An intelligent optimization control method and device for the firing process of sintered brick tunnel kiln

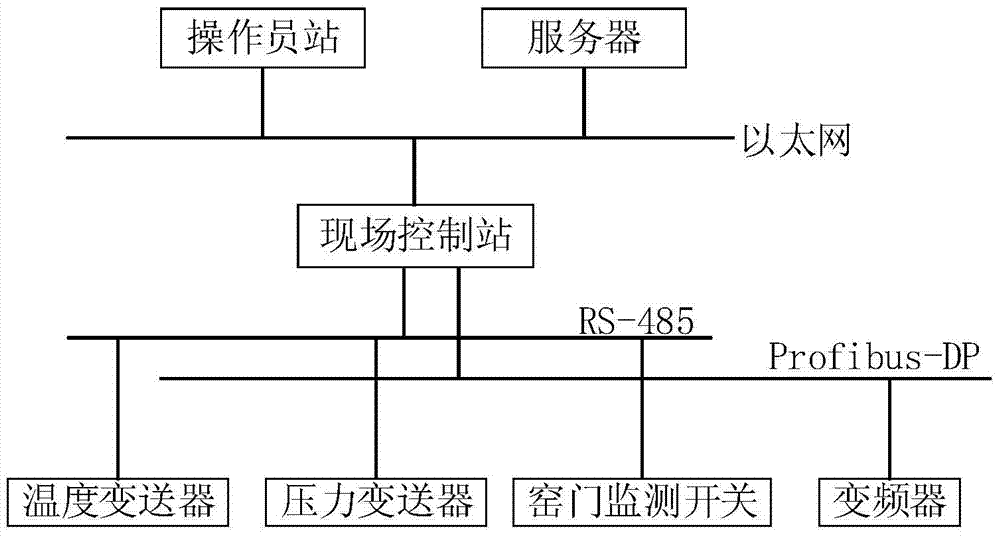

An intelligent optimization and tunnel kiln technology, which is applied in the fields of electrical equipment and material science, instrumentation, and industrial automatic control, can solve the problems of uneven product quality, high production energy consumption, and low production efficiency, so as to stabilize the quality of sintered bricks and reduce Energy consumption, the effect of real-time monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

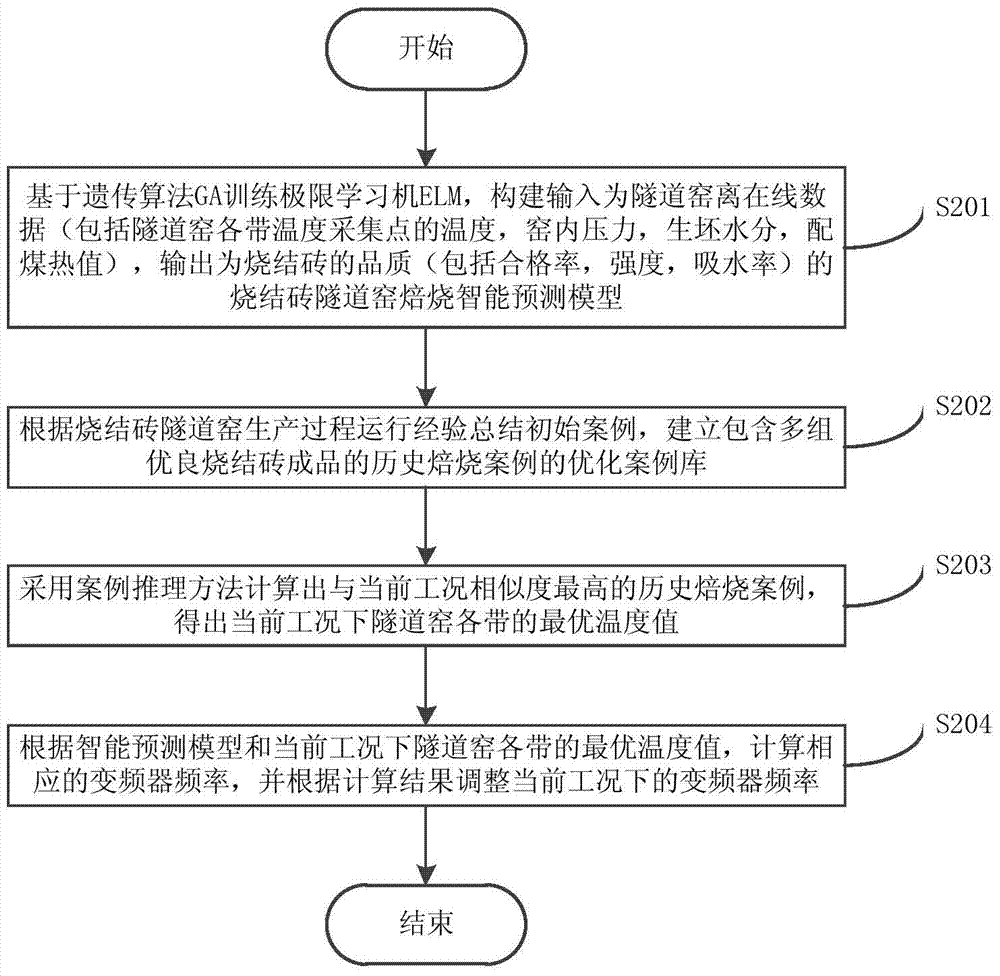

[0051] This embodiment mainly describes the intelligent optimization control method for the sintered brick tunnel kiln roasting process of the present invention, such as figure 2 As shown, the method includes:

[0052] Step S201: Train the extreme learning machine ELM based on the genetic algorithm GA, construct the offline data of the tunnel kiln as the input (including the temperature of the temperature collection points in each zone of the tunnel kiln, the pressure in the kiln, the moisture content of the green body, and the calorific value of the coal blending), and the output is the sintering Brick quality (including pass rate, strength, water absorption rate) intelligent prediction model for fired brick tunnel kiln firing.

[0053] Step S202: Summarize the initial cases according to the operation experience of the fired brick tunnel kiln production process, and establish an optimized case base containing multiple groups of historical firing cases of excellent fired bric...

Embodiment 2

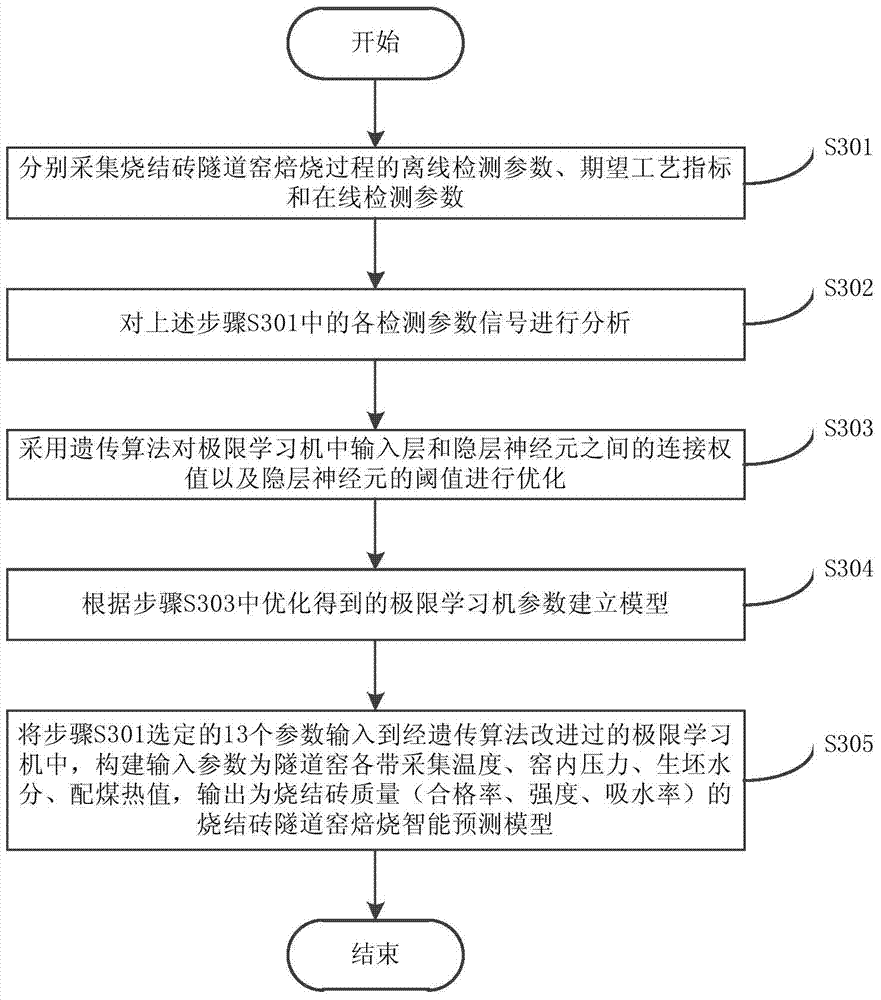

[0058] This embodiment describes in detail the method for creating an intelligent prediction model for sintered brick tunnel kiln firing in step S201, as follows: image 3 shown, including:

[0059] Step S301: separately collect the offline detection parameters, expected process indicators and online detection parameters of the firing process of the sintered brick tunnel kiln;

[0060] The collected offline detection parameters include: raw body moisture, coal blending calorific value, strength of fired bricks, water absorption rate of fired bricks, frost resistance, pass rate and other test data; expected process indicators include pass rate of fired bricks, strength, water absorption rate, etc.; The online detection parameters include: the temperature data and pressure values of each zone of the tunnel kiln transmitted by the thermocouple and pressure probe through the I / O module of the DCS system.

[0061] Step S302: Use data processing software to analyze each detection...

Embodiment 3

[0067] like Figure 4 As shown, this embodiment describes the steps of optimizing the parameters in the extreme learning machine using the genetic algorithm in step S303, including:

[0068] Step S401: Initialize the genetic algorithm, mainly the process of parameter control: there are four parameters in the genetic algorithm that need to be set in advance, and in practical applications, it takes multiple tests to determine the reasonable values of these parameters, mainly including the following four parameter.

[0069] M: It is called the population size. The efficiency of the genetic algorithm is obviously affected by M. If the population size is too small, the diversity of the population will be reduced, and if it is too large, the efficiency of the algorithm will be reduced. For different problems, the population size is also different, and the generally recommended value range is 20-100.

[0070] N: It is called the terminal evolution algebra, and the generally recom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com