Apparatus for laser cutting and/or marking

A marking and laser beam technology, applied in laser welding equipment, large fixed members, program control manipulator, etc., can solve the problem of high motor cost, achieve low cost, ensure productivity, and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

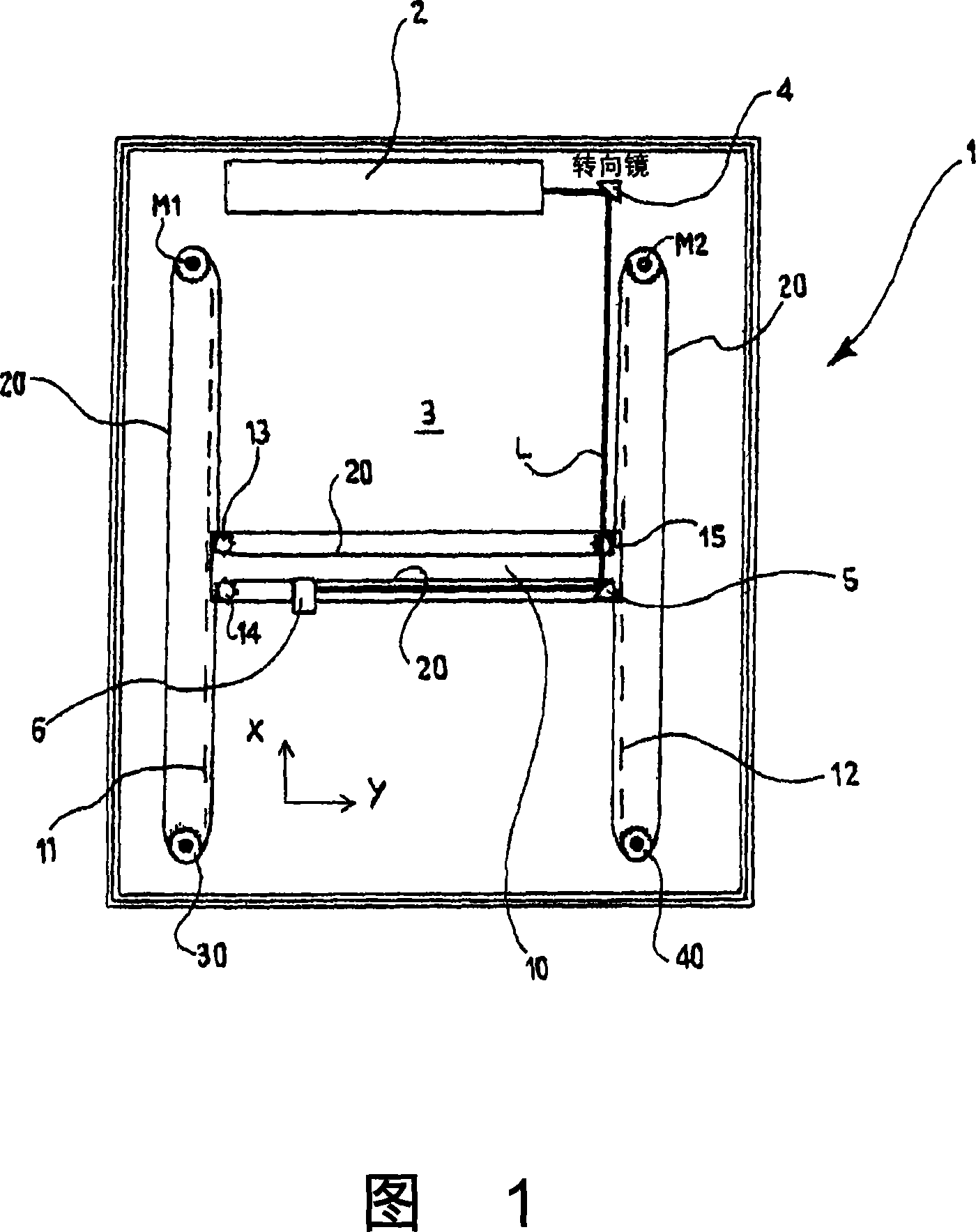

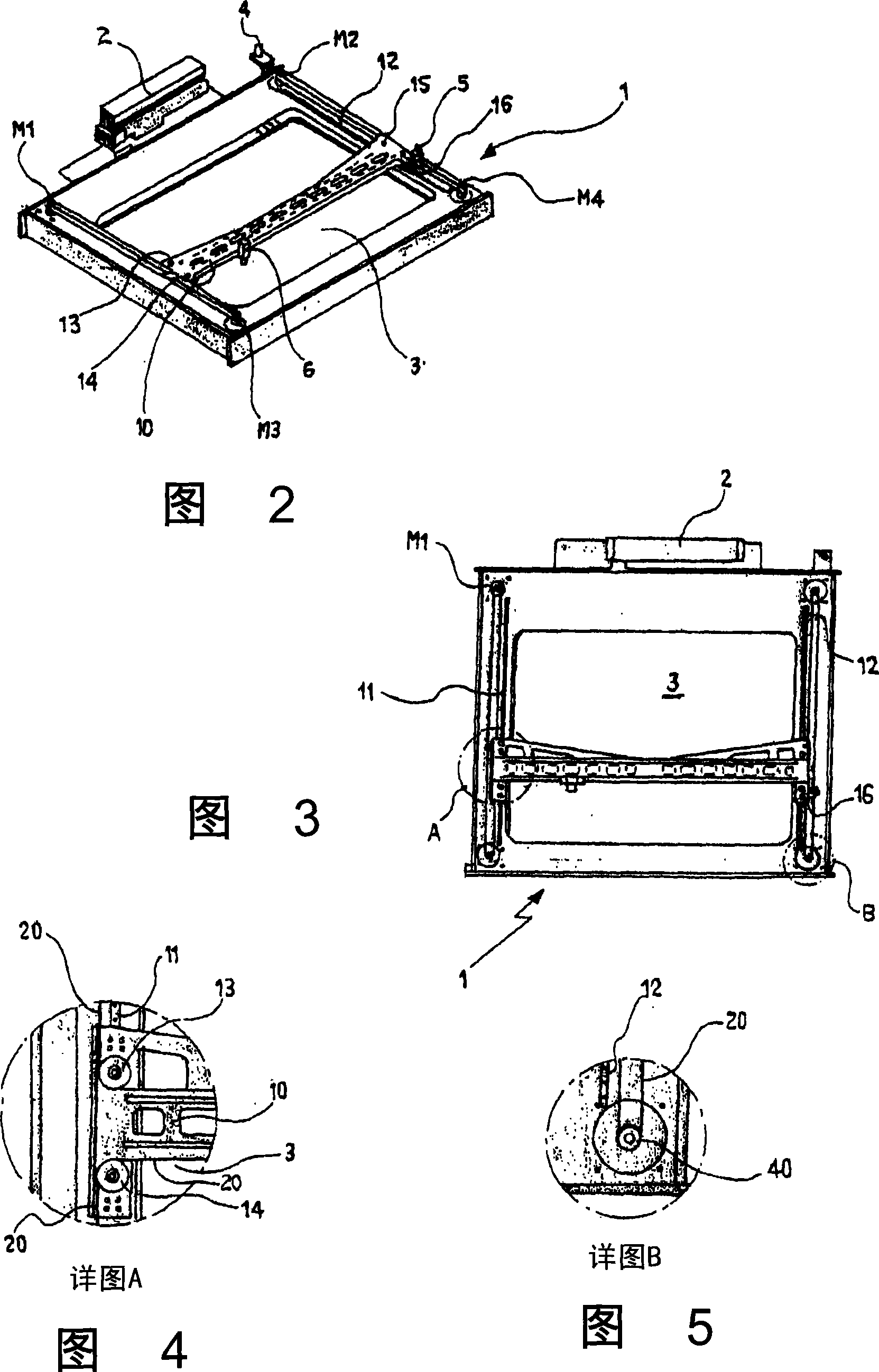

[0045] Figure 1 is a diagram of a device 1 according to the invention. The device comprises a laser source 2 arranged at a fixed position, which generates a laser beam L suitable for cutting and marking the product to be processed. For example a laser source may have a power of about 500W. The laser beam L generated by the laser source 2 is directed towards the working plane 3 by means of a series of focusing and reflecting optics 4, 5, 6 such as prisms, lenses, mirrors, focusing heads etc.

[0046] A product with a substantially planar structure is positioned on the working plane 3 for cutting or marking by the laser beam L. In the illustrated embodiment, the working plane 3 has a 1000×700mm 2 size, but in general its size can be different, for example 300×300mm 2 or 1000×1000mm 2 and bigger.

[0047] The focusing head 6 receives the laser beam L transferred by the mirrors 4 and 5 and focuses it on the product positioned on the working plane 3 . The focusing head 6 may ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com