Dielectric film, dielectric element, and process for producing the dielectric element

A manufacturing method and technology of dielectric components, applied in semiconductor/solid-state device manufacturing, electrical components, semiconductor devices, etc., to achieve the effects of avoiding substrate interface degradation, easy operation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

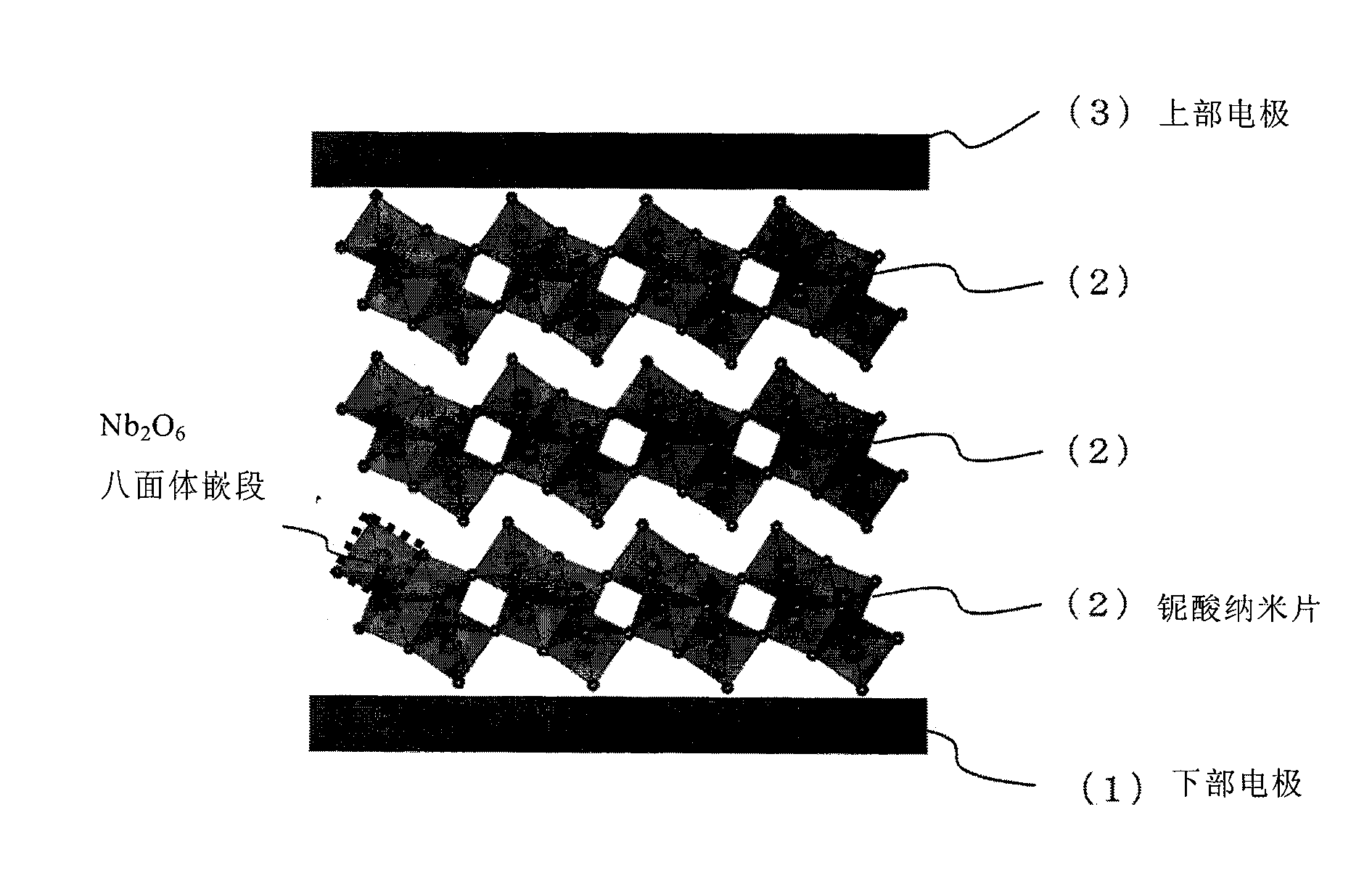

[0063] In this embodiment, layered niobium oxide (such as KTiNbO 5 ) as the starting material to make niobic acid nanosheets (2), such as figure 1 As shown, fabricated in atomically flat epitaxy SrRuO as follows 3 The substrate (1) alternately has the above-mentioned niobic acid nanosheets (2) and the multilayer film of cationic polymer (4) polyethyleneimine (PEI).

[0064] layered niobium oxide (KTiNbO 5 ) is obtained as follows, potassium carbonate (K 2 CO 3 ), titanium oxide (TiO 2 ) and niobium oxide (Nb 2 o 5 ) were mixed at a ratio of K:Ti:Nb of 1.05:2:1, calcined at 900° C. for 1 hour, and then calcined at 1100° C. for 20 hours.

[0065] 1 g of this powder was subjected to acid treatment in 100 mL of a predetermined 1 hydrochloric acid aqueous solution at room temperature to obtain a hydrogen exchange body (HTiNbO 5 ), then, add tetrabutylammonium hydroxide (hereinafter referred to as TBAOH) aqueous solution 100mL in 0.4g of this hydrogen exchange body, stir at ...

Embodiment 2

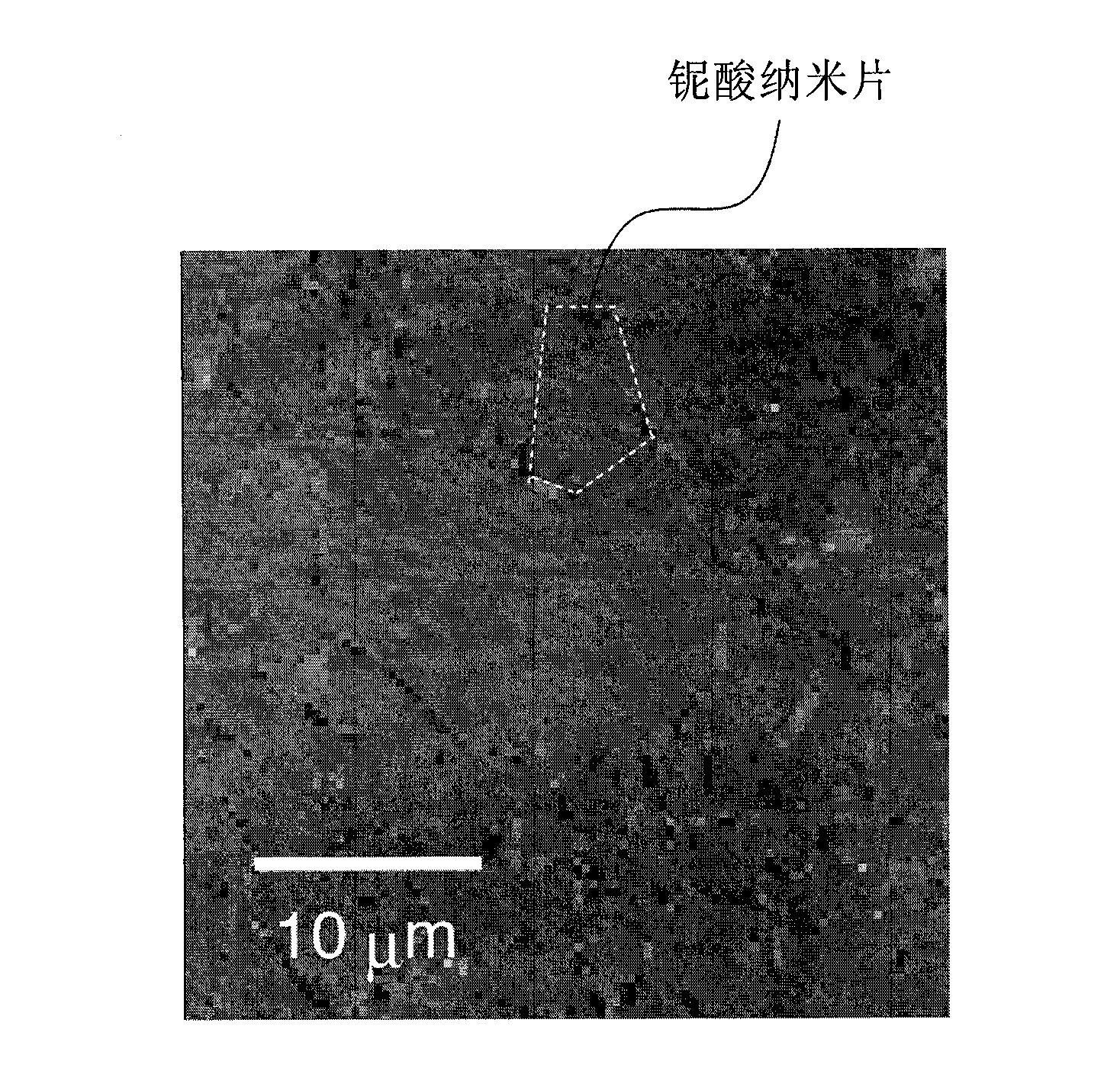

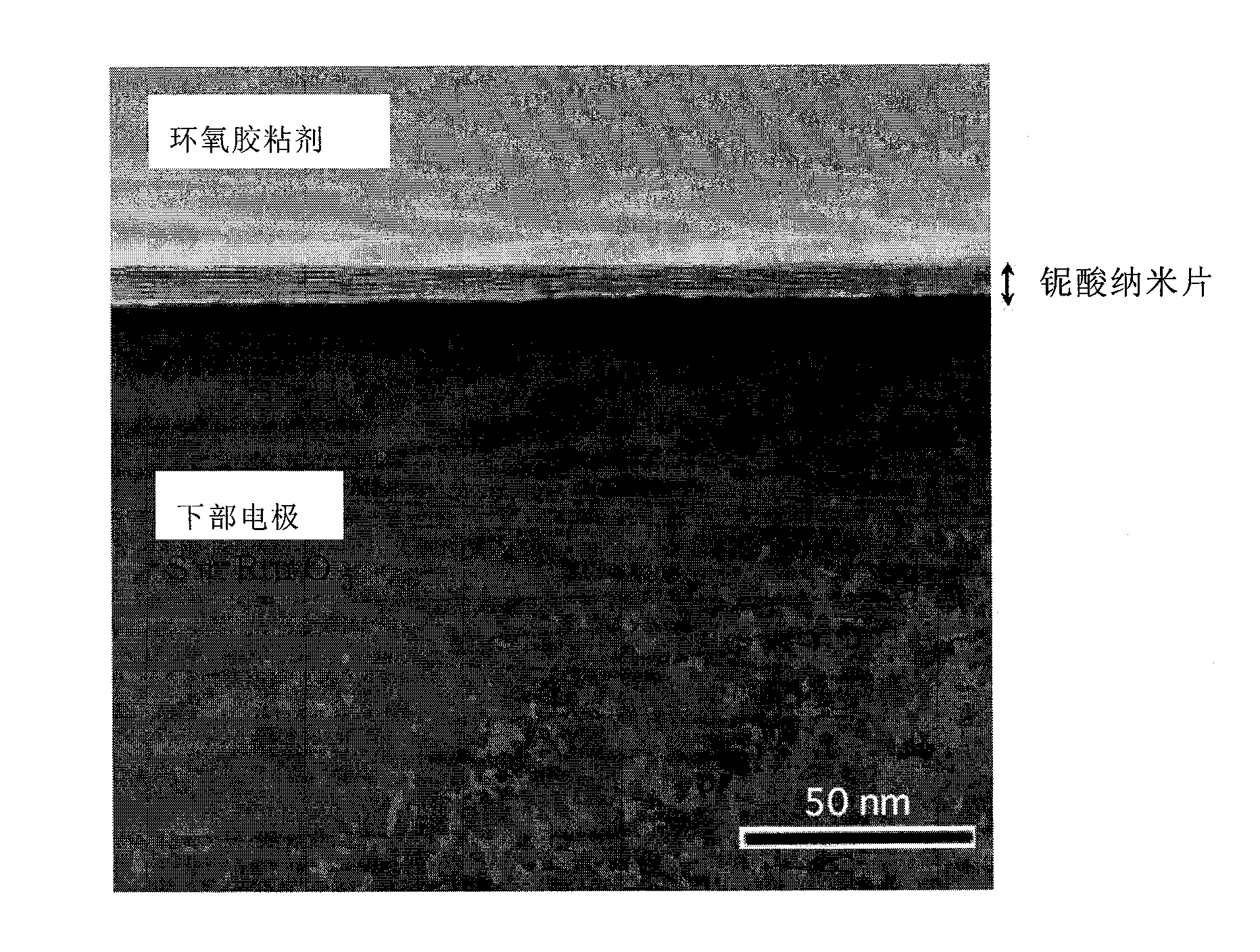

[0079] In this embodiment, layered niobium oxide (such as KTiNbO 5 ) as the starting material to produce niobate nanosheets (TiNbO 5 ),Such as figure 1 As shown, the atomically planar epitaxial SrRuO used as the lower electrode substrate 3 A multilayer film of the above-mentioned niobate nanosheets (2) was produced on the substrate (1) by the LB method (Langmuir-Blodgett method) as follows.

[0080] By the same method as in Example 1, the layered niobium oxide (KTiNbO 5 ) single-layer peeling, making and dispersing the composition formula TiNbO 5 It represents a milky white sol solution of rectangular nanosheets with a thickness of about 1 nm and a lateral dimension of 100 nm to 5 μm.

[0081] Epitaxial SrRuO by atomic planarity 3 The conductive substrate (1) of the lower electrode constituted was irradiated with ultraviolet rays under an ozone atmosphere to clean the surface, and then immersed in a solution of hydrochloric acid: methanol = 1:1 for 1 / 3 hour, and then imme...

Embodiment 3

[0092] In this embodiment, layered niobium oxide (for example, CsTi 2 NbO 7 、K 3 Ti 5 NbO 14 , KNb 3 o 8 ) as the starting material to produce niobate nanosheets (Ti 2 NbO 7 、Ti 5 NbO 14 , Nb 3 o 8 ),Such as figure 1 As shown, the atomically planar epitaxial SrRuO used as the lower electrode substrate 3 A multilayer film of the above-mentioned niobate nanosheets (2) was produced on the substrate (1) by the LB method (Langmuir-Blodgett method) as follows.

[0093] Niobate nanosheets (Ti 2 NbO 7 、Ti 5 NbO 14 , Nb 3 o 8 ) were synthesized in the following order respectively.

[0094] 2 NbO 7 Nanosheets>: cesium nitrate (CsNO 3 ), titanium oxide (TiO 2 ) and niobium oxide (Nb 2 o 5 ) were mixed in a ratio of 2.1:4:1 according to the ratio of Cs:Ti:Nb, calcined at 950°C for 1 / 2 hour, and then fired at 1100°C for 20 hours to synthesize the layered oxide CsTi 2 NbO 7 . 1 g of this powder was acid-treated in 100 mL of a prescribed hydrochloric acid aqueous s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com