Agricultural sowing equipment

An equipment and agricultural technology, applied in the field of agricultural seeding equipment, can solve the problems of waste, easy spacing errors, low seeding efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0040] Wherein, the accompanying drawings are only for illustrative purposes, showing only schematic diagrams, rather than physical drawings, and should not be construed as limitations on this patent; in order to better illustrate the embodiments of the present invention, some parts of the accompanying drawings will be omitted, Enlarged or reduced, does not represent actual product size.

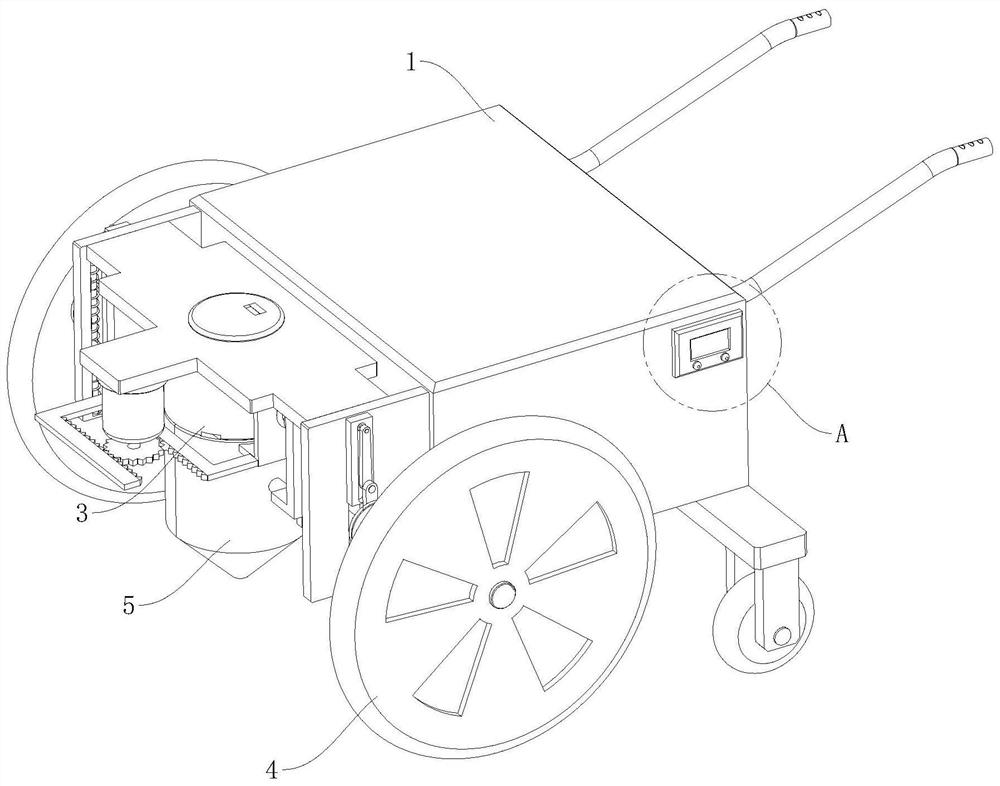

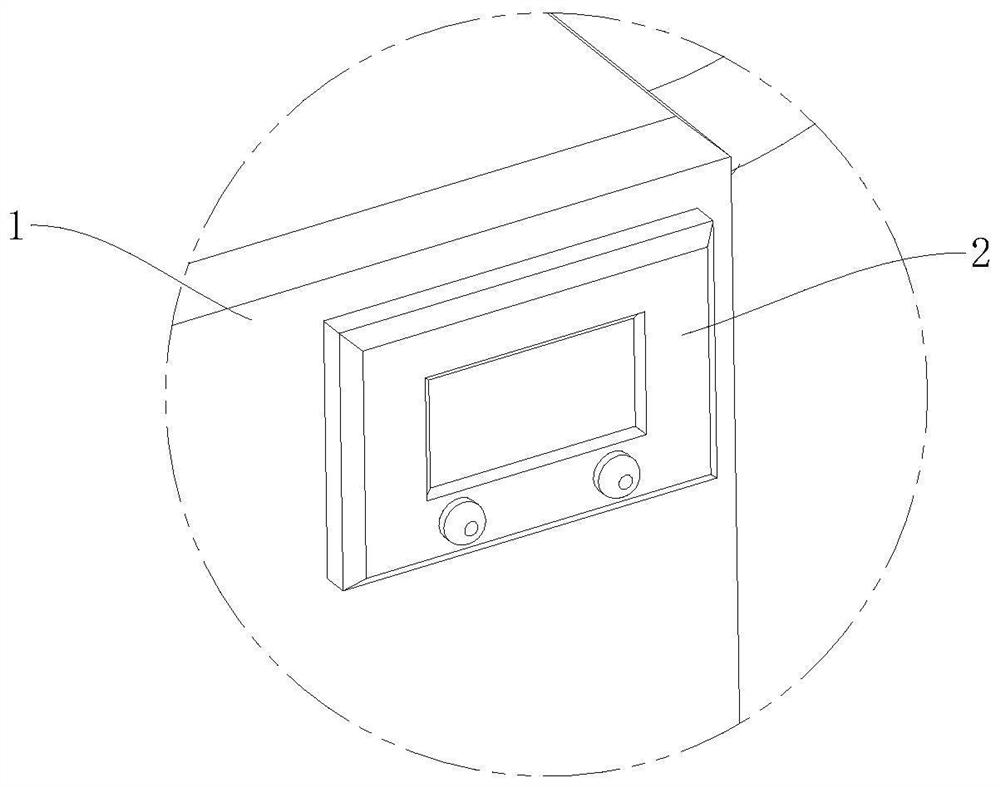

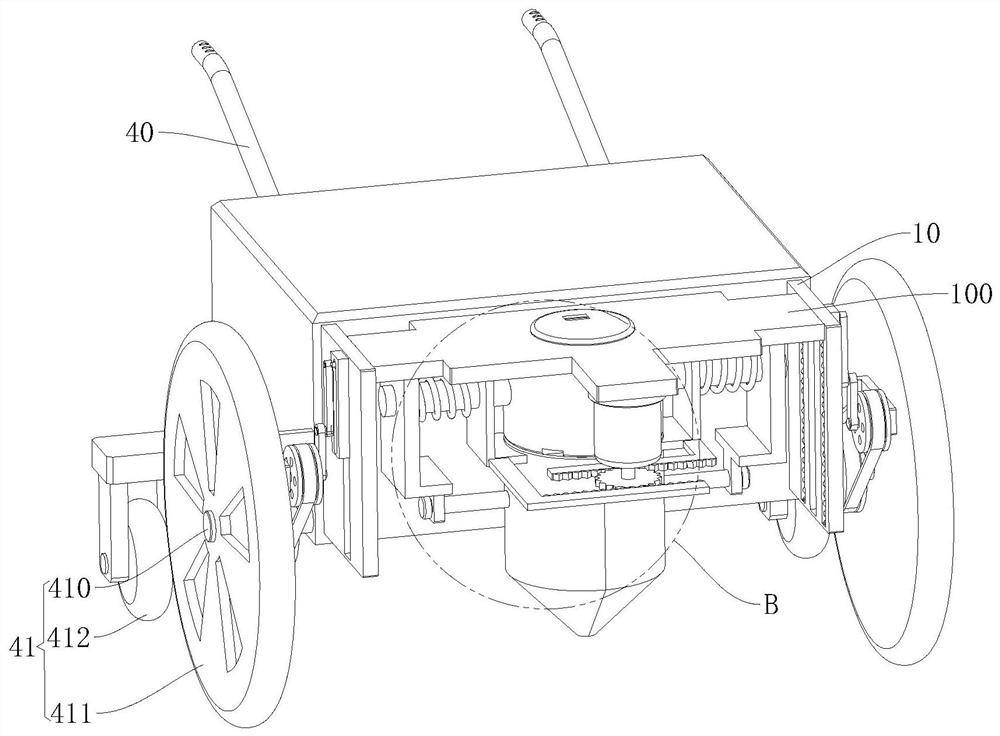

[0041] refer to Figure 1 to Figure 9 The agricultural seeding equipment shown includes a vehicle body 1, and also includes a controller 2, a spreading mechanism 3, a traveling mechanism 4 and a soil expanding mechanism 5. The controller 2 is fixed on the outer wall of the vehicle body 1, and the traveling mechanism 4 are arranged on both sides of the vehicle body 1 to support the walking of the equipment. The tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com