Planetary transmission hoisting mechanism used for charging crane and operation method thereof

A technology of planetary transmission and hoisting mechanism, applied to clockwork mechanism, winch device, etc., can solve problems affecting the completion of production plan and economic loss of production unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

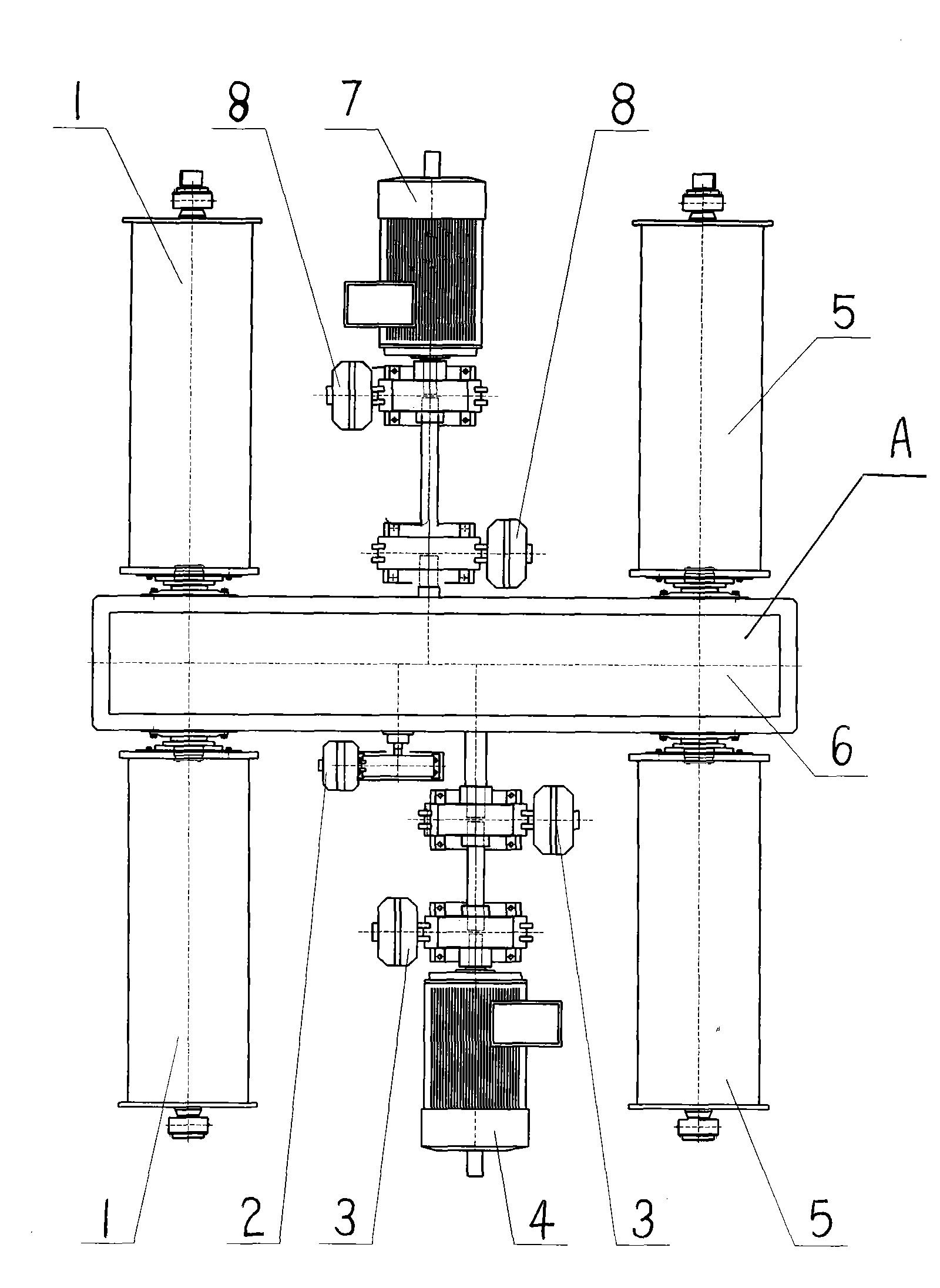

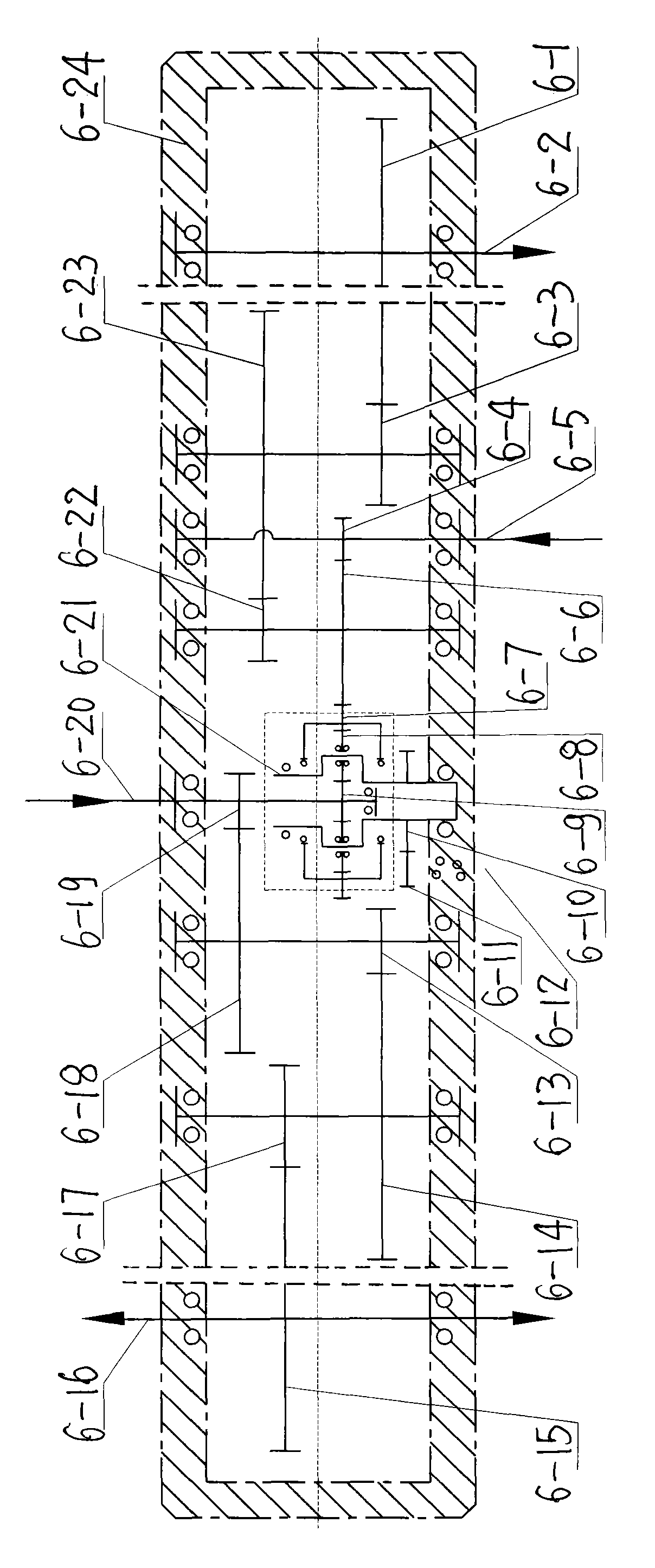

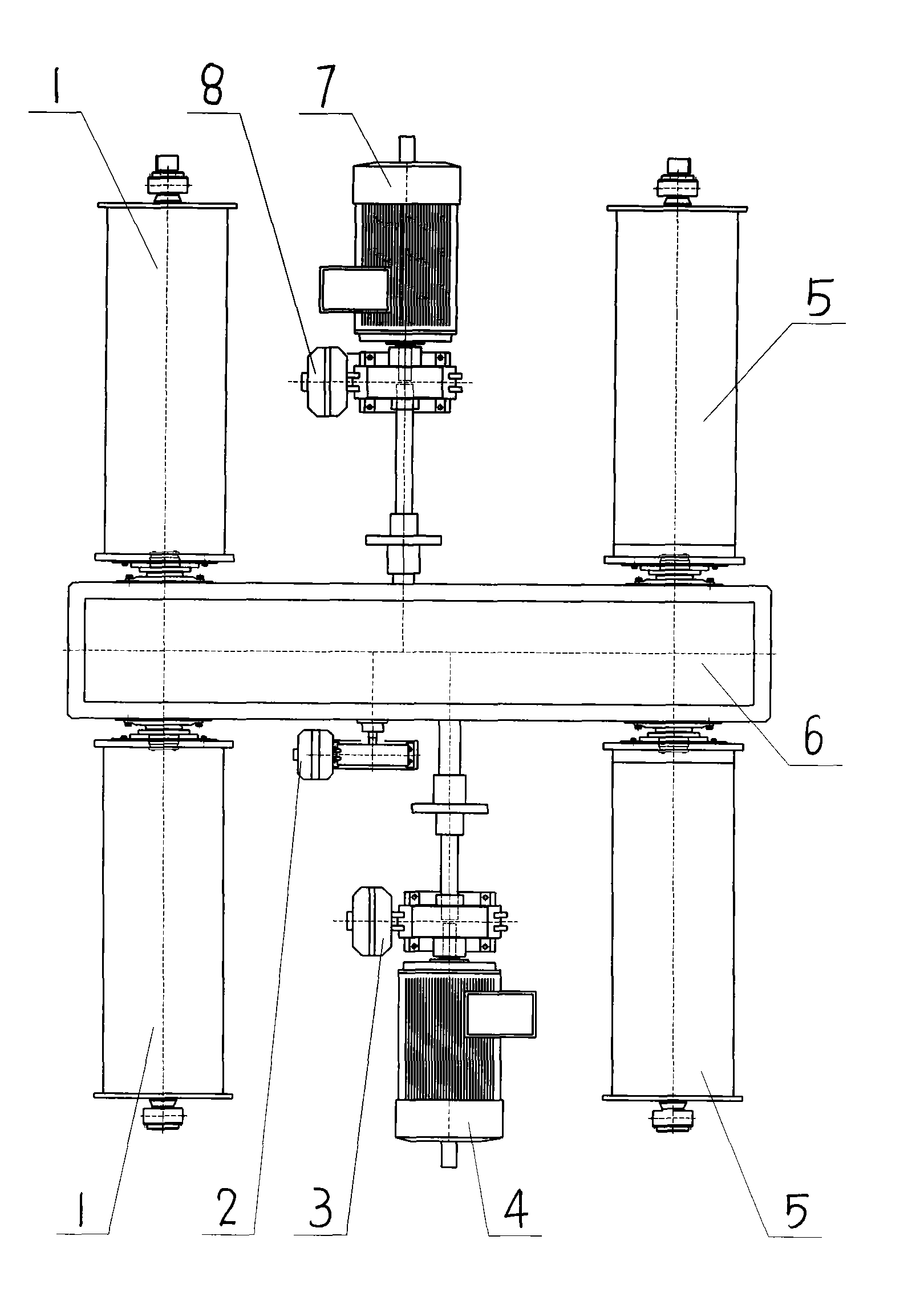

[0038] figure 1 , 2 Shown is one of the embodiments of the present invention, which is a planetary transmission hoisting mechanism for a feeding crane installed on a 60+60t-25.1m-A8 type feeding crane in a steelworks; including a motor, a brake and a reel It is characterized in that: a planetary reducer 6 containing a 2K-H planetary gear transmission code-named NGW is used, and the motor, brake and reel group are combined and connected to the planetary reducer 6 to form a planetary drive. Lifting mechanism, the planetary reducer is composed of a box body 6-24, a Z16 gear 6-1, a first output shaft 6-2, a Z15 gear 6-3, a Z14 gear 6-23, a first input shaft 6-5, Z13 gear 6-22, Z11 gear 6-4, Z12 gear 6-6, second input shaft 6-20, Z21 gear 6-19, Z22 gear 6-18, planetary gear train, random shaft 6-12, Z32 Gear 6-11, Z31 gear 6-10, Z23 gear 6-13, Z24 gear 6-14, Z25 gear 6-17, the second output shaft 6-16 and Z26 gear 6-15 are formed in the casing 6-24 The first output shaft 6-2, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com