Edible fungus inoculation device

An inoculation device and a technology for edible fungi, applied in the fields of application, horticulture, and botanical equipment and methods, can solve the problems of unsuitable operation, high labor intensity, and high production cost, so as to reduce the chance of infection, reduce labor intensity, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The content described in the embodiment of this specification is only an example of the implementation form of the inventive concept, and the protection scope of the present invention should not be regarded as limited to the specific form stated in the embodiment. Equivalent technical means that a person can think of based on the inventive concept.

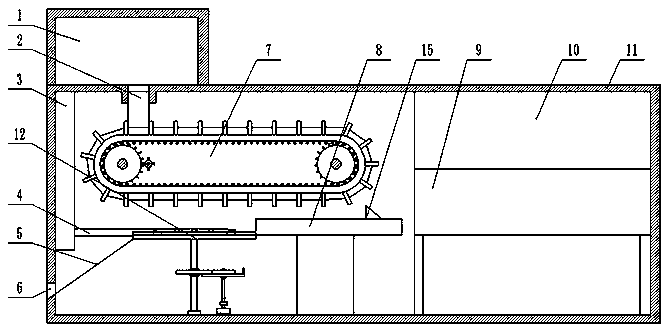

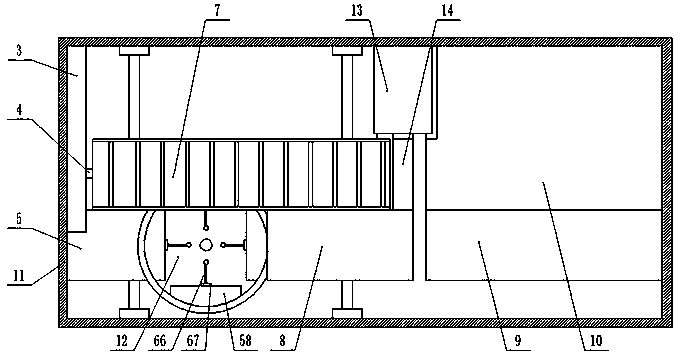

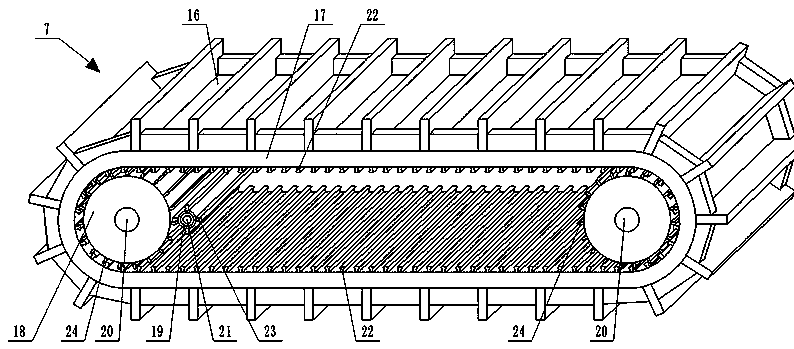

[0034] combined with Figure 1-13 , 1. Bacteria stick disinfection box, 2. Bacteria stick feeding outlet, 3. Bacteria box, 4. Inoculation pipe, 5. Discharging inclined plate, 6. Outlet, 7. Bacteria stick conveying device, 8. Bacteria stick channel , 9. Bacteria stick vertical push device, 10. Bacteria stick punching device, 11. Body, 12. Inoculation device, 13. Bacteria stick horizontal push device, 14. Bacteria stick punching groove, 15. Auxiliary inclined plate, 16. Groove, 17. conveyor belt, 18. driven drive shaft, 19. belt pulley, 20. driven drive shaft center shaft, 21. drive drive shaft, 22. drive belt drive shaft, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com