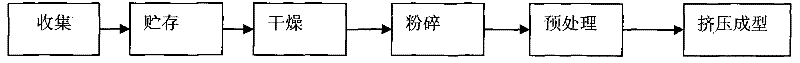

Method for producing shaped fuel from tobacco stalk biomass

A technology for forming fuel and biomass, which is applied in the field of tobacco stalk processing to achieve the effects of ensuring productivity, increasing cohesiveness and facilitating collection of tobacco stalks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Tobacco companies in Bijie area have established a tobacco stalk biomass fuel processing plant every 10km in the concentrated tobacco area, concentrating the tobacco stalk raw materials in this area, and each field is equipped with a processing plant with a production capacity of 1t / h’s biomass molding fuel extruder; the raw materials are stored in a bundled vertical stacking method, even if they are exposed to rain, not only will they not rot, but also gradually remove the soil clods at the root of the tobacco stalk (generally, the root of the tobacco stalk is molded under pressure) When it is cut off due to a large amount of soil), the root of the tobacco stalk with high calorific value can be fully utilized. The wax on the surface of the tobacco stalk is removed by rain in the early stage, and it is easy to move to the open shed for drying in the later stage. The moisture content of the raw material of the tobacco stalk is controlled below 30%. The crushing and knea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com