A special machine for automatic lamp cap riveting

A technology of riveting point and special machine, which is applied to lamp head riveting machine. , In the field of riveting mechanism, it can solve problems such as large working error, low riveting efficiency, and unsuccessful riveting, and achieve the effects of reducing assembly and debugging time, improving work efficiency, and reducing power requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

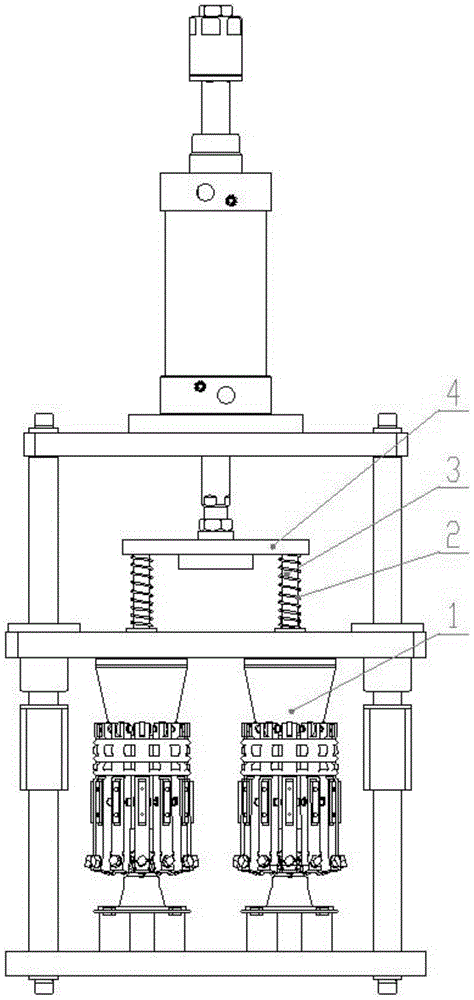

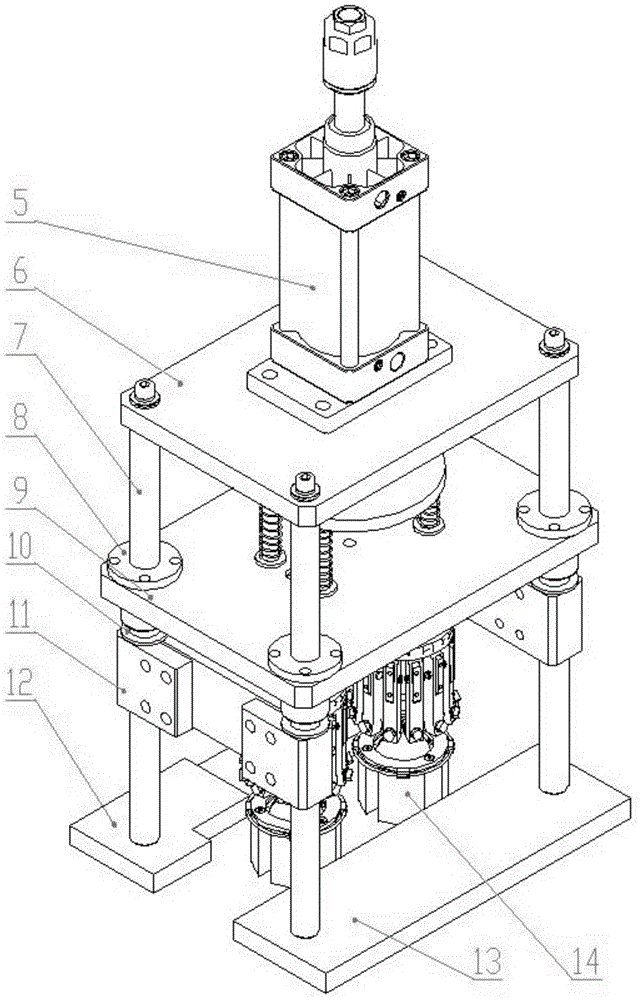

[0034] Such as figure 1 with figure 2 As shown, this embodiment is mainly composed of a riveting device 1, a compression spring 2, a connecting rod 3, a connecting plate 4, a cylinder 5, a top plate 6, a column 7, a linear bearing 8, a lifting plate 9, a rubber pad 10, and a limit splint 11 , Front base plate 12, rear base plate 13 are formed.

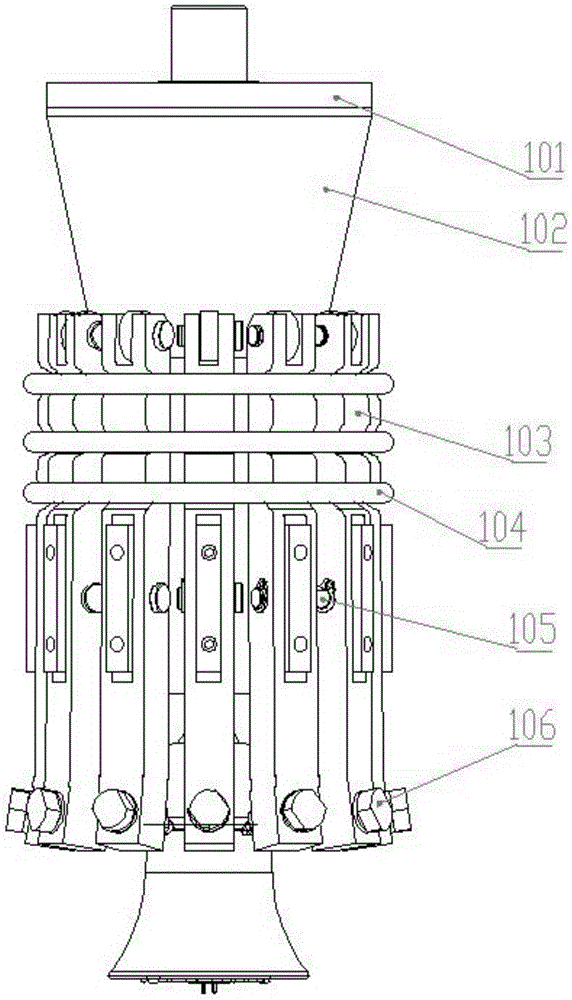

[0035] Such as image 3 with Figure 4 As shown, the pressure riveting device 1 is composed of a polyoxymethylene cover 101, a tapered platform 102, a strip lever 103, a small extension spring 104, a round pin 105, a riveting needle 106, a fixed shaft seat 107, a roller 108, a roller shaft 109, a small Square 110, little stage clip 111, stuffy cover 112, push post 113 form.

[0036] The polyoxymethylene sleeve 101 and the conical platform 102 are screwed together. The polyoxymethylene cover 101 is enclosed within the fixed shaft seat 107 top, and can slide up and down in its shaft. The fixed shaft seat 107 is fixed with a small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com