water heater

A technology for water heaters and containers, applied in water heaters, fluid heaters, burners, etc., can solve the problems of complicated assembly operations and increased number of parts, reduce the number of parts, reduce flow path resistance, and simplify assembly operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

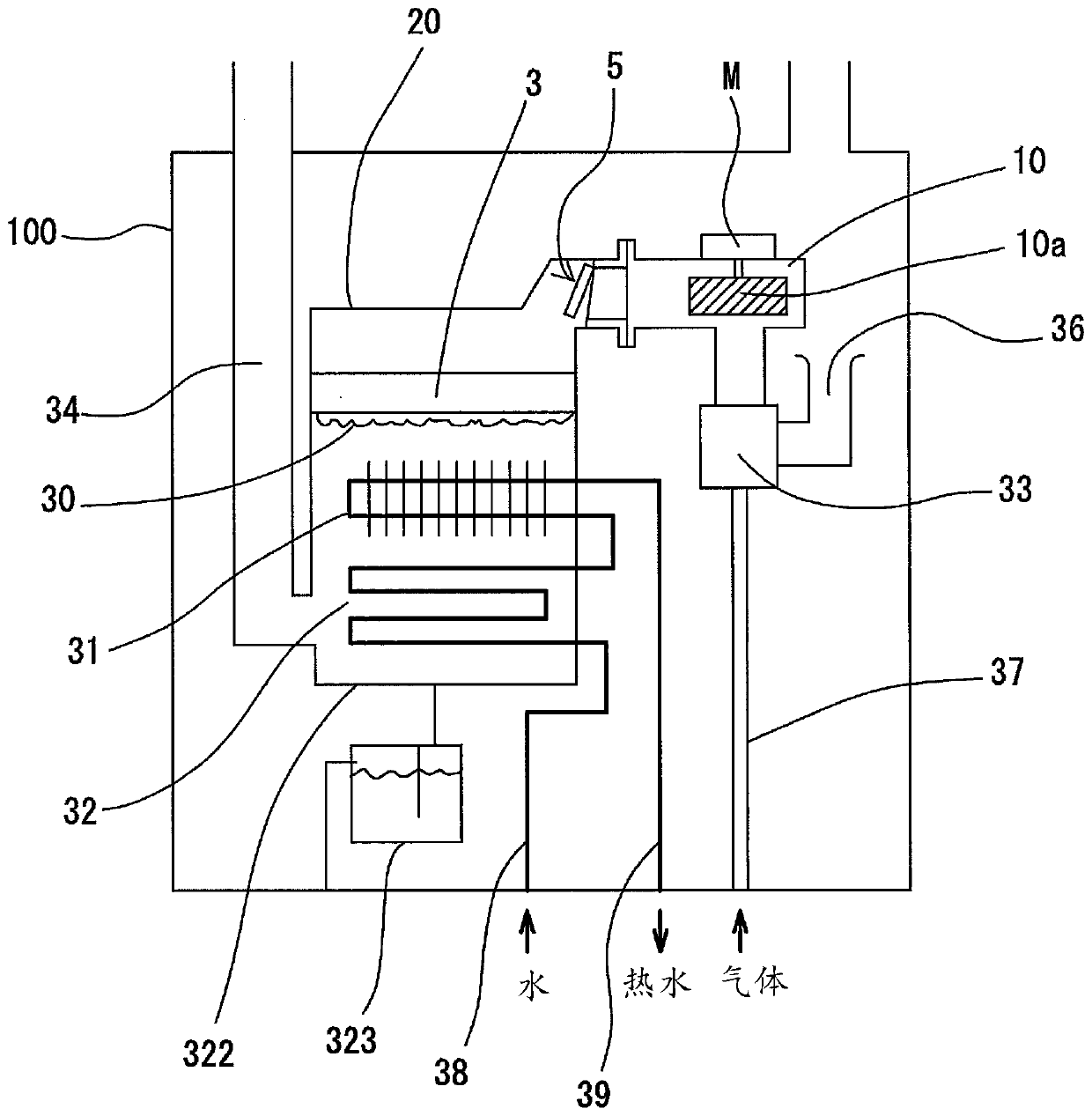

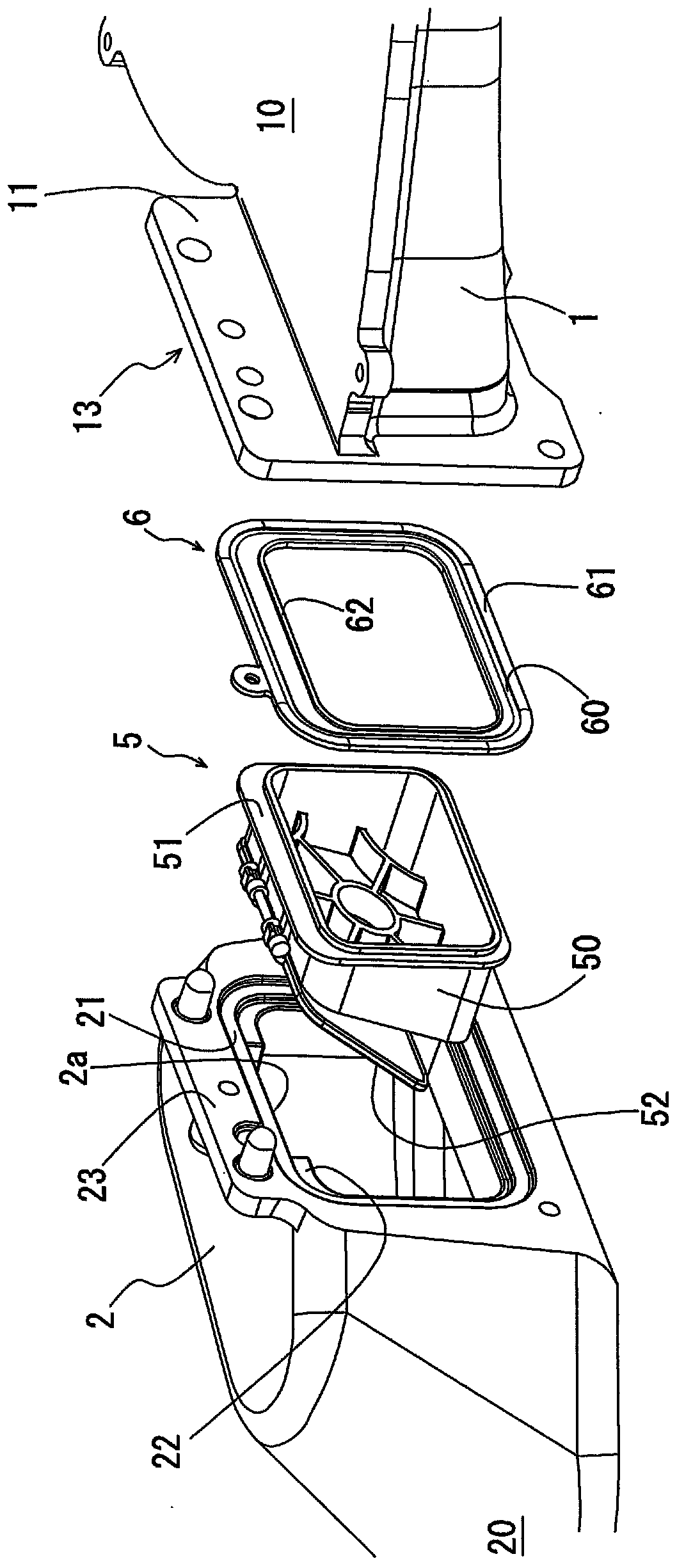

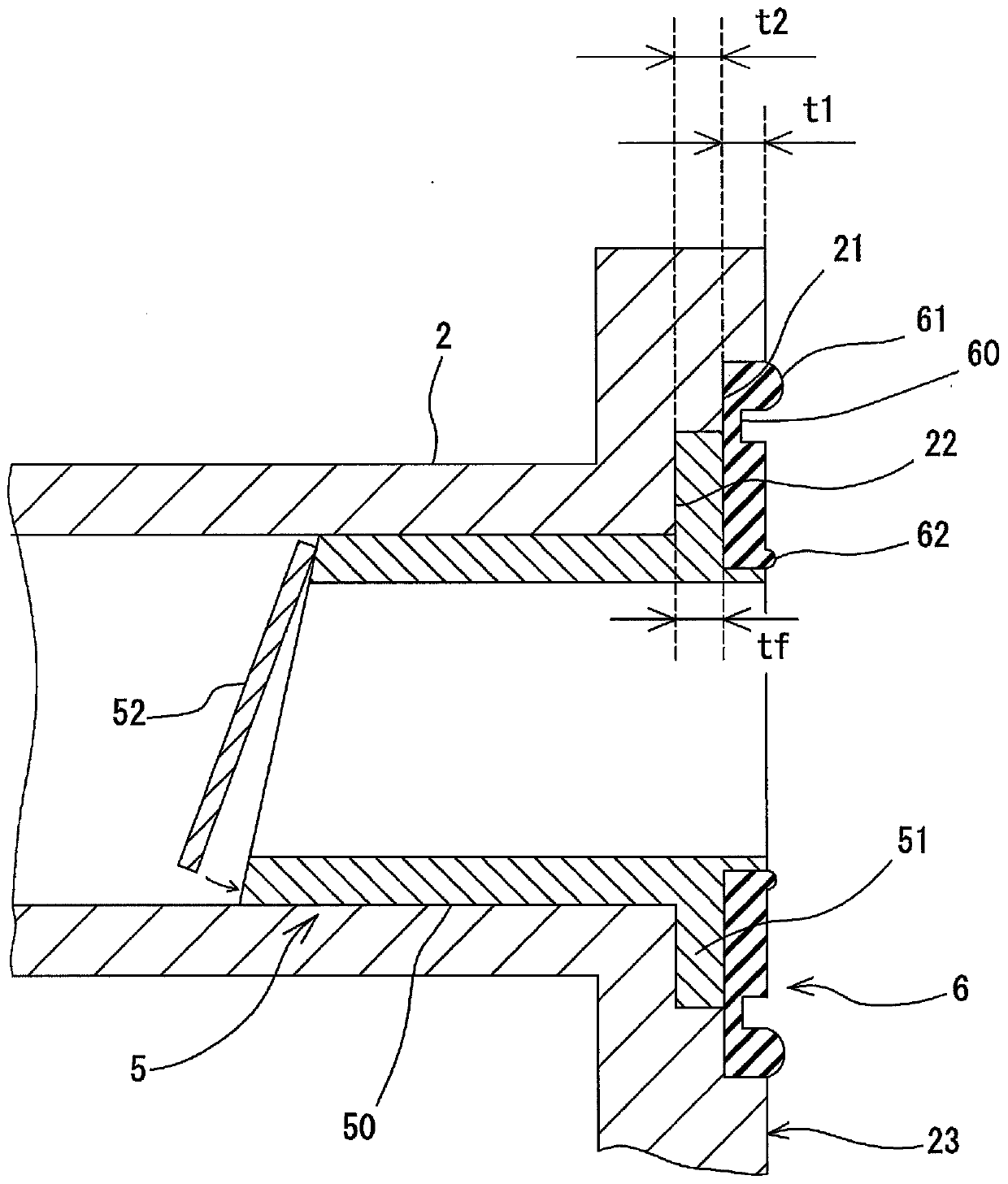

[0038] Hereinafter, with regard to the water heater according to the embodiment of the present invention, while referring to the attached Figure 1 Face specific instructions.

[0039] figure 1It is a schematic diagram of the latent heat recovery type gas water heater having the complete primary air combustion type burner 3 according to the first embodiment. Inside the housing 100 there is provided a container 20 provided with a burner 3 having a downwardly facing combustion face 30 and communicating therewith a fan housing 10 . Inside the fan case 10, a fan 10a that sends a mixture of air and fuel gas into the burner 3 inside the container 20 is housed. In addition, in this specification, along the flow path formed by the operation of the fan 10a, the side of the fan case 10 is called an upstream side, and the side of the container 20 is called a downstream side.

[0040] Below the burner 3 in the container 20, first and second heat exchangers 31 and 32 for hot water supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com