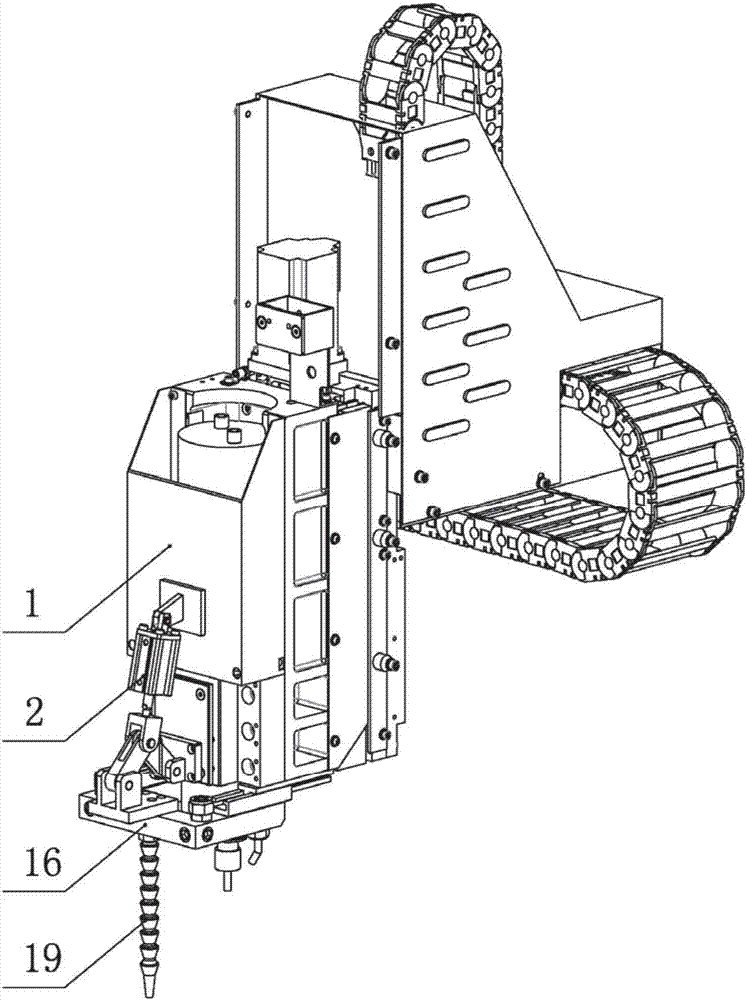

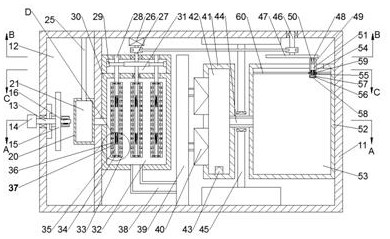

Automatic stamping assembly line

PendingCN110355296AReduce manual labor intensityGuaranteed productivityMetal-working feeding devicesPositioning devicesAssembly lineEngineering

An automatic stamping assembly line is sequentially provided with an automatic feeding platform, multiple mechanical hand assemblies, multiple press machines and a conveying belt assembly located at the rear ends of the mechanical hand assemblies, wherein the mechanical hand assemblies and the press machines are arranged alternatively. The automatic feeding platform is arranged longitudinally andis provided with a lifting platform provided with two stacking platforms, and the lifting platform is driven by a drive device to move front and back. Each mechanical hand assembly comprises a mechanical hand with two mechanical arms and a transfer station located in front of the mechanical hand. Each mechanical hand is arranged on a bottom plate capable of vertically ascending and descending andmoving left and right. According to the motion track of the two mechanical arms of each mechanical hand, the two mechanical arms move to the corresponding transfer station from the lifting platform ofthe automatic feeding platform and move a work platform of the corresponding press machine from the corresponding transfer station. The press machines are used for stamping workpieces. The mechanicalhand assemblies and the press machines are arranged alternatively, and the workpieces stamped by the previous press machine are transferred to the station of the next press machine to be pressed. Theconveying belt assembly conveys the workpieces output by the last mechanical hand assembly to other stations. Automatic stamping of automobile parts can be achieved.

Owner:WUXI HUAGUANG METAL TECH

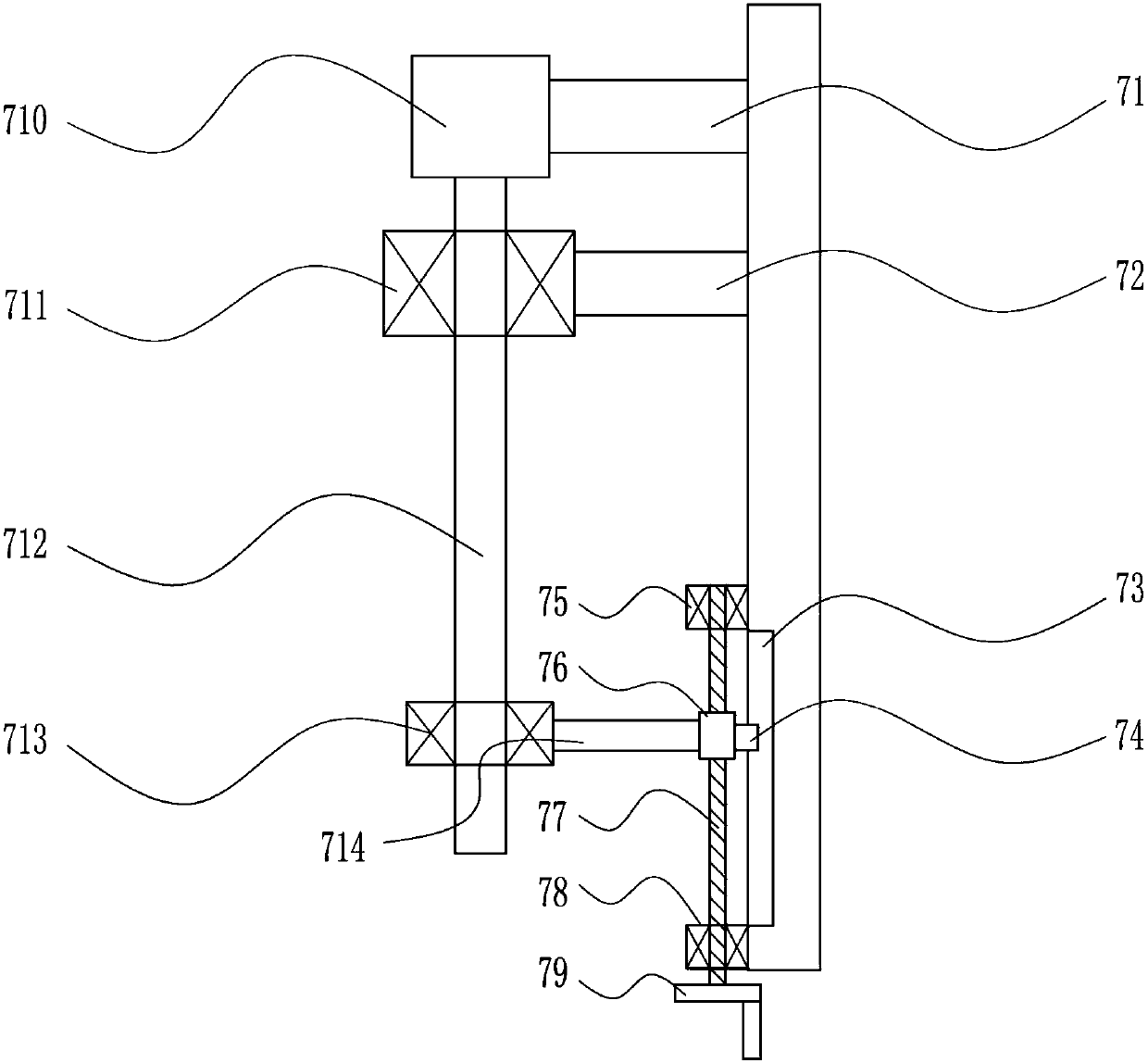

Slidable workpiece cooling mechanism

ActiveCN107116396AResolve mutual interferenceImprove cooling efficiencyMaintainance and safety accessoriesNumerical controlMachine tool

The invention relates to the technical field of numerically-controlled machine tool equipment, in particular to a slidable workpiece cooling mechanism. The slidable workpiece cooling mechanism comprises an air cylinder rear support fixed to a headpiece part and hinged to an air cylinder tailstock; the air cylinder tailstock is fixed to the rear end of an air cylinder, a piston rod of the air cylinder extends out of the front end and is fixed to an air cylinder connector; the air cylinder connector is provided with a first rotary shaft, and the upper ends of a first connecting rod and a second connecting rod movably penetrate through the first rotary shaft; the lower end of the second connecting rod is hinged to a second hinged seat which is fixed to the headpiece part; the lower end of the first connection rod is hinged to a first hinged seat which is fixed to a cooling pipe holder; the cooling pipe holder is provided with a universal pipe and a first guide rail; and the first guide rail is matched with a second guide rail fixed to the bottom of the headpiece part. According to the slidable workpiece cooling mechanism, mutual interference between the universal pipe and a tool changer is avoided, the tool changing efficiency and the workpiece cooling efficiency are improved, and therefore, the precision, quality and production rate of machined workpieces are guaranteed.

Owner:深圳市创智激光智能装备有限公司

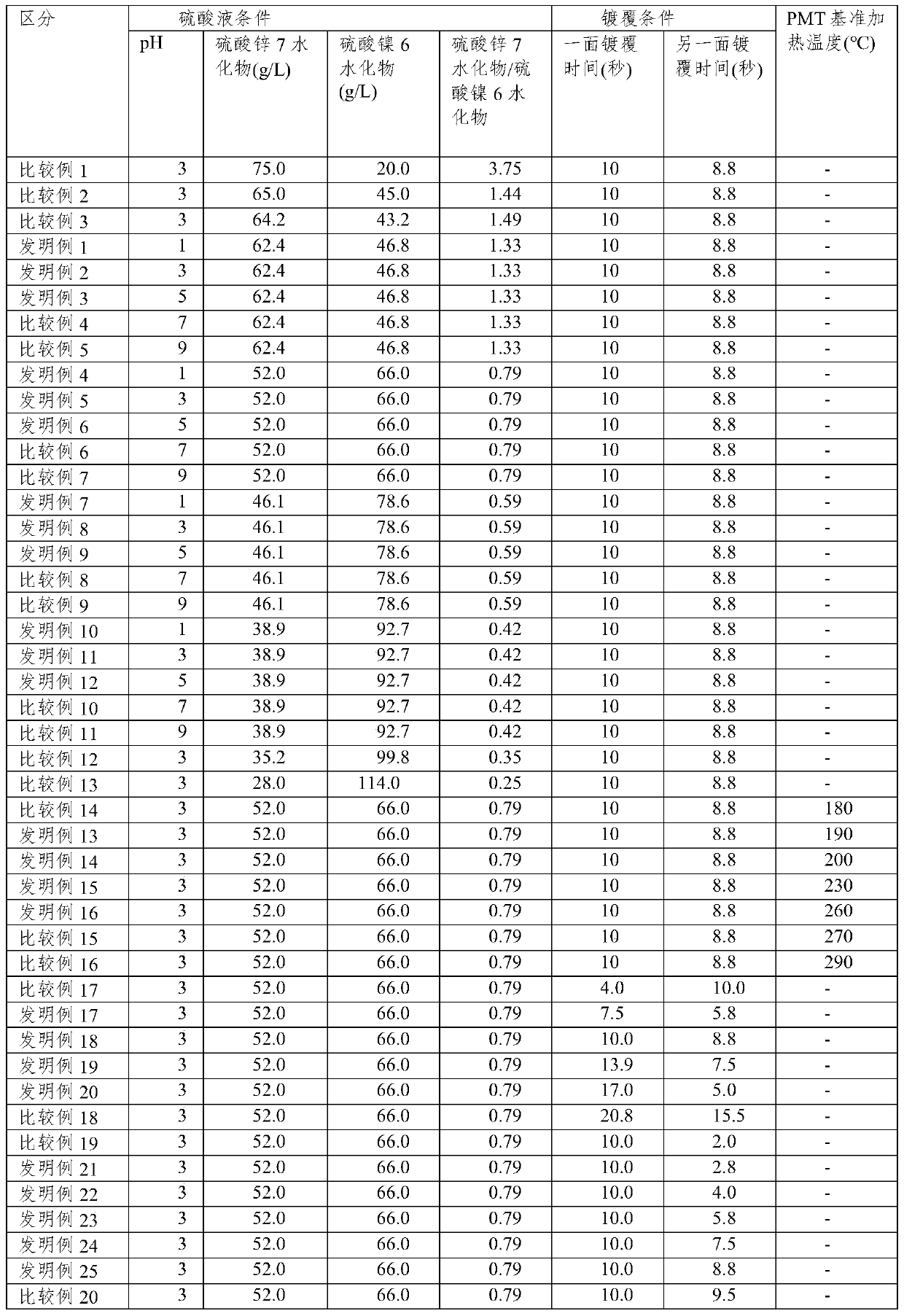

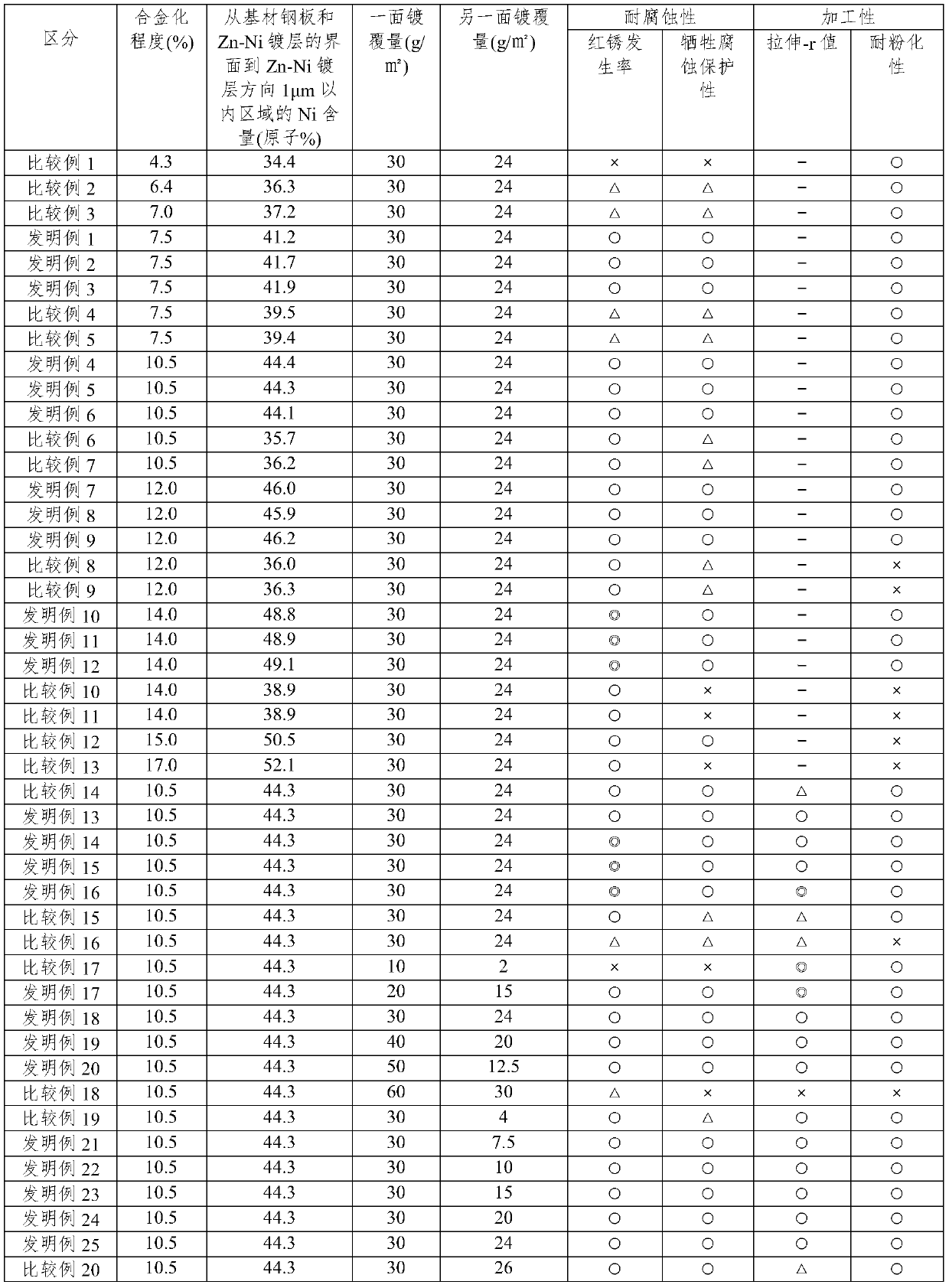

Zn-ni electroplated steel sheet having excellent corrosion resistance and formability and manufacturing method therefor

ActiveCN110114514ALow degree of nickel alloyingAccelerated corrosionSuperimposed coating processThin material handlingNickel alloyCorrosion resistant

The present invention relates to a Zn-Ni electroplated steel sheet having excellent corrosion resistance and formability and a manufacturing method therefor. One embodiment of the present invention provides a Zn-Ni electroplated steel sheet comprising: a base steel sheet; and a Zn-Ni plated layer formed on the base steel sheet, wherein a Ni alloying degree within the Zn-Ni plated layer is 7.5-14%,and the Ni amount is 40-50 atom% in a region within 1 [mu]m toward the Zn-Ni plated layer from an interface of the base steel sheet and the Zn-Ni plated layer. According to the present invention, provided is a Zn-Ni electroplated steel sheet, which has superior corrosion resistance and formability despite having a relatively low nickel alloying degree, has excellent price competitiveness comparedwith that of a conventional Zn-Ni plated steel sheet and two-layer plated steel sheet, and can ensure high productivity.

Owner:浦项股份有限公司

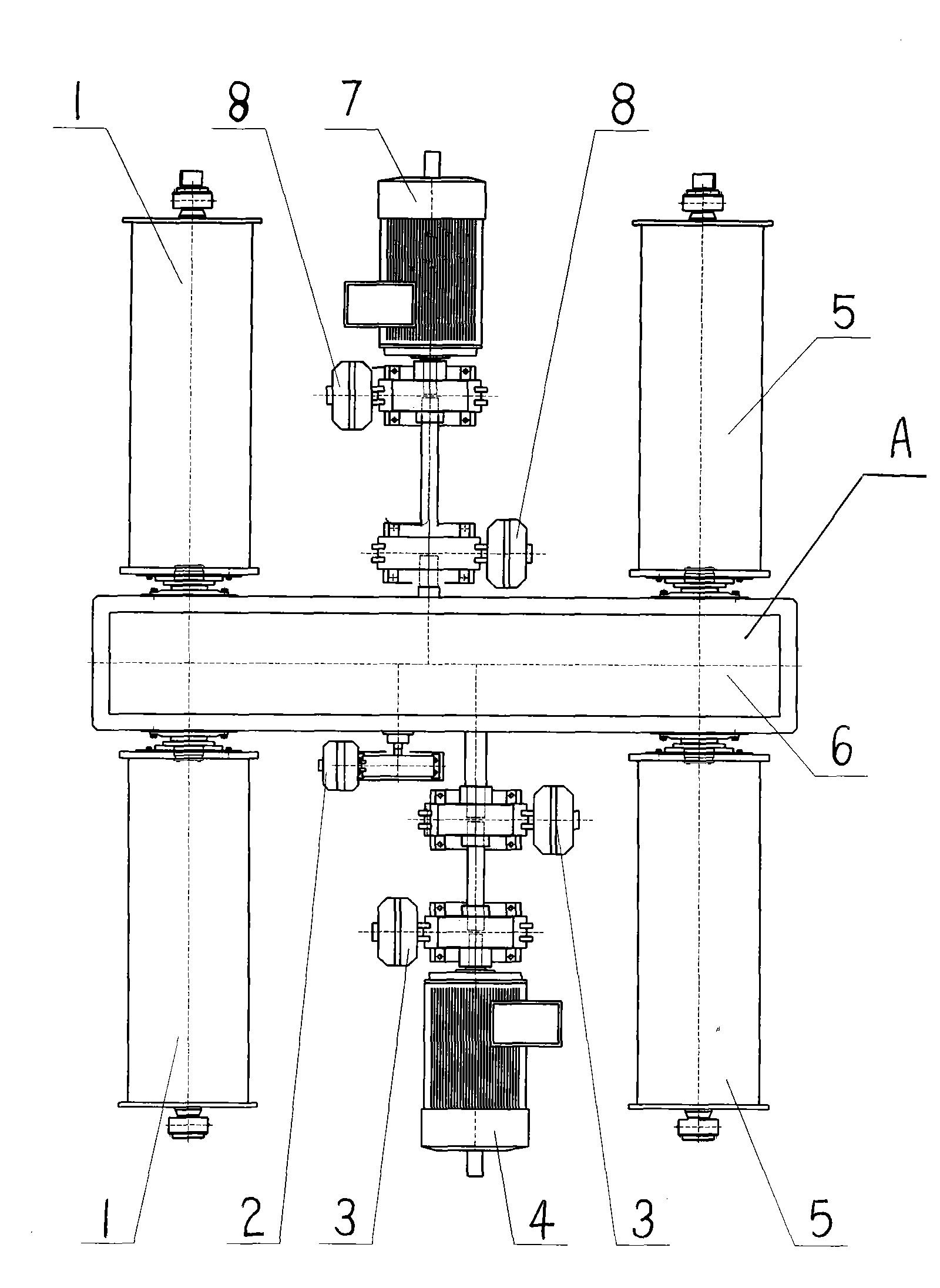

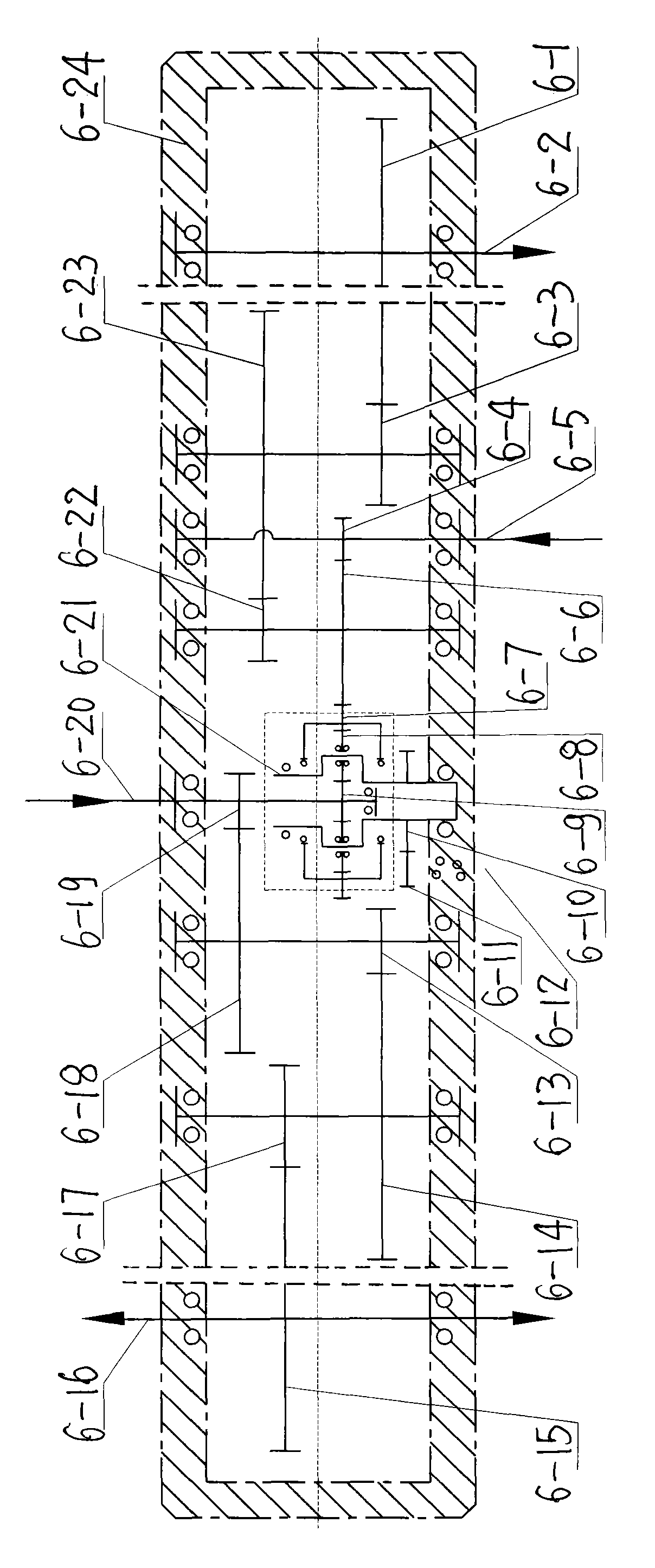

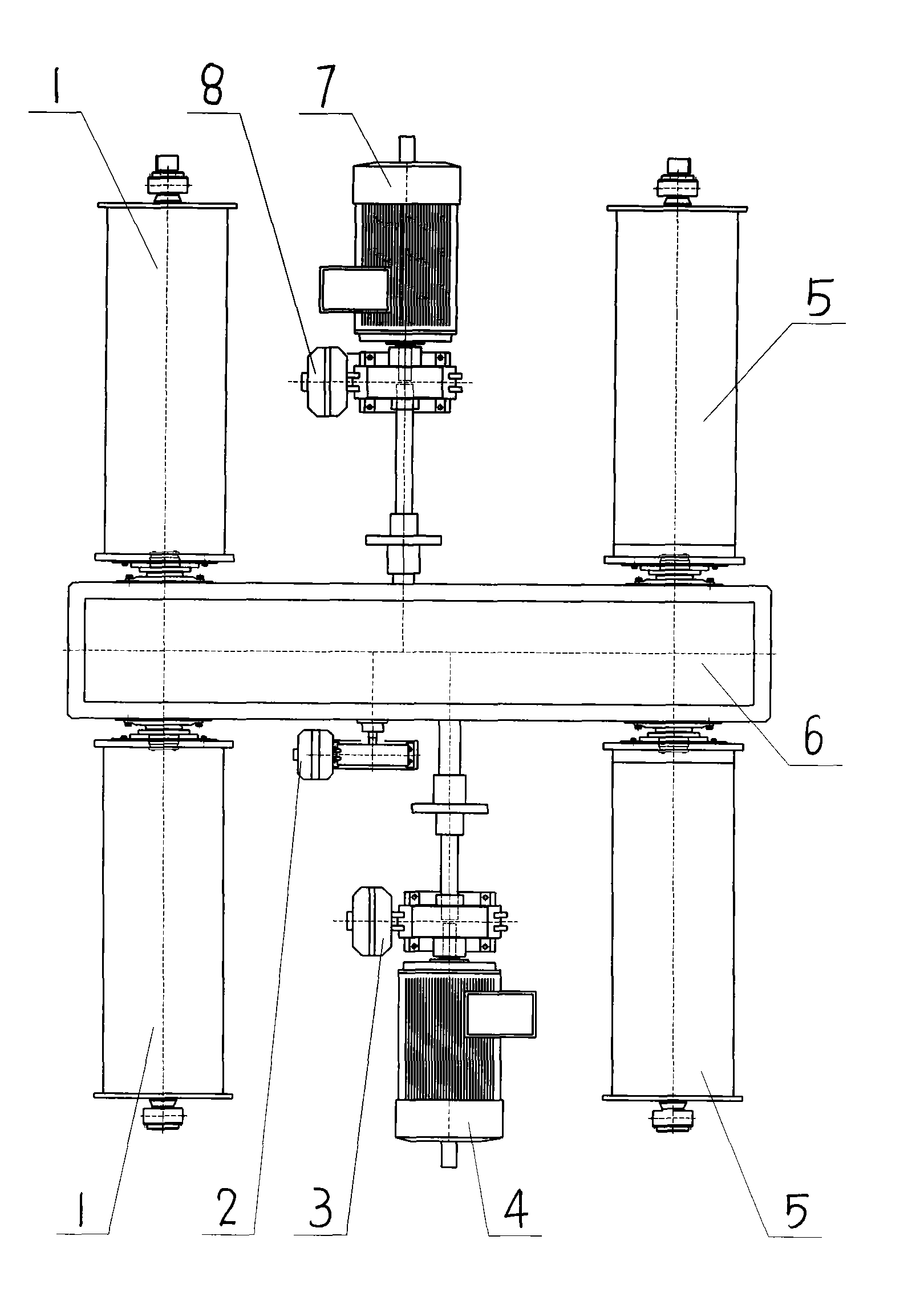

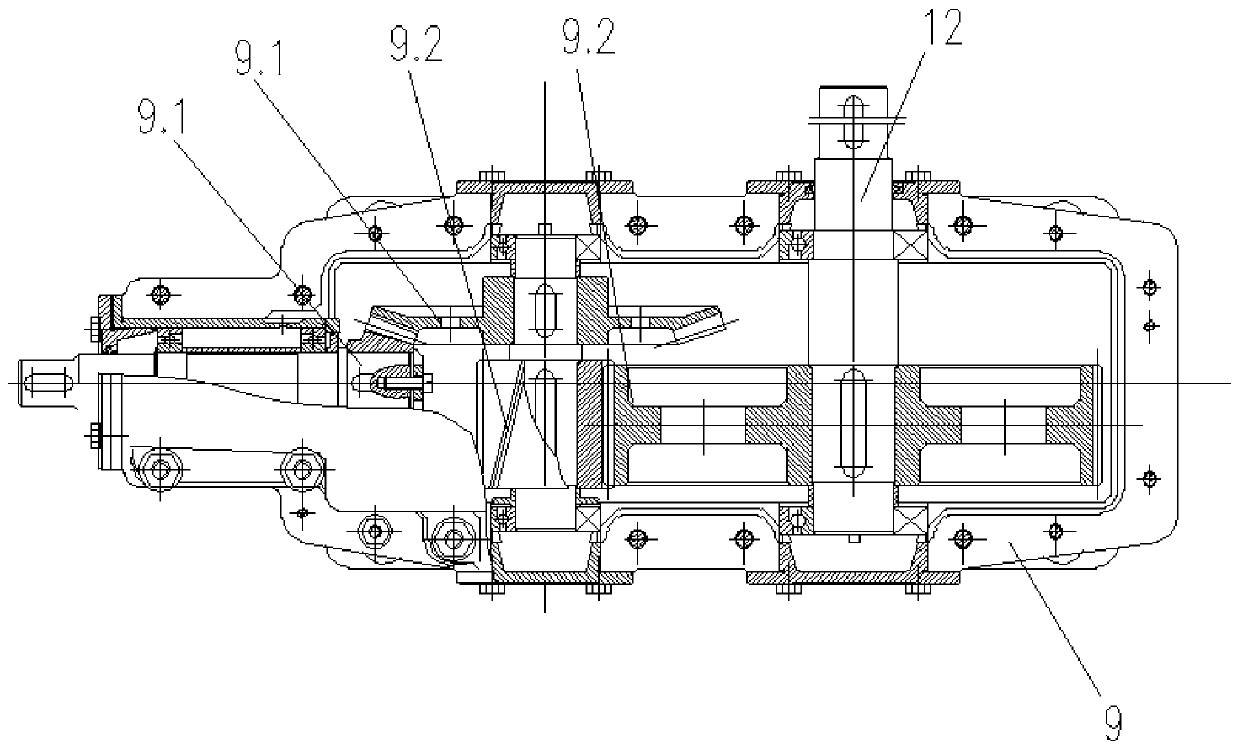

Planetary transmission hoisting mechanism used for charging crane and operation method thereof

ActiveCN101549837AScientific and reasonable designCompact structureWinding mechanismsEngineeringConductor Coil

The invention belongs to the hoisting mechanism used for a charging crane and an operation method thereof, particularly relating to a planetary transmission hoisting mechanism used for the charging crane and an operation method thereof. The method is characterized in that a planetary reduction gear contained a 2K-H-shaped planetary gearing of NGW is adopted, the combination of a motor, a brake and a winding drum group is connected on the planetary reduction gear to form the planetary transmission hoisting mechanism, wherein the planetary reduction gear consists of a case body, a Z16 gear, a first output shaft, a Z15 gear, a Z14 gear, a first input shaft, a Z13 gear, a Z11 gear, a Z12 gear, a second input shaft, a Z21 gear, a Z22 gear, a planetary gearing, a random shaft, a Z32 gear, a Z31 gear, a Z23 gear, a Z24 gear, a Z25 gear, a second output shaft and a Z26 gear. The mechanism has scientific design and compact structure, thus not only being applicable to different working conditions and operated flexibly, but also being capable of finishing the charging work under fault condition so as to guarantee that the production plan is finished; in addition, the mechanism has the advantages of safe and reliable operation, energy-saving, convenient usage and the like.

Owner:DALIAN HUARUI HEAVY IND GROUP

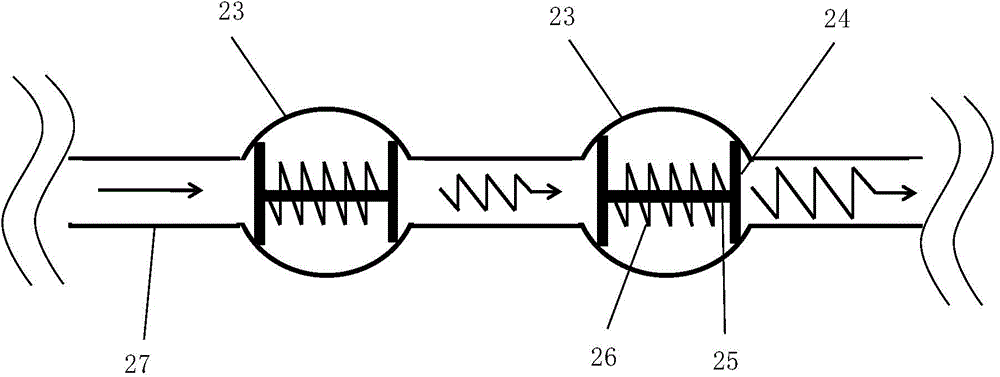

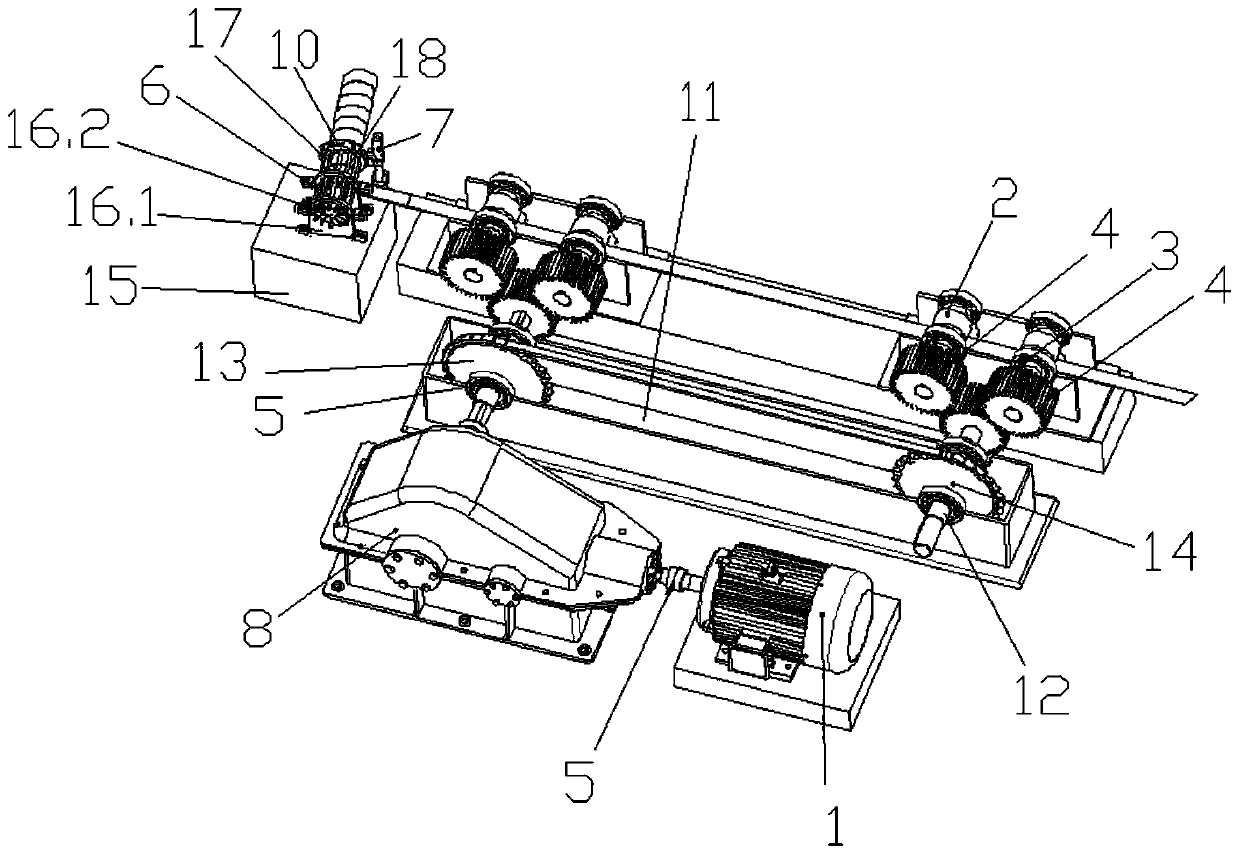

Ultrasonic tube coiling machine

PendingCN110014659AAchieve mechanical propertiesIncrease production capacityProduction rateEngineering

The invention discloses an ultrasonic tube coiling machine. The ultrasonic tube coiling machine comprises a transmission mechanism, a feeding mechanism, a spiral curling mechanism and an ultrasonic emitter, the transmission mechanism comprises a motor, a speed reducing mechanism and a chain transmission; the feeding mechanism comprises two groups of feeding devices which are identical in groups, the chain transmission is connected with the feeding devices, the rotation speed of the chain transmission is reduced, and then the movement is transmitted to the feeding devices; the spiral curling mechanism comprises a curling mechanism and a welding mechanism, the feeding devices convey materials to the curling mechanism, the curling mechanism rolls the materials into a tube shape, the ultrasonic emitter transmits the energy to the welding area, the local high temperature is generated, and the welding mechanism is used for welding and forming the tubular material. By means of the reasonablestructural design, the mechanical and automatic production of the coiled material is realized, the labor can be saved while the productivity is ensured, the labor are saved, and the production safetyis ensured.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

Lump coal bunker automatic unloading method

InactiveCN104071588ASafe working environmentReliable working environmentControl devices for conveyorsLoading/unloadingProduction rateProgrammable logic controller

Disclosed is a lump coal bunker automatic unloading method. The lump coal bunker automatic unloading method includes the following steps that an ultrasonic wave sensor is added on a portion of an unloading dolly, where a coal falling groove is located, drop signals fed back by the ultrasonic wave sensor are collected by a programmable logic controller (PLC) in periodicity mode, and the result that whether the dolly moves or not is confirmed after the drop signals are compared with a set numerical value; when the unloading dolly moves, the PLC sends signals to a coal feeding hand wheel above a belt and enables the coal feeding hand wheel to stop feeding lump coal and a plow unloading machine of the unloading dolly is uplifted firstly, and then the whole unloading dolly moves forwards; when the unloading dolly moves to the terminal point of a coal bunker, the unloading dolly automatically returns to the initial point of the coal bunker, and the unloading dolly runs in continuous circulation mode. The lump coal bunker automatic unloading method is high in automatic degree, accurate in drop control, and safe, reliable and efficient in run, achieves work environment optimization of employees, prevents the employees from working in a work environment large in noise intensity and large in dust quantity for a long term, guarantees health of the employees, can guarantee continuity and reliability of production, guarantees that dropping points of the lump coal are located in a prescribed range, guarantees production rate of the lump coal, and improves economic benefit.

Owner:YONGCHENG COAL & ELECTRICITY HLDG GRP

Efficient hydrogen chloride gas preparation equipment

InactiveCN113353887ABurn fullyGuaranteed productivityHydrogen chloride preparationElectrolysisReciprocating motion

The invention discloses efficient hydrogen chloride gas preparation equipment which comprises a machine body shell, a machine body cavity is formed in the machine body shell, a feeding mechanism is arranged in the machine body cavity, and the feeding mechanism comprises a first transmission shaft rotationally connected to the inner wall of the machine body shell. By means of an ingenious mechanical structure, workers can easily mix and electrolyze sodium chloride and water in a safe environment, and the sodium chloride and the water are fully mixed by means of a planetary gear structure and a centrifugal force principle, so that the electrolysis efficiency is improved.Moreover, after chlorine and hydrogen are separated, hydrogen is ignited and then chlorine is introduced, so that chlorine is fully combusted, excessive chlorine is prevented from harming health of people, set of reciprocating motion is utilized to spray water flow into cooled hydrogen chloride gas, and water flow and hydrochloric acid are fully mixed, so that production rate of hydrochloric acid is ensured, and production rate of hydrochloric acid is ensured.

Owner:厦门芝鹅贸易有限公司

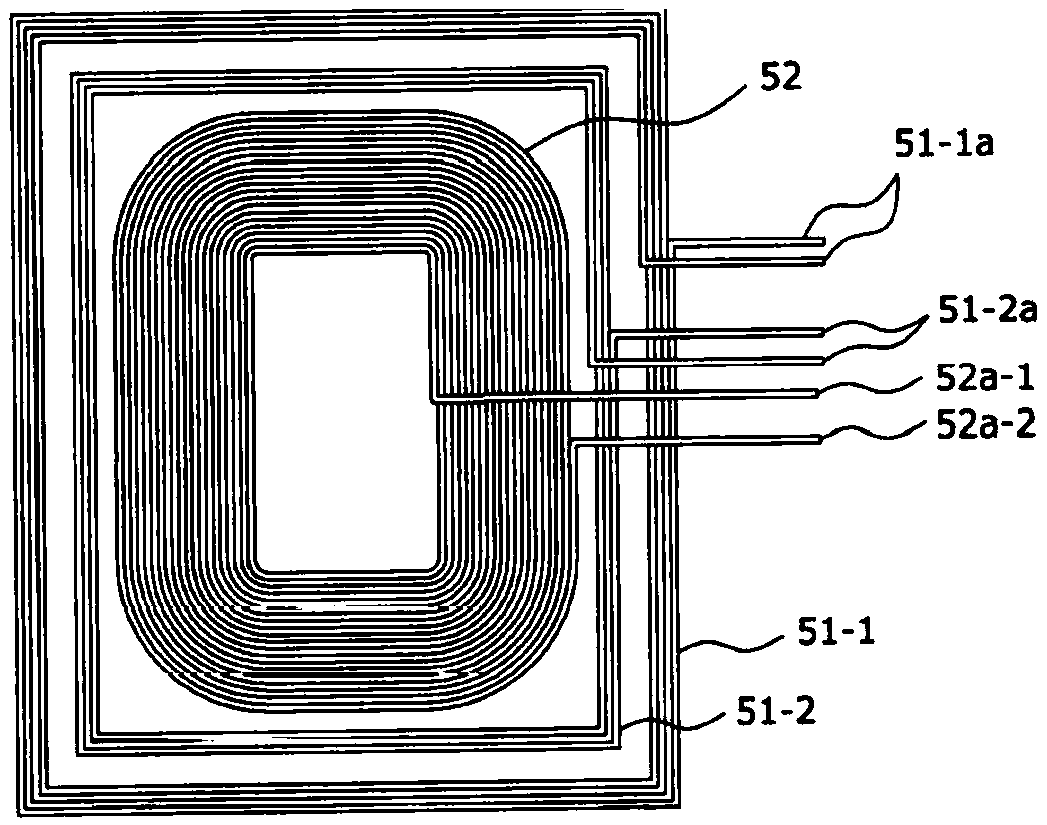

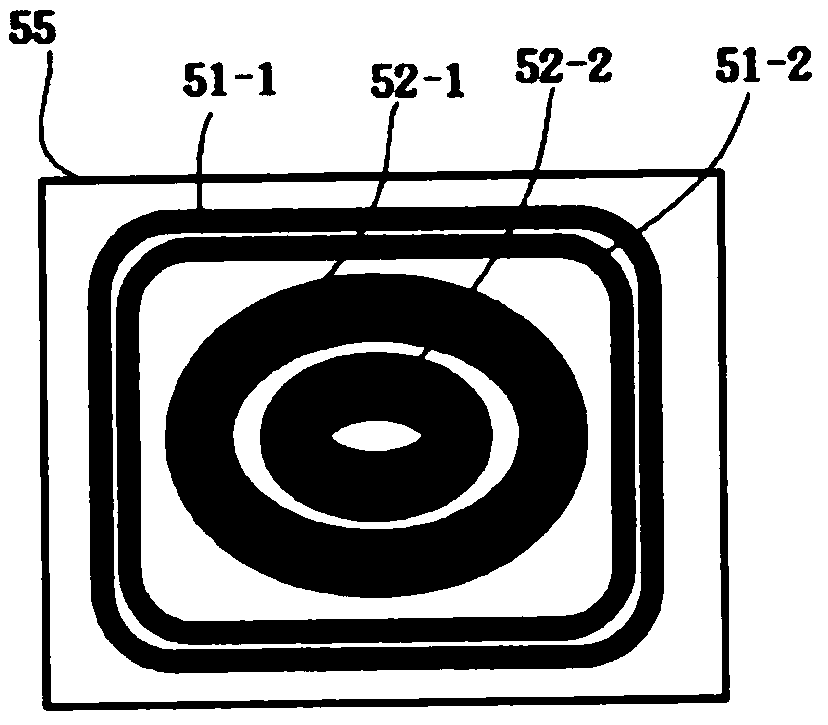

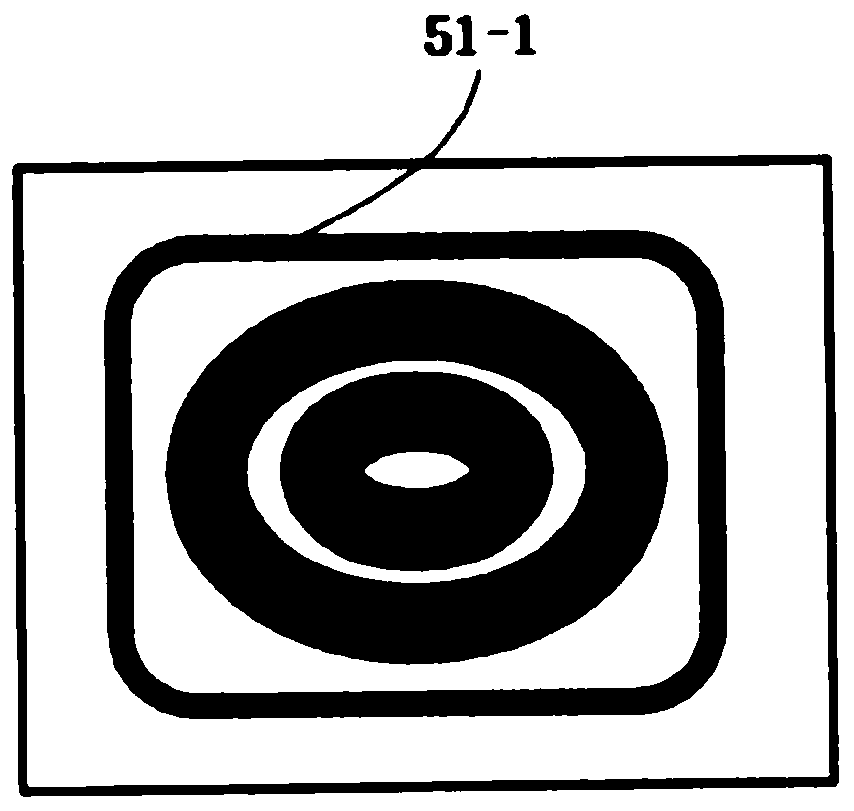

A method for manufacture a wireless communication antenna

ActiveCN109167161AThe effect of improving productivityReduce wasteLoop antennas with ferromagnetic coreVacuum evaporation coatingMetalShort range wireless

A method for manufacture a wireless communication antenna includes for a surface metal layer on one side surface of a flexible film, forming a surface metal layer on one side surface of that flexiblefilm, forming a surface metal lay on the surface metal layer, and forming a surface metal layer on the surface metal layer. S20, patterning the surface metal layer to form a helical antenna; Step S30,the metal is vacuum deposited on the other side surface of the flexible film to form an inner metal layer. The invention realizes better short-range wireless communication and also realizes heat dissipation of various components in the portable terminal.

Owner:SHENZHEN ACCOMTECH COMM ELECTRONICS CO LTD

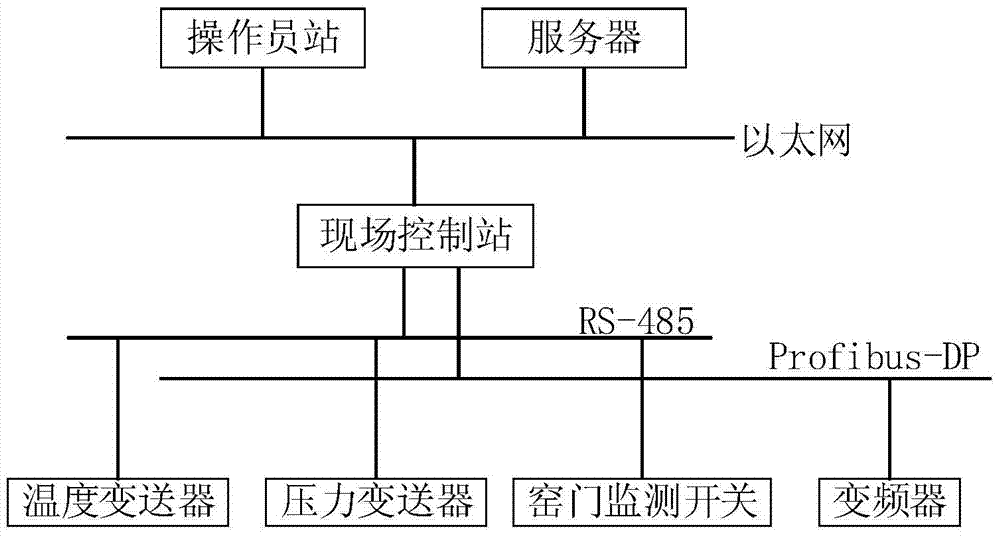

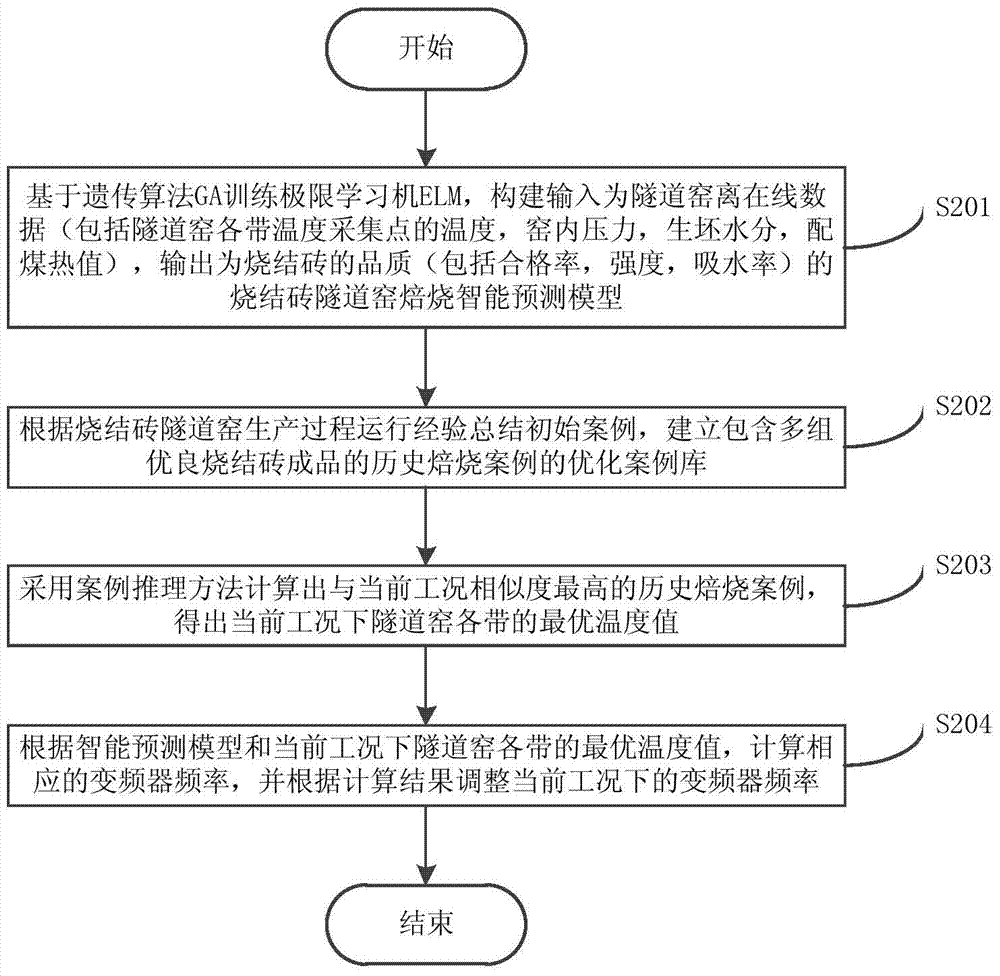

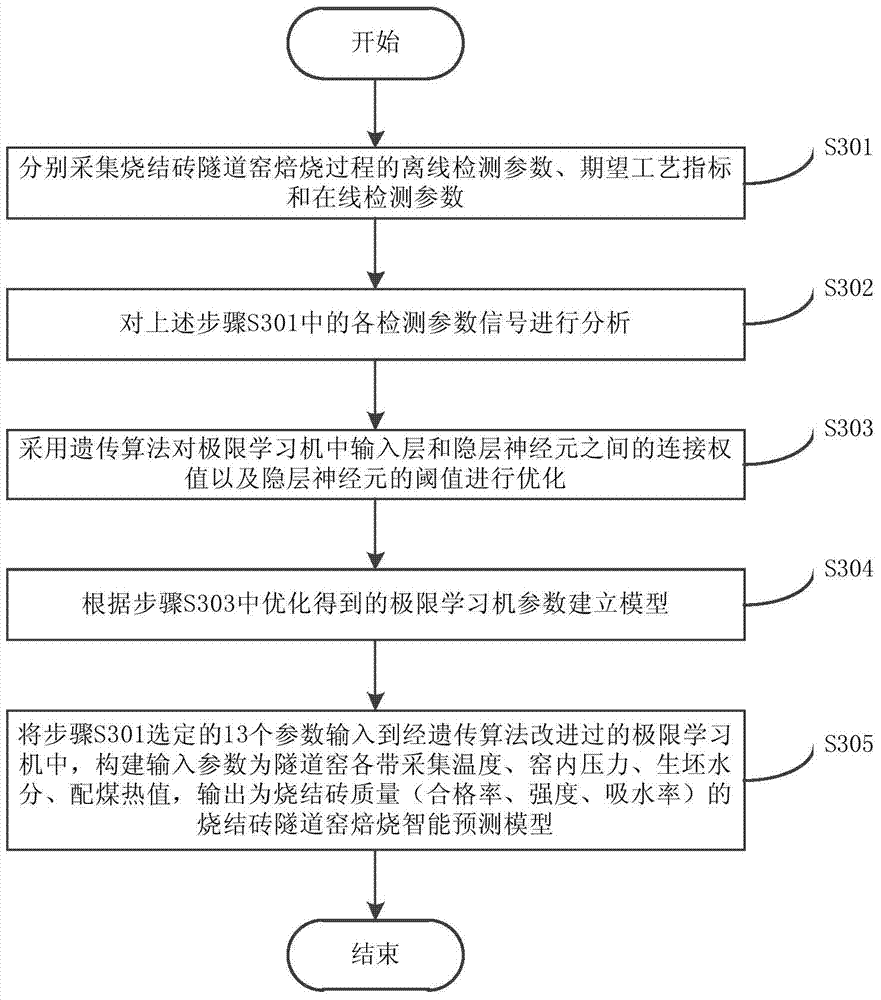

An intelligent optimization control method and device for the firing process of sintered brick tunnel kiln

The invention discloses an intelligent optimization control method and device for the roasting process of a sintered brick tunnel kiln, wherein the method includes: step A: training an extreme learning machine ELM based on a genetic algorithm GA, constructing the input as the off-line data of the tunnel kiln, and the output as the sintering The intelligent prediction model of fired brick tunnel kiln firing for brick quality; Step B: Summarize the initial case according to the operation experience of the fired brick tunnel kiln production process, and establish an optimized case library containing multiple groups of historical firing cases of excellent fired brick products; Step C: Use The case reasoning method calculates the historical roasting case with the highest similarity with the current working condition, and obtains the optimal temperature value of each zone of the tunnel kiln under the current working condition; Step D: According to the intelligent prediction model and the tunnel kiln under the current working condition The optimal temperature value of each zone of the kiln, calculate the corresponding inverter frequency, and adjust the inverter frequency under the current working condition according to the calculation results.

Owner:GUANGXI UNIV

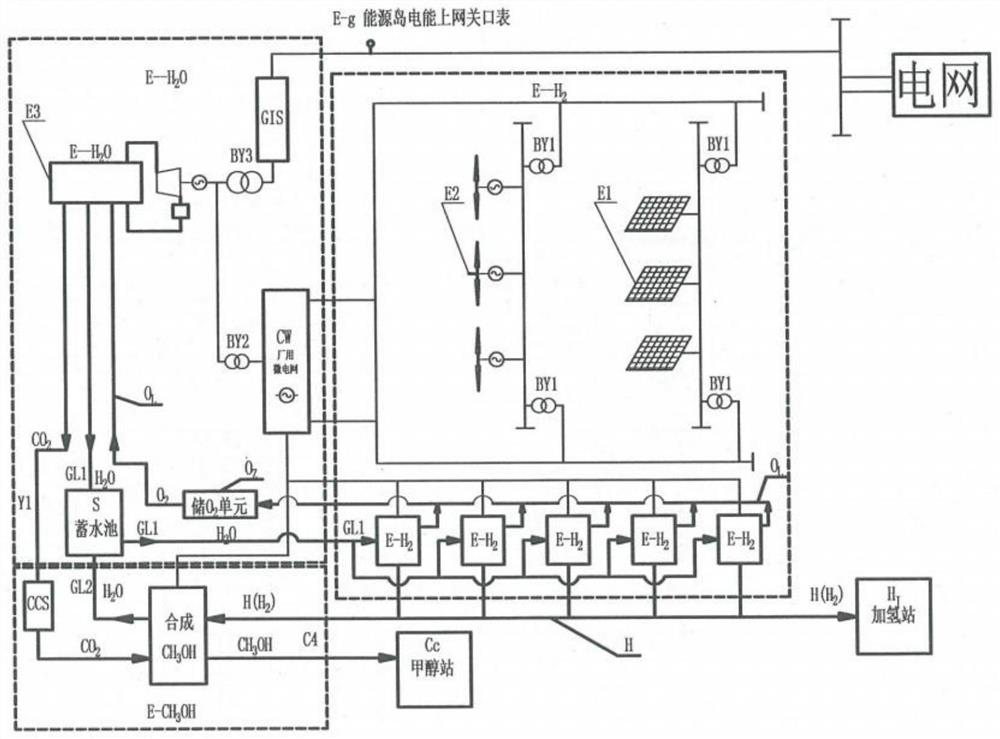

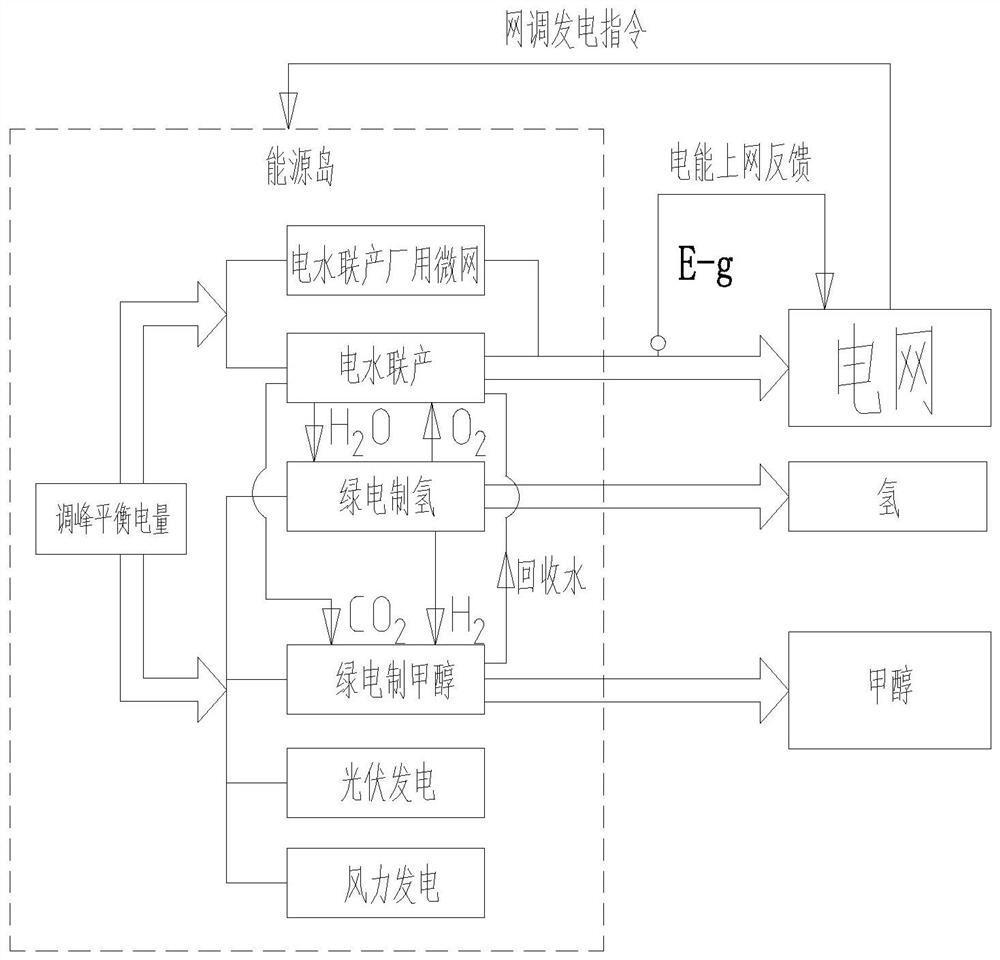

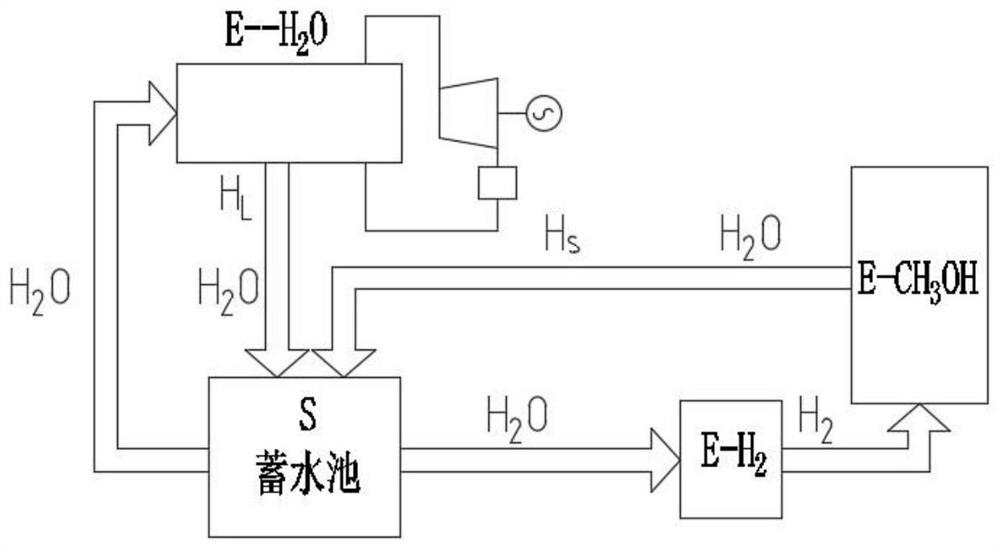

Electricity, water, hydrogen and methanol poly-generation energy island and method

PendingCN114000979ARealize resource utilizationEmission reductionWind motor with solar radiationElectrolysis componentsHydrogen storage systemHydrogen production

The invention discloses an electricity, water, hydrogen and methanol poly-generation energy island and method, and belongs to the technical field of energy utilization. The energy island comprises a flue gas water extraction electricity and water co-generation system, a coupling power generation hydrogen production and storage system and a carbon collection methanol production system. The electricity, water, hydrogen and methanol poly-generation method specifically comprises the following steps: 1) a carbon neutralization method in an energy island; 2) a zero water taking method; and 3) a wind-light-fire coupling energy-saving power generation method. According to the energy island provided by the invention, green electricity hydrogen production is integrated by recovering flue gas condensate water, carbon dioxide is further recovered, meanwhile, methanol is produced by green electricity, green electric energy gap is compensated by peak regulation balance electric quantity in the island, and zero water taking outside the island and carbon neutralization in the island are realized by coupling an electricity-water poly-generation unit with a wind turbine generator and photovoltaic power generation.

Owner:JINGNENG (XILINGUOLE) POWER CO LTD +1

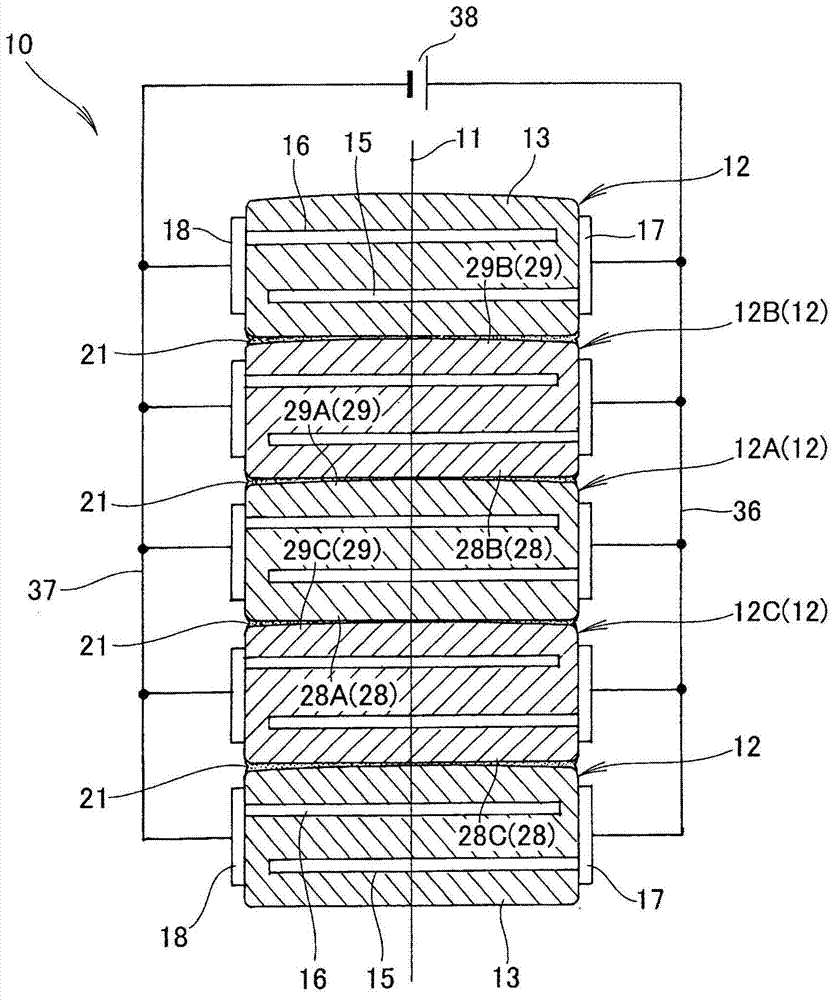

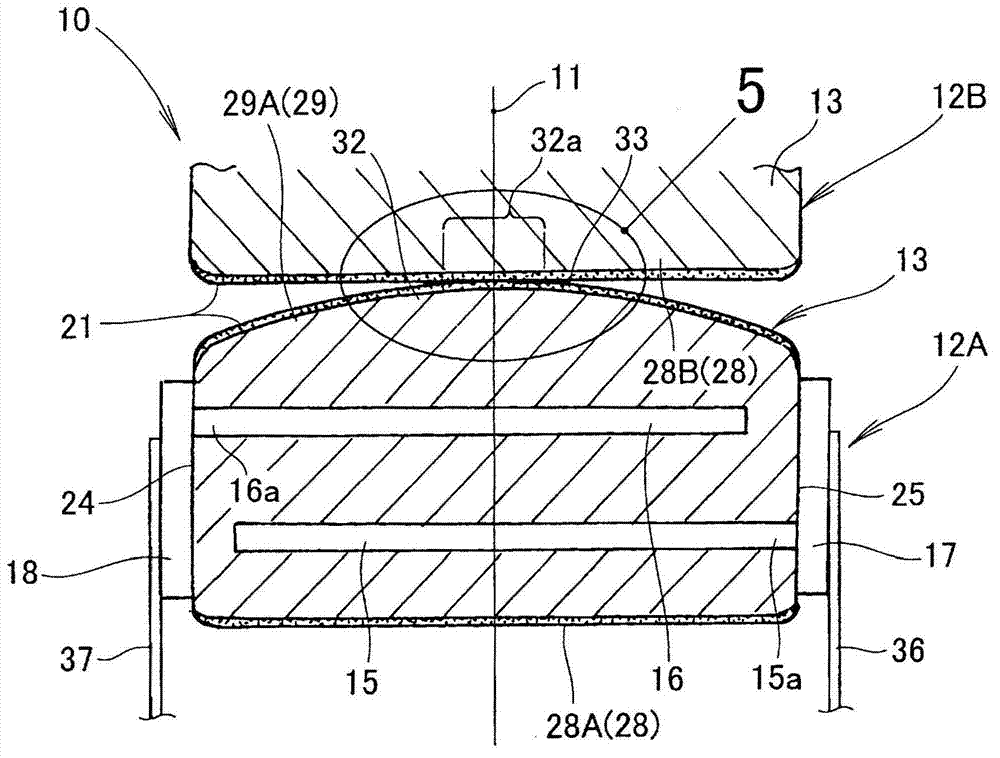

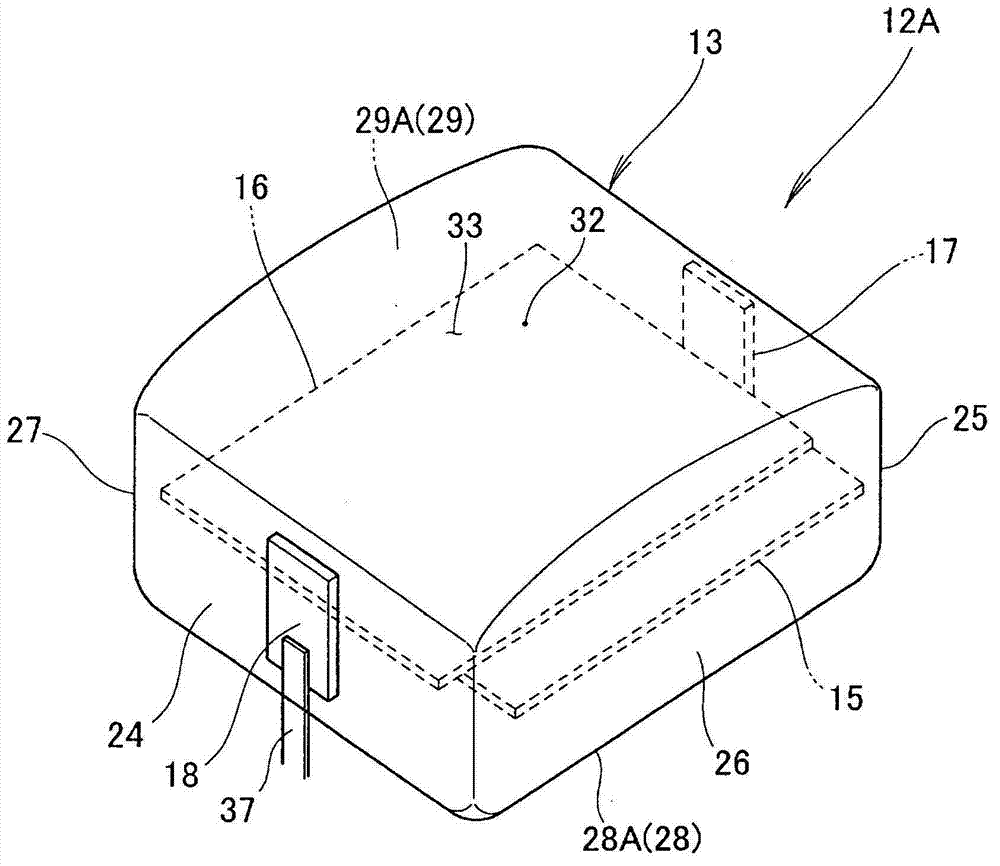

Laminated piezoelectric body

InactiveCN103370804AIncreased durabilityThe grinding process is simplePiezoelectric/electrostrictive device manufacture/assemblyCentral projectionEngineering

A laminated piezoelectric body (10) in which an internal positive electrode (15) and an internal negative electrode (16) are arranged at a predetermined distance from each other in the lamination direction of a plurality of piezoelectric element segments (12), while being arranged so as to be perpendicular to the lamination direction of the plurality of piezoelectric element segments (12). A piezoelectric element segment (12A) has an upper contact portion (29A) that comes into contact with a lower contact portion (28B) of an upper piezoelectric element segment (12B). The upper contact portion (29A) has a central projection (32), which protrudes toward the lower contact portion (28B), in the central portion.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com