Dibber for crop breeding and exact cultivation test

A technology of precision testing and seeding device, applied in the field of seeding device, agricultural and scientific research machinery, can solve the problems of labor and time-consuming, expensive machinery, complicated procedures, etc., and achieve the effect of high efficiency, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

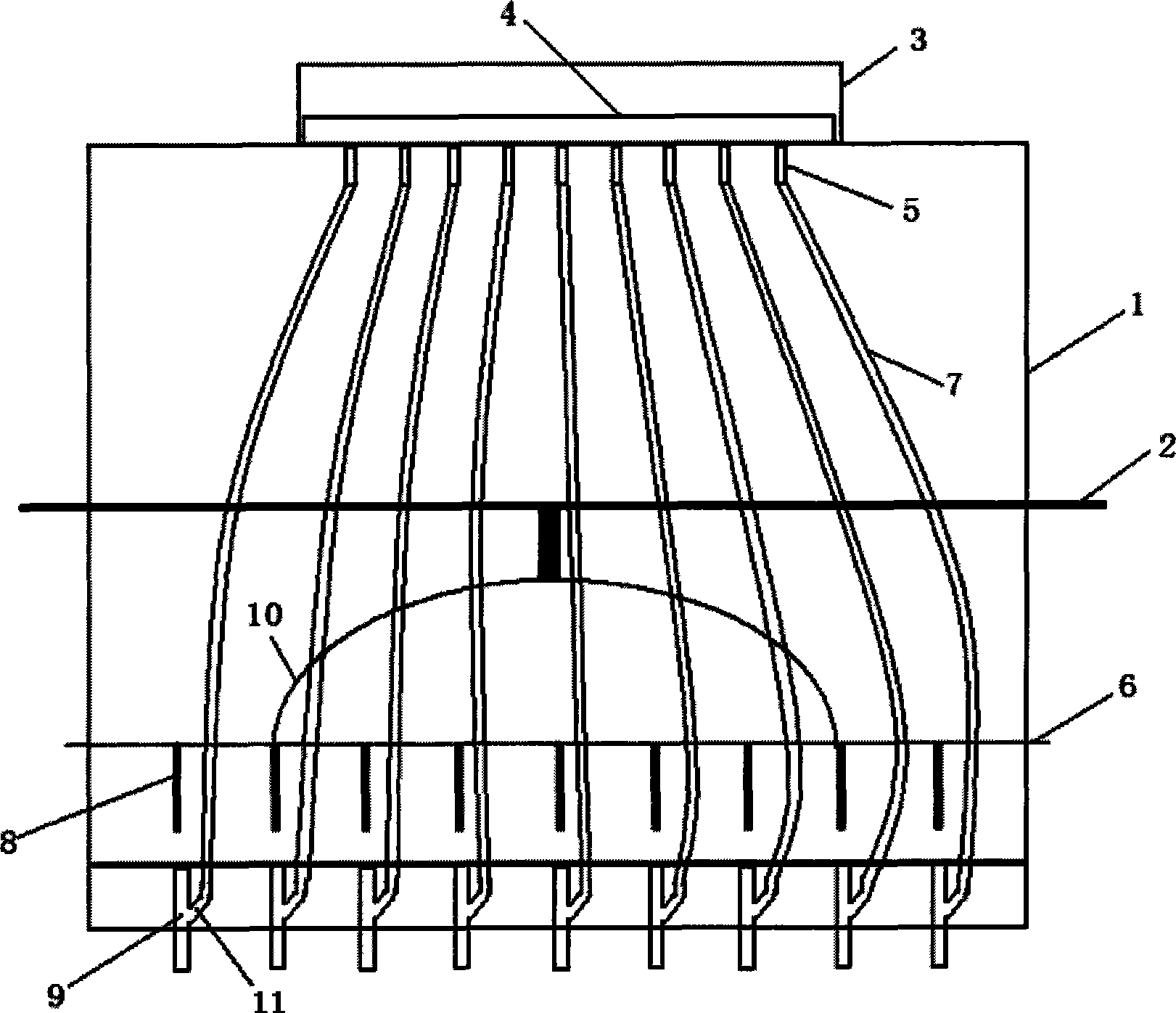

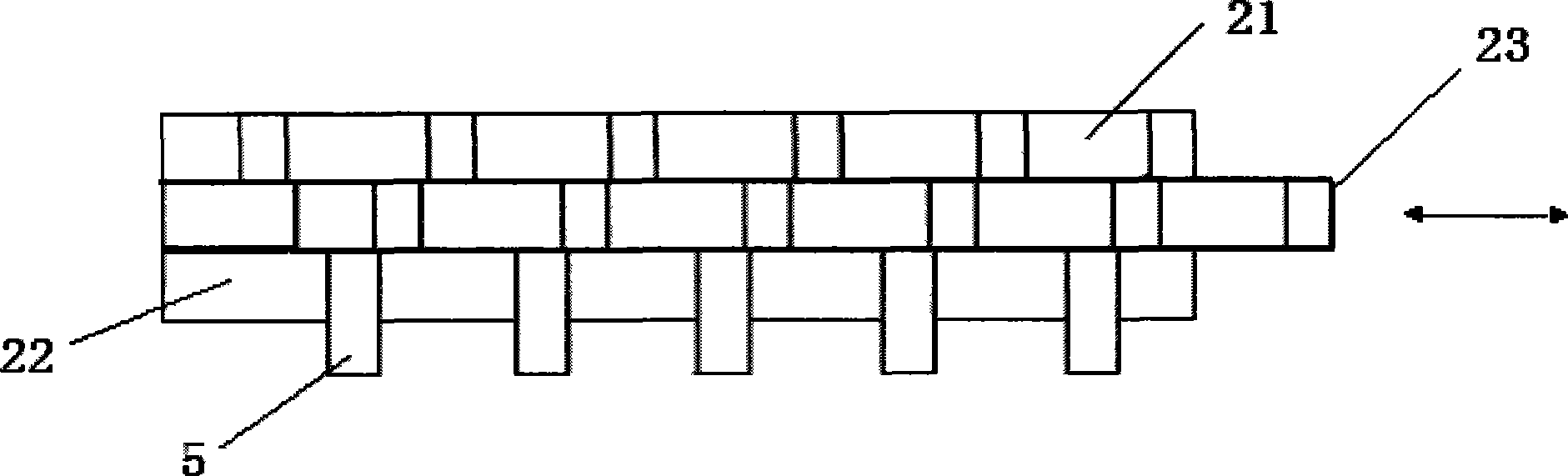

[0011] see figure 1 , the present invention is used for crop breeding and the sowing device of precision cultivation test, comprises a frame 1 and the container 3 that is used to place seed, is arranged with a plurality of steel pipes 9 evenly at the bottom of frame 1, and each steel pipe 9 has a The steel bar 8 that can be inserted into the steel pipe 9, the length of the steel bar 8 is greater than the length of the steel pipe 9, and runs through the steel pipe 9, all the steel bars 8 are connected together by the horizontal tube 6, and the horizontal tube 6 is connected to a steel bar with a length greater than The rod 2 of the frame 1 is connected, and the rod 2 slides up and down in the middle of the frame 1. An inclined pipe 11 is also provided on the side of the steel pipe 9. The inclined pipe 11 is connected with a pipeline 7, and the pipeline 7 is connected to the bottom of the container 3. The seed outlet 5 is connected; the container 3 is arranged above the frame 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com