Automatic lamp holder riveting pressure device

A riveting needle and strip technology, applied in the field of lamp head riveting and pressing device and riveting mechanism, can solve the problems of lamp head displacement, affecting lamp head, driving lamp head to deviate, etc., and achieve the effect of simplifying structure, uniform distribution, and avoiding lamp head deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

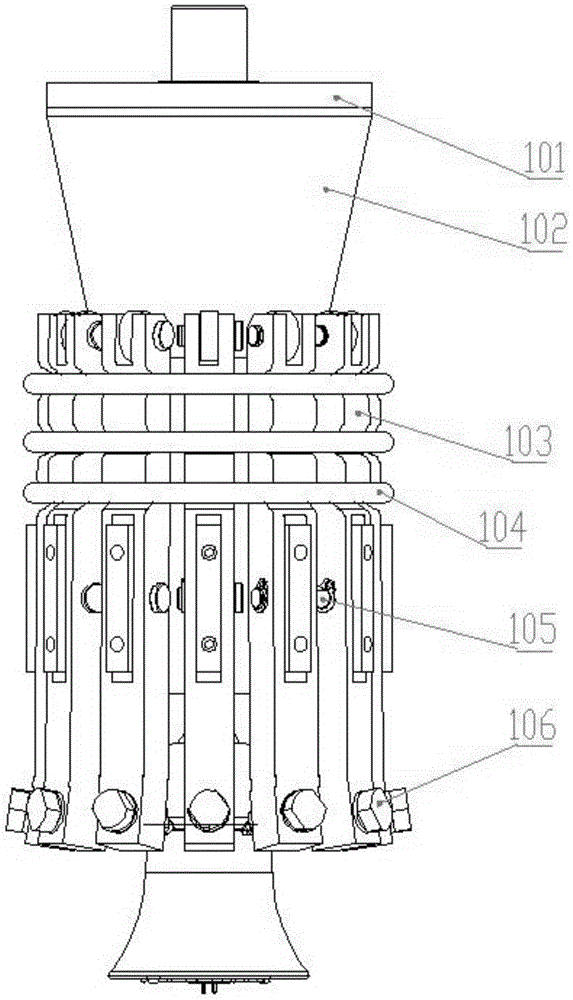

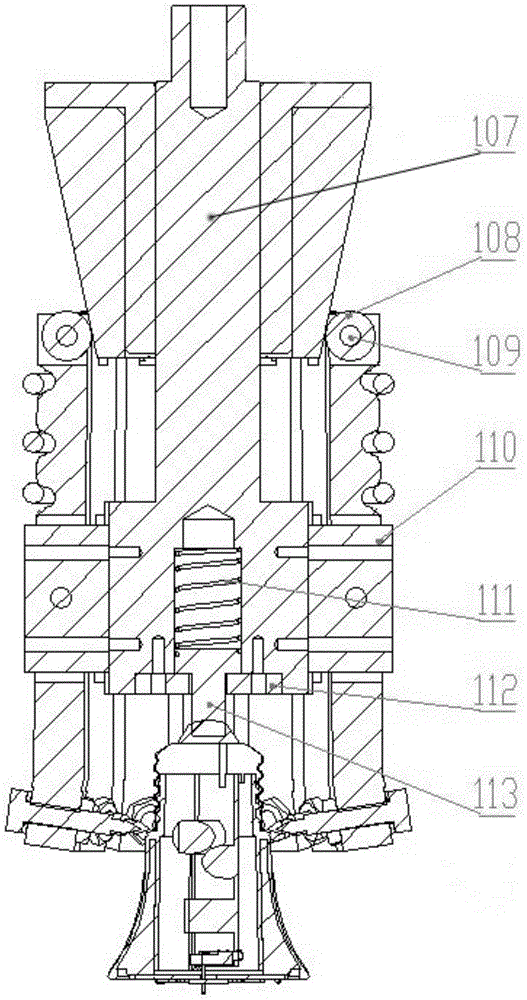

[0029] Such as figure 1 and figure 2 As shown, the pressure riveting device consists of a polyoxymethylene sleeve 101, a conical table 102, a strip lever 103, a small extension spring 104, a round pin 105, a riveting needle 106, a fixed shaft seat 107, a roller 108, a roller shaft 109, and a small square 110, small stage clip 111, stuffy cover 112, top post 113 form.

[0030] The polyoxymethylene sleeve 101 is threadedly connected with the conical table 102. The polyoxymethylene sleeve 101 is circular and is placed on the upper part of the fixed shaft seat 107, and can slide up and down in its shaft. The polyoxymethylene sleeve 101 is made of polyoxymethylene material. The polymeric material is a lightweight material with a density of 1.4g / cm 3 Left and right, it has high hardness, wear resistance, and is easy to process. When the riveting device and the cylinder work together, the polyoxymethylene sleeve 101 can be processed into a form suitable for connecting with the cyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com