Metal plate punching process

A blanking and process technology, which is applied in the field of sheet metal blanking process with high-precision section quality, can solve the problems of increasing product manufacturing cost, low production efficiency, and inability to meet the high production capacity of the factory, so as to achieve the effect of ensuring productivity and saving high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

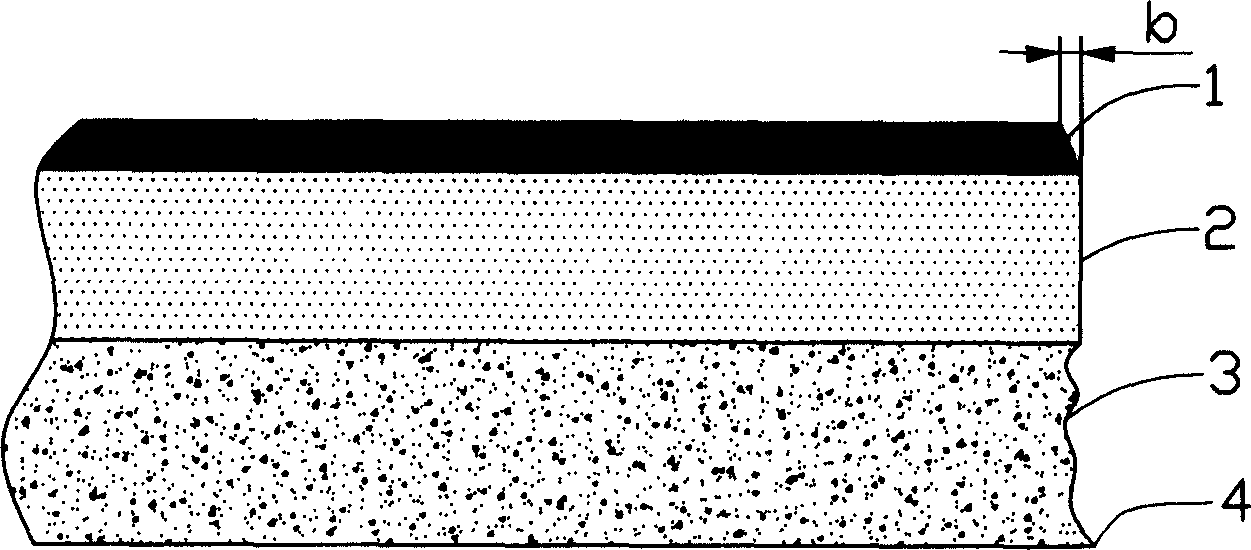

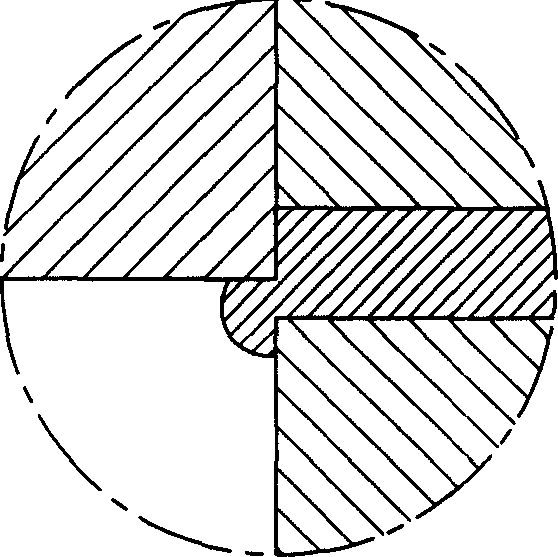

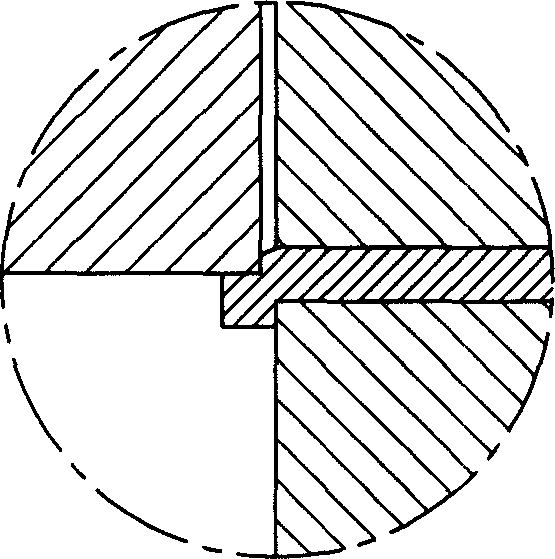

[0016] The sheet metal stamping process of the present invention is to obtain a blanking piece with high-precision cross-section quality through reasonable selection and design of the blanking gap, punching allowance, pressing force and punch edge structure. It is not only suitable for aluminum and copper materials with a thickness of 2mm to 12mm, but also suitable for punching and edge trimming of low-carbon steel materials with a carbon content of less than 0.15%.

[0017] In order to ensure the smoothness of the section of the blanking part and minimize the influence of factors such as blanking gap, cutting allowance, and pressing force on the quality of the section of the blanking part, the blanking part can be roughly machined once, and then finished one or several times . In rough machining, each parameter value can be the same or similar to that in ordinary blanking process.

[0018] The blanking gap has a great influence on the section quality of the punched part. To ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com