Patents

Literature

56results about How to "Reduce flow path resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

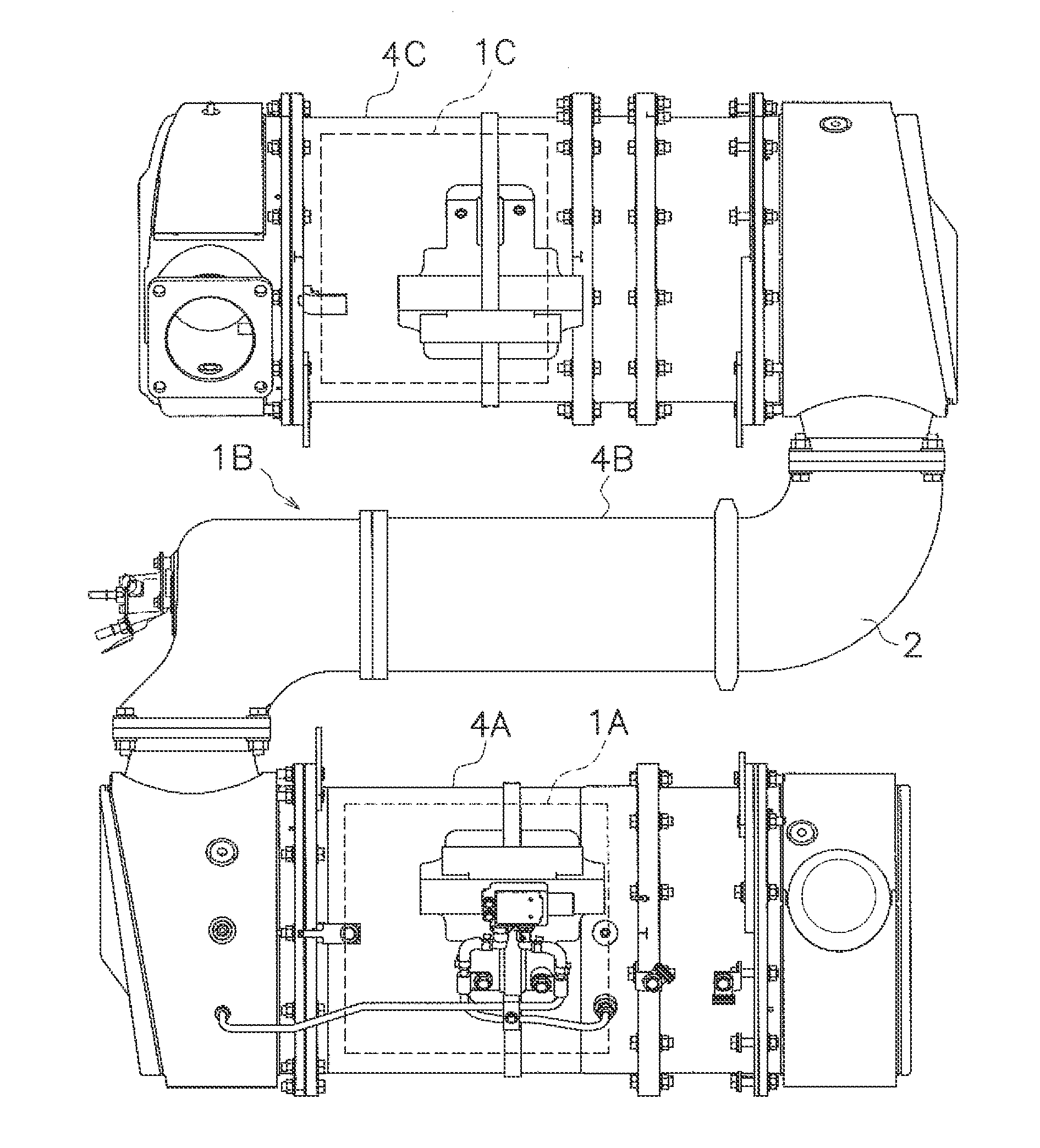

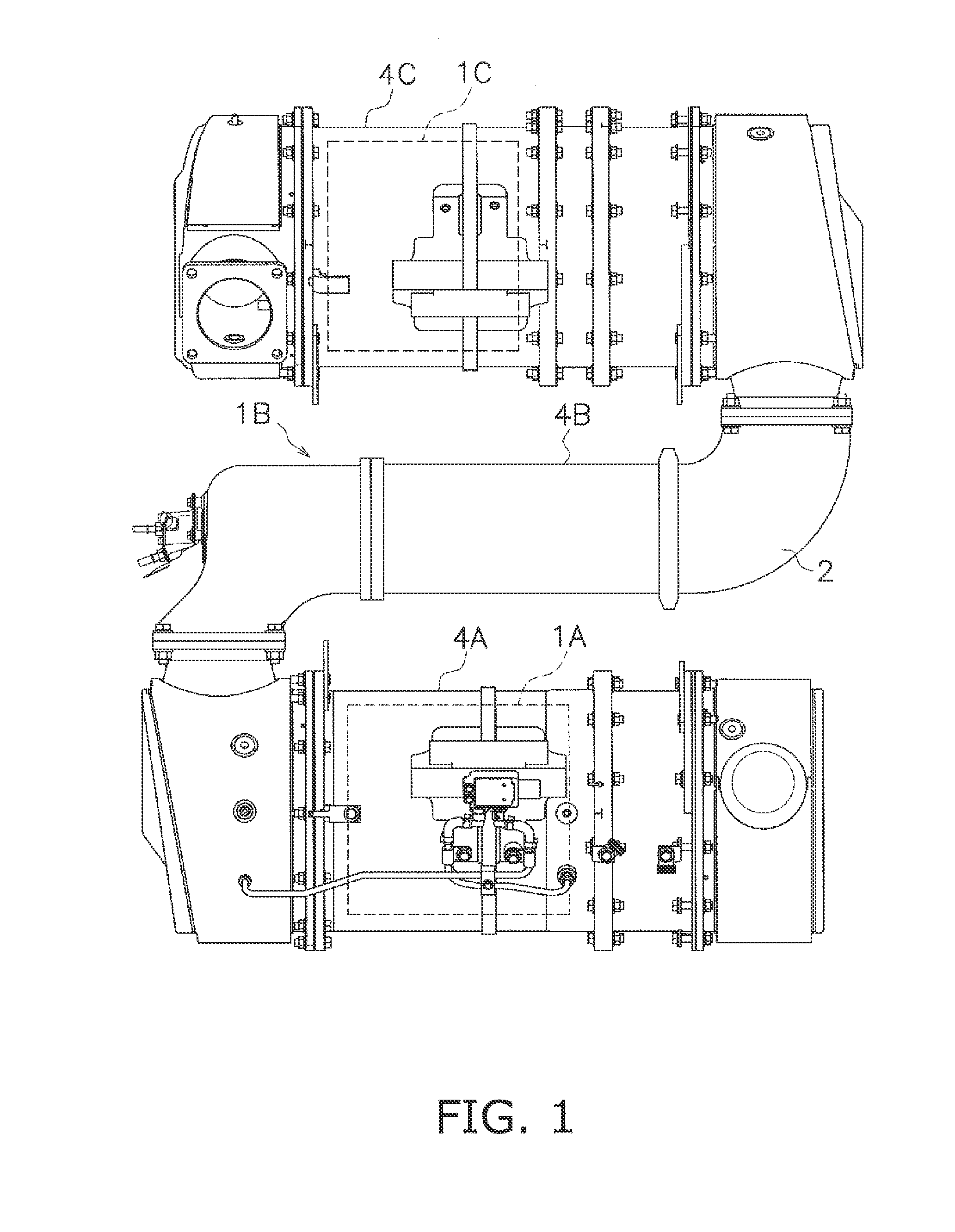

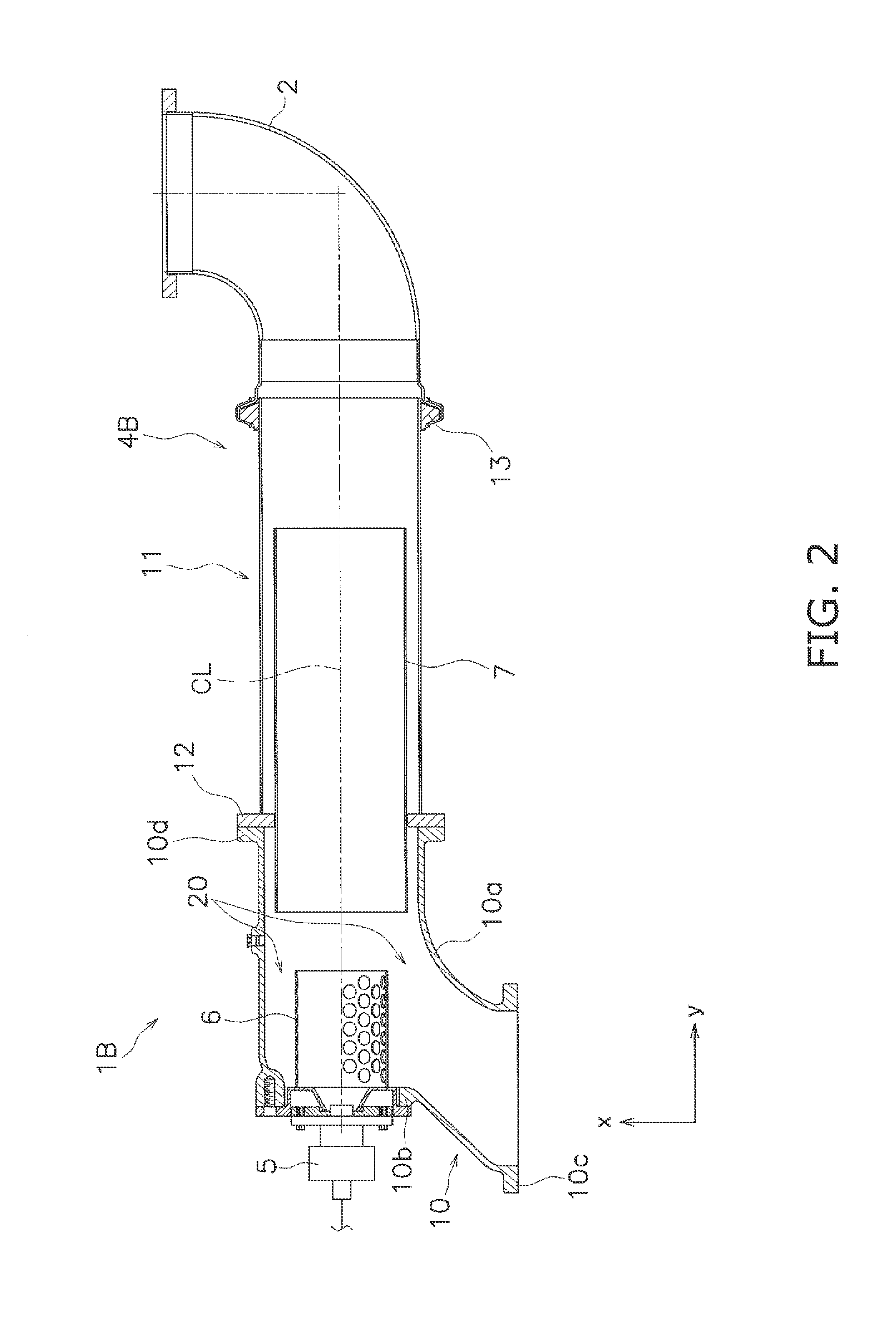

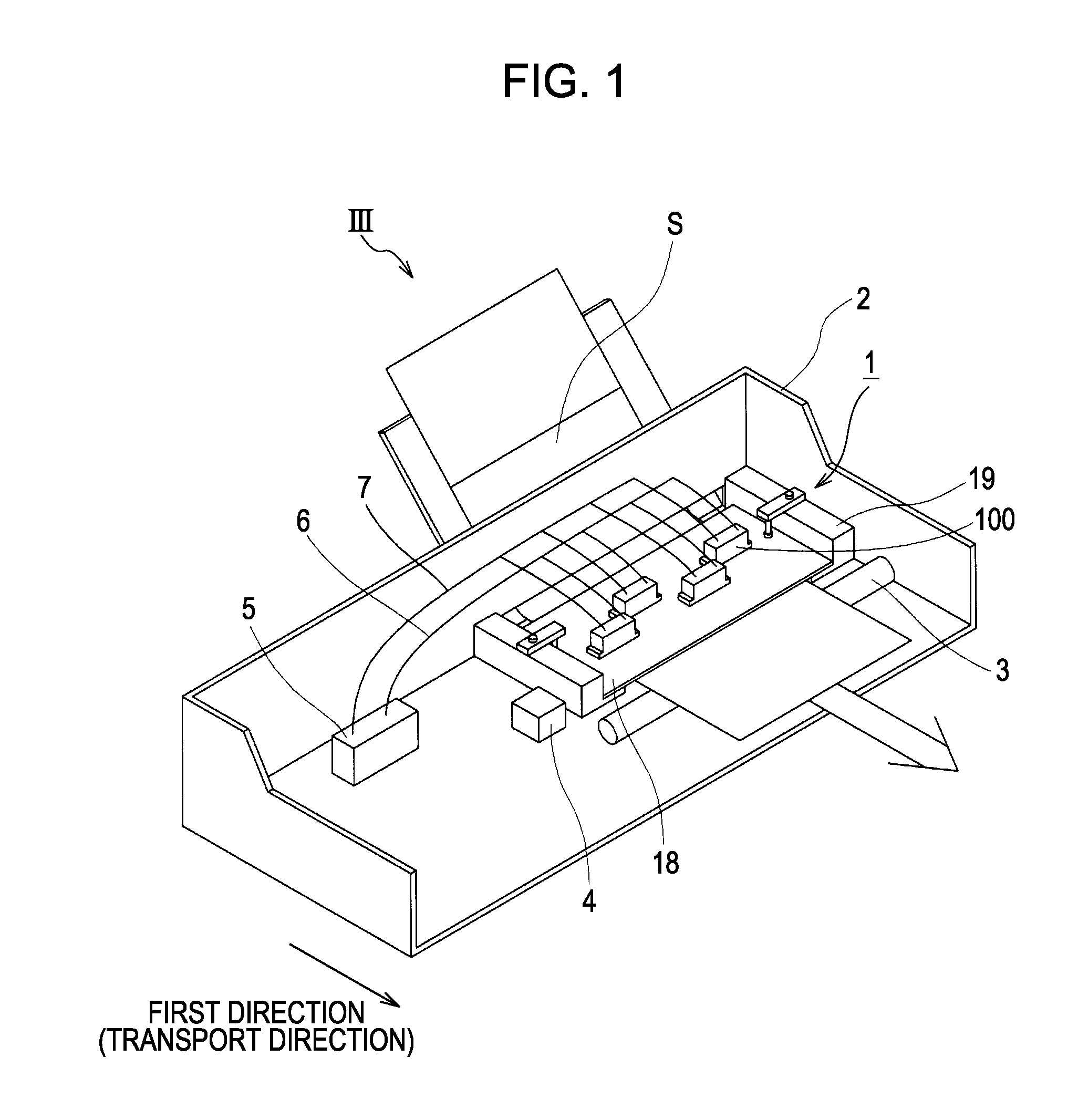

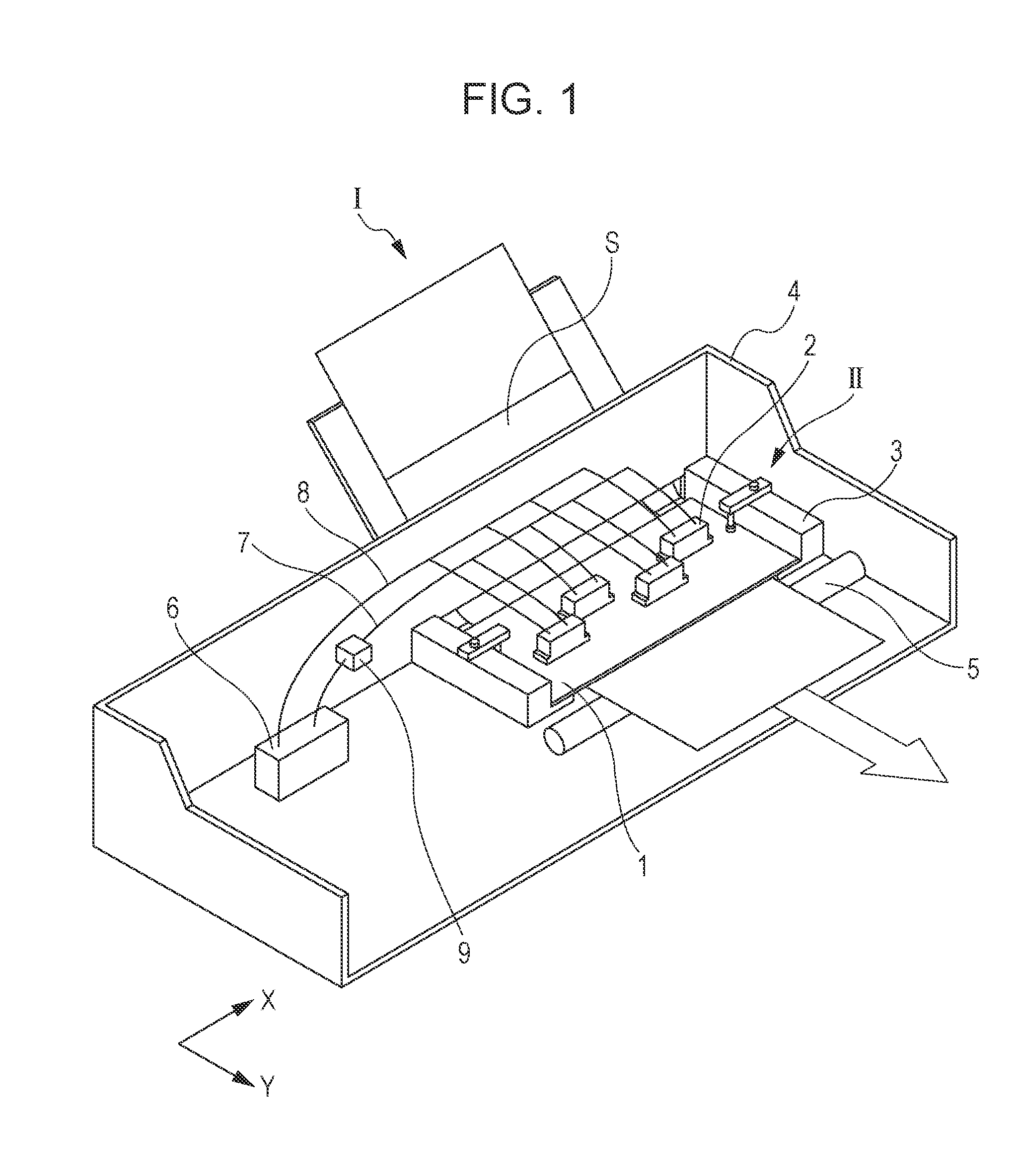

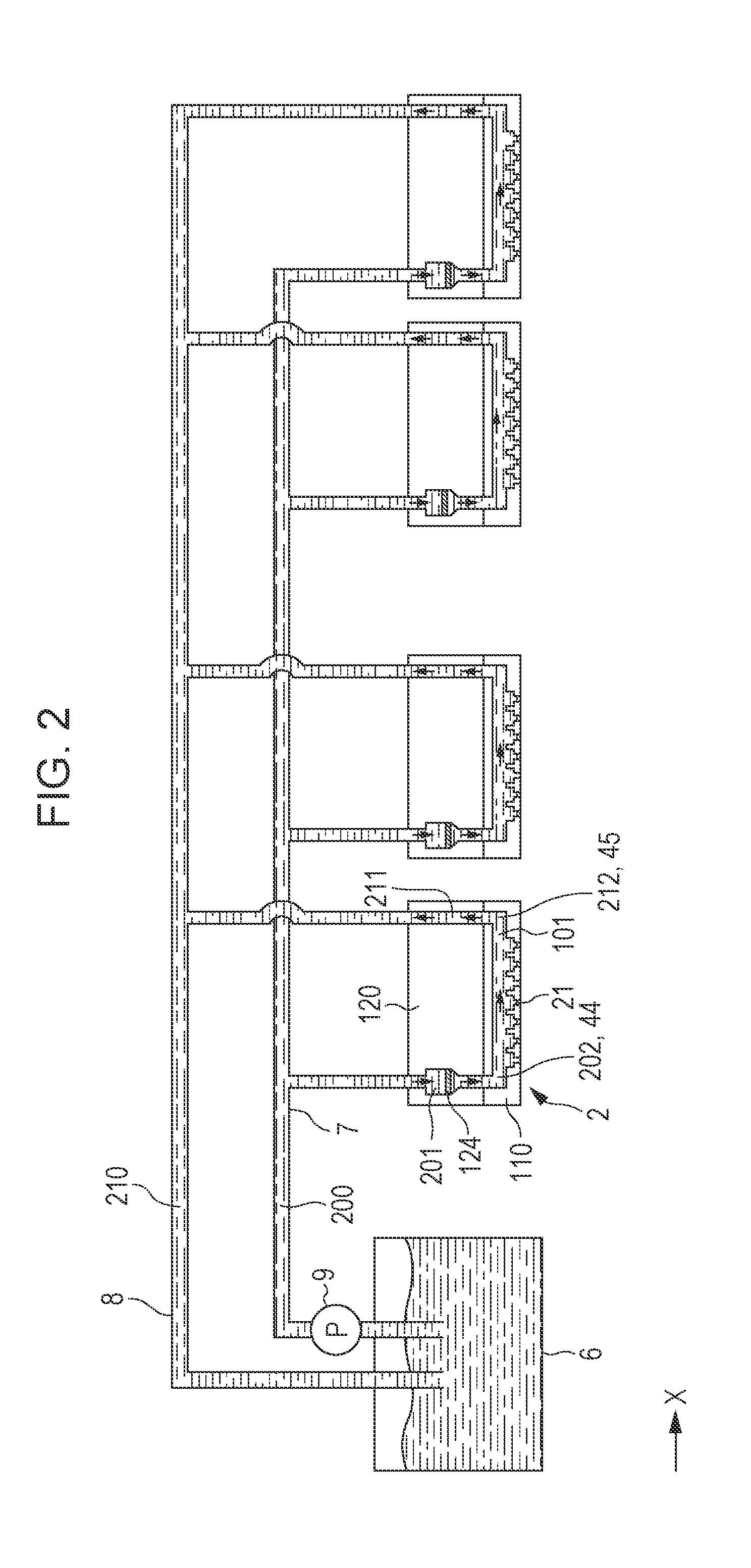

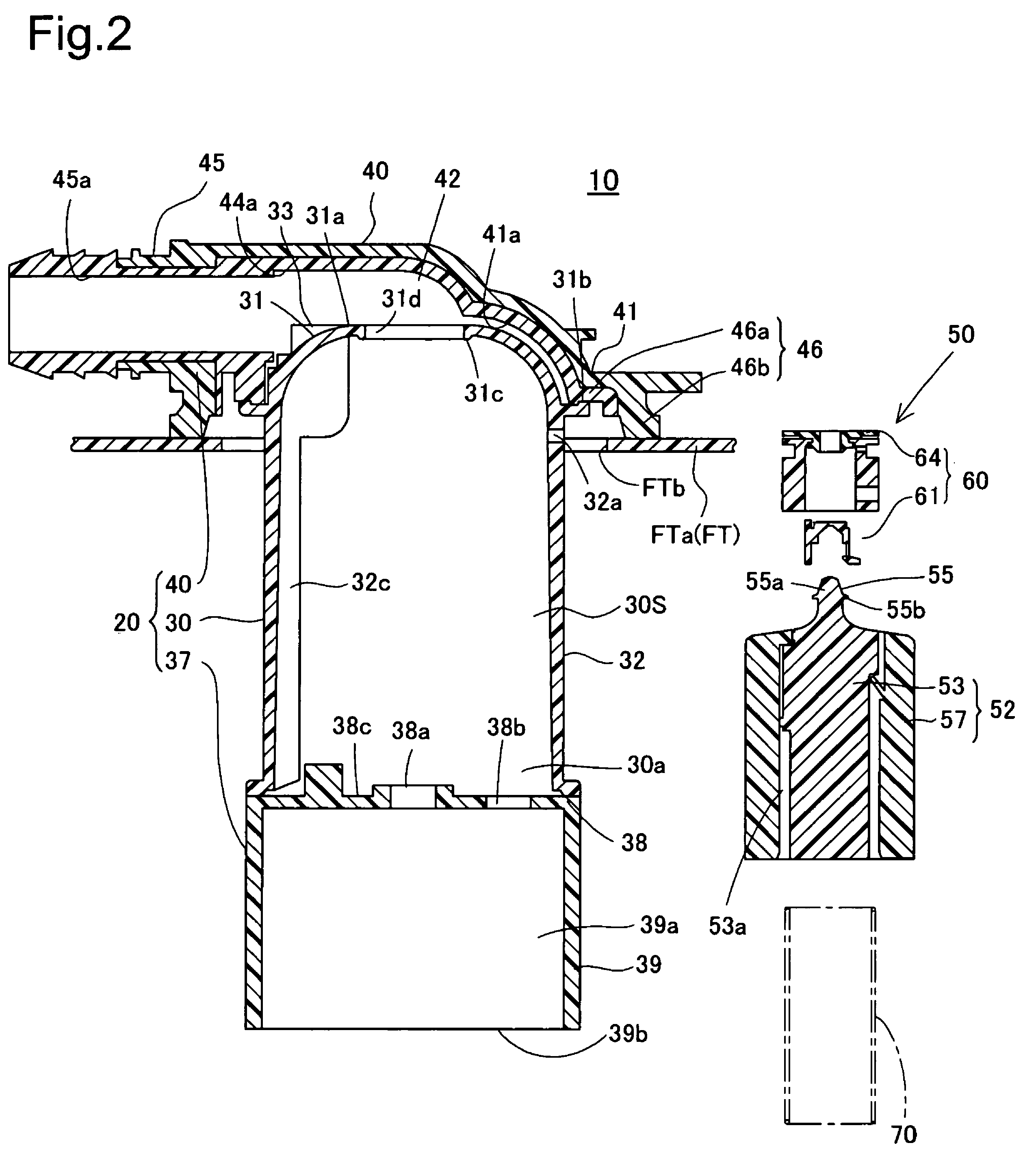

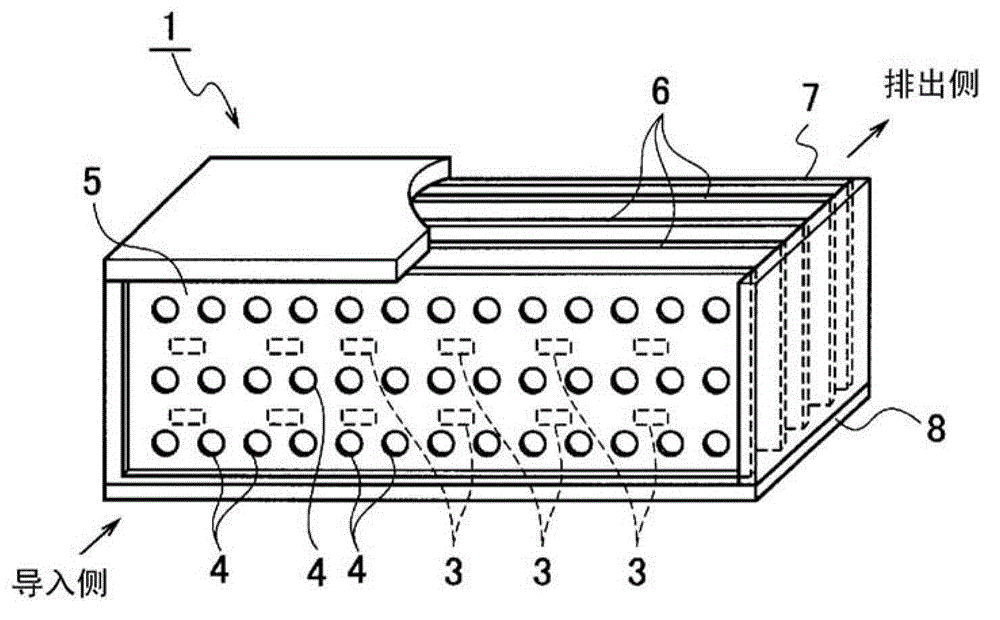

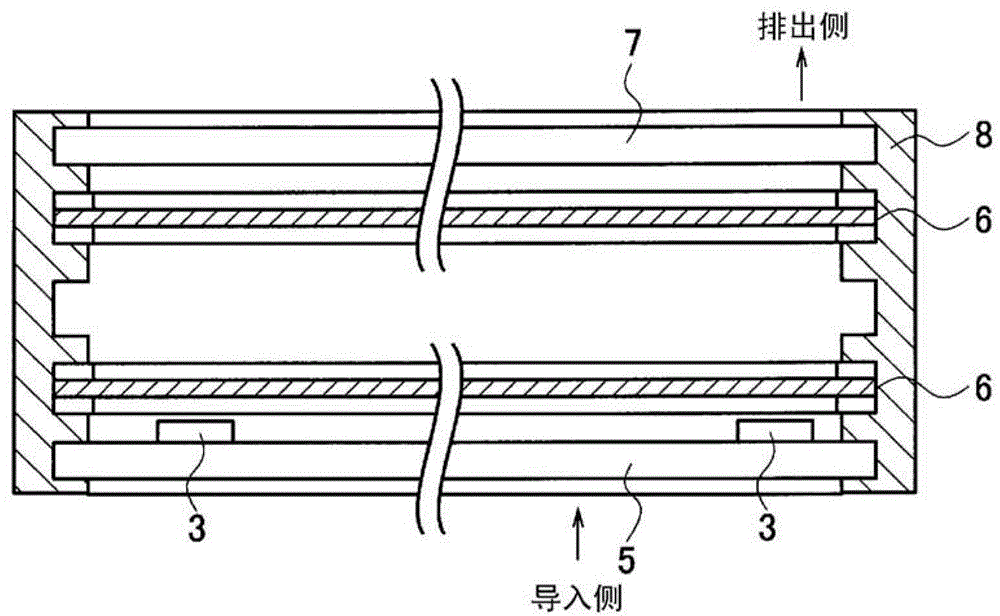

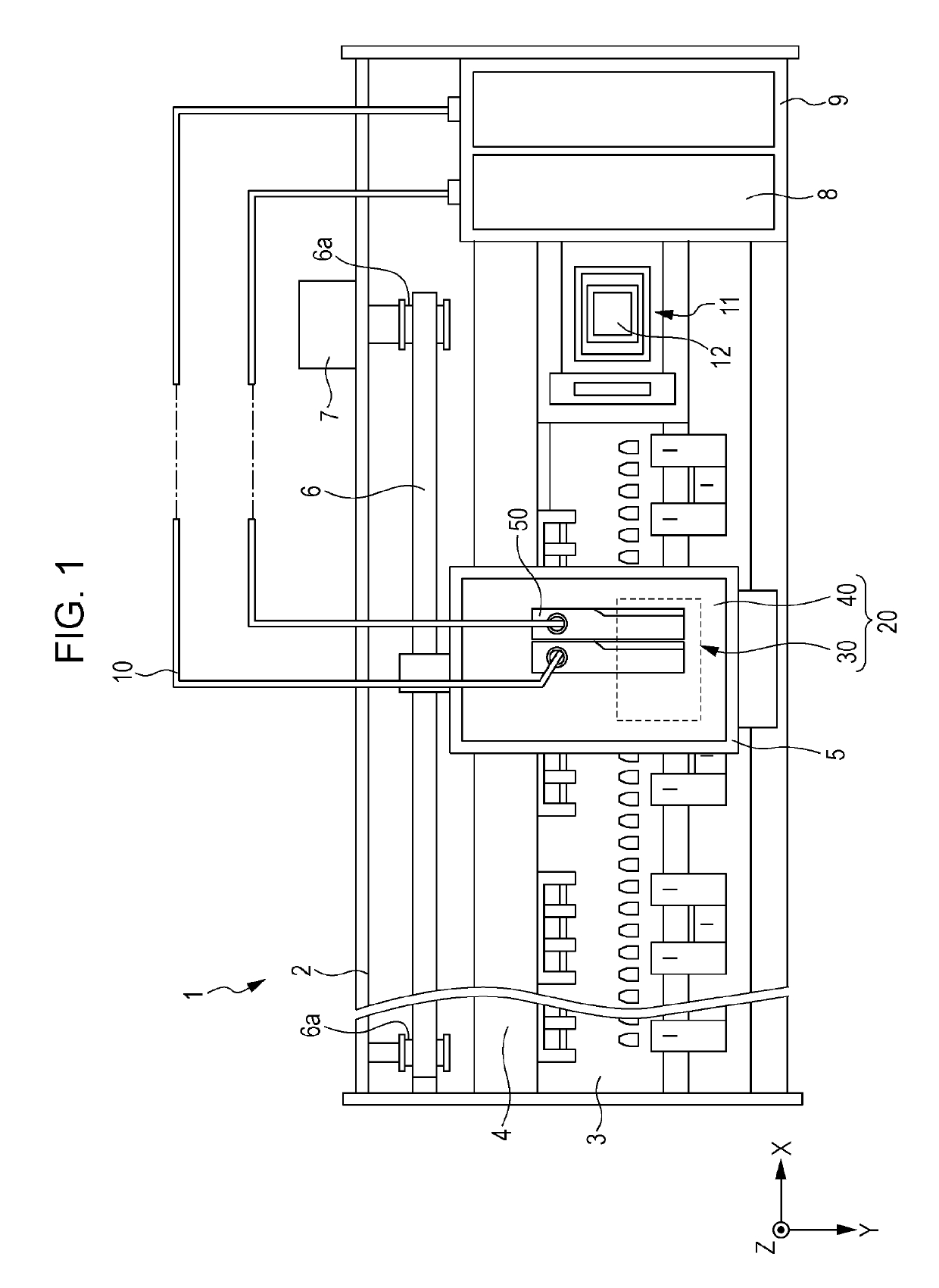

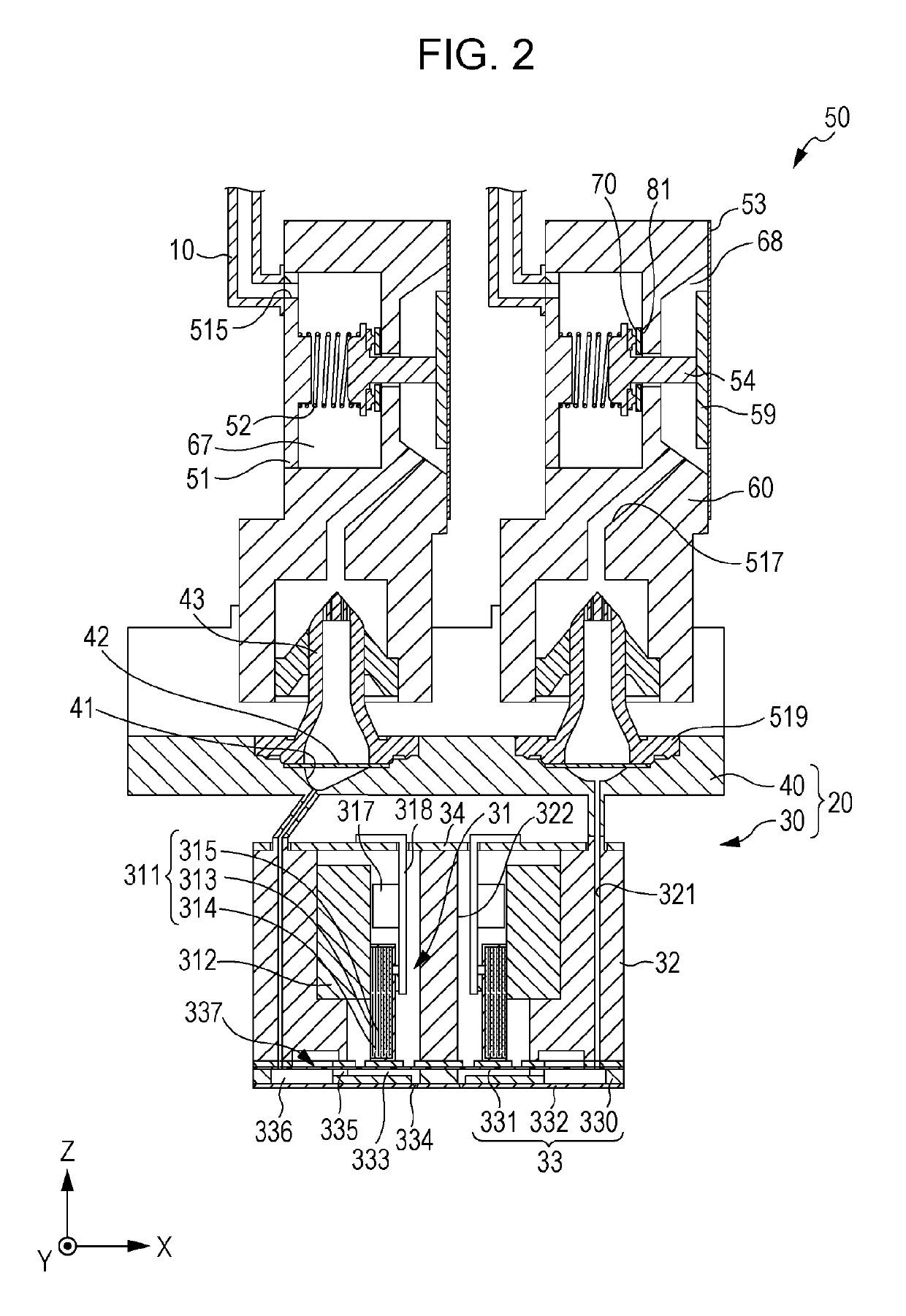

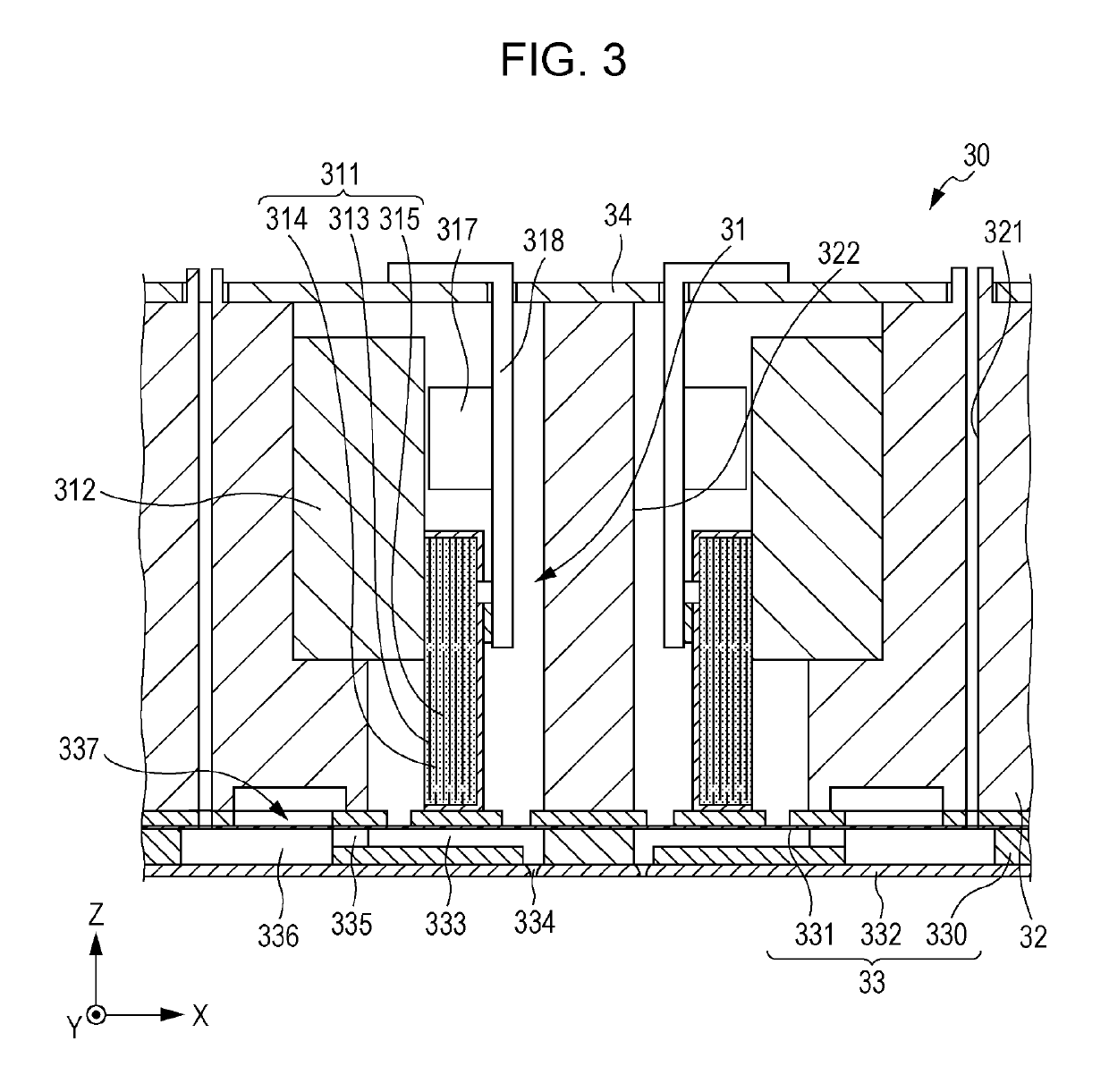

Reducing agent aqueous solution mixing device and exhaust gas post-treatment device

ActiveUS20130164183A1Reduce flow path resistanceInhibition of attachmentCombination devicesInternal combustion piston enginesEngineeringAqueous solution

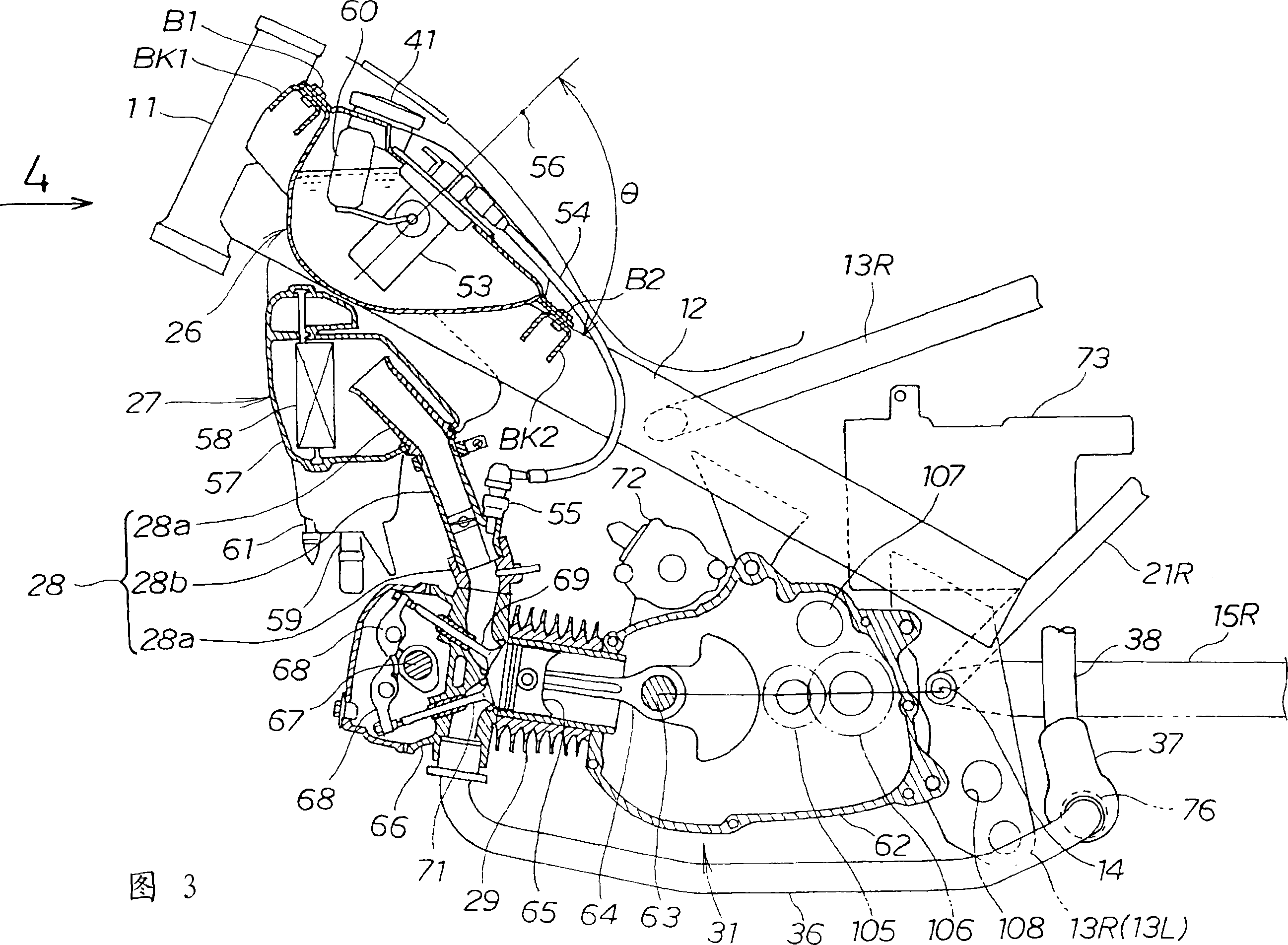

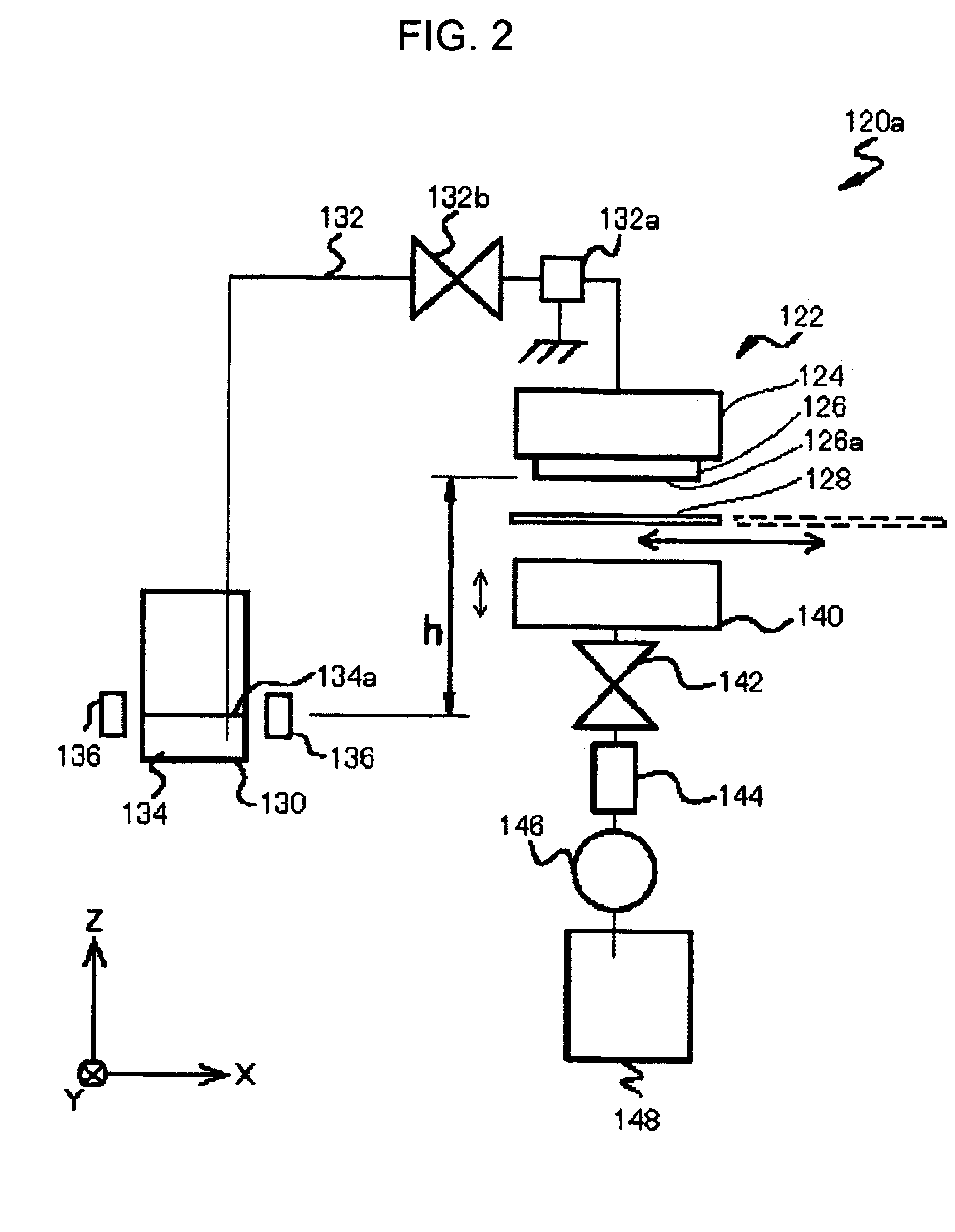

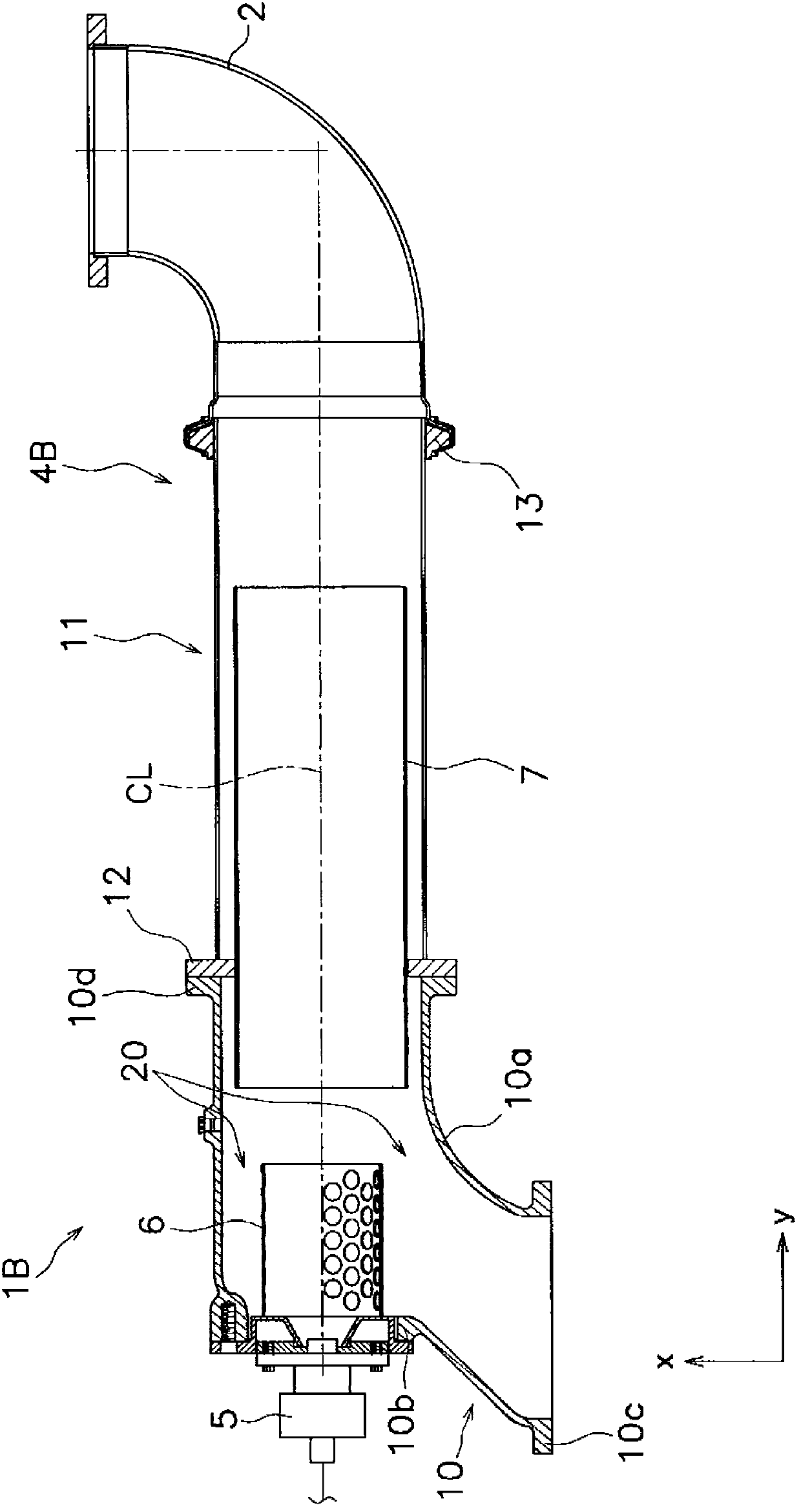

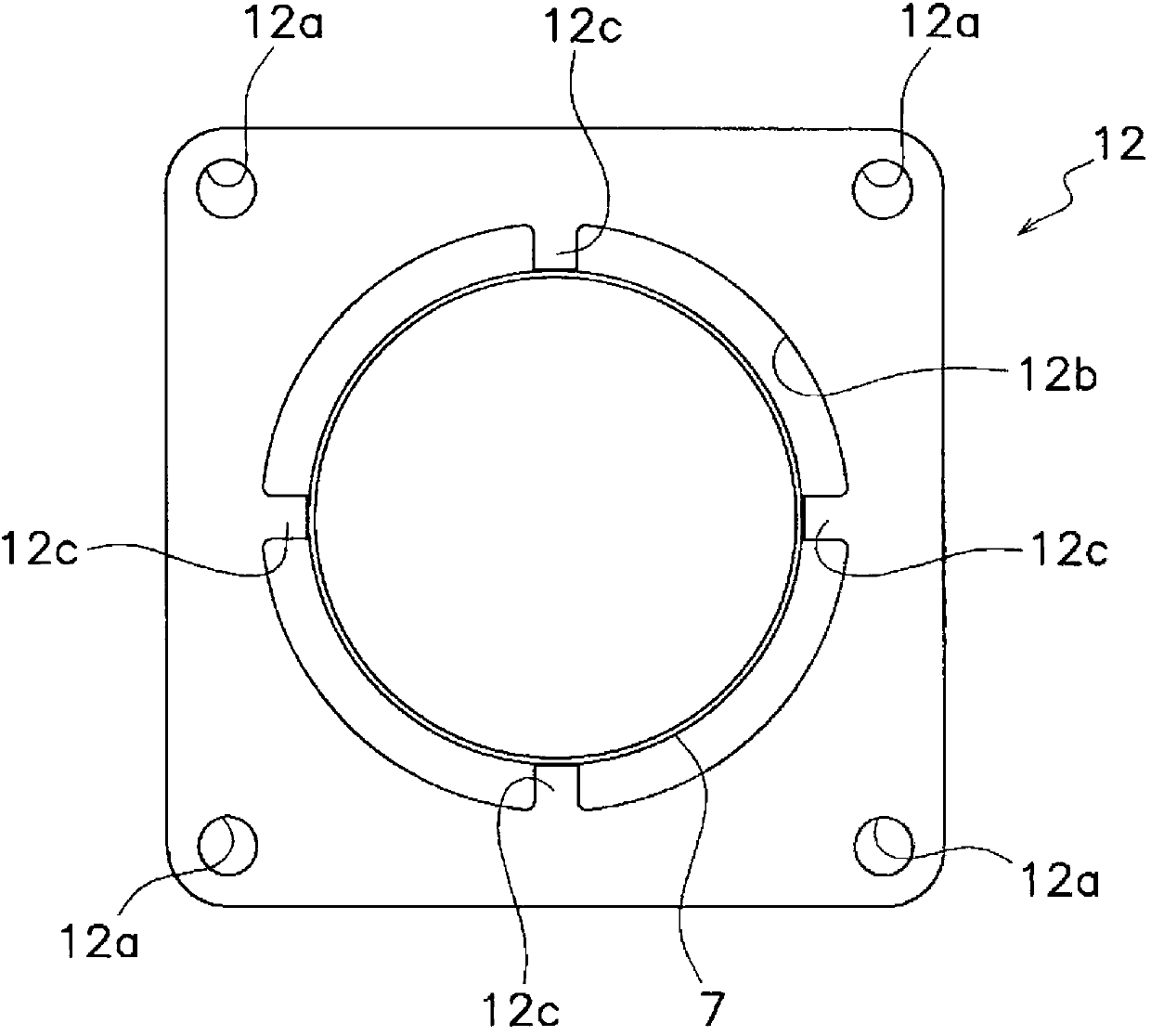

A reducing agent aqueous solution mixing device includes an exhaust pipe, an injector, a mixing pipe, an inner pipe and a flow section. The exhaust pipe includes an elbow part and a linear part. The injector is disposed in the elbow part and injects a reducing agent aqueous solution. The mixing pipe is disposed to enclose a surrounding of the reducing agent aqueous solution injected from the injector, and includes an outlet portion formed spaced apart from an inner wall of the exhaust pipe, and a plurality of openings formed on the outer peripheral surface thereof. The inner pipe is disposed in the linear part and allows the exhaust gas to flow through the inside and the outer periphery thereof. The flow section is formed between the outlet portion of the mixing the inner wall of the exhaust pipe and directs the exhaust gas to the inner pipe.

Owner:KOMATSU LTD

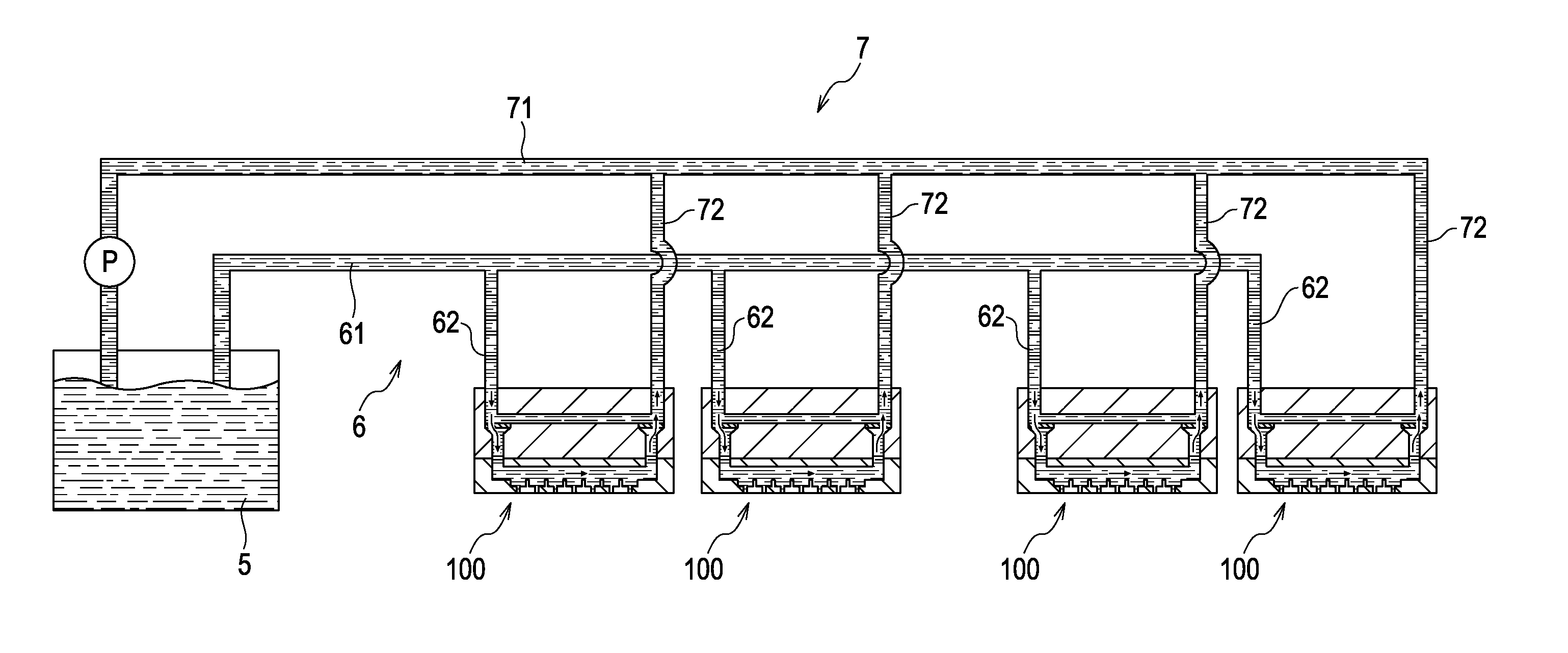

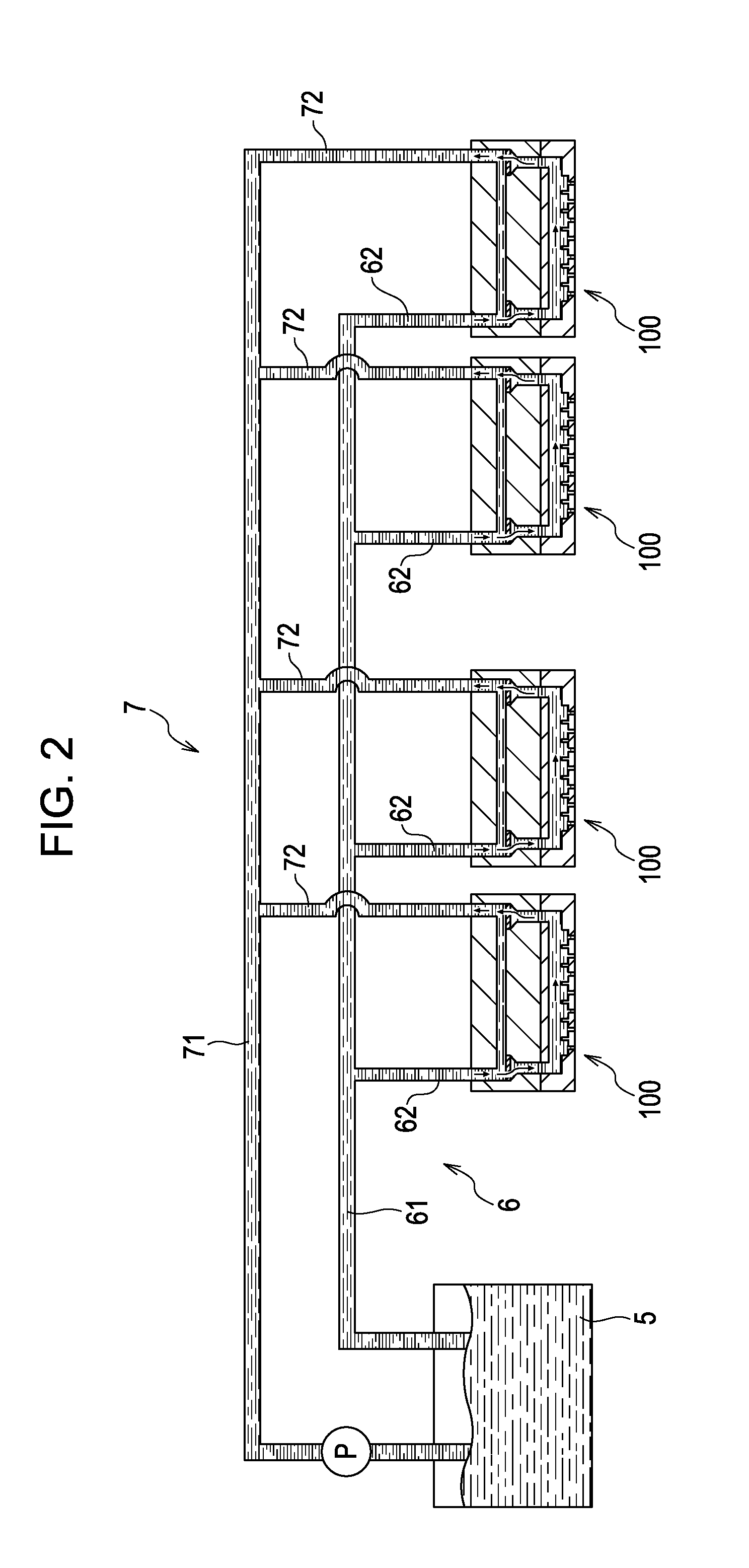

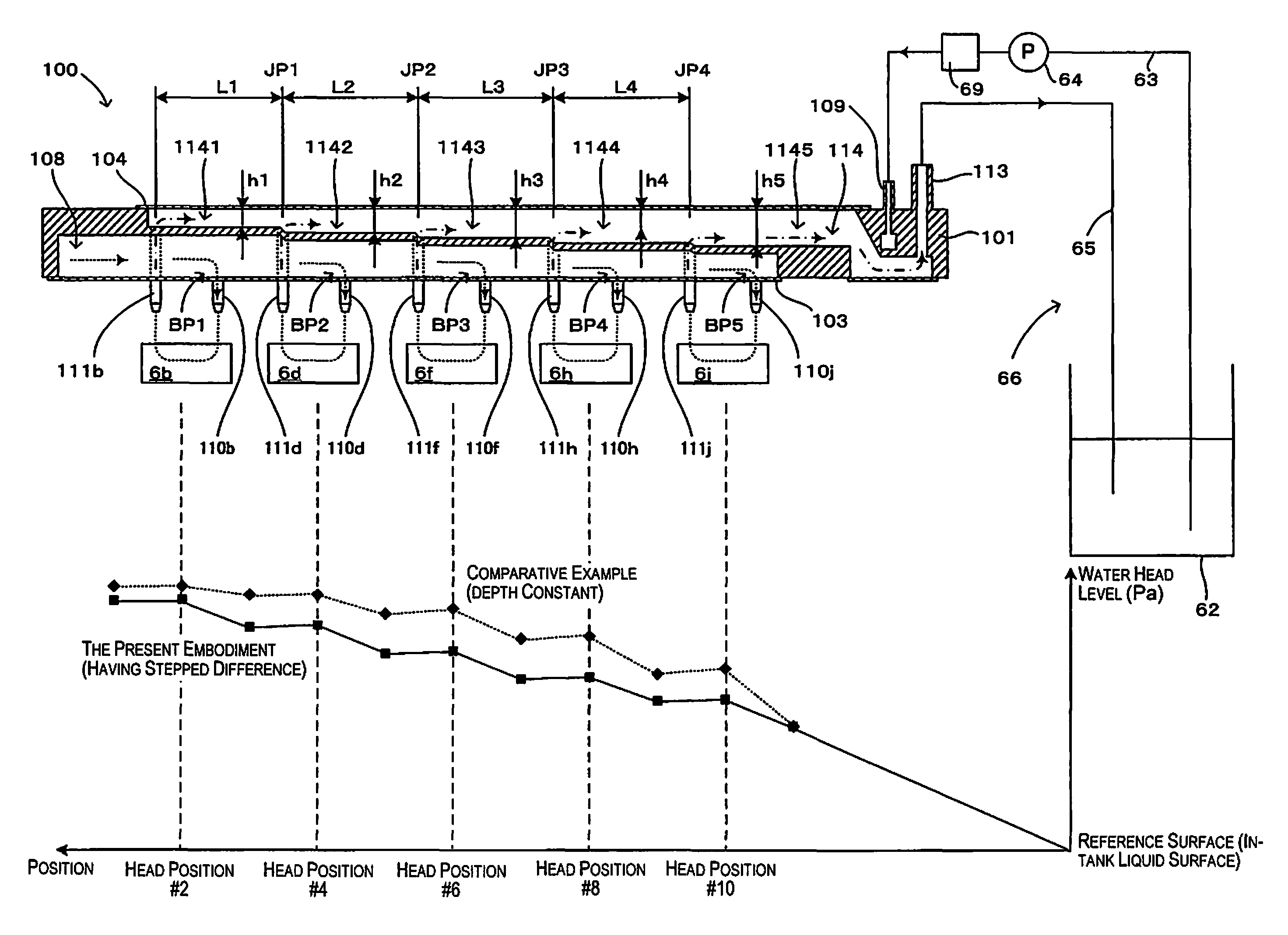

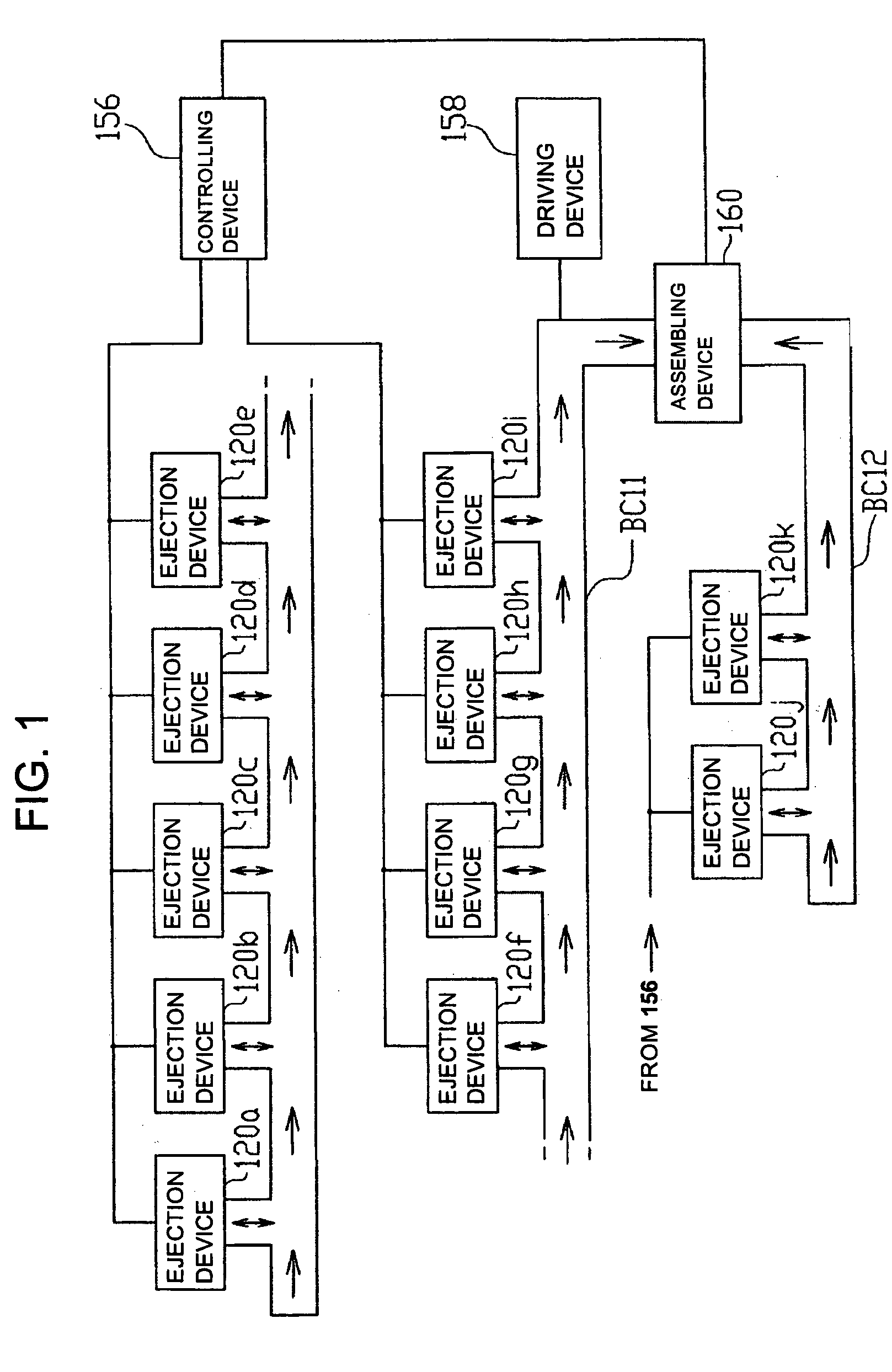

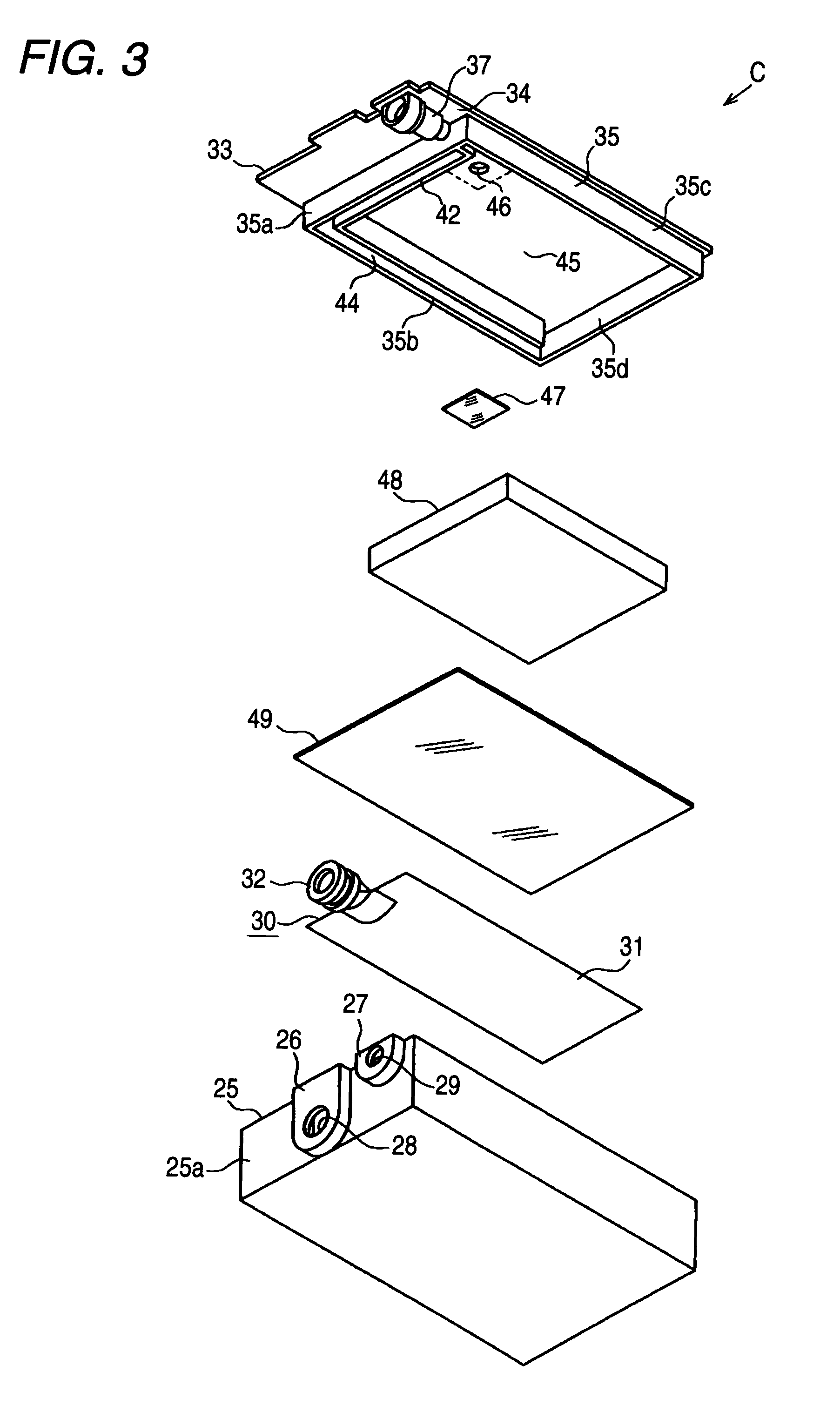

Liquid ejecting head, liquid ejecting unit, and liquid ejecting apparatus

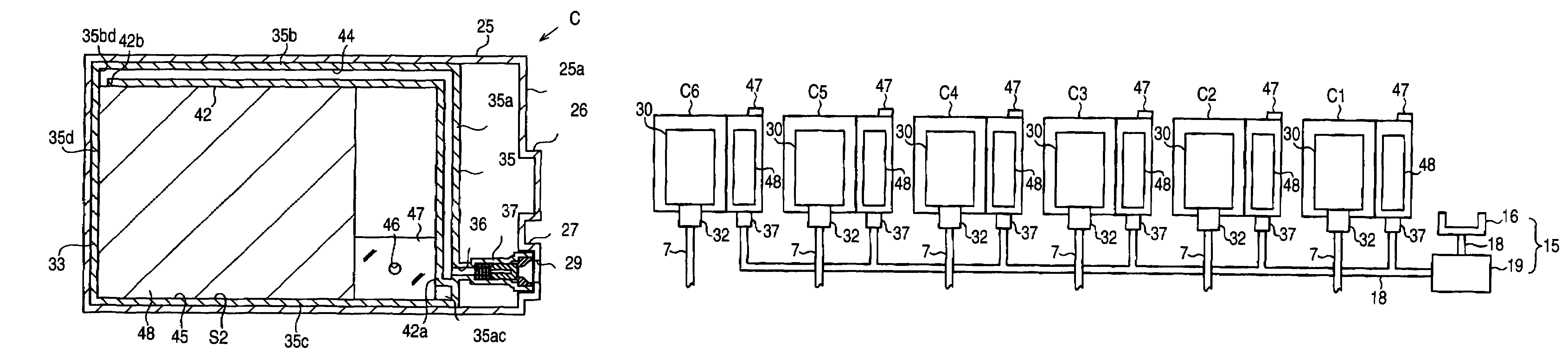

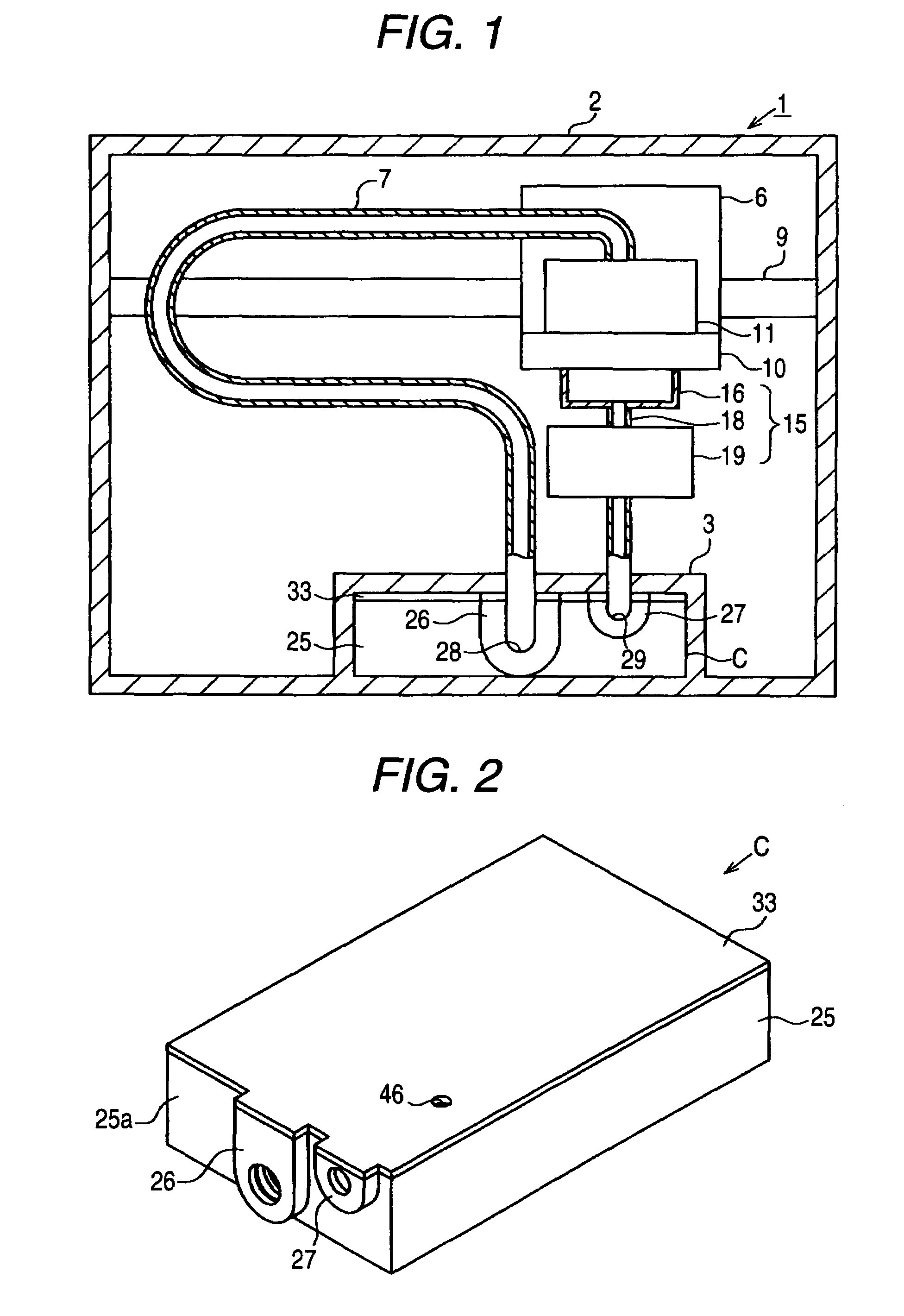

InactiveUS20110242237A1Uniform ejection propertySufficient holdInking apparatusOther printing apparatusLiquid jetLiquid circulation

A liquid ejecting head includes a plurality of nozzle openings, a first flow path, a supply path, a recovery path, a first filter, a second filter, and a second flow path. The nozzle openings eject a liquid, the first flow path is communicated with the plurality of nozzle openings and the liquid is circulated through the first flow path. The supply path supplies the liquid to the first flow path from the outside, and the recovery path recovers the liquid from the first flow path to the outside. The first filter is provided in the supply path and the second filter is provided in the recovery path. The second flow path connects the supply path provided in the upstream side of the first filter and the recovery path provided in downstream side of the second filter.

Owner:SEIKO EPSON CORP

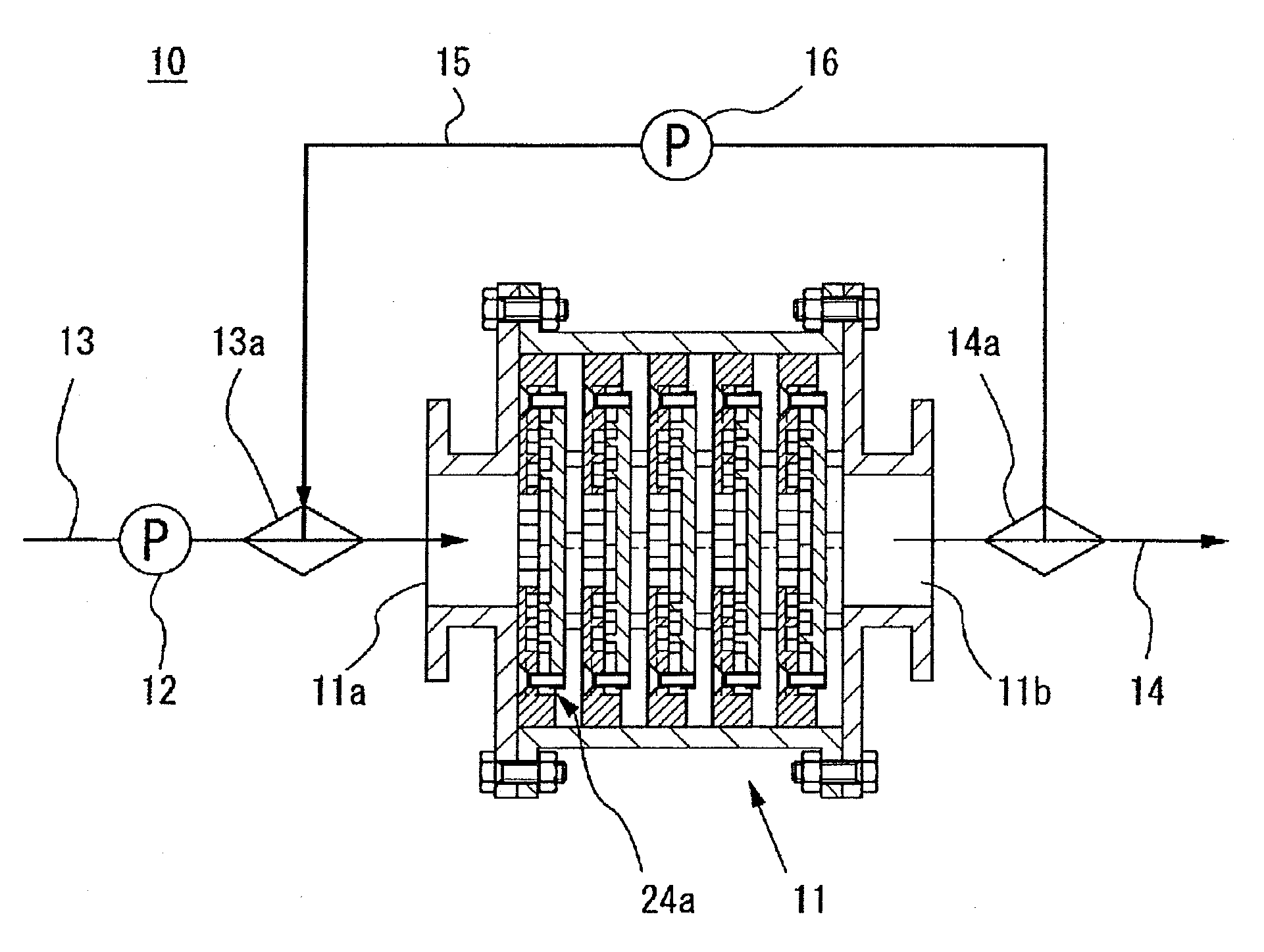

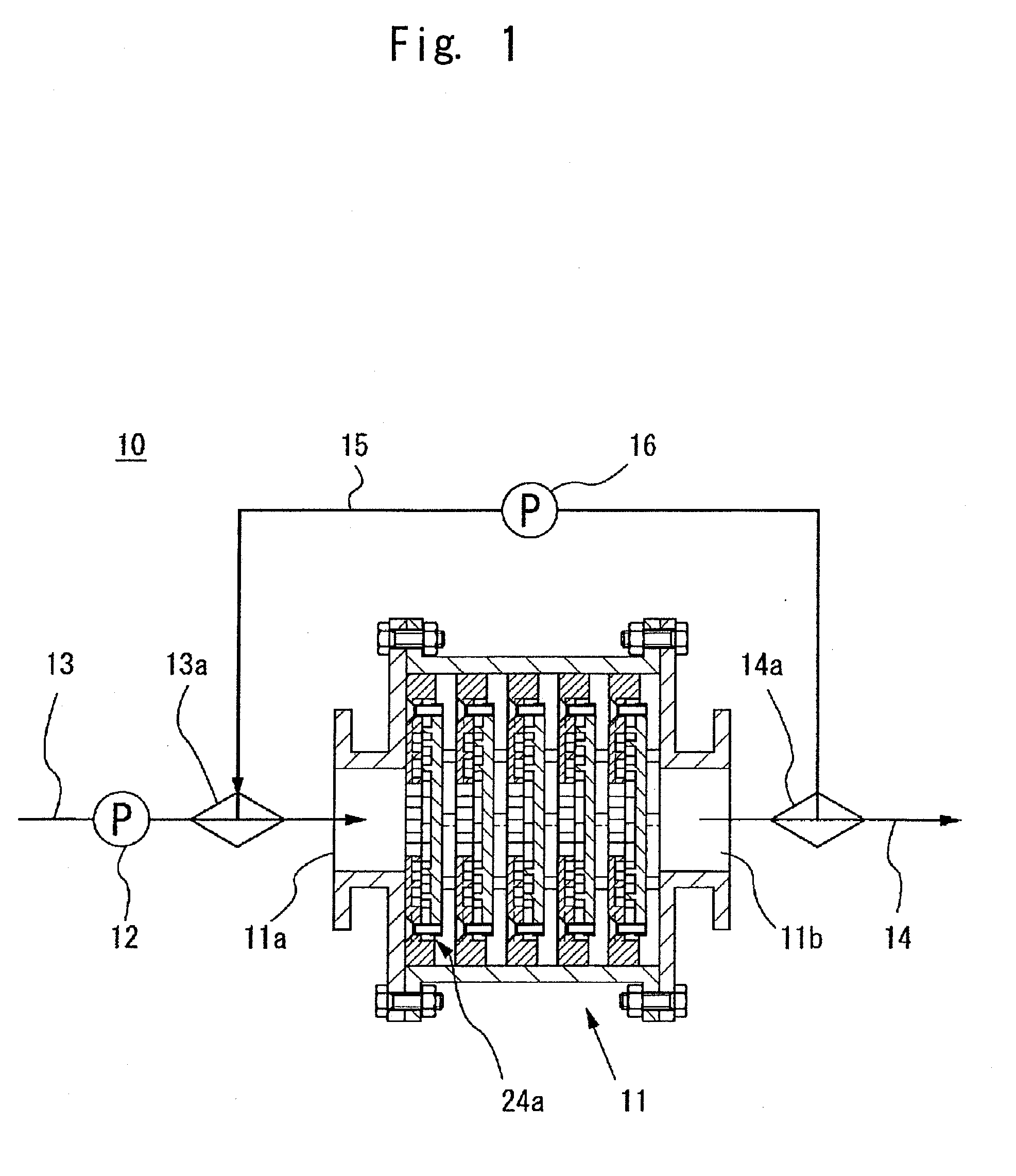

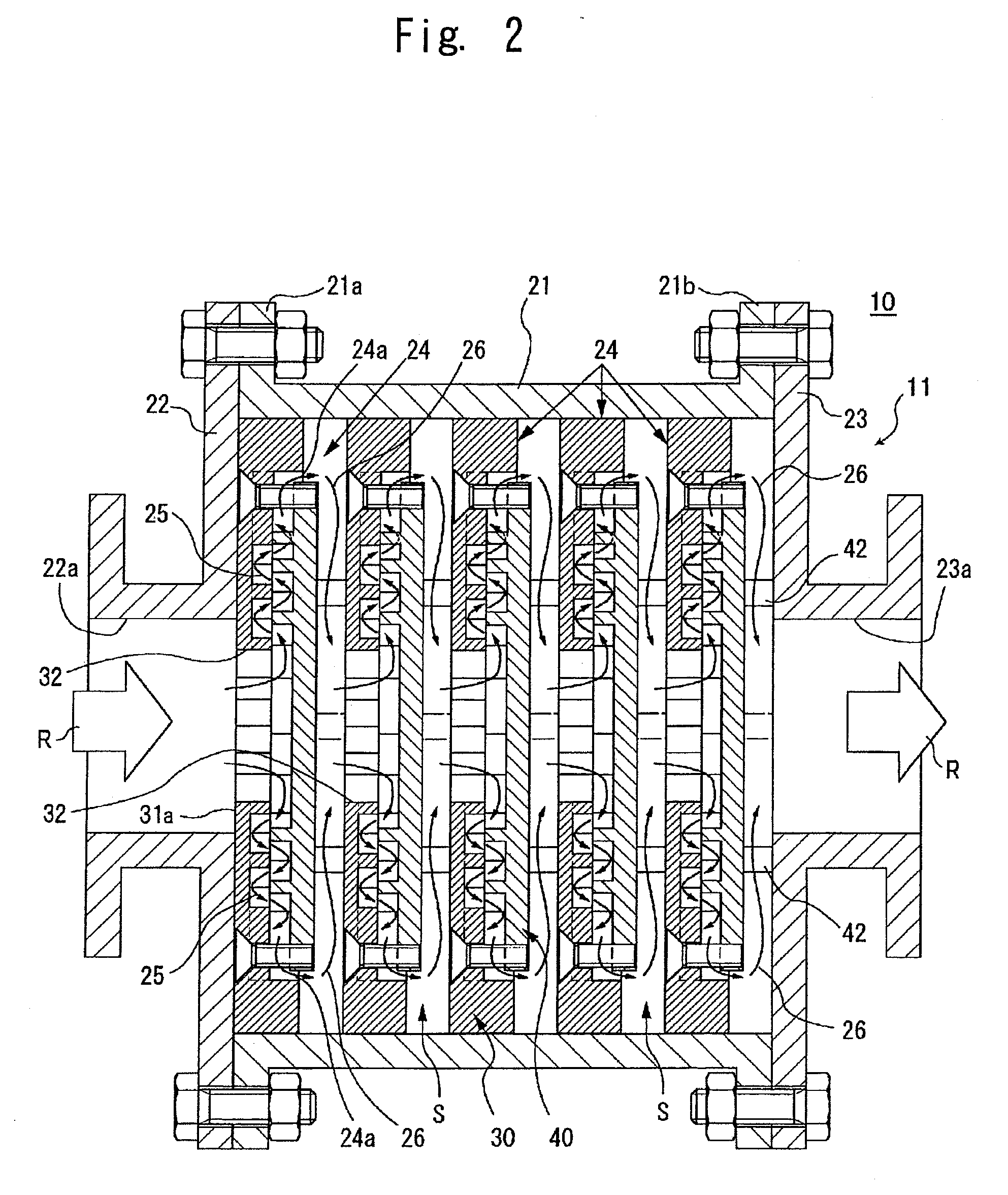

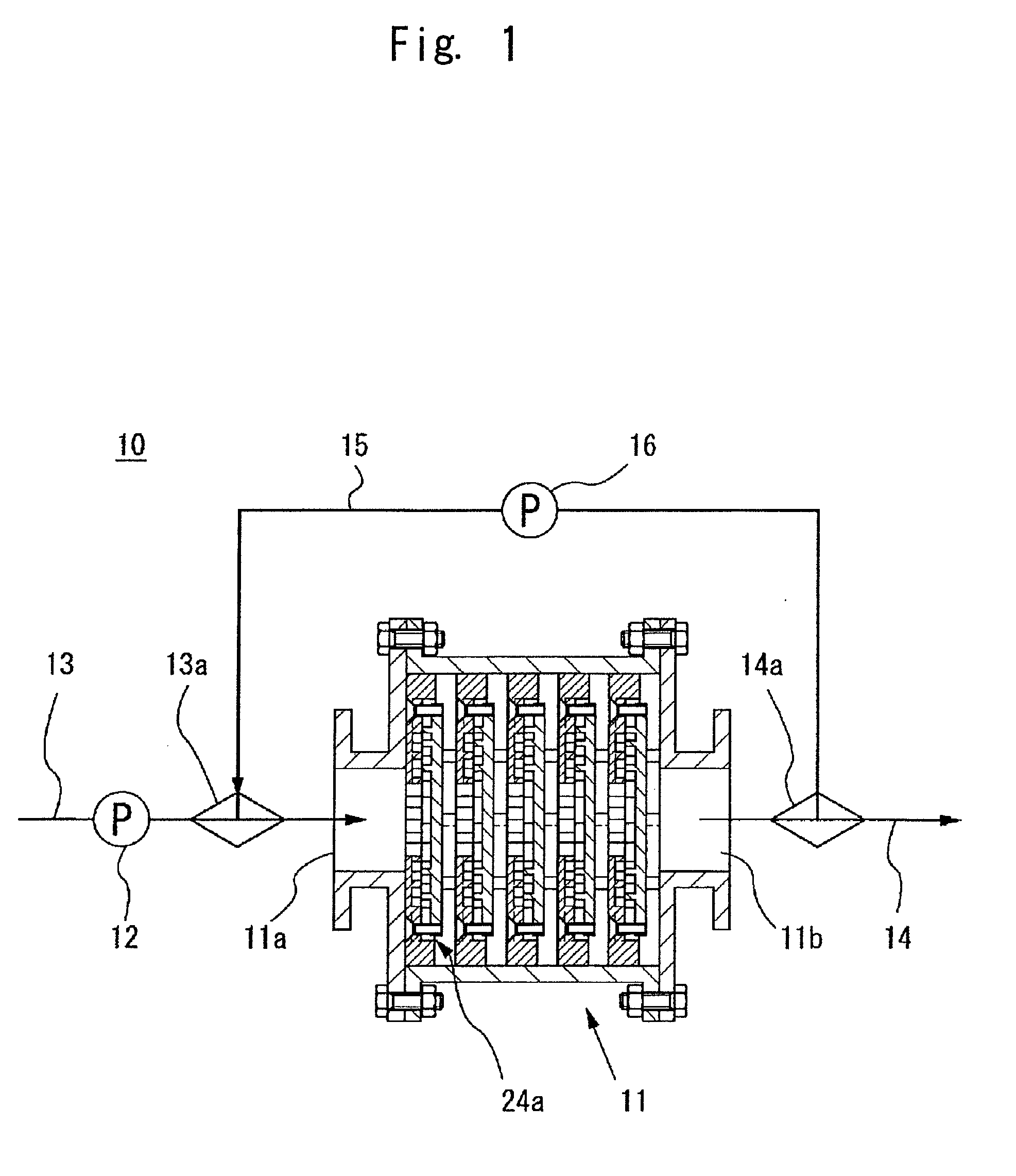

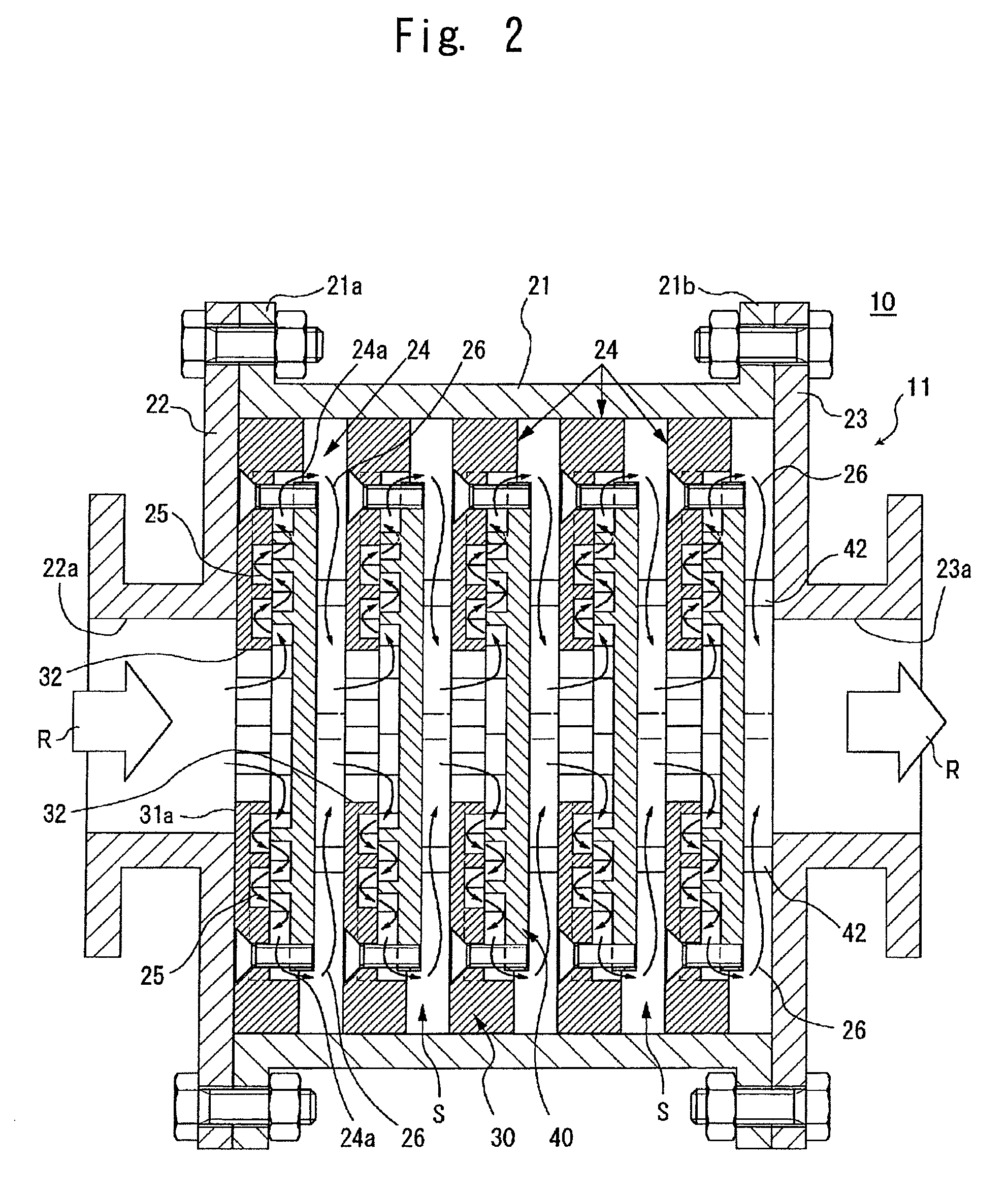

Static fluid mixer

InactiveUS20100276820A1Reduce flow path resistanceReduce pressure lossFlow mixersMixing methodsEngineeringMechanical engineering

A static fluid mixer which can perform processing such as generation of ultrafine uniform bubbles and has small pressure loss. A static fluid mixer has mixing units having outflow openings for allowing fluid having passed through mixing flow paths to flow through the outflow openings. The mixing units are arranged in a tubular casing body at intervals in the axis direction of the casing body. Adjacent mixing units and the casing body forma flow path forming space. Each mixing unit has an annular outflow path communicating with the end of each mixing flow path. The annular outflow path is open in a ring-like form having a substantially constant width along the entire circumference. The opening at the end of the annular outflow path functions as an outflow opening connecting to the flow path forming space. In the outflow path forming space is formed a collection flow path into which liquid having passed through the mixing flow path collects after flowing from the entire circumference of the outflow opening which is open in the ring-like form and moving toward the axis of the casing body.

Owner:MG GROW UP CORP +1

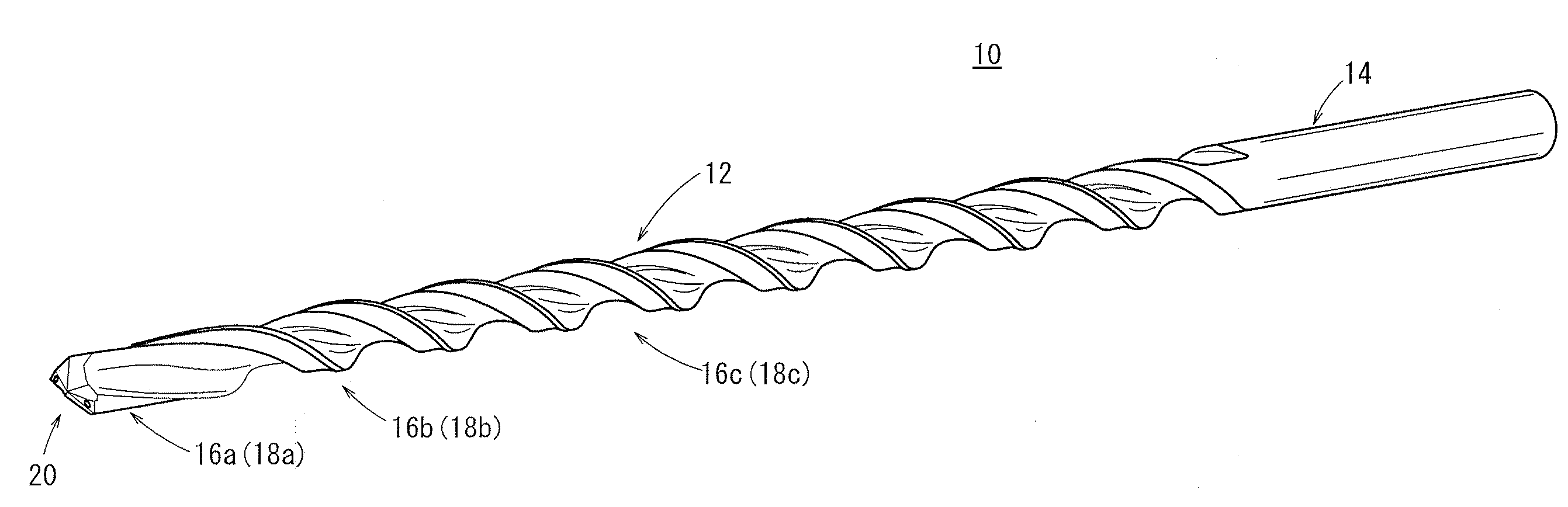

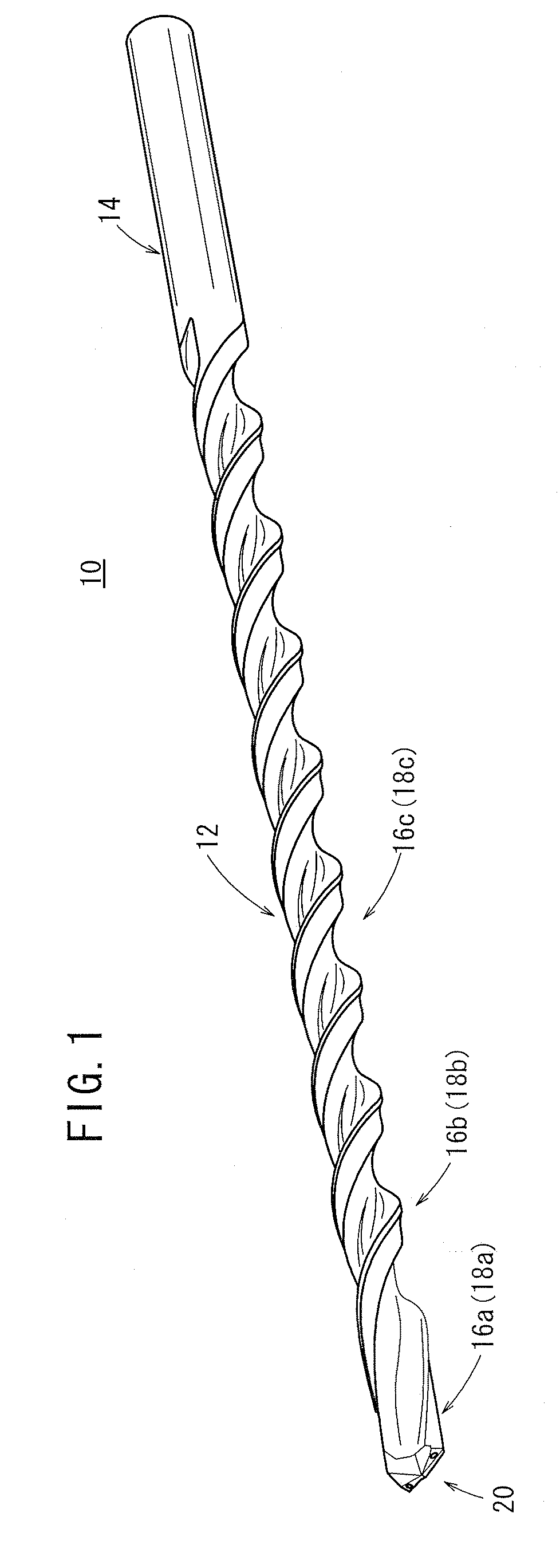

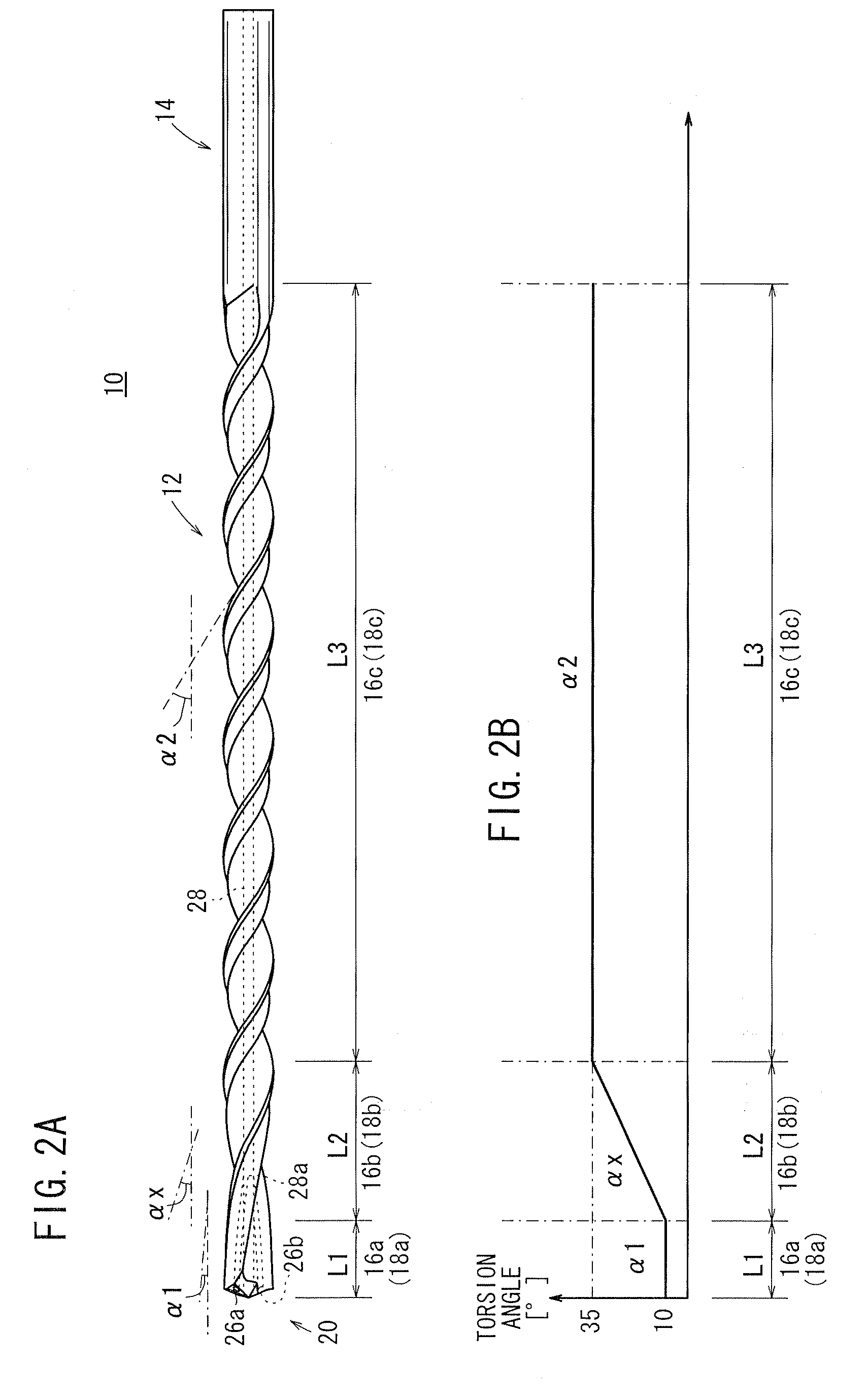

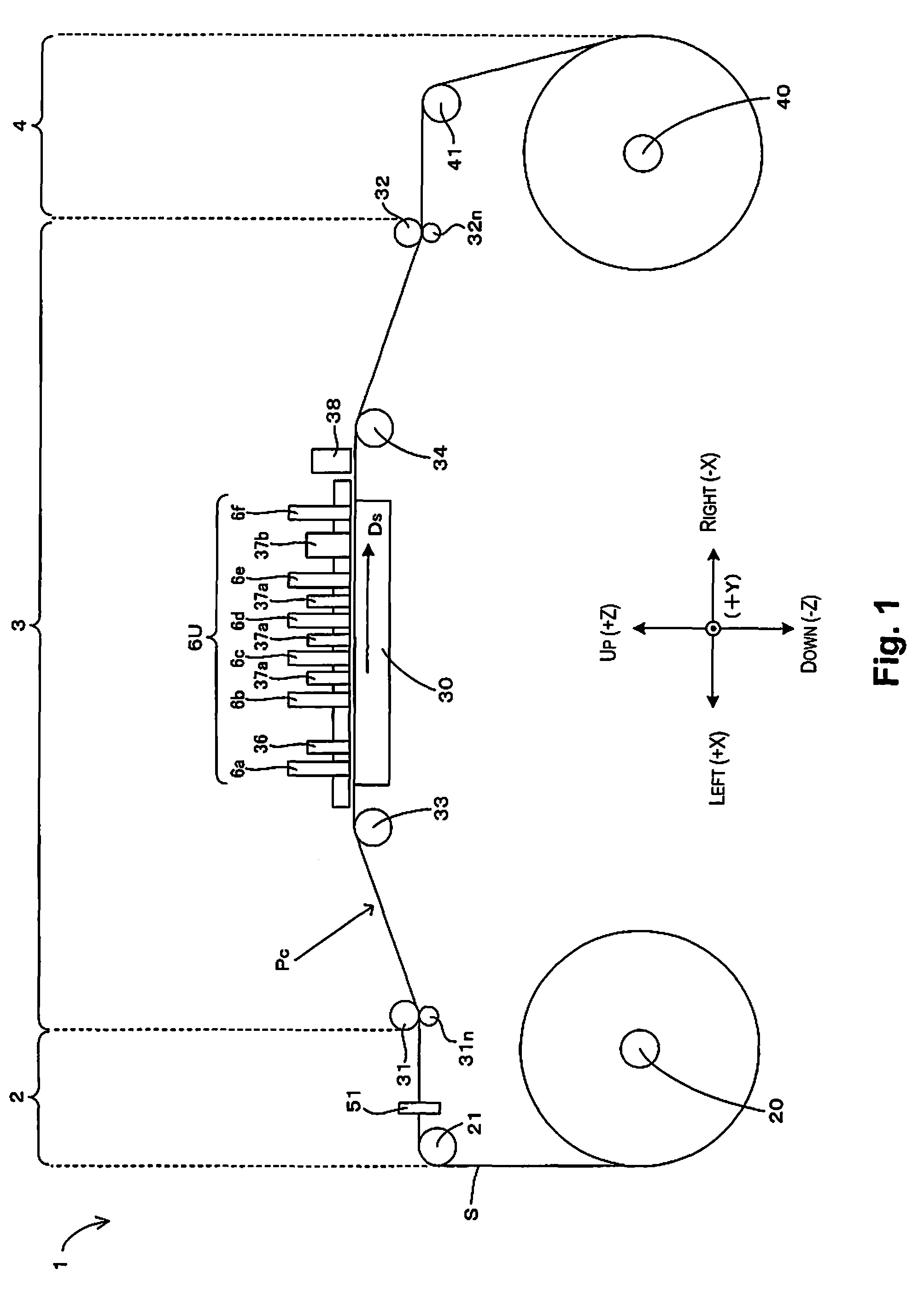

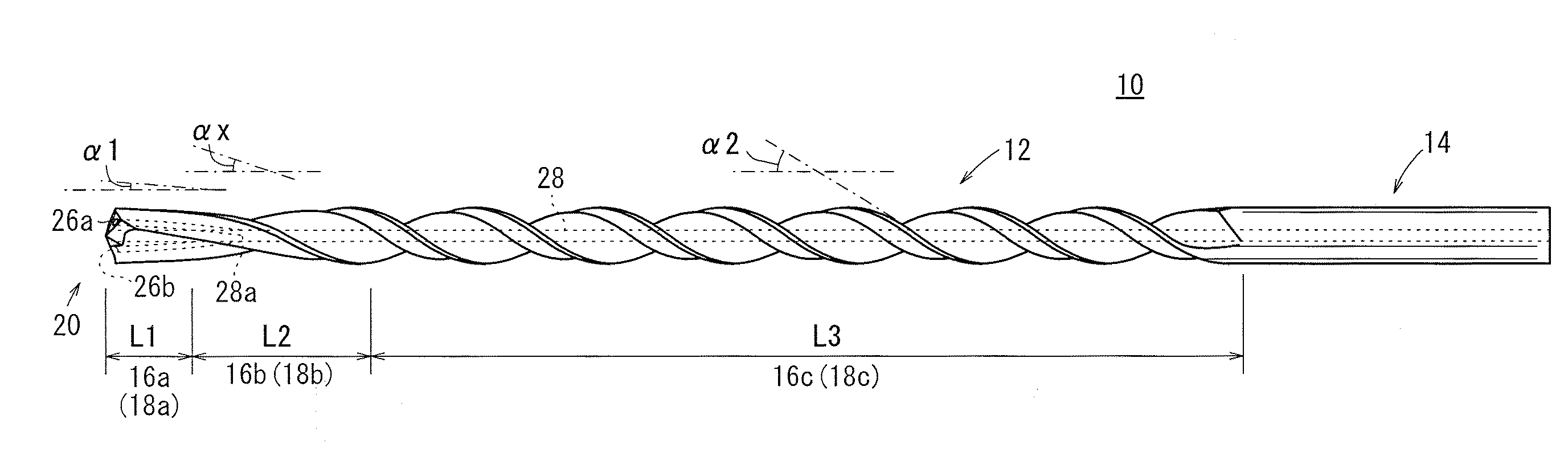

Drill

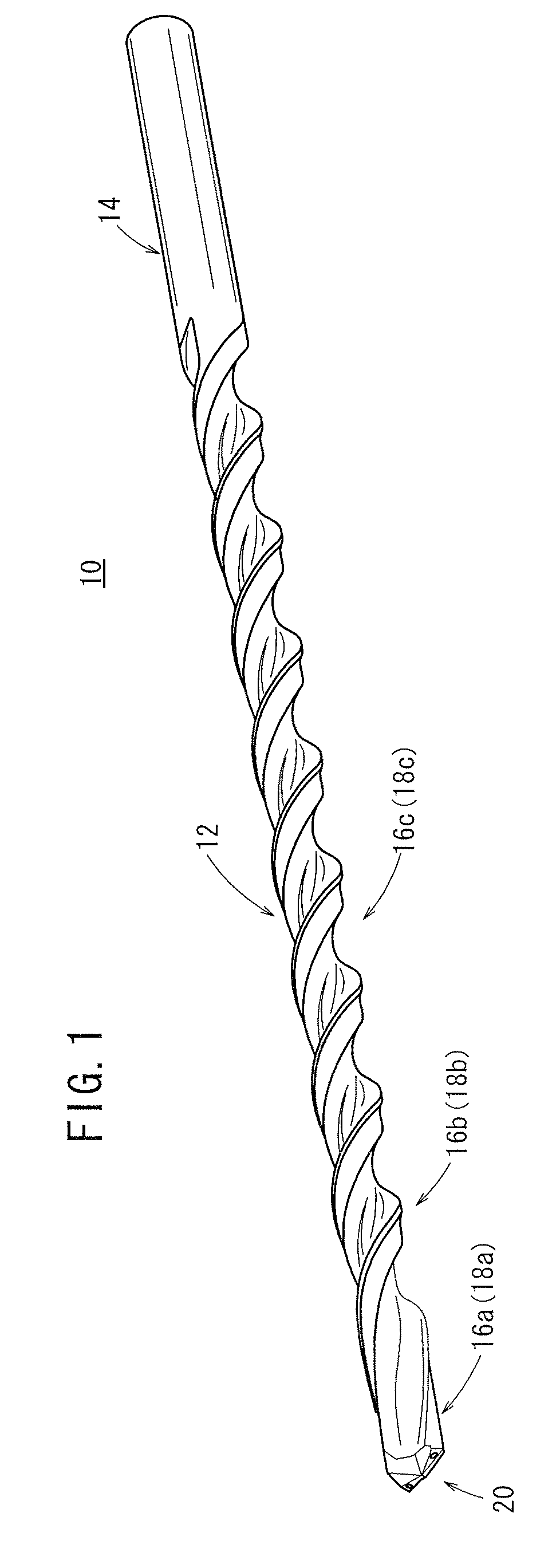

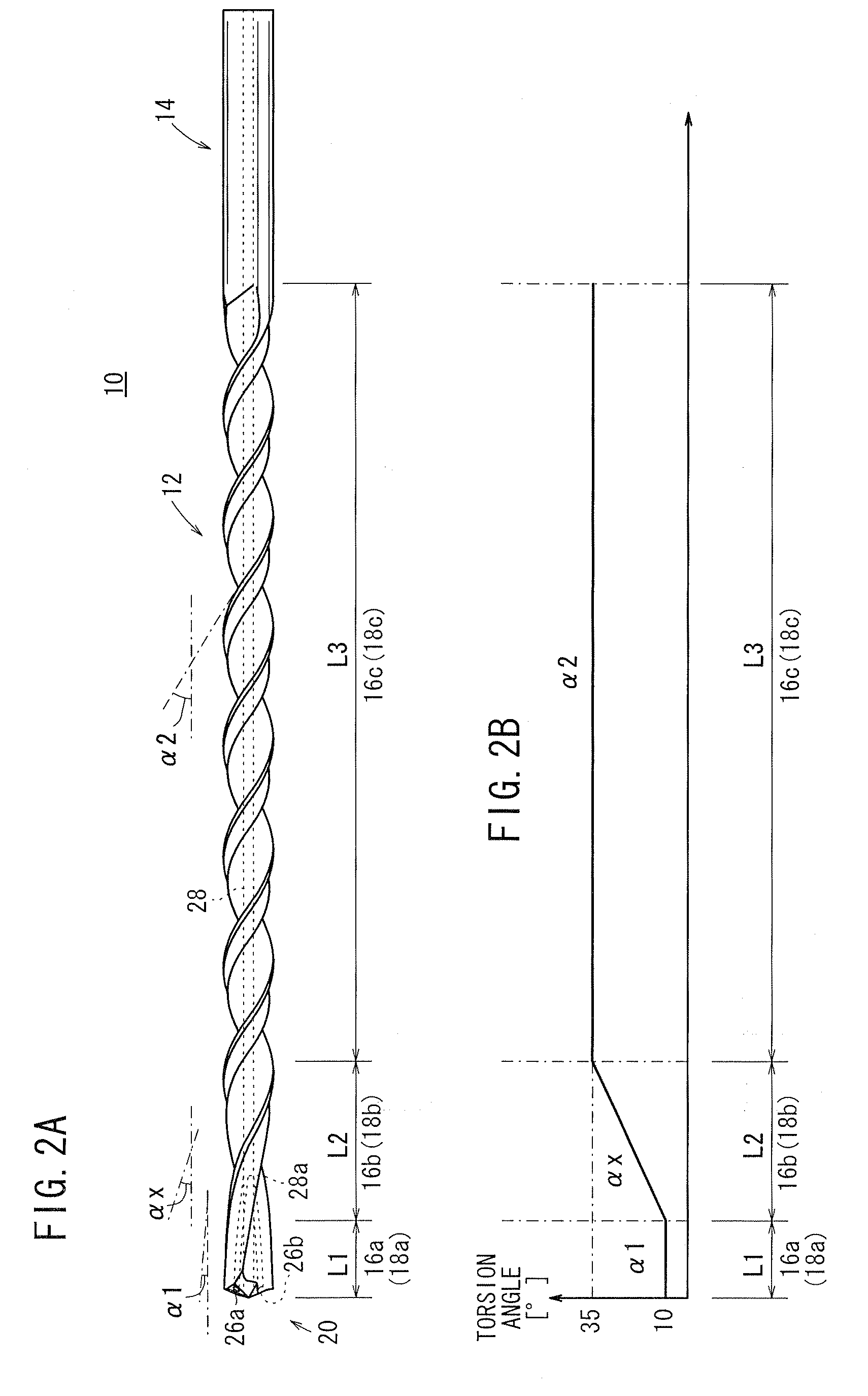

InactiveUS20090016832A1Reduce load appliedTool lifetime be significantly increasedWood turning toolsTransportation and packagingEngineeringHelix

A drill includes a blade portion provided with spiral cutting blades along a cutting direction from a tip end to a rear end, and a shank portion formed consecutively on a rear side of the blade portion. The blade portion includes distal-side cutting blades provided from the distal end of the blade portion along the cutting direction and angled at a constant first torsion angle, intermediate grooves formed at a variable torsion angle that varies gradually from the first torsion angle to a second torsion angle, and rear-side grooves formed at the constant second torsion angle. The rear-side grooves are longer than the distal-side cutting blades in the cutting direction, and the second torsion angle is greater than the first torsion angle.

Owner:HONDA MOTOR CO LTD

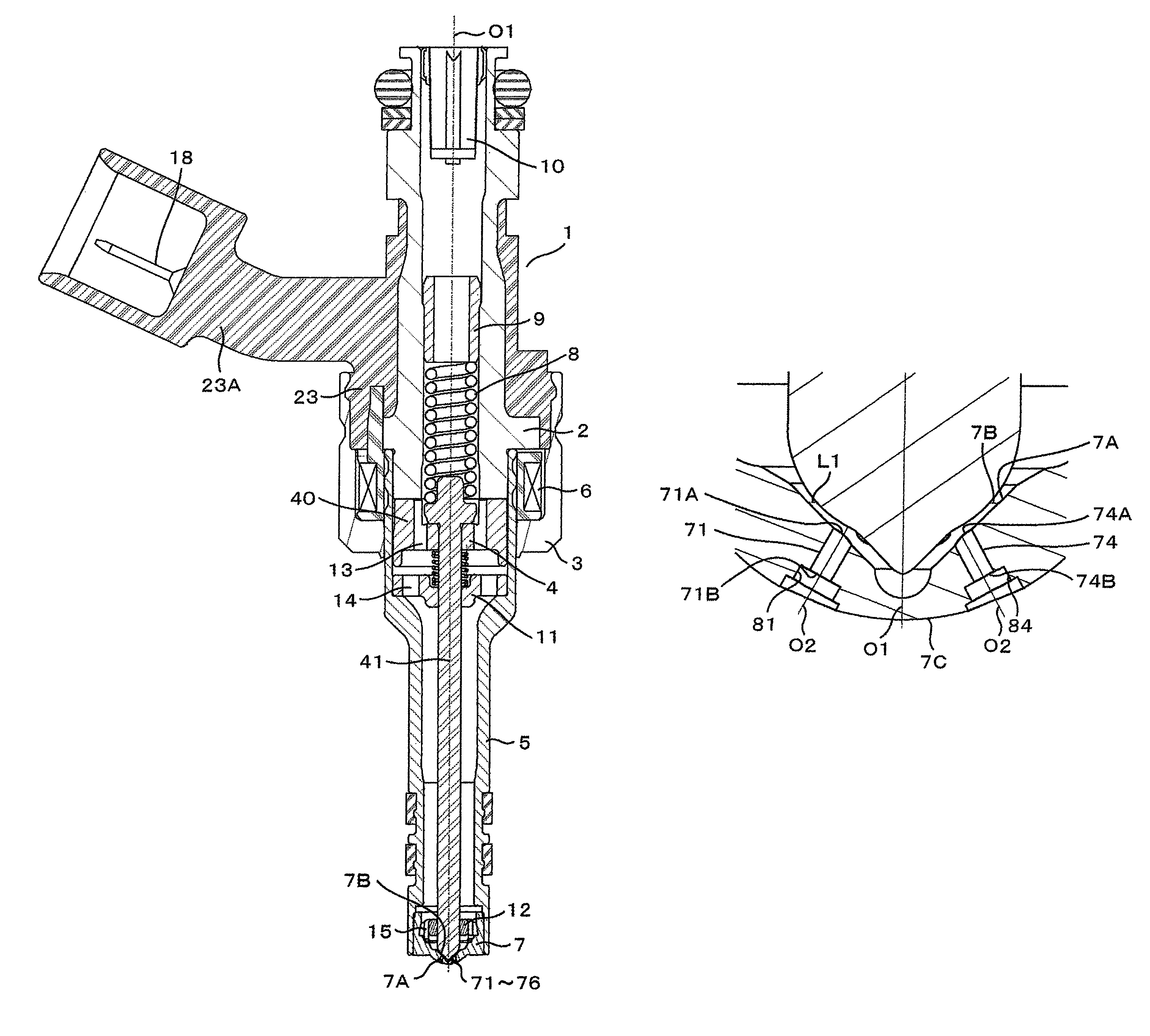

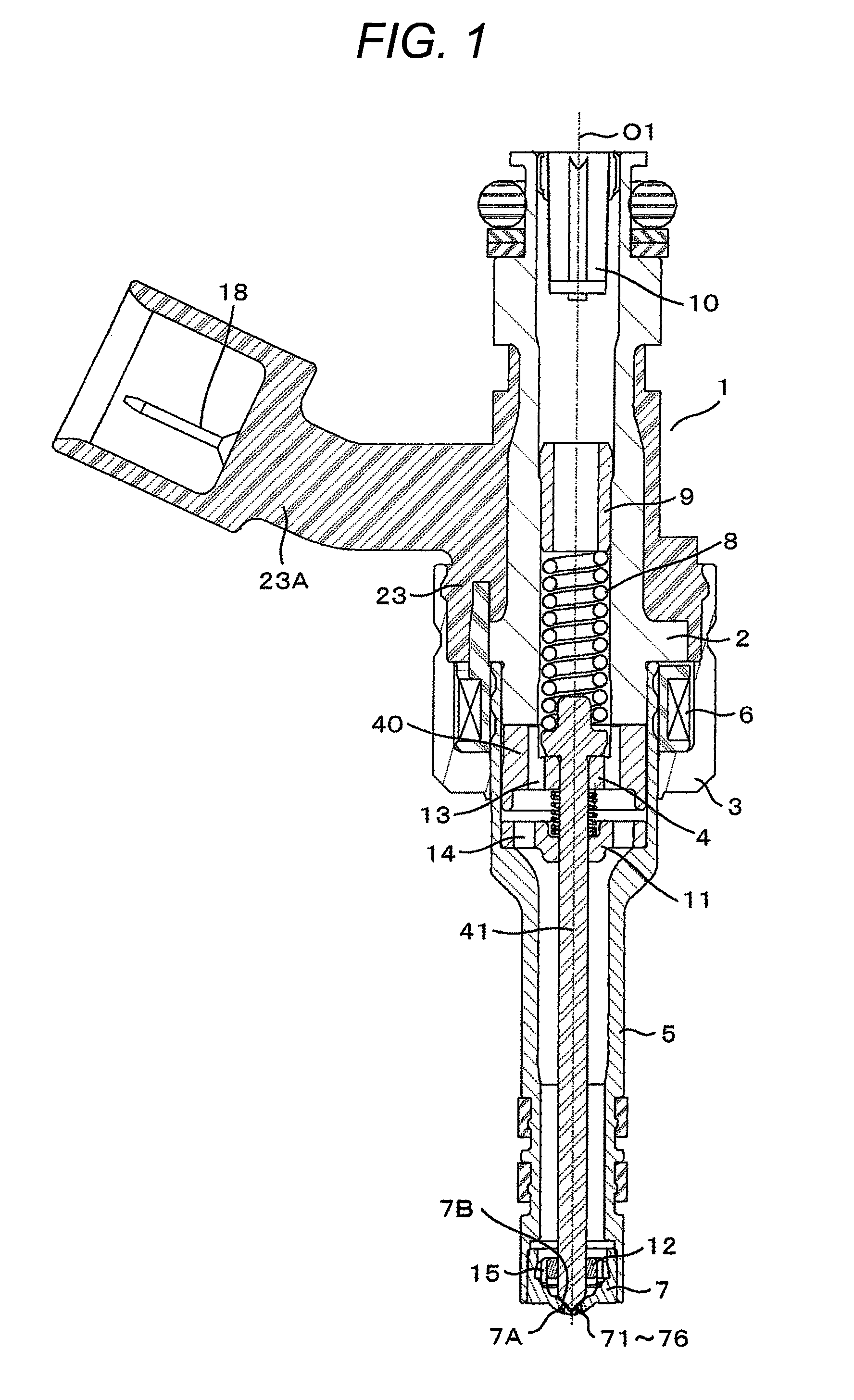

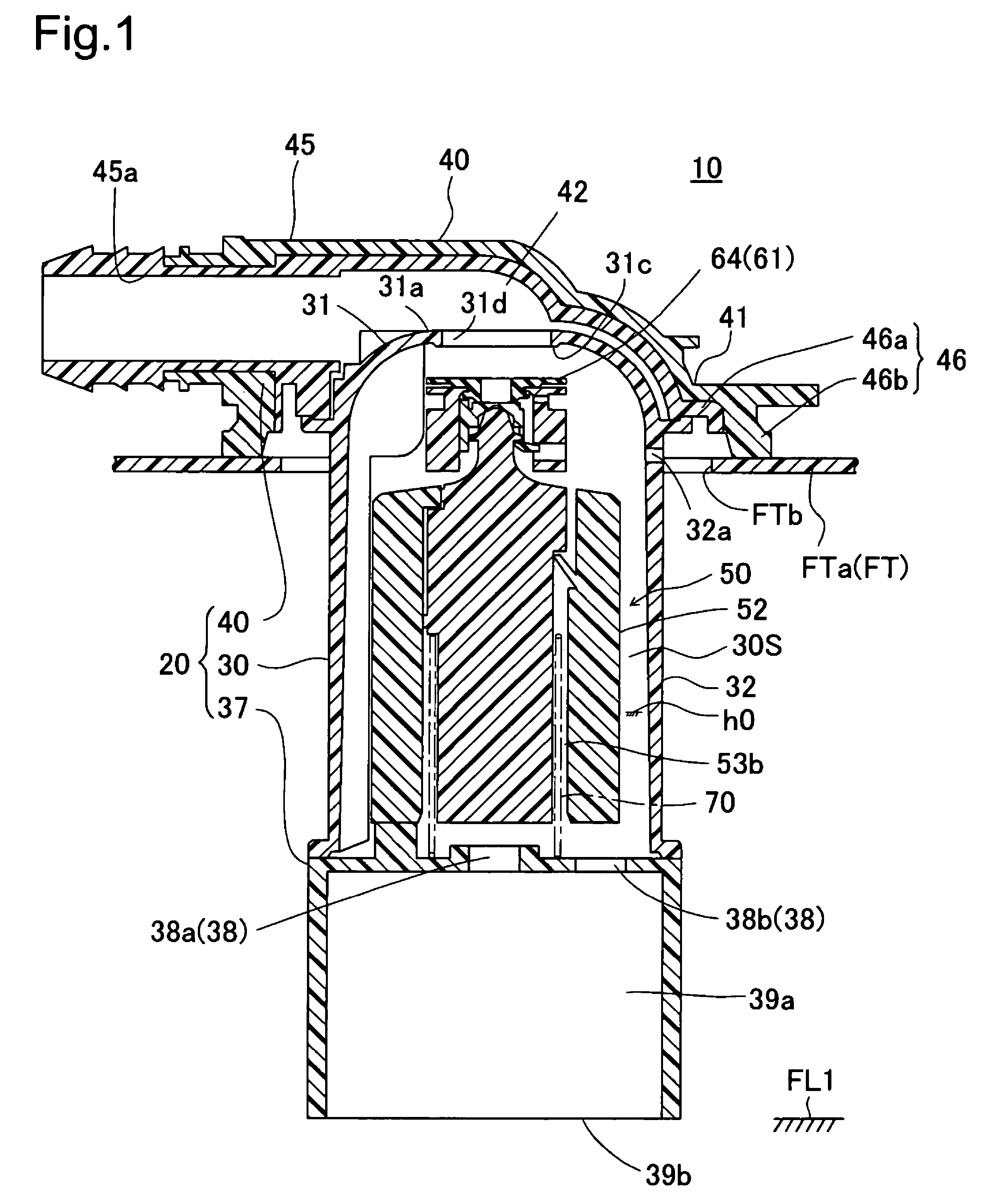

Fuel injector

InactiveUS8672239B2Shorten the lengthSection decreasesSpray nozzlesFuel injection apparatusCircular coneSpray nozzle

Owner:HITACHI ASTEMO LTD

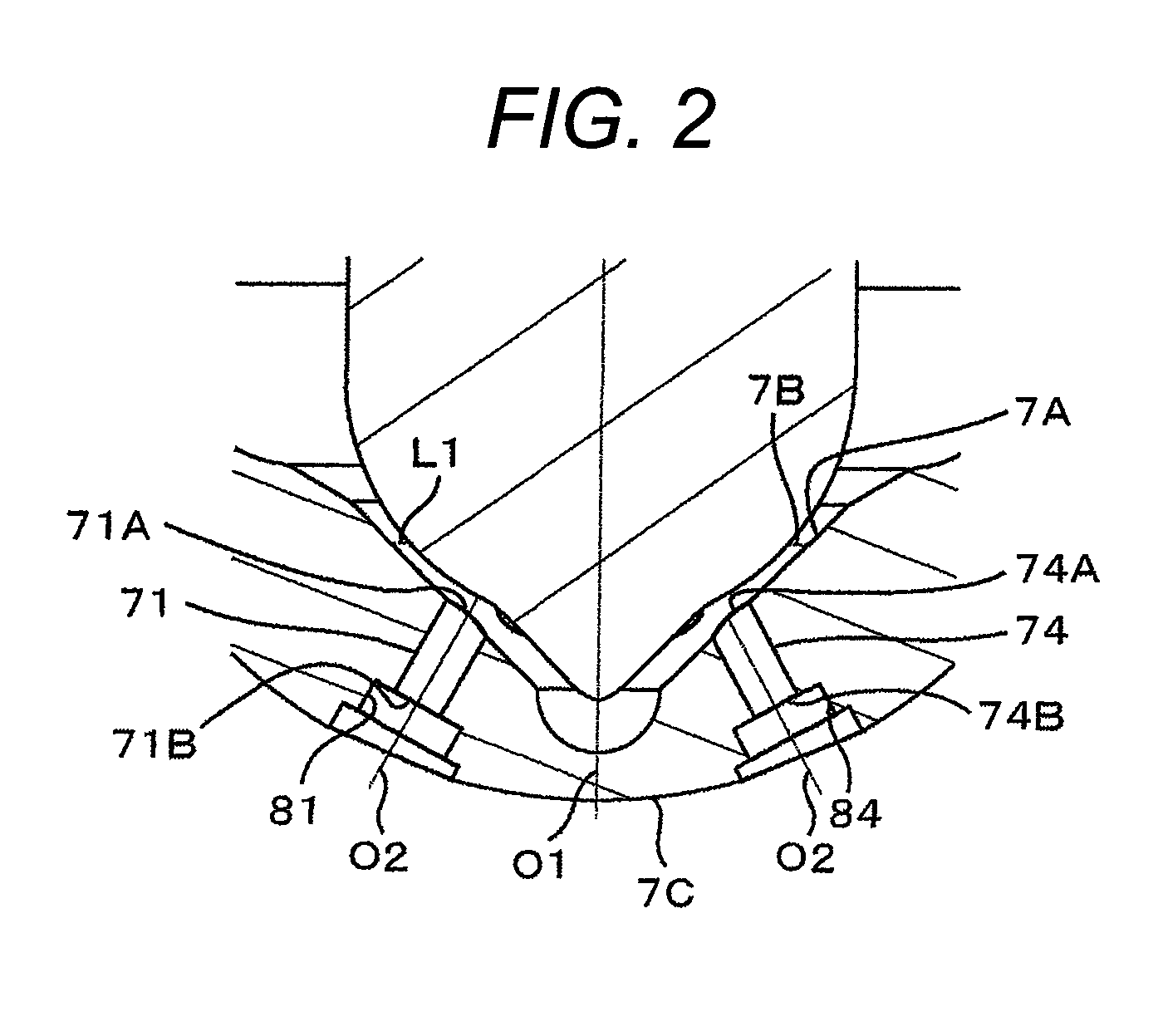

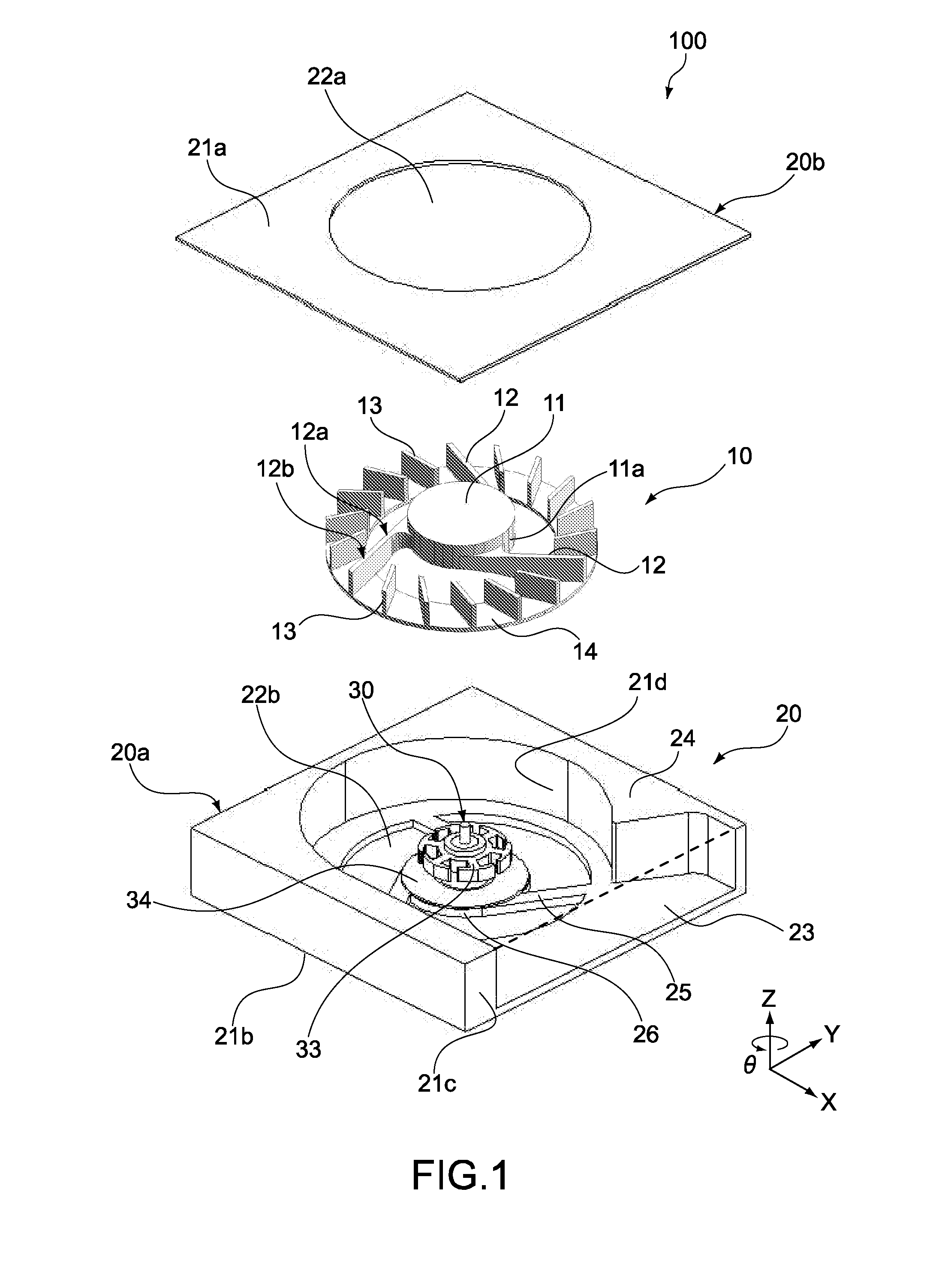

Centrifugal impeller, fan apparatus, and electronic device

InactiveUS20080226446A1Shorten the flow pathSuppress noisePump componentsDigital data processing detailsImpellerCoupling

There is provided a centrifugal impeller that includes a boss portion, a plurality of first centrifugal blades, a plurality of second centrifugal blades, and a coupling portion. The boss portion is capable of rotating. The plurality of first centrifugal blades are provided to the boss portion such that the plurality of first centrifugal blades extend from the boss portion. The plurality of second centrifugal blades are provided around the boss portion such that the plurality of second centrifugal blades are spaced apart from the boss portion. The coupling portion couples the plurality of first centrifugal blades and the plurality of second centrifugal blades.

Owner:SONY CORP

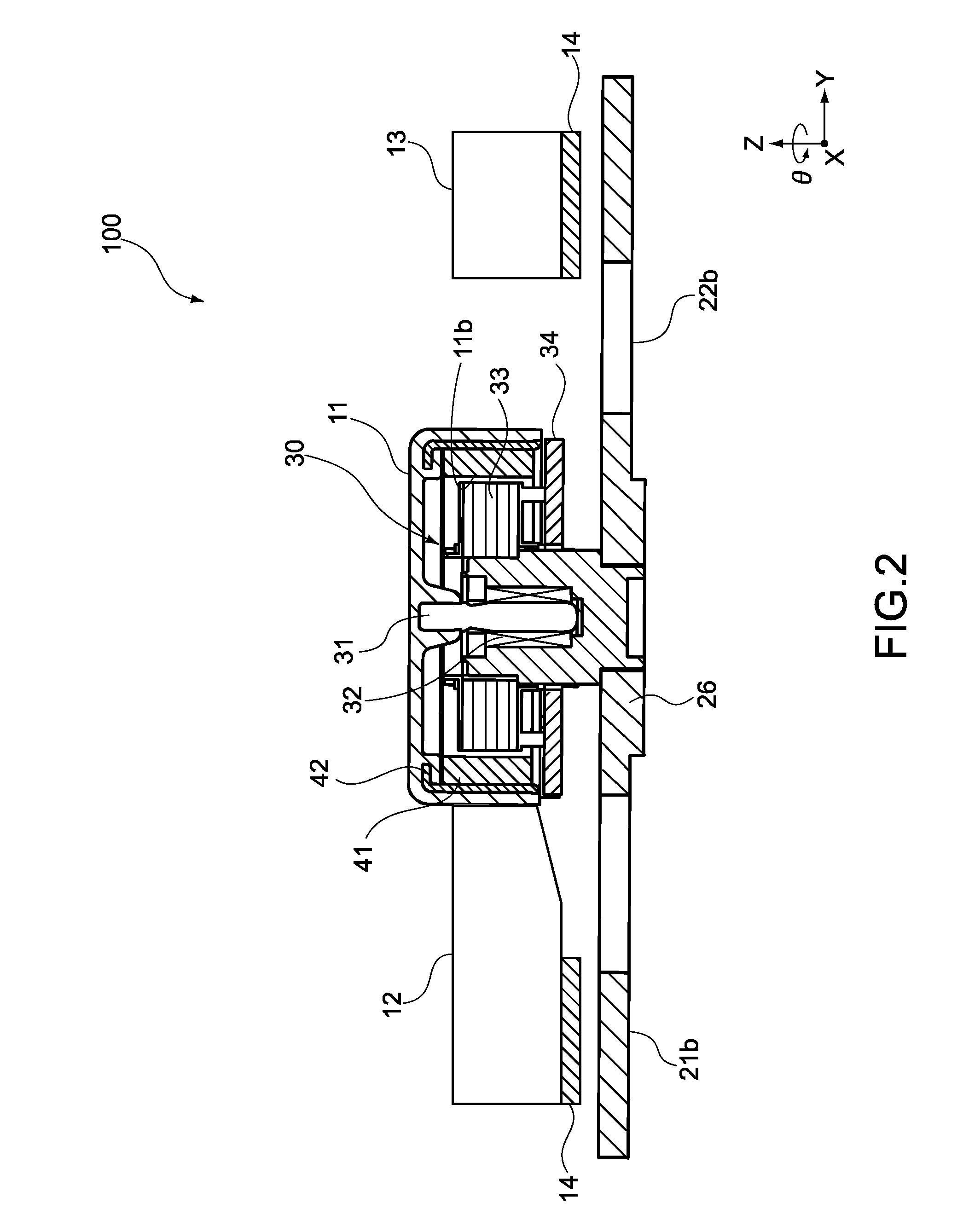

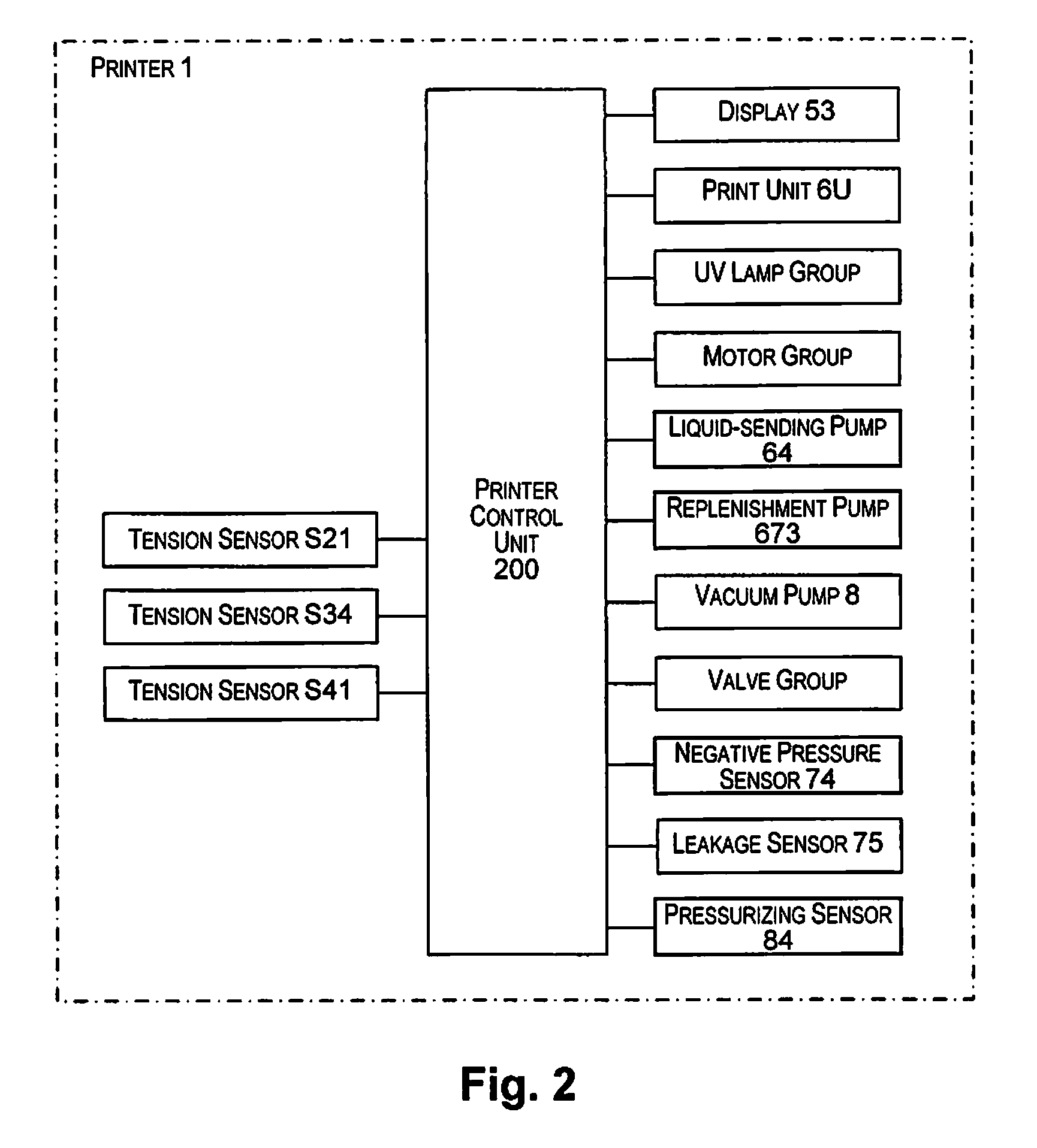

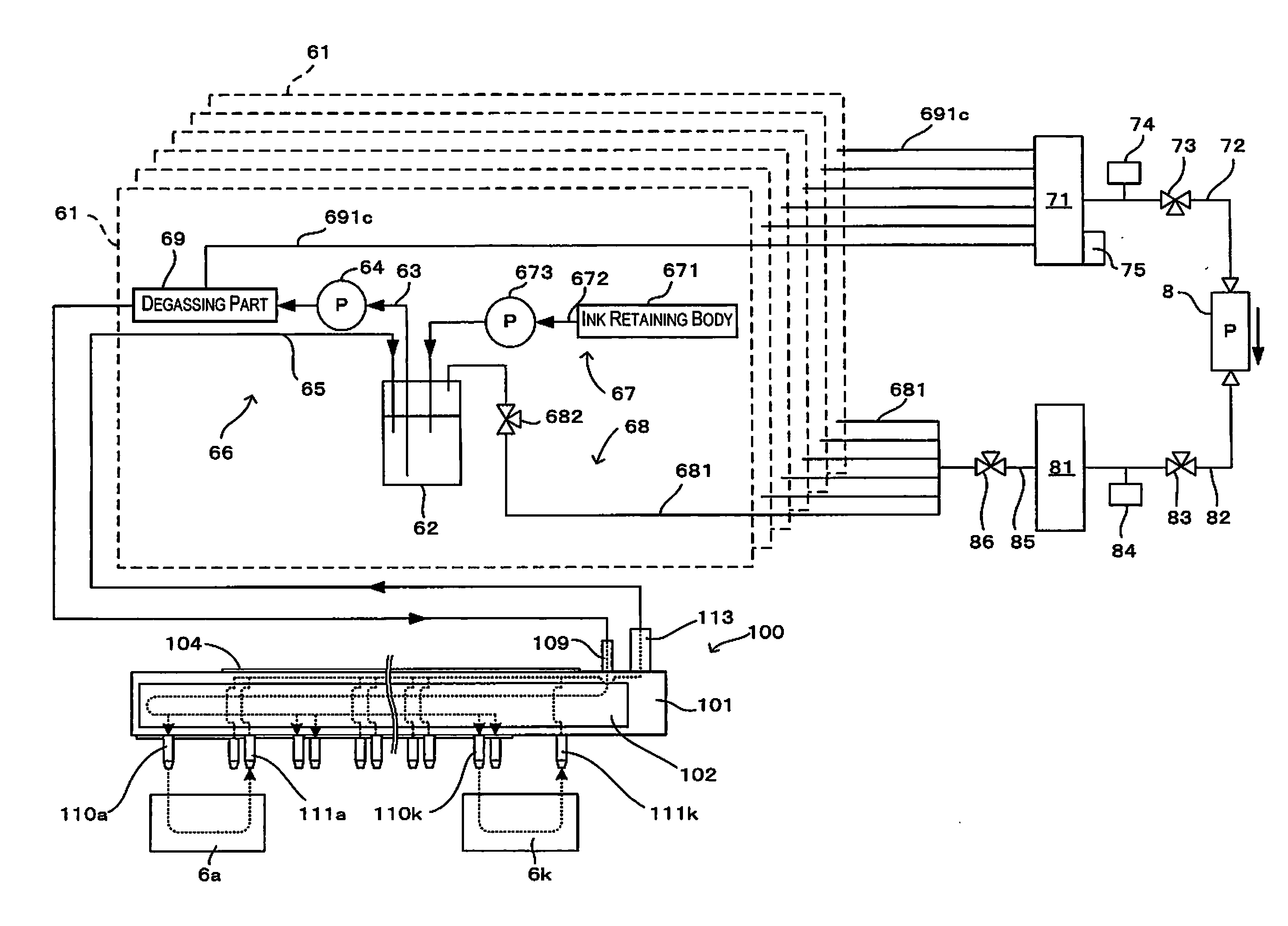

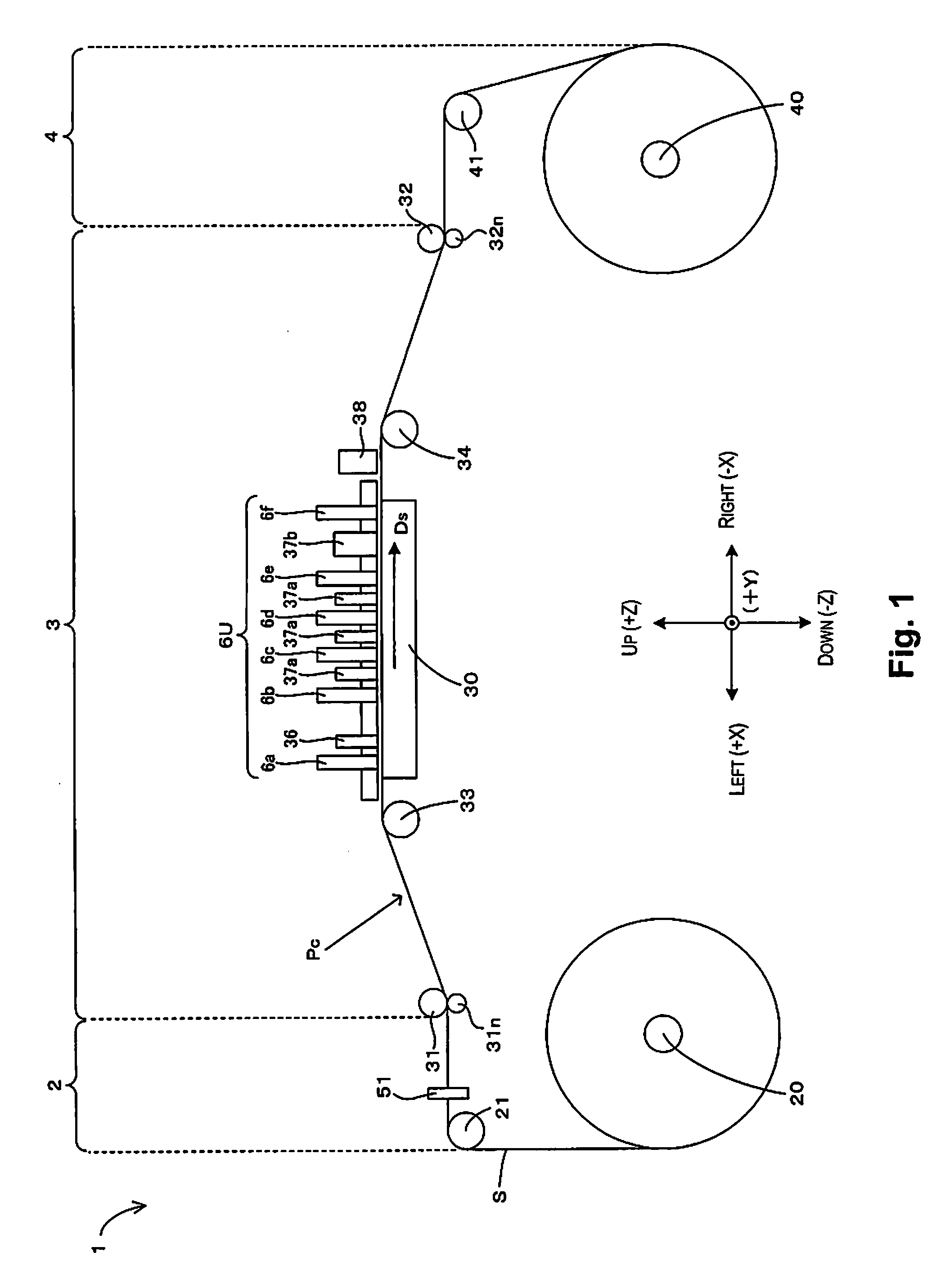

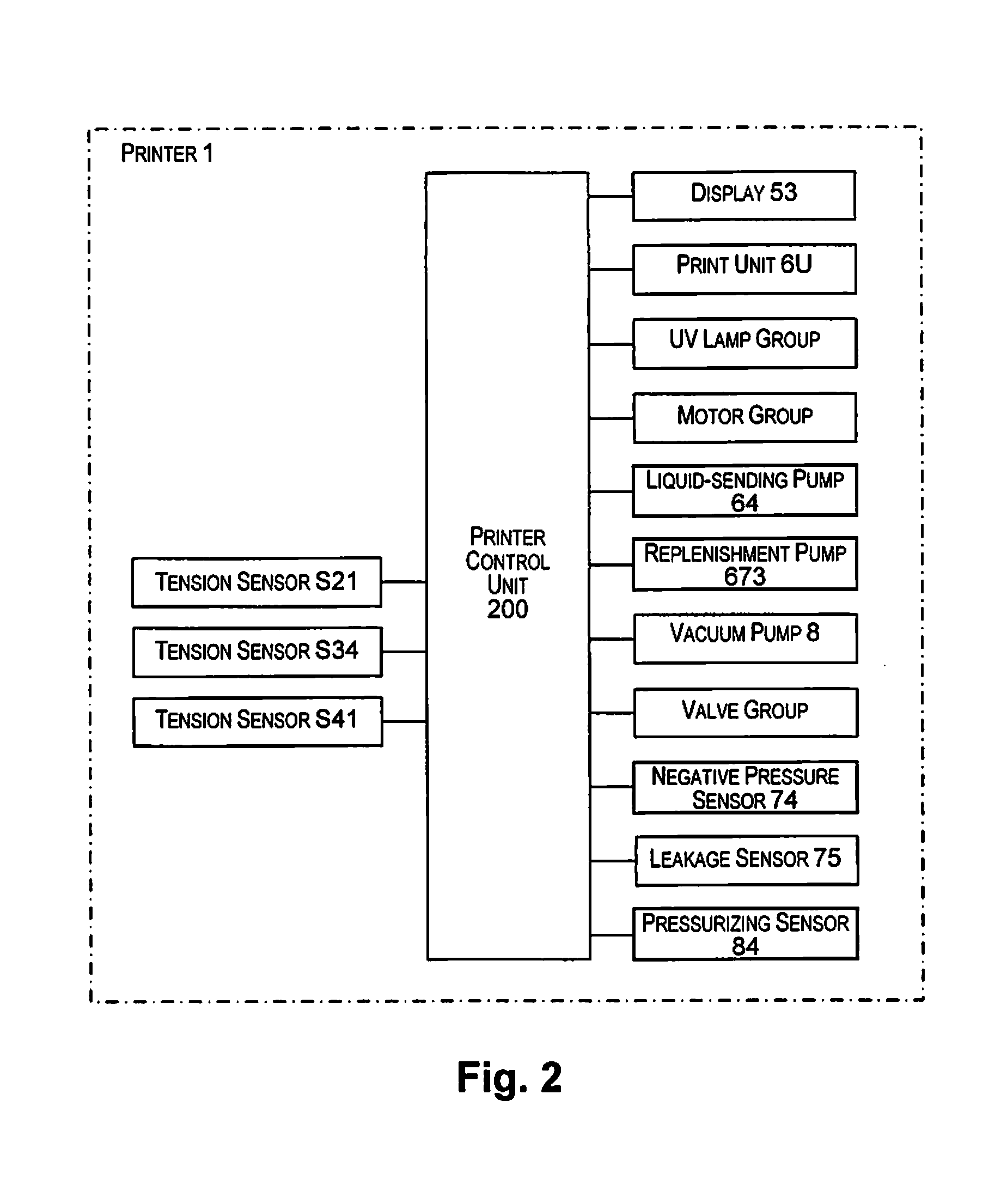

Liquid ejecting apparatus

ActiveUS9216587B2Uniform pressureLarge fluctuationsInking apparatusTypewritersLiquid jetLiquid circulation

A liquid circulation part has a recovery path where a liquid flows into a retaining part from a first head and a second head. The recovery path has a first merging point where the liquid flowing from the first head and the liquid flowing from the second head are merged, a first recovery path part where the liquid flowing from the first head flows into the first merging point, and a second recovery path part where the liquid flows from the first merging point. The cross-sectional area of the second recovery path part, orthogonal to a direction of flow of the liquid in the second recovery path part, is greater than the cross-sectional area of the first recovery path part, orthogonal to the direction of flow of the liquid in the first recovery path part.

Owner:SEIKO EPSON CORP

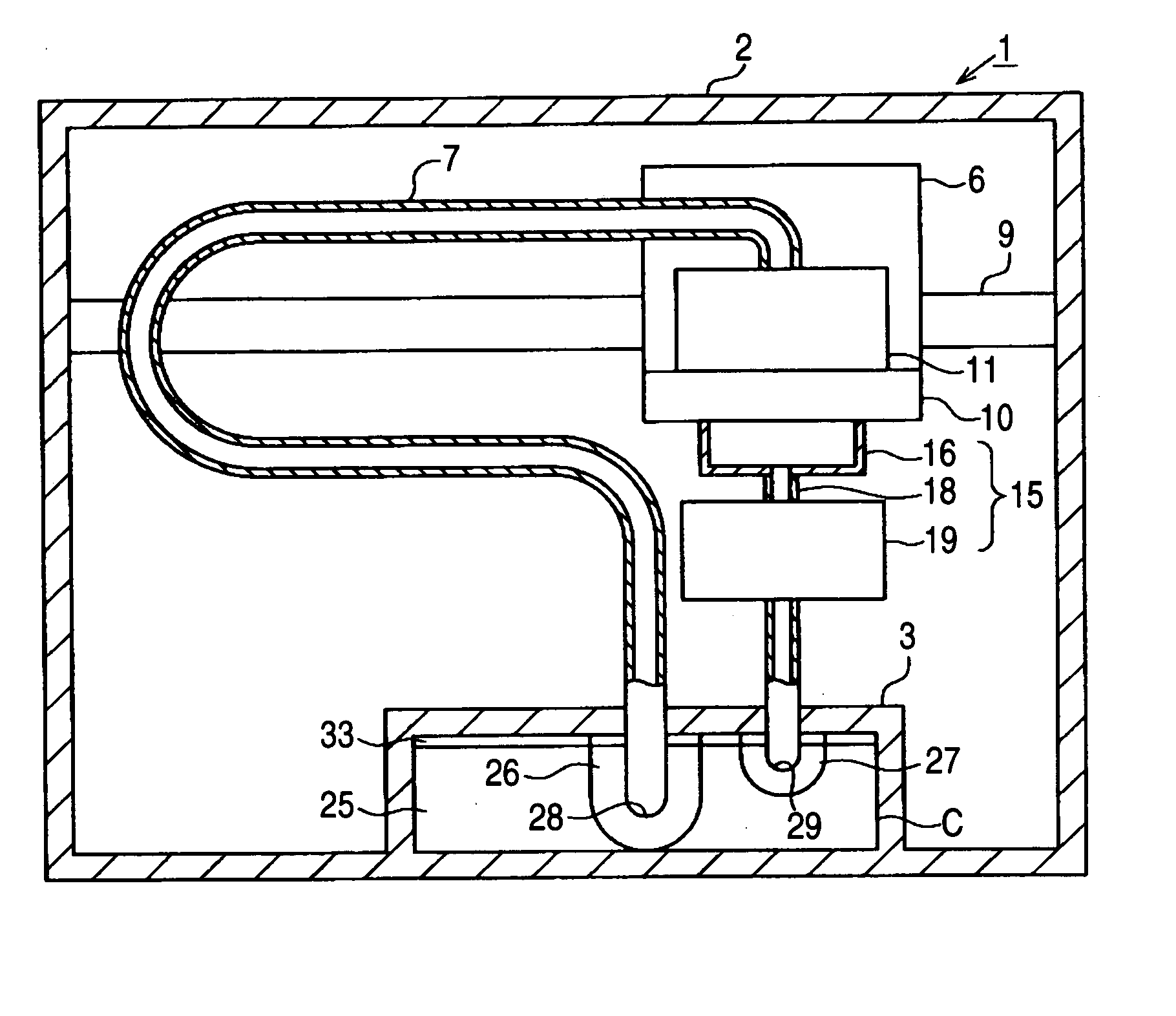

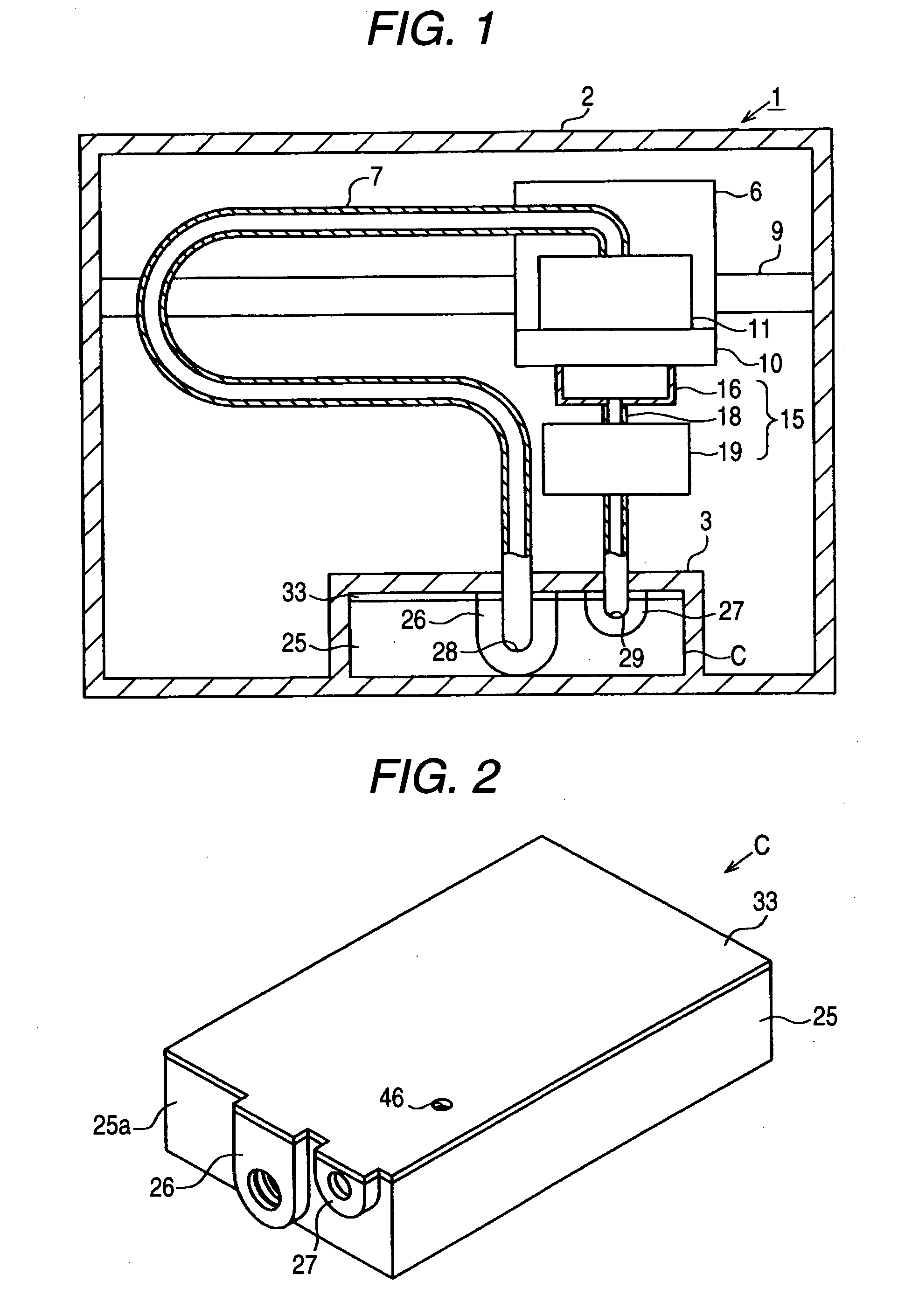

Waste liquid collecting method, liquid injecting apparatus and cartridge set

A printer includes a recording head and a maintenance mechanism for sucking an ink in the recording head. A plurality of cartridges to be attached to the printer includes a first housing portion for storing an ink to be supplied to the recording head and a second housing portion for storing a waste ink discharged from the maintenance mechanism. In a first one of the cartridges, the flow path resistance of a cartridge side flow path from a waste ink introducing portion to an air communicating hole for discharging air in a waste ink reservoir portion to an outside through the waste ink reservoir portion is lower than the flow path resistance of each of the cartridge side flow paths of the other cartridges.

Owner:SEIKO EPSON CORP

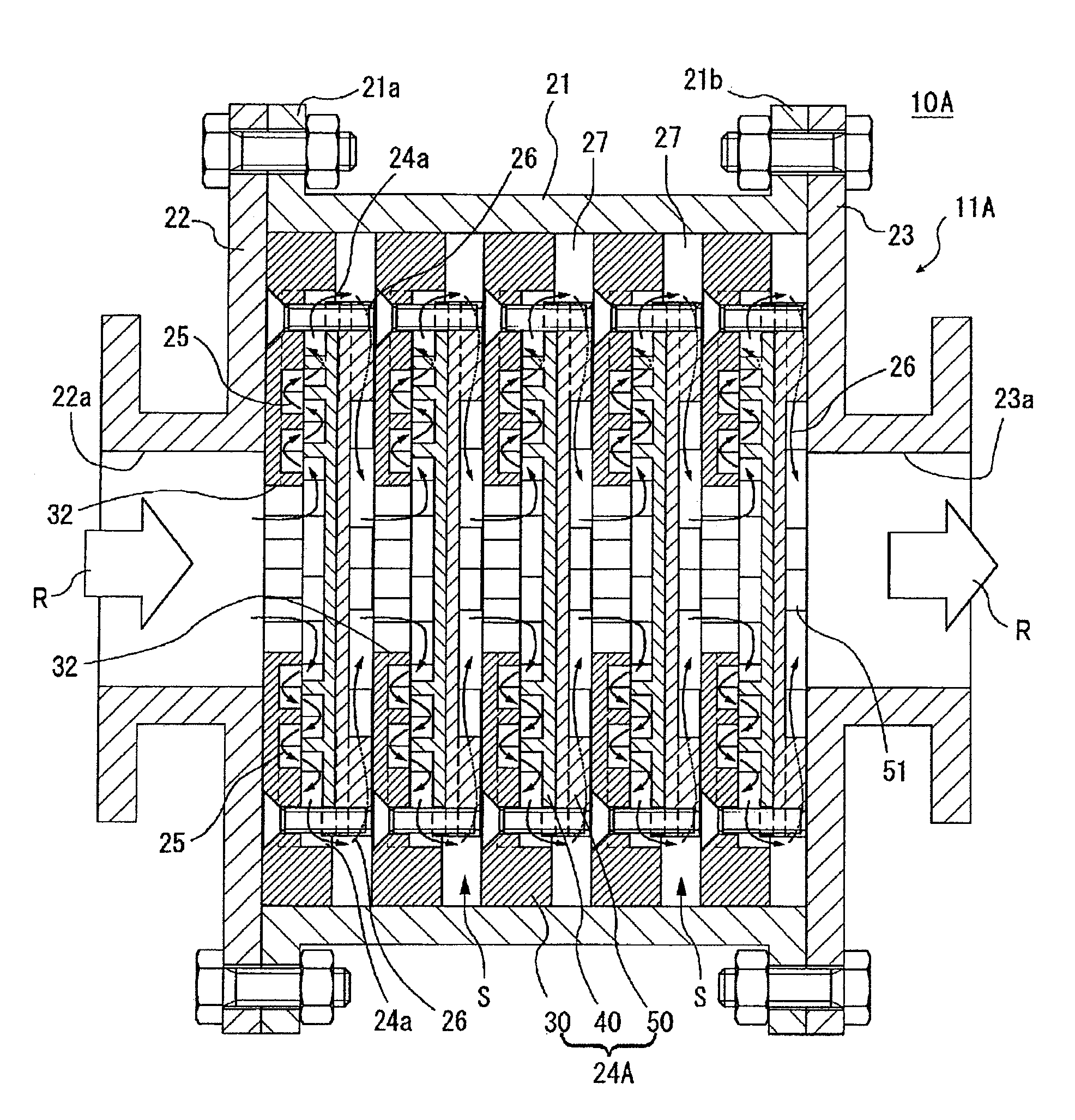

Static fluid mixer capable of ultrafinely mixing fluids

InactiveUS8740450B2Miniaturized more finelyReduce flow path resistanceFlow mixersUsing liquid separation agentEngineeringMechanical engineering

A static fluid mixer which can perform processing such as generation of ultrafine uniform bubbles and has small pressure loss. A static fluid mixer has mixing units having outflow openings for allowing fluid having passed through mixing flow paths to flow through the outflow openings. The mixing units are arranged in a tubular casing body at intervals in the axis direction of the casing body. Adjacent mixing units and the casing body form a flow path forming space. Each mixing unit has an annular outflow path communicating with the end of each mixing flow path. The annular outflow path is open in a ring-like form having a substantially constant width along the entire circumference. The opening at the end of the annular outflow path functions as an outflow opening connecting to the flow path forming space. In the outflow path forming space is formed a collection flow path into which liquid having passed through the mixing flow path collects after flowing from the entire circumference of the outflow opening which is open in the ring-like form and moving toward the axis of the casing body.

Owner:MG GROW UP CORP +1

Liquid Ejecting Apparatus

A liquid ejecting apparatus includes a liquid ejecting head that ejects liquid in a manifold as liquid droplets from a nozzle opening; a supply path that supplies the liquid to the manifold; a pump unit that is disposed in the supply path and pumps the liquid; and a discharge path that discharges the liquid from the manifold, wherein a flow path resistance of the discharge path from the manifold is smaller than a flow path resistance of the supply path from the pump unit to the manifold.

Owner:SEIKO EPSON CORP

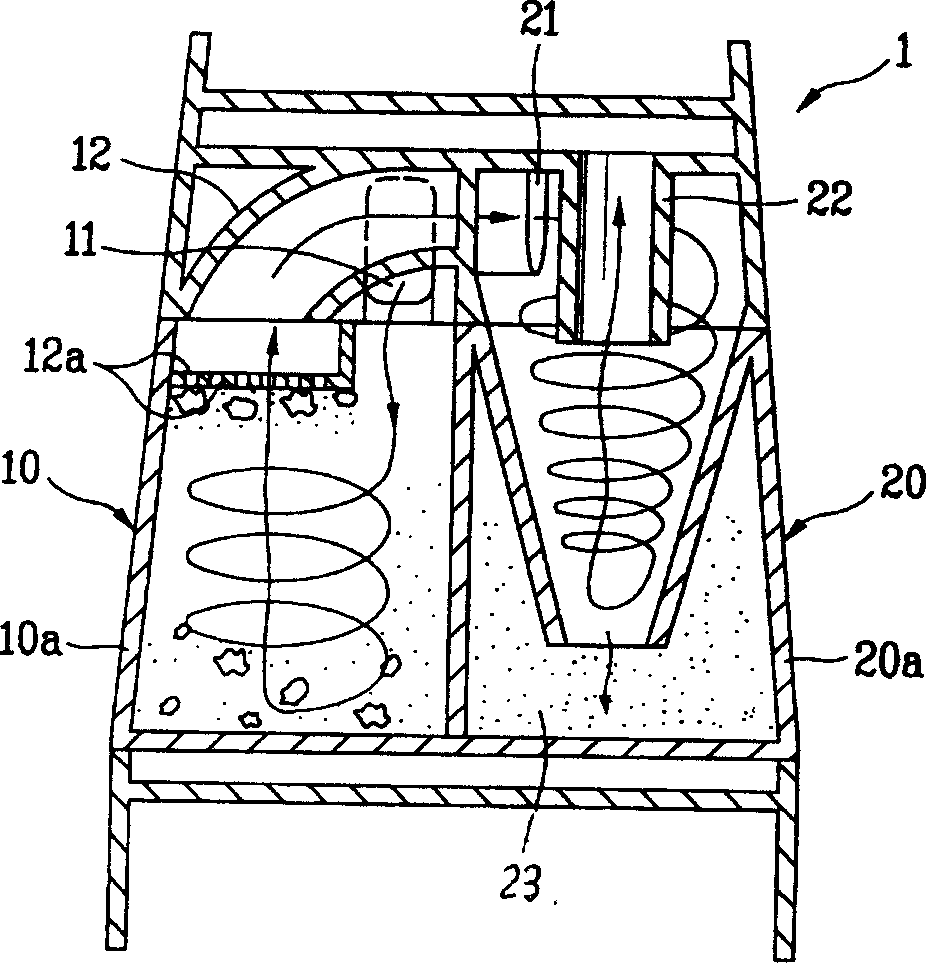

Multiple spiral dust collector

InactiveCN1548245AReduce flow path resistanceSmall pressure lossSuction filtersVortex flow apparatusPollutantAirflow

The present invention is multiple vortex dust collector in duster. The multiple vortex dust collector includes cylindrical vortex body with partitioning wall to separate it two parts including the lower or first part and the upper or the second part. The first vortex part is provided with sucking pipe, pollutant exhaust hole, the first dust collecting chamber with exhaust port in the center of the partitioning wall, and leading pipe to the second vortex part. The second vortex part has central exhaust pipe with filtering part and sucking force generator, pollutant exhaust hole, and the second dust collecting chamber. The present invention has basically the same pollutant and air sucking direction and vortex and exhaust direction, reduced conflict between the ascending airflow and vortex, reduced friction resistance, less pressure loss, less noise and less pollutant jamming in filtering part.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Liquid ejecting apparatus

ActiveUS20150085032A1Extend the flow pathFlow path resistance increaseInking apparatusTypewritersLiquid jetLiquid circulation

A liquid circulation part has a recovery path where a liquid flows into a retaining part from a first head and a second head. The recovery path has a first merging point where the liquid flowing from the first head and the liquid flowing from the second head are merged, a first recovery path part where the liquid flowing from the first head flows into the first merging point, and a second recovery path part where the liquid flows from the first merging point. The cross-sectional area of the second recovery path part, orthogonal to a direction of flow of the liquid in the second recovery path part, is greater than the cross-sectional area of the first recovery path part, orthogonal to the direction of flow of the liquid in the first recovery path part.

Owner:SEIKO EPSON CORP

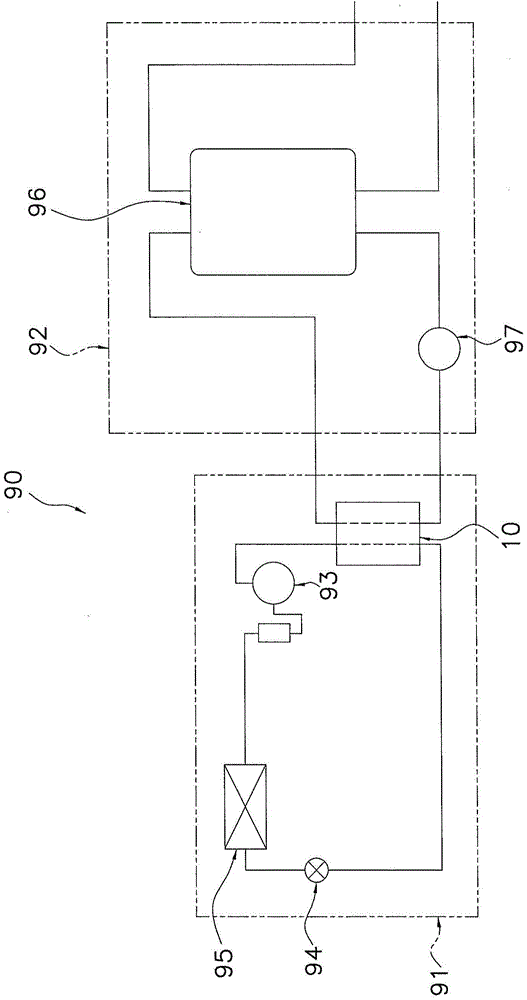

Refrigeration cycle apparatus

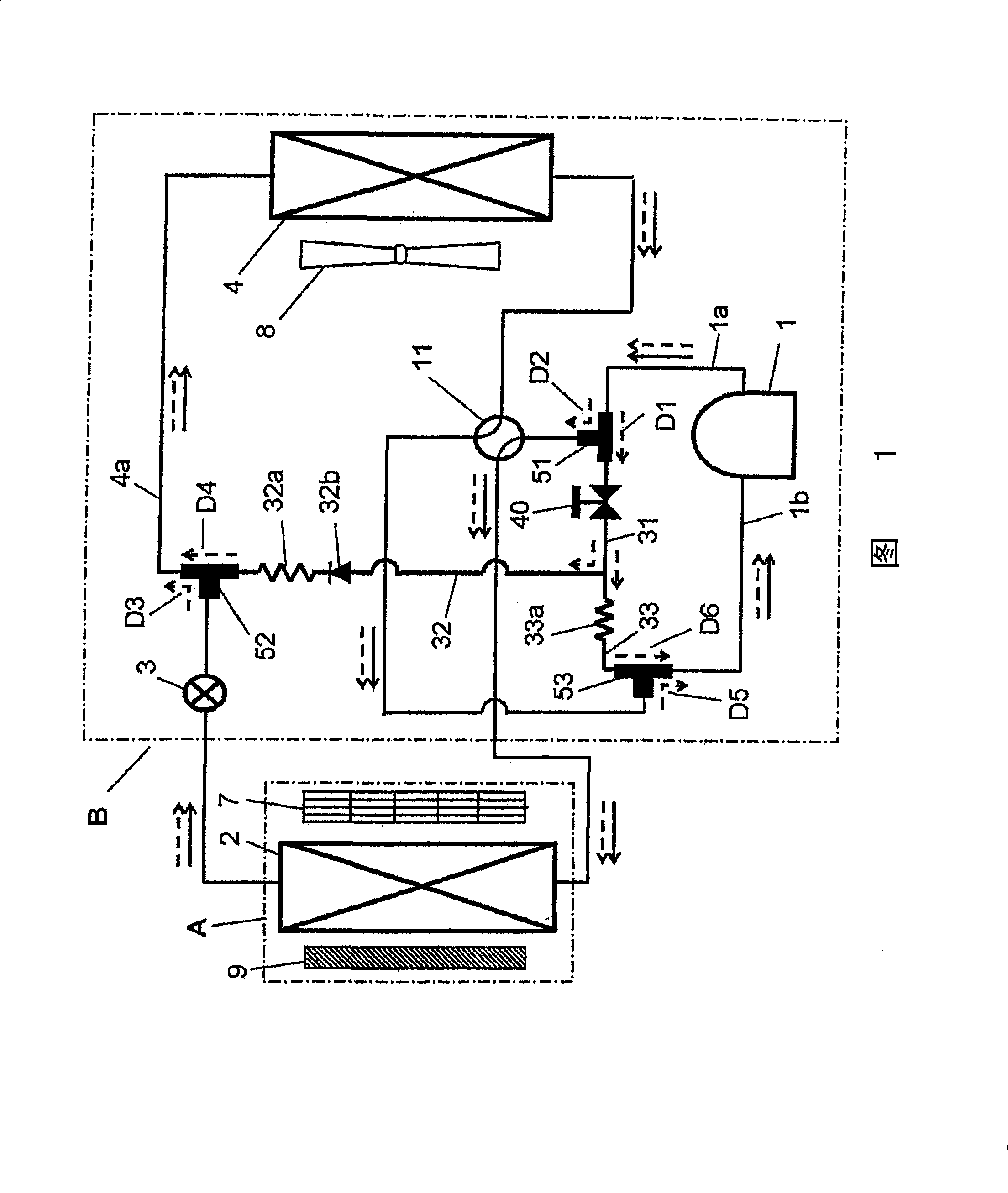

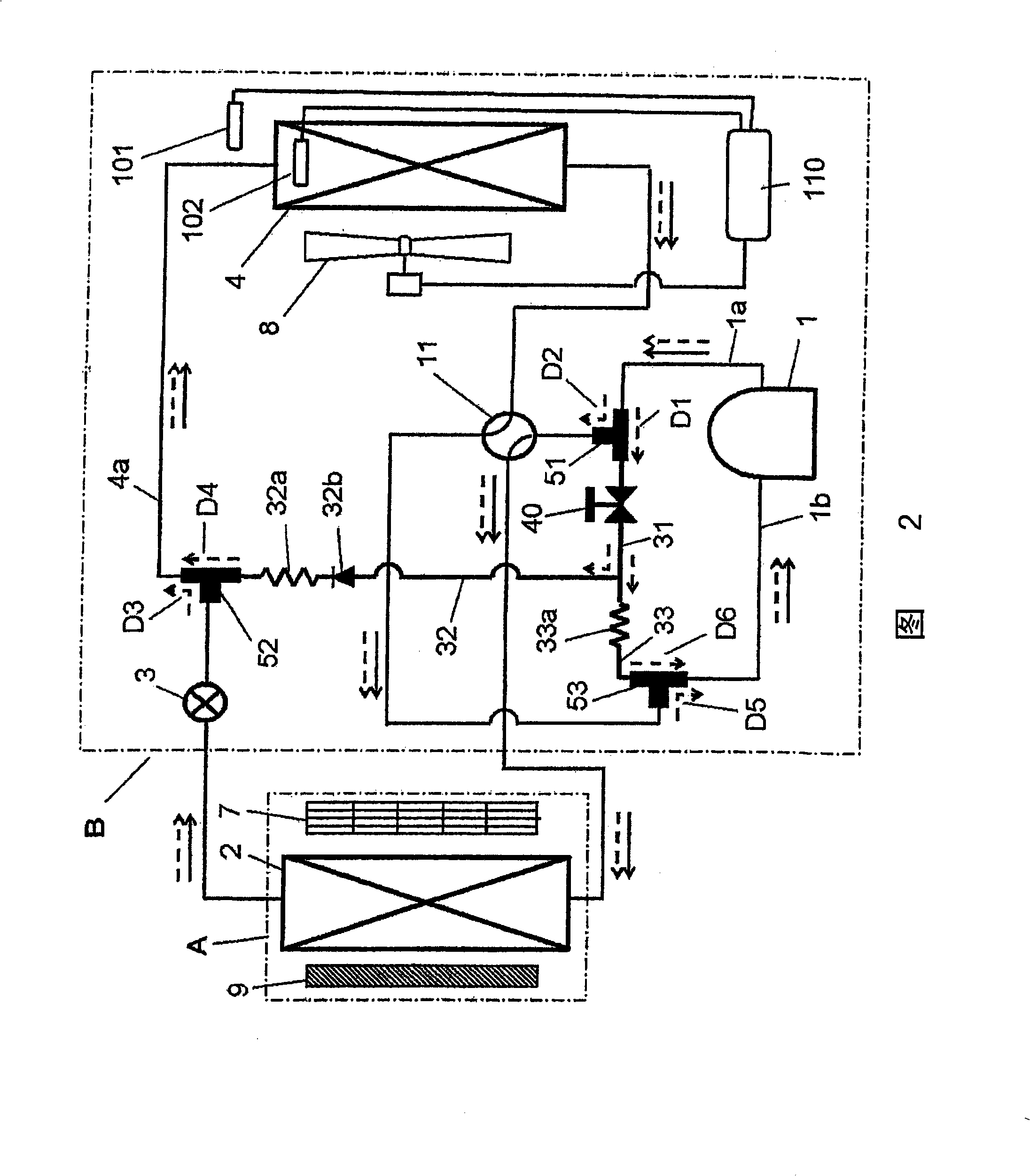

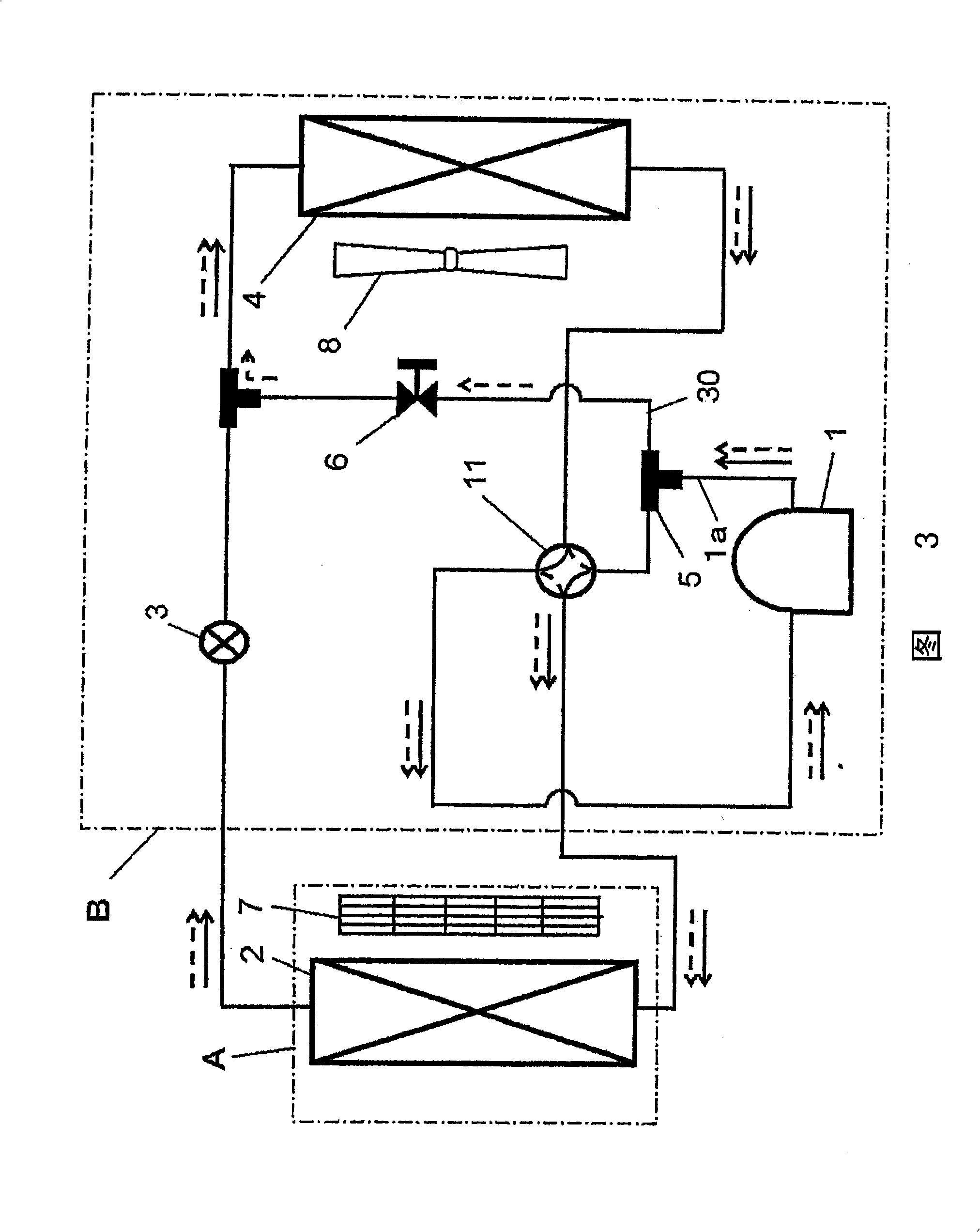

InactiveCN101307964AReduce flow path resistanceReduce the impactCorrosion preventionCompression machines with reversible cycleRefrigerantEvaporator

A refrigeration cycle apparatus for effectively performing defrosting, in which a compressor (1), a four-way valve (11), a condenser (2), a throttling device (3), and an evaporator (4) are connected via pipes, including: discharge gas bypasses (31, 32, 33) for flowing a discharge refrigerant to at least one of a suction pipe (1b) of the compressor and an evaporator pipe (4a) for connecting the throttling device and the evaporator, from a discharge pipe (1a) for connecting the compressor and the four-way valve; and a refrigerant controller (40) capable of optionally flowing the discharge refrigerant to the discharge gas bypasses, wherein the discharge refrigerant of the compressor is partially passed through the discharge gas bypasses during defrosting in a heating operation, and a flow rate to the discharge gas bypasses is larger than a flow rate to the four-way valve.

Owner:PANASONIC CORP

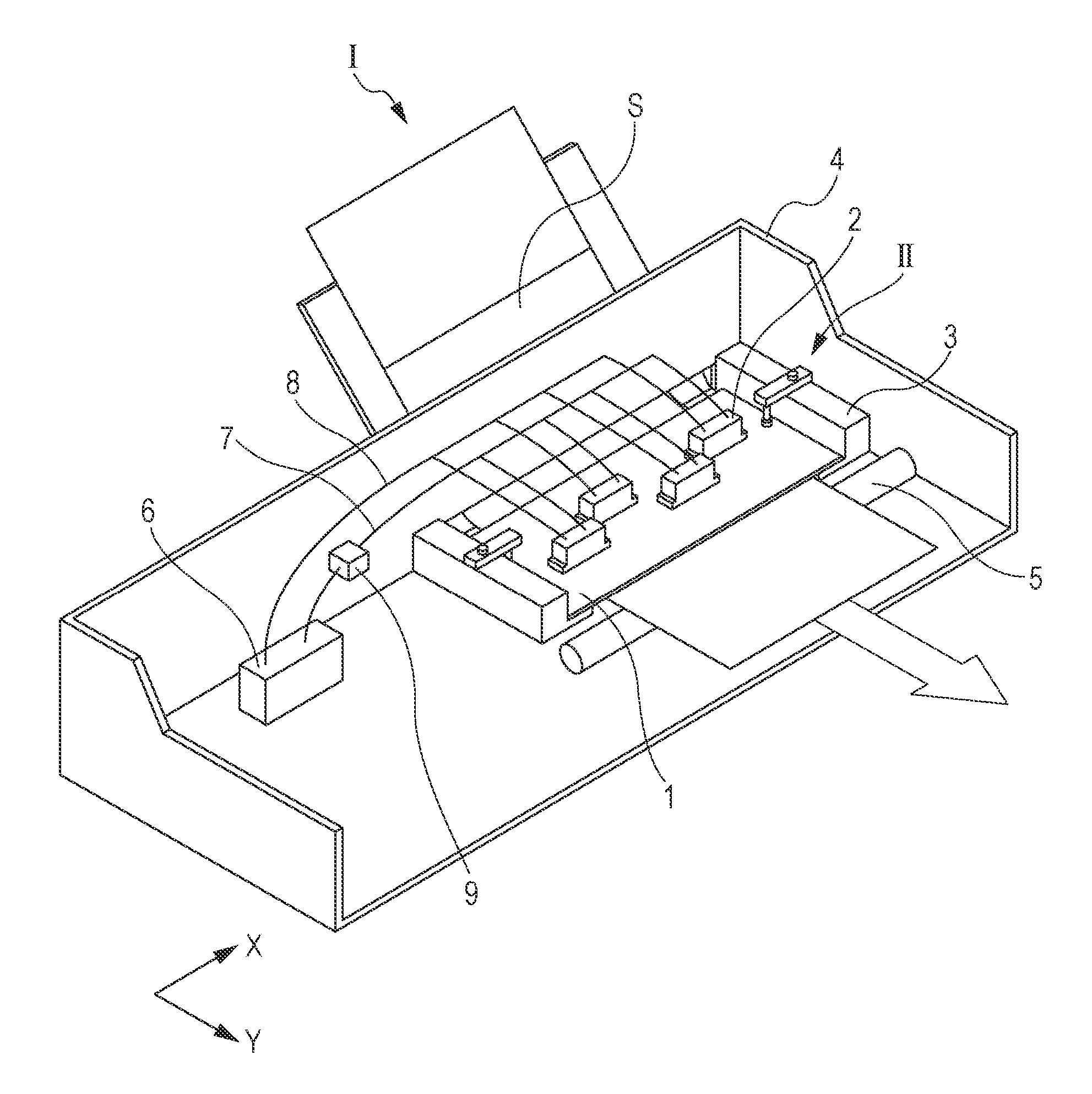

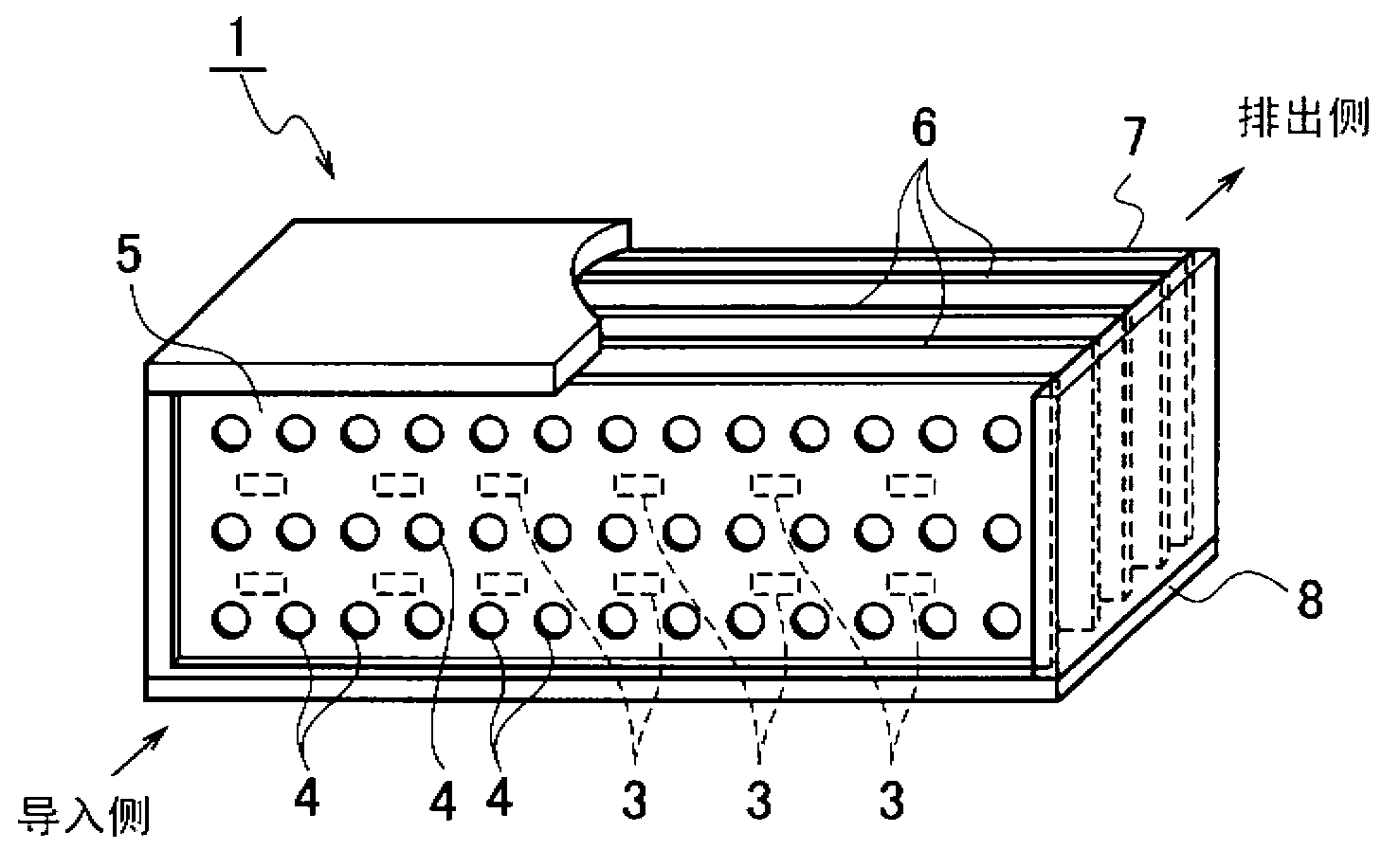

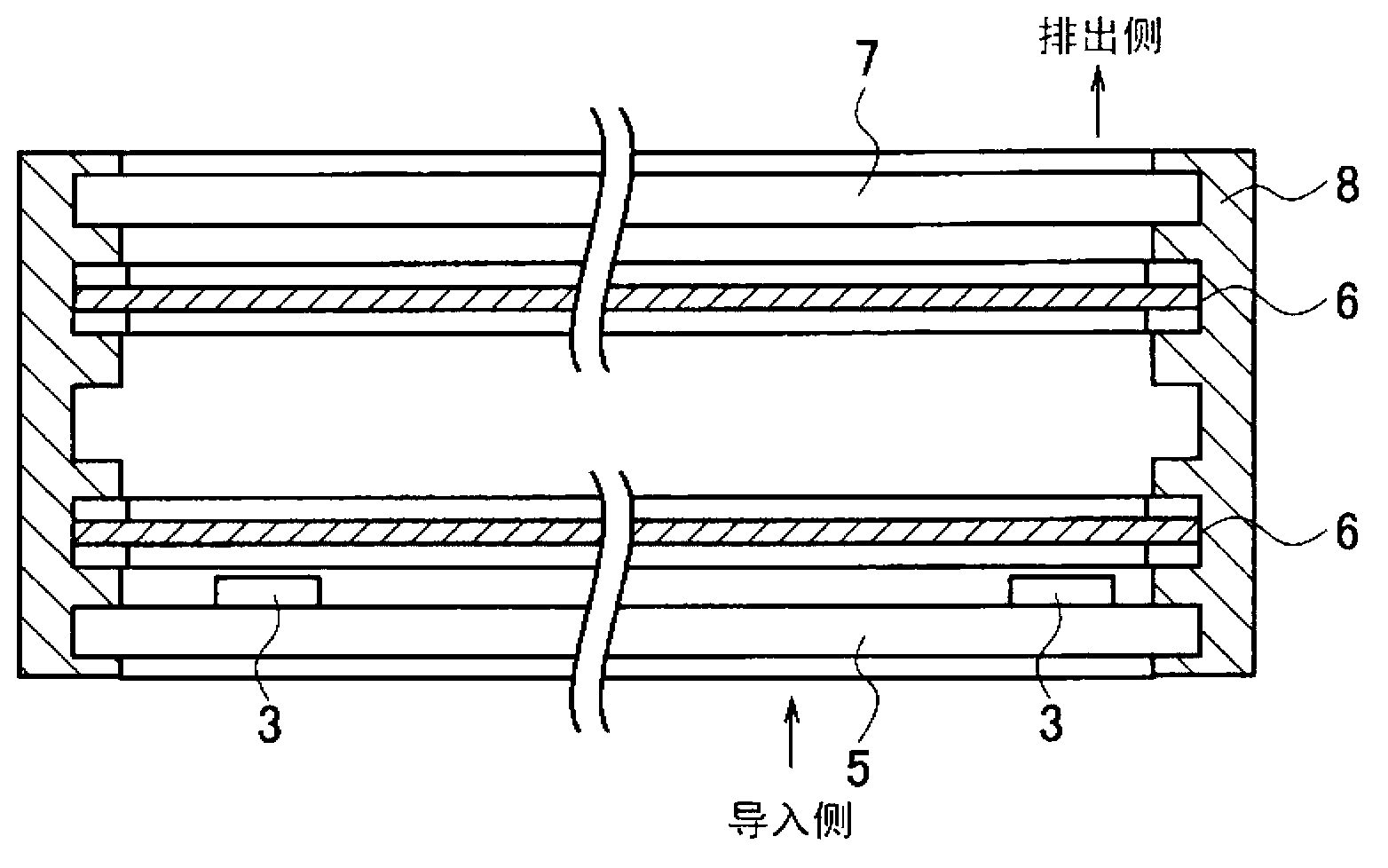

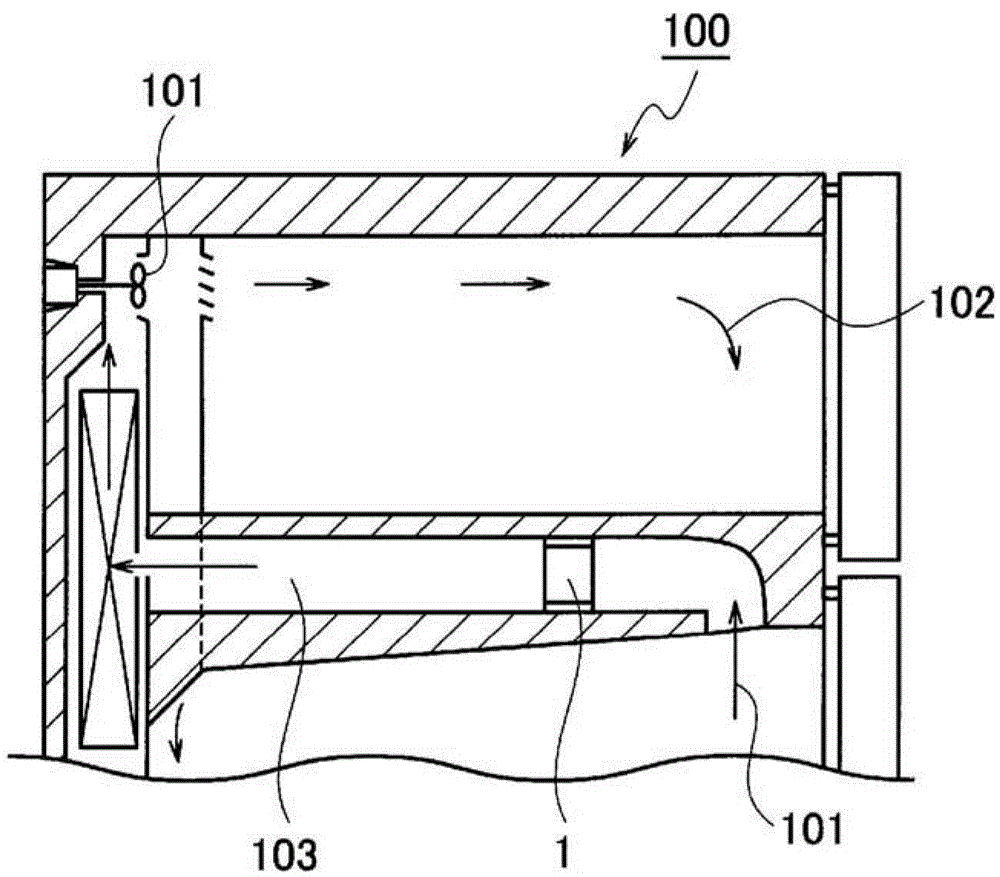

Photocatalyst deodorization device

ActiveCN102985116AReduce flow path resistanceMaximum absorptionGas treatmentPhysical/chemical process catalystsGlass fiberFiber

Disclosed is a long-life photocatalyst deodorization device (1) which effectively excites photocatalysts over the entire surface of a photocatalyst sheet and is capable of maintaining deodorization performance over a long period. Substrates (5 and 7) upon which vent holes (4) have been provided are disposed in parallel, and upon at least one substrate (5) of the two substrates, LEDs (3) are mounted. Between the two substrates, photocatalyst sheets (6) constituted by woven glass fiber material (6A) carrying photocatalyst particles (6B) and a frame (6C) supporting the material are disposed. The photocatalyst sheets and the two substrates are fixed to a housing (8), whereupon emitting surfaces of the LED light sources for exciting the photocatalysts and the photocatalyst sheets are disposed in parallel. Air fed from the vent holes is caused to pass through the photocatalyst sheets. The photocatalyst sheets are constituted by bundling glass fibers and weaving the fibers in a crisscross manner so as to have a predetermined aperture ratio such that ventilation is possible under low wind speed. The photocatalyst particles are mechanically held in contact between the glass fibers of the photocatalyst sheets.

Owner:TOSHIBA LIGHTING & TECH CORP

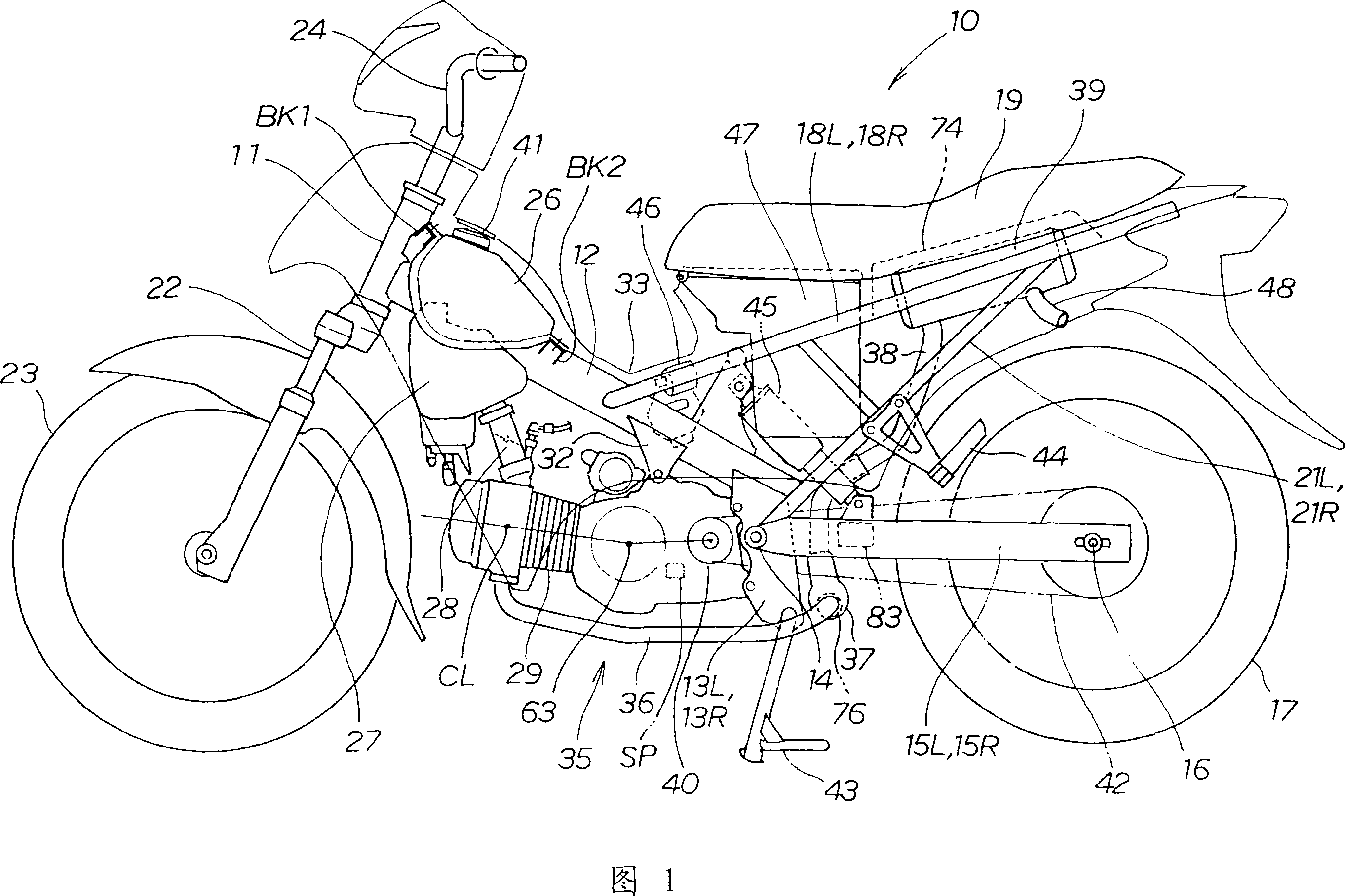

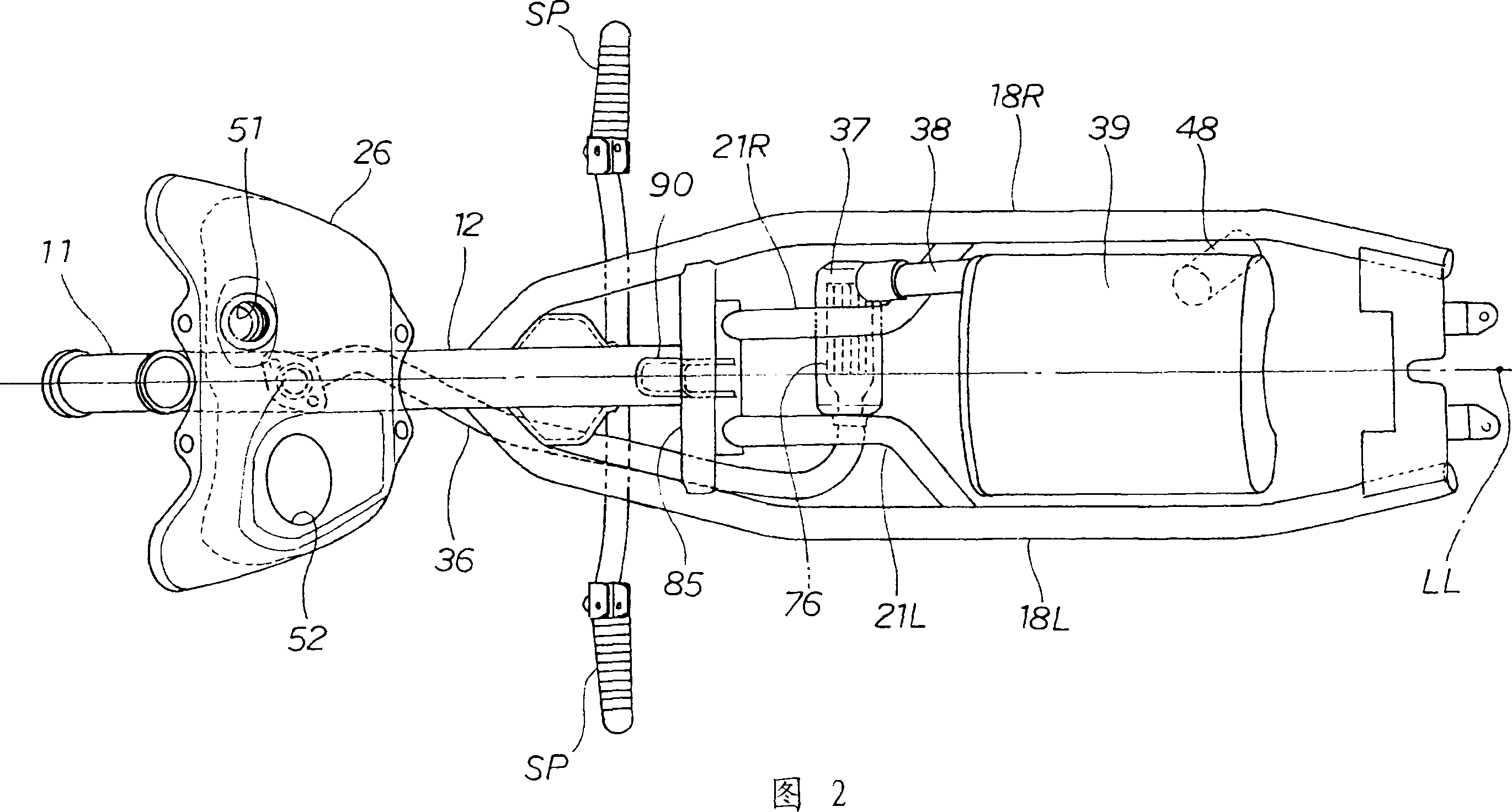

Automotive tumbrel

InactiveCN101172504AImprove purification effectReduce flow path resistanceExhaust apparatusSilencing apparatusAutomotive engineeringEngineering

The invention aims at providing a flexible tumbrel for configuring a catalyst more easily. The figure is the condition viewing from the back of the vehicle body. A beam part (37) arranged at the vehicle width direction internally arranges a cylinder catalyst (76) of the horizontal length whose length L is larger than the outside diameter D. The vent gas discharged from the front part of the vent pipe (36) flows like an arrow (1) and (2) and reaches the back part of the vent pipe(38). The back part of the vent pipe (38) passes through between a left and right rear arms (15L,15R) and through the right side of a single suspension (45) reaching a silencer (39). As the catalyst is arranged at the direction of the vehicle width without the influence of the front and back length of the vehicle body, the catalyst of the length is configured, thereby improving the purifying performance.

Owner:HONDA MOTOR CO LTD

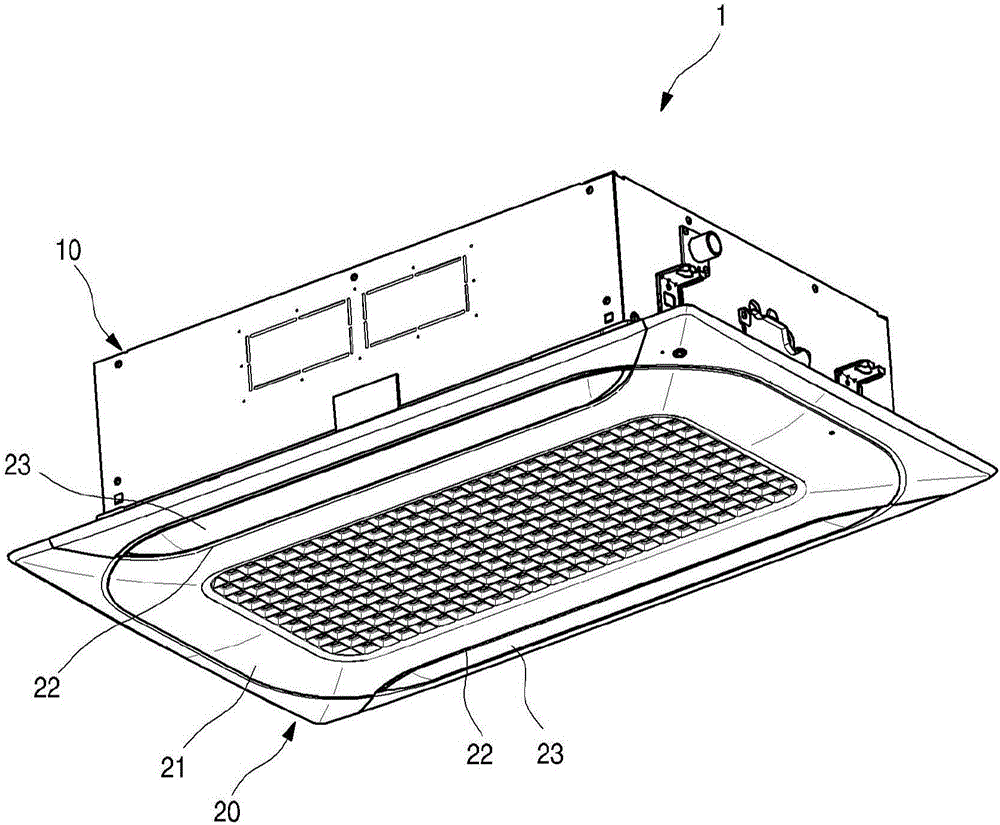

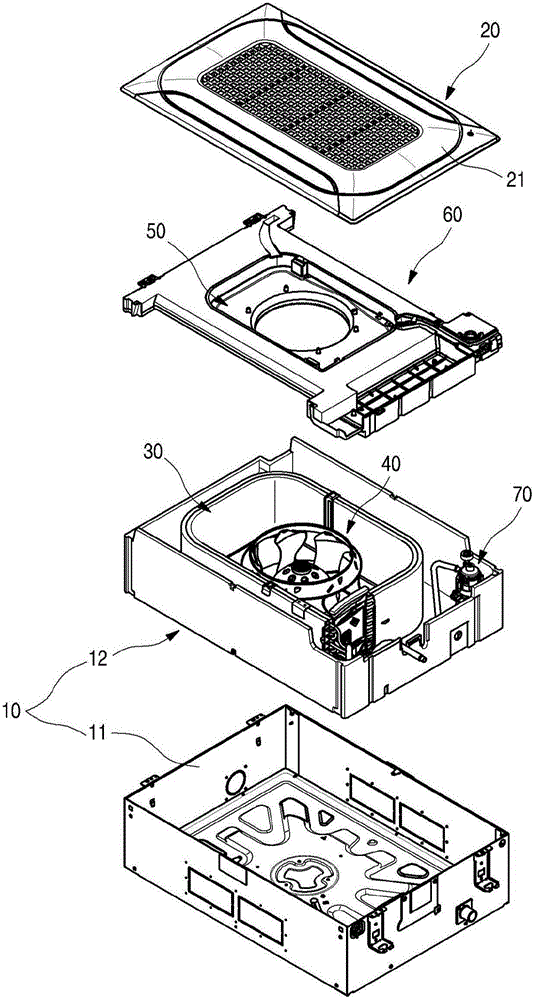

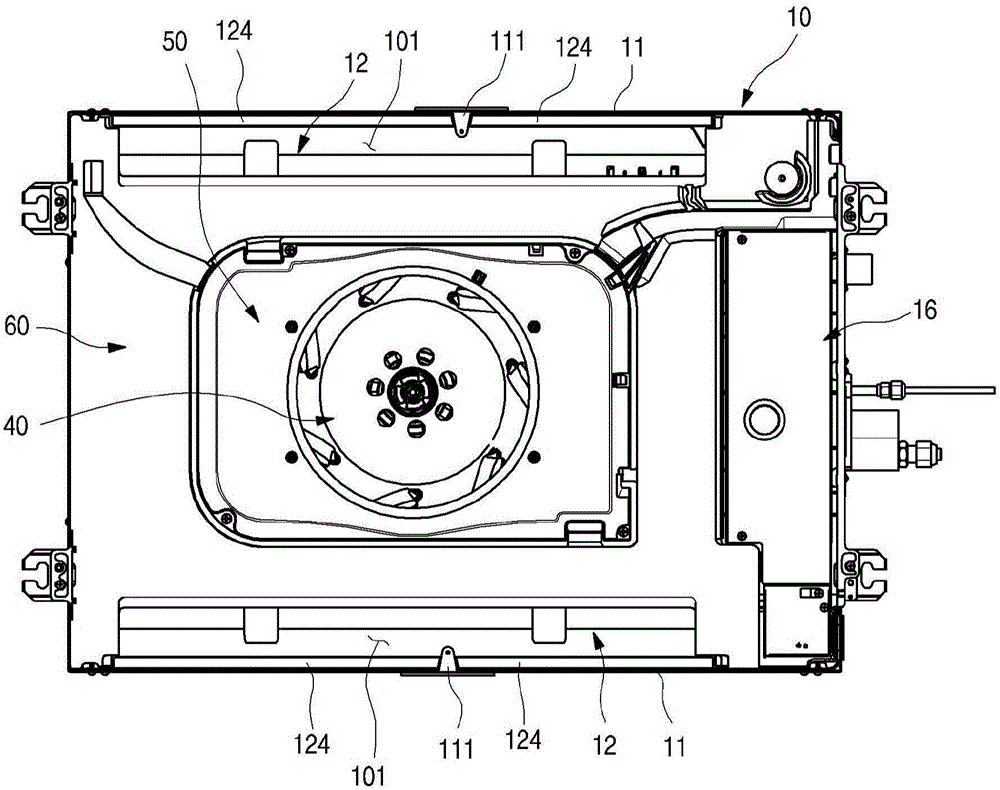

Indoor device of air conditioner

ActiveCN106403016AHigh strengthReduce noiseMechanical apparatusCondensate preventionEngineeringIndoor air

An indoor unit or device of an air conditioner is provided that may include an outer plate configured to form an exterior of a cabinet configured to be installed at a ceiling of an indoor space; an inner case accommodated inside of the outer plate, and configured to form an internal space of the cabinet; a fan provided inside of the inner case; a heat exchanger provided to cover an outer side of the fan; a panel configured to shield the cabinet, and having an inlet port through which indoor air may be suctioned in and a panel outlet port through which heat-exchanged air may be discharged; and a drain pan assembly seated on an upper end of the inner case, and configured to collect condensate generated from the heat exchanger. An extension that extends to an open end of the outer plate may be formed at a side surface of the inner case corresponding to the panel outlet port, and a recess, which may be recessed in a shape corresponding to the panel outlet port, may be formed at an outer end of the drain pan assembly. Both ends of the extension may be in contact with an inner side surface of the recess, and form an outlet port which is in communication with the panel outlet port.

Owner:LG ELECTRONICS INC

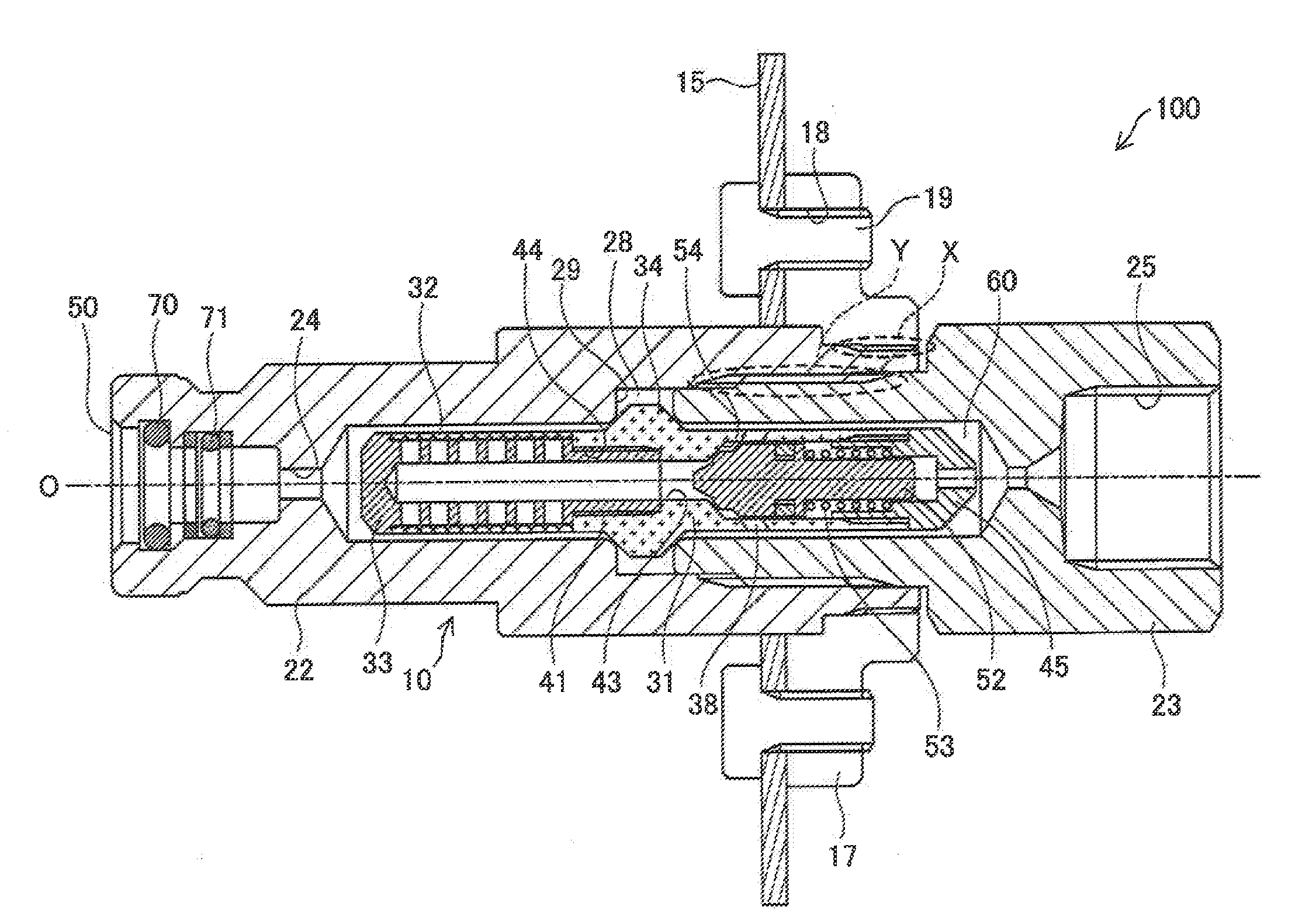

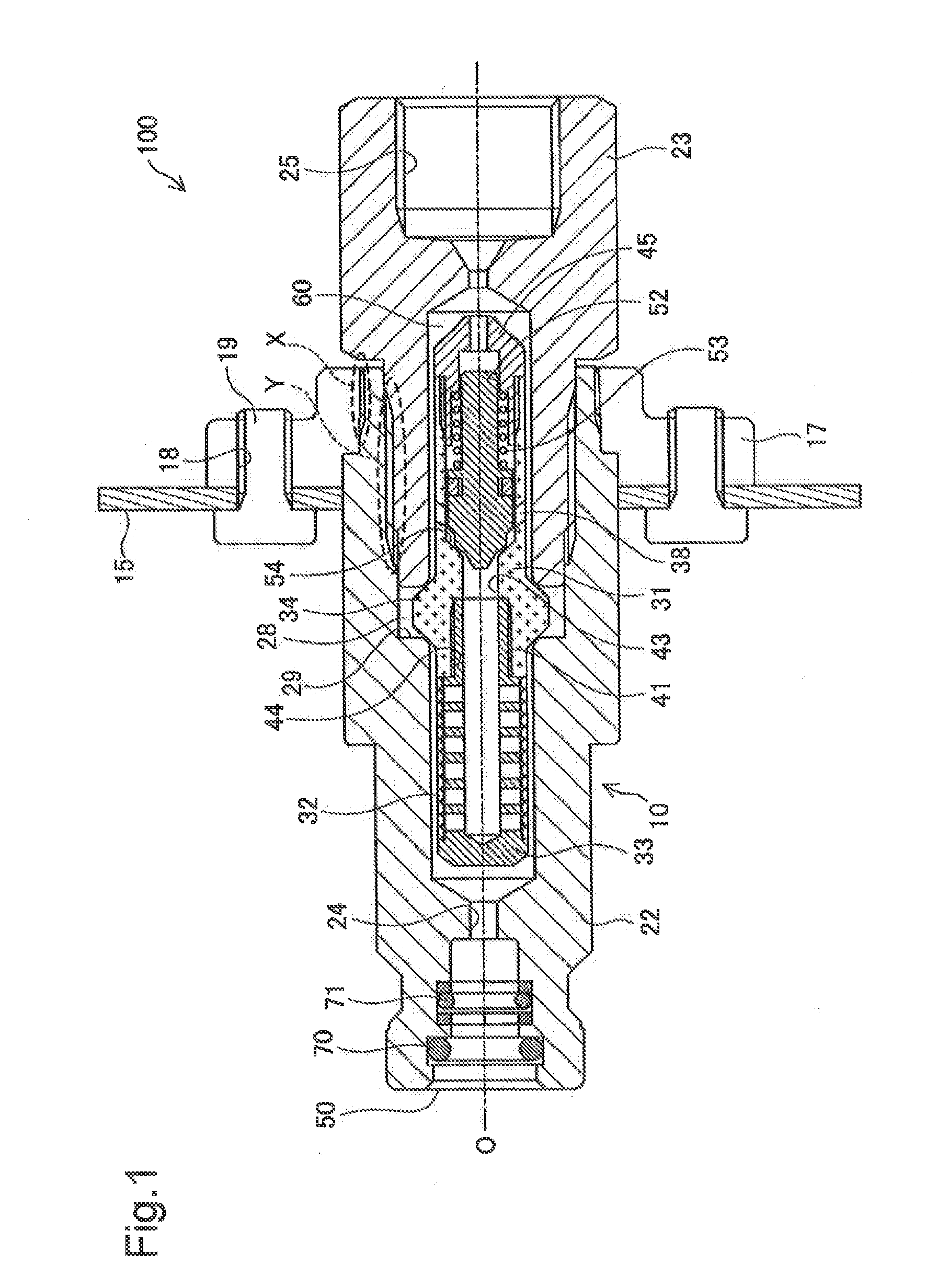

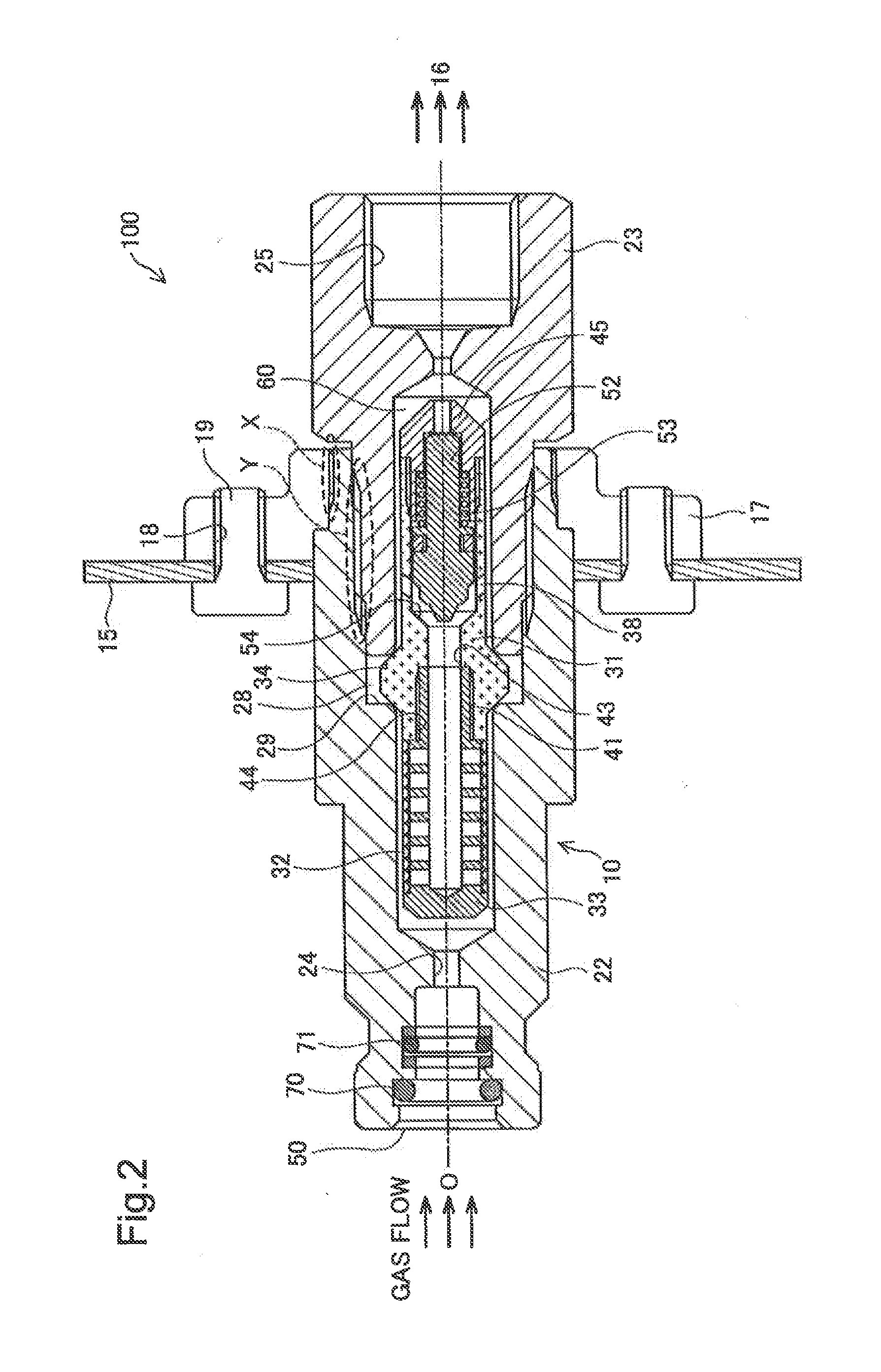

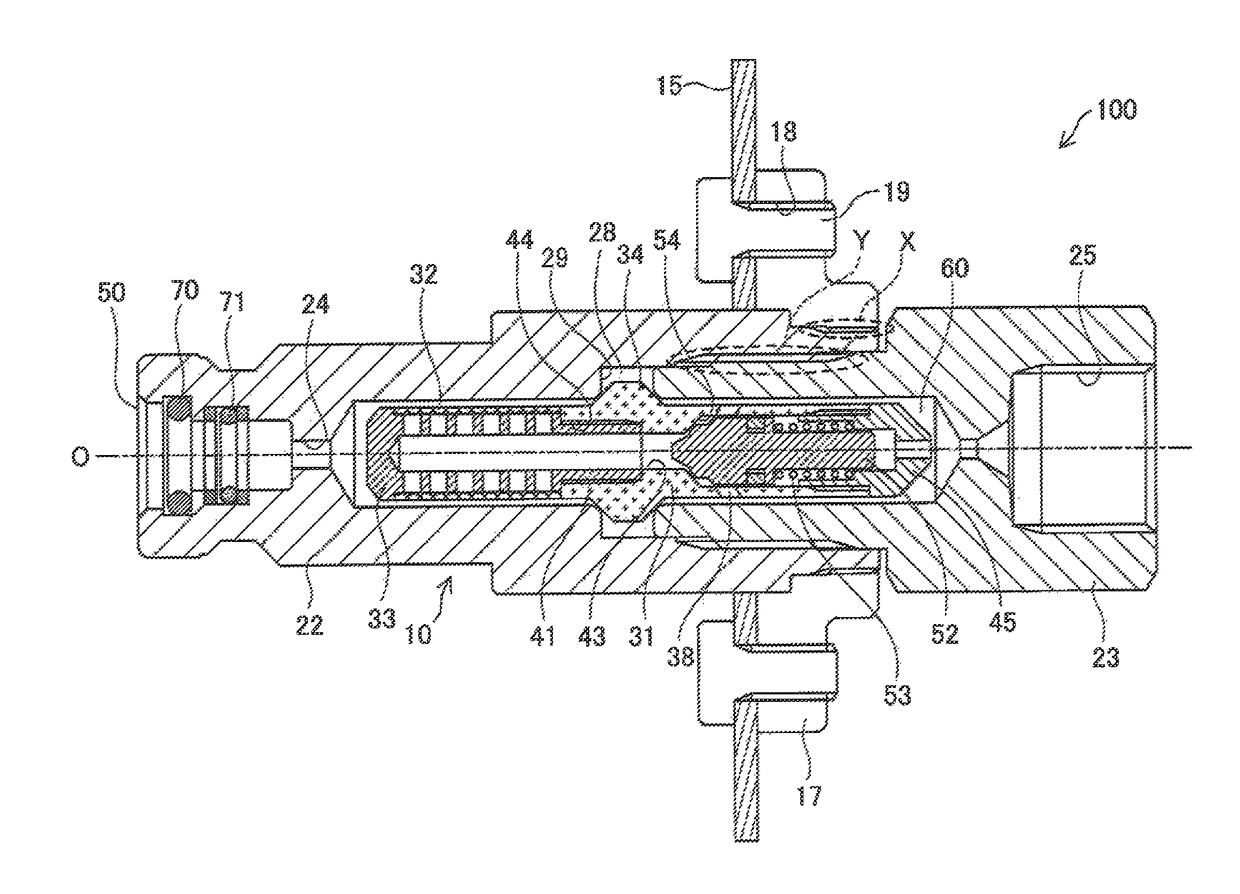

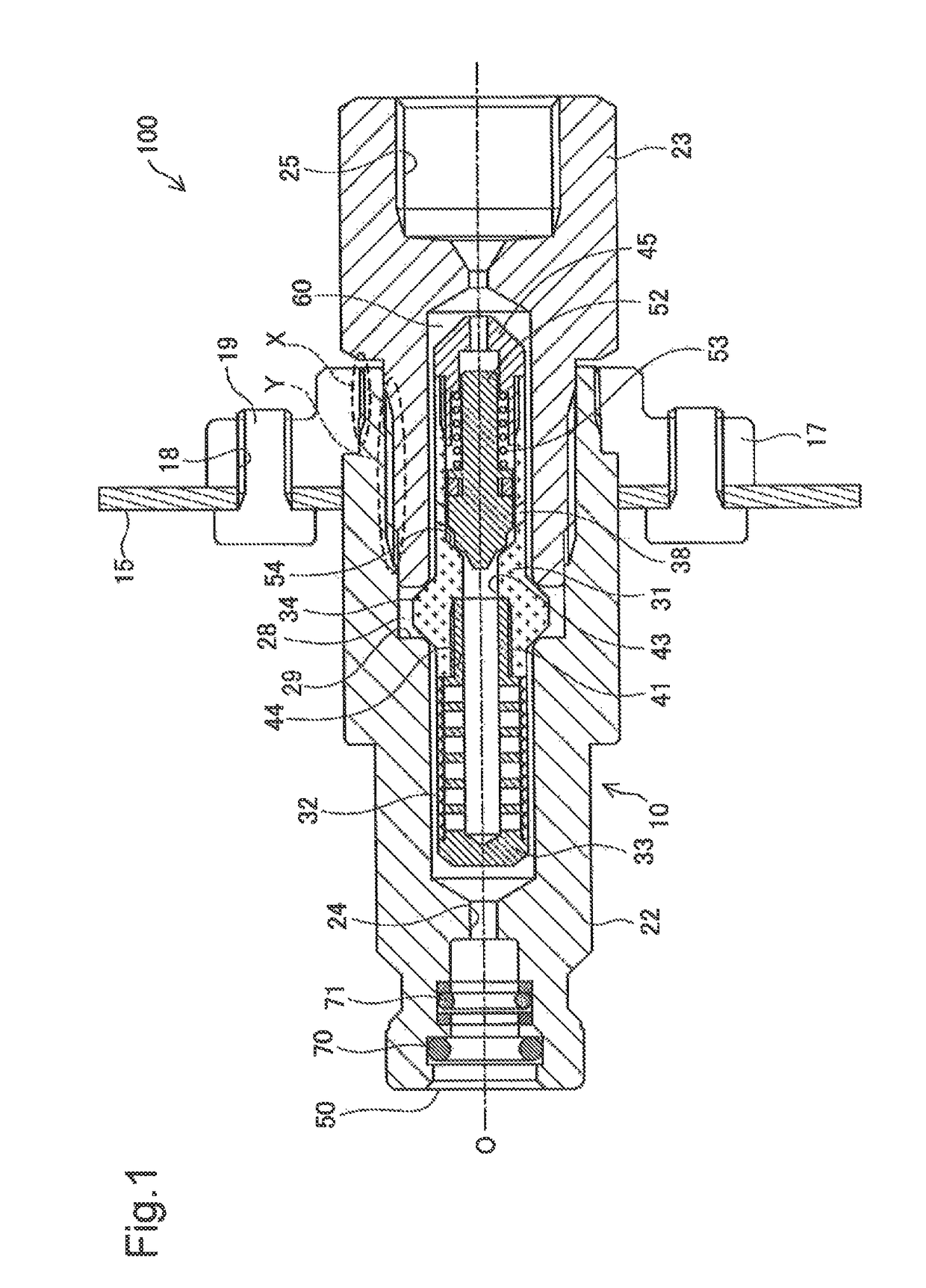

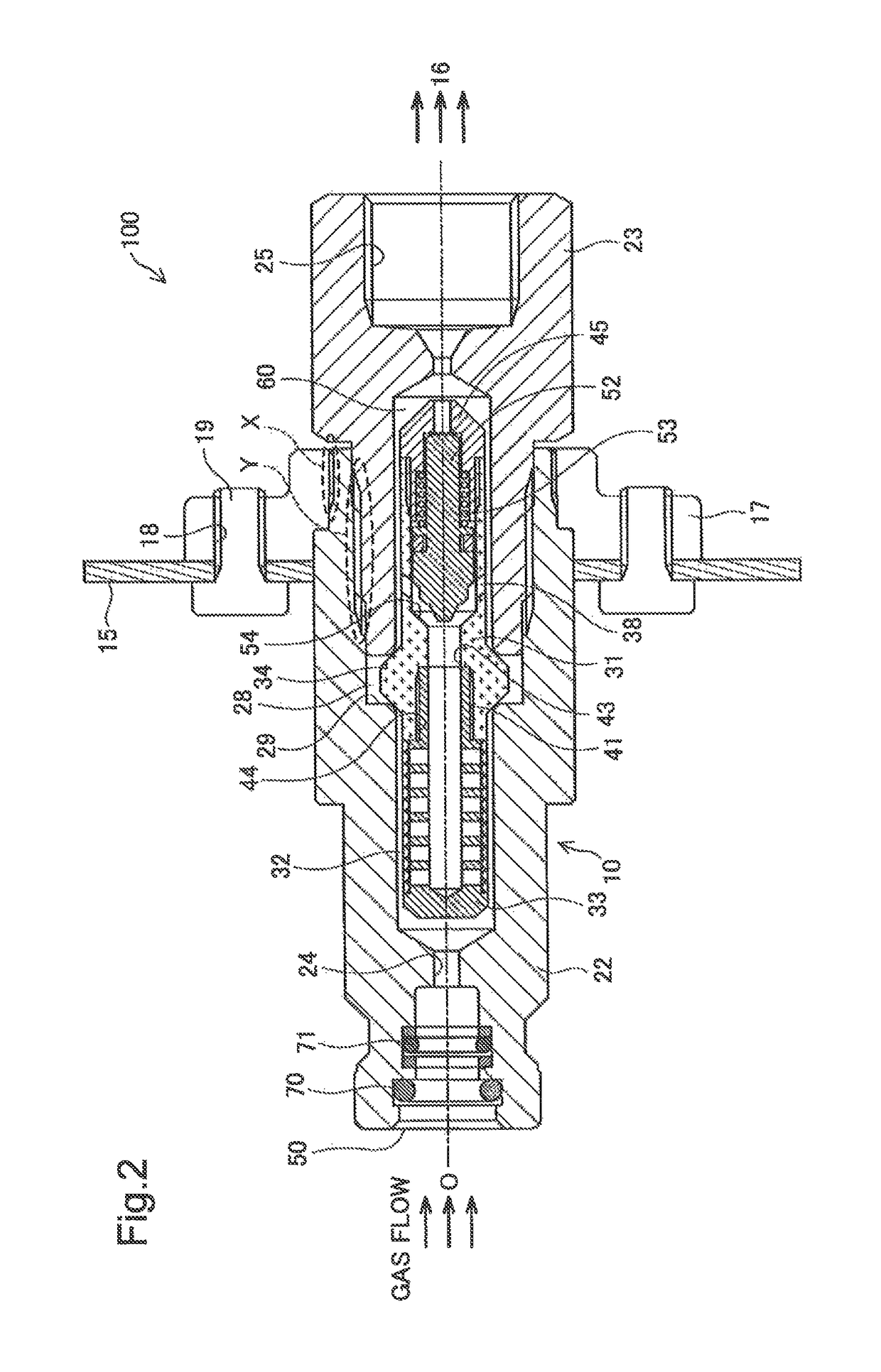

Check valve and receptacle structure

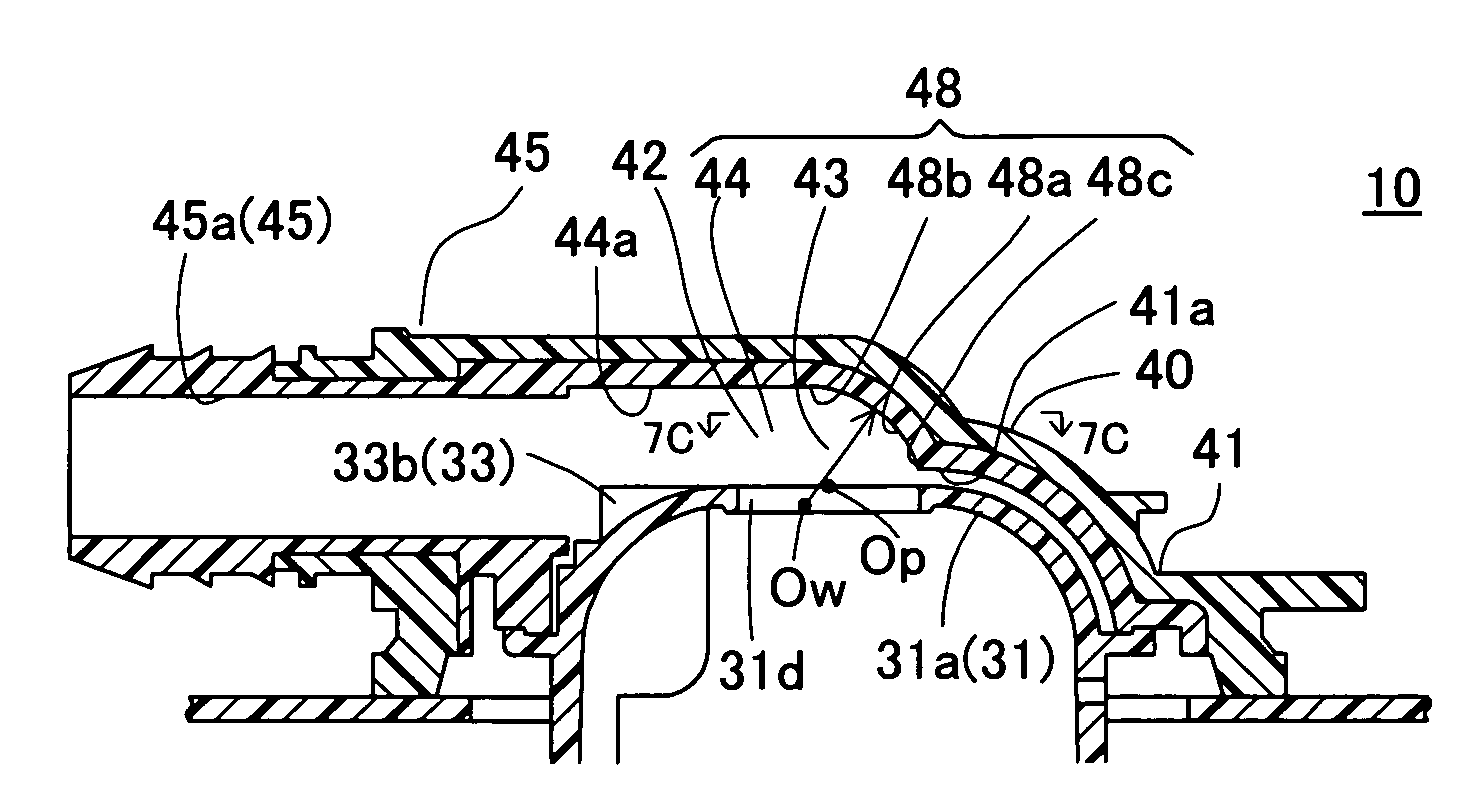

ActiveUS20160131273A1Simplify manufacturing processImprove durabilityContainer filling methodsCheck valvesPipingCheck valve

In order to reduce a pressure loss in a check valve and simplify a manufacturing process, a check valve (10) configured to be disposed in piping of fluid is provided, which includes a valve housing (31) including a valve element (52) and a valve seat (54) therein, a casing (20) that is configured to place the valve housing therein, in which a casing flow path (60) is provided between the casing and the valve housing to make a flow of the fluid in an axial direction of the valve housing. In the valve housing, a communicating hole (38) and sealing portion (34) are formed. The communicating hole that is formed through the valve housing in a thickness direction thereof introduces the fluid, which flows through between the valve element and the valve seat at the open position of the check valve, into the casing flow path. The sealing portion that is provided on an outer surface of the valve housing upstream of the communicating hole in a flow direction of the fluid in the casing flow path, is configured to come into contact with an inner surface of the casing to seal the casing flow path and position the valve housing in a radial direction perpendicular to the axial direction relative to the casing.

Owner:TOYOTA JIDOSHA KK +1

Drill

InactiveUS8257000B2Reduce loadSmooth dischargeWood turning toolsTransportation and packagingEngineeringHelix

A drill includes a blade portion provided with spiral cutting blades along a cutting direction from a tip end to a rear end, and a shank portion formed consecutively on a rear side of the blade portion. The blade portion includes distal-side cutting blades provided from the distal end of the blade portion along the cutting direction and angled at a constant first torsion angle, intermediate grooves formed at a variable torsion angle that varies gradually from the first torsion angle to a second torsion angle, and rear-side grooves formed at the constant second torsion angle. The rear-side grooves are longer than the distal-side cutting blades in the cutting direction, and the second torsion angle is greater than the first torsion angle.

Owner:HONDA MOTOR CO LTD

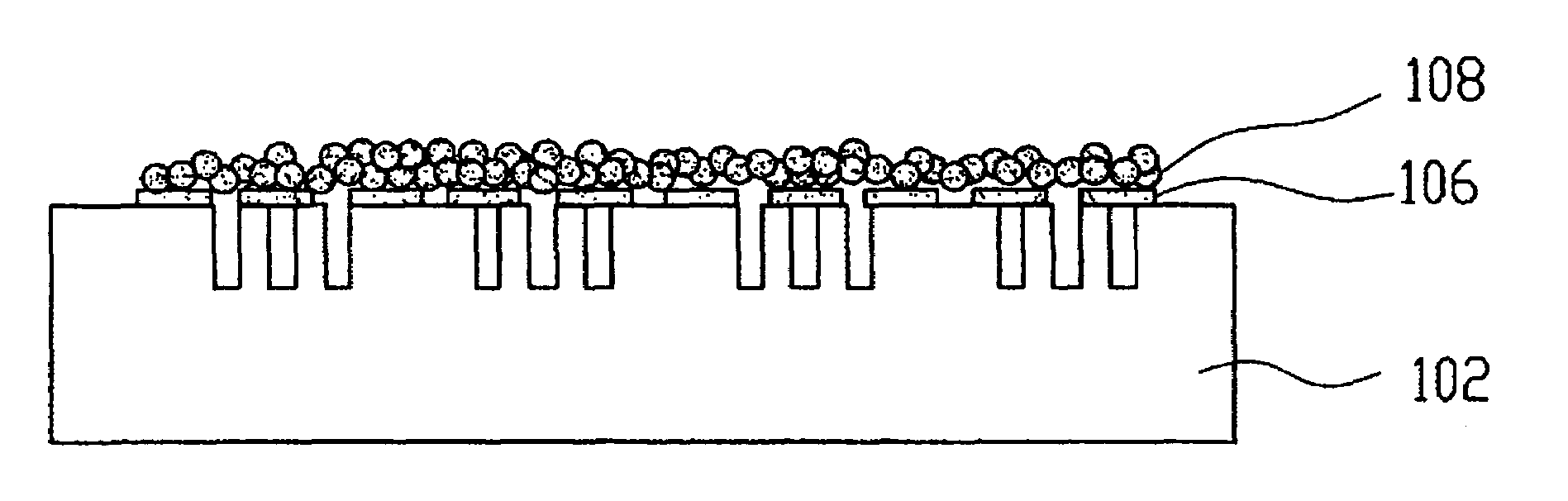

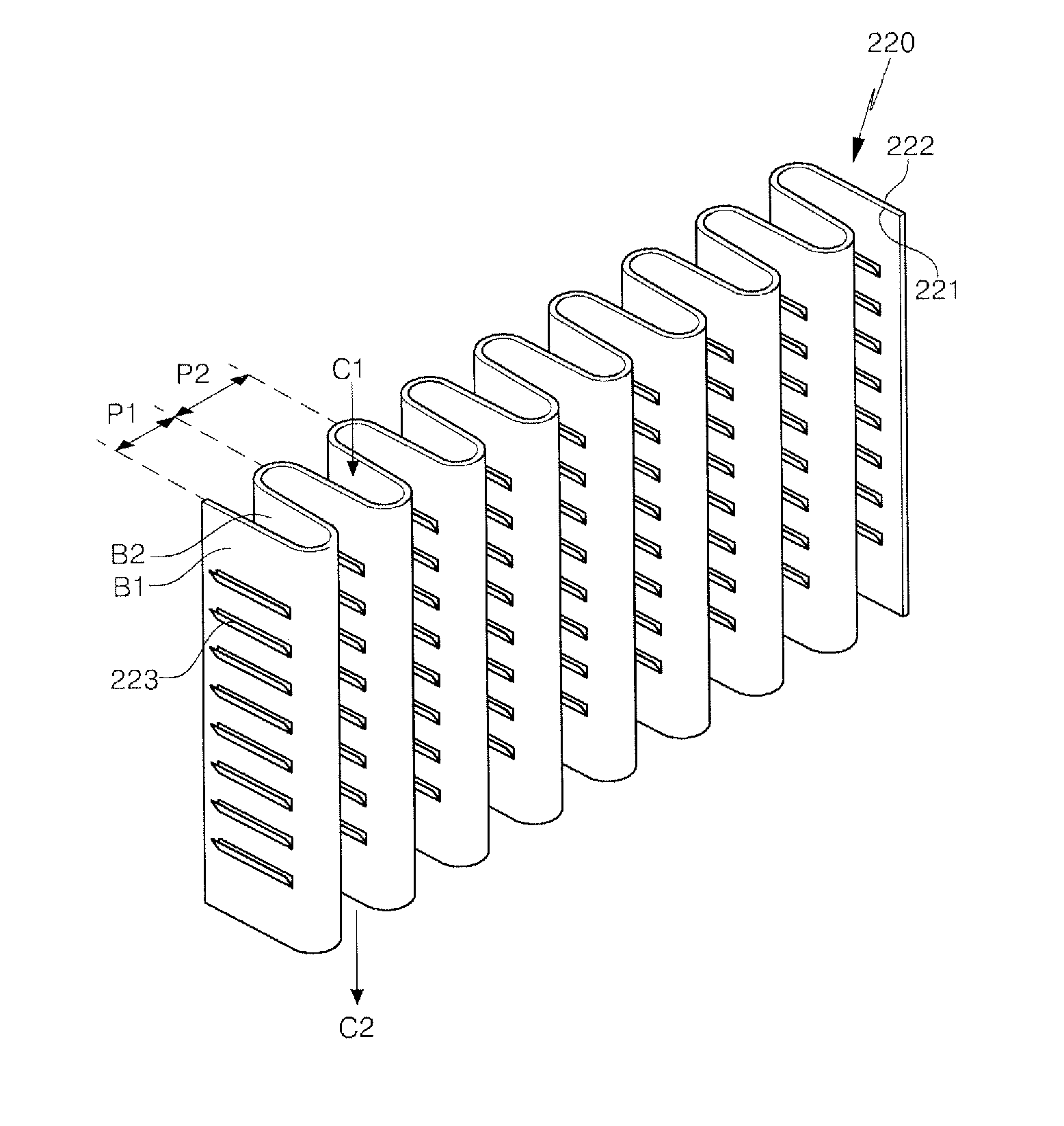

Fuel cell and process for the production thereof

InactiveUS7390588B2Reduce widthReduce pressure lossFinal product manufactureFuel cell auxillariesProduct gasEngineering

A first gas flow path is formed in a first substrate. The first substrate is processed in an ejection device to form a first collector layer, a first gas diffusion layer, a first reactive layer, and an electrolyte membrane. Similarly, the first substrate is processed to form a second reactive layer, a gas diffusion layer, and a second collector layer. A second substrate which has been processed to form a second gas flow path is then disposed on the first substrate to complete production of a fuel cell having a gas flow path formed therein the opening width of which is smaller than the particle diameter of the material constituting the gas diffusion layer.

Owner:SEIKO EPSON CORP

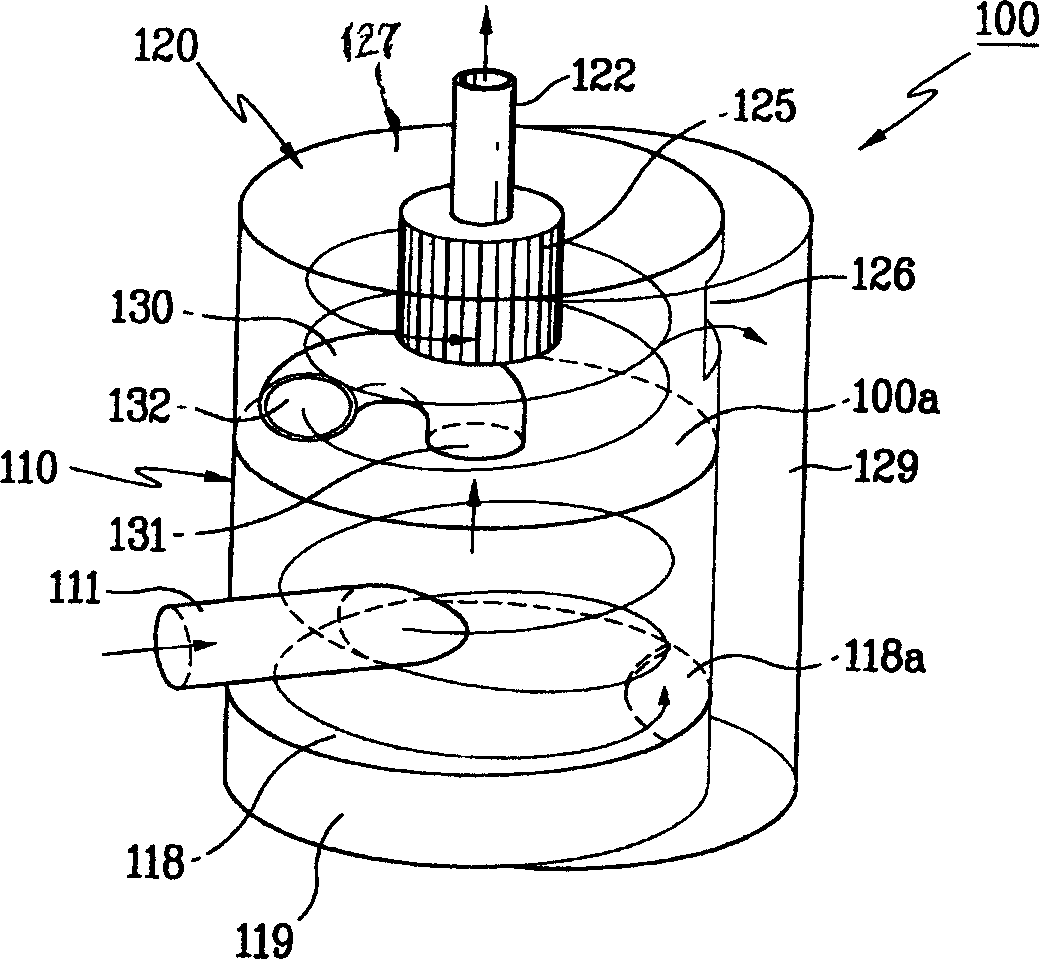

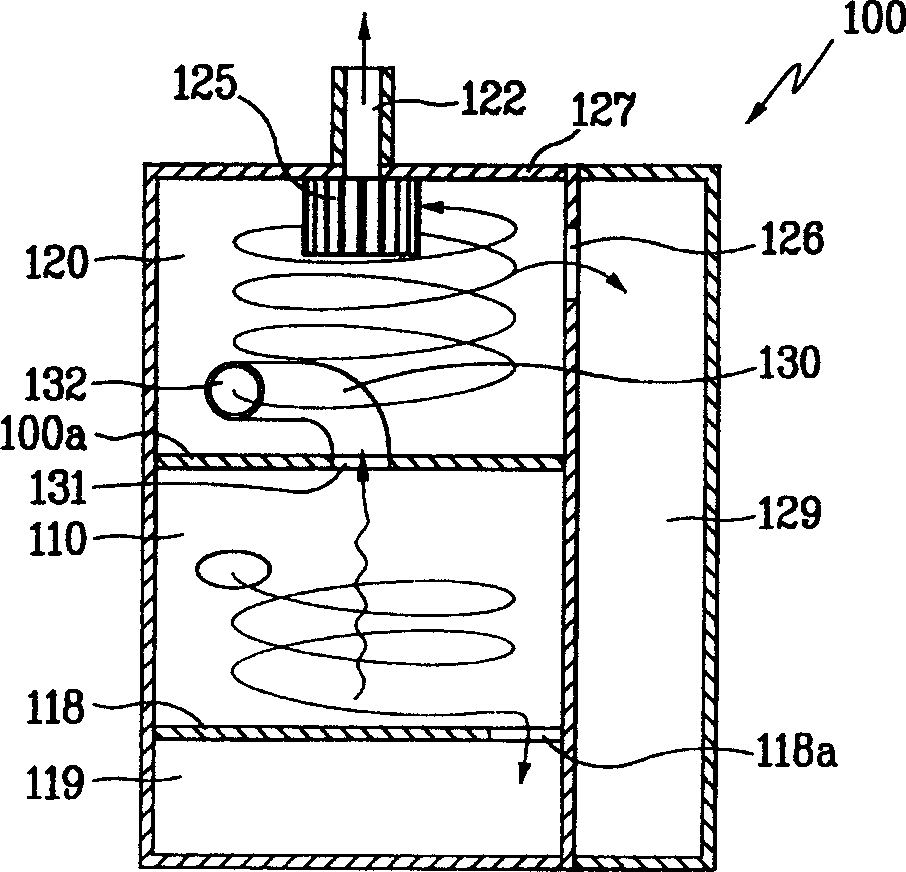

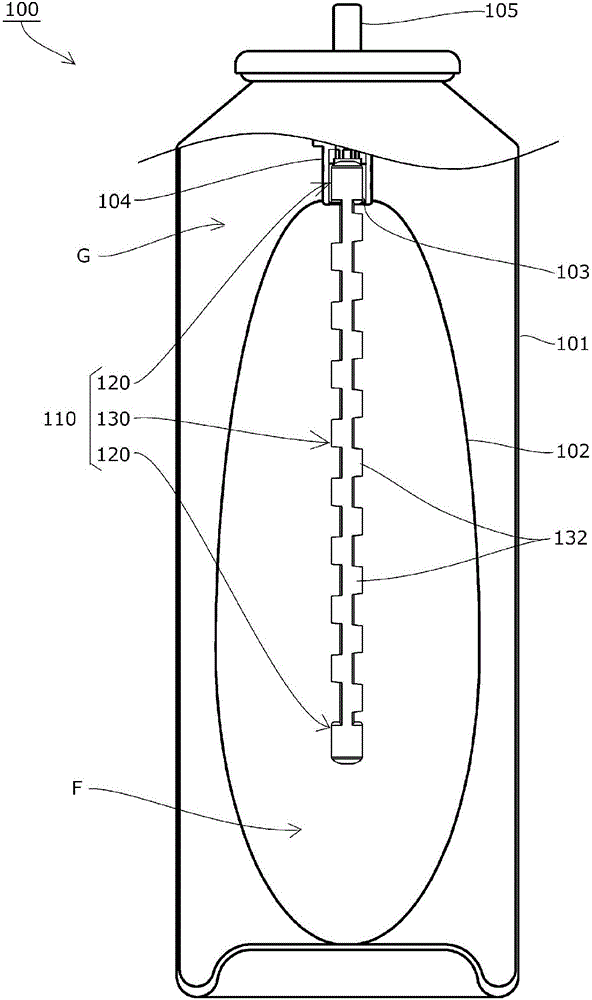

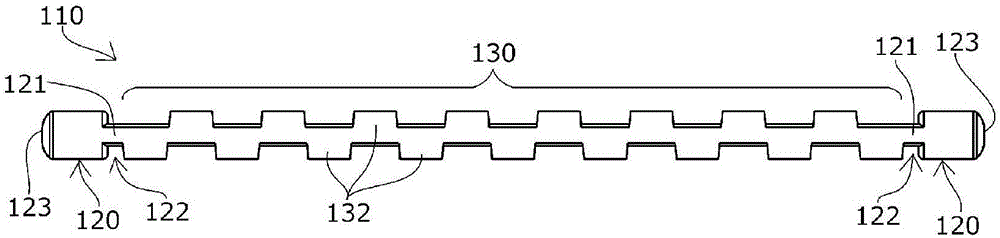

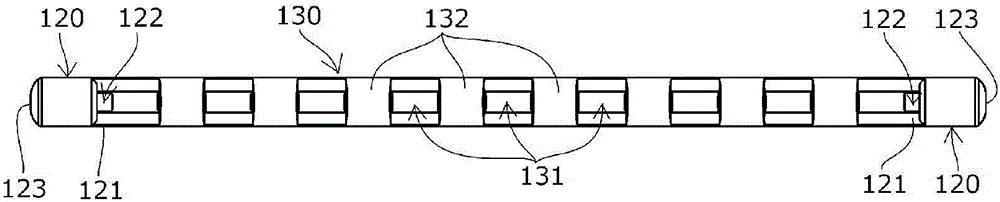

Residual quantity-reducing member

ActiveCN106660692AReduce the final remaining amountPrevent closed spacesLiquid dispensingRigid containersEngineeringMechanical engineering

The present invention provides a residual quantity-reducing member, which: reduces the final residual amount of contents to be discharged by preventing the occurrence of spaces, the perimeter of which is blocked by a pressurized fluid; stabilizes the amount of contents discharged per unit time; and makes it possible to discharge the contents smoothly to the end. Inside a flexible inner bag (102) that is disposed in an aerosol container (100), a residual quantity-reducing member (110) for reducing the final residual amount of contents (F) to be discharged is installed. The residual quantity-reducing member (110) is provided with a mounting part (120) that is mounted on an inflow port (103) of the inner bag (102) so as to allow inflow of the contents F, and a guide part (130) obtained by connecting multiple grooved blocks (132), which have a longitudinal guiding groove (131), in a row in the longitudinal direction.

Owner:TOYO AEROSOL IND CO LTD

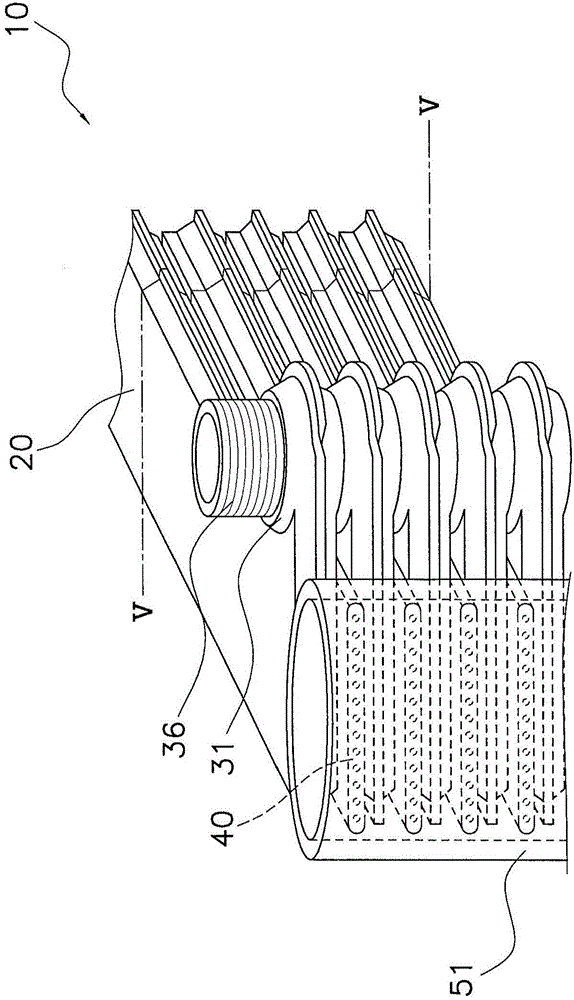

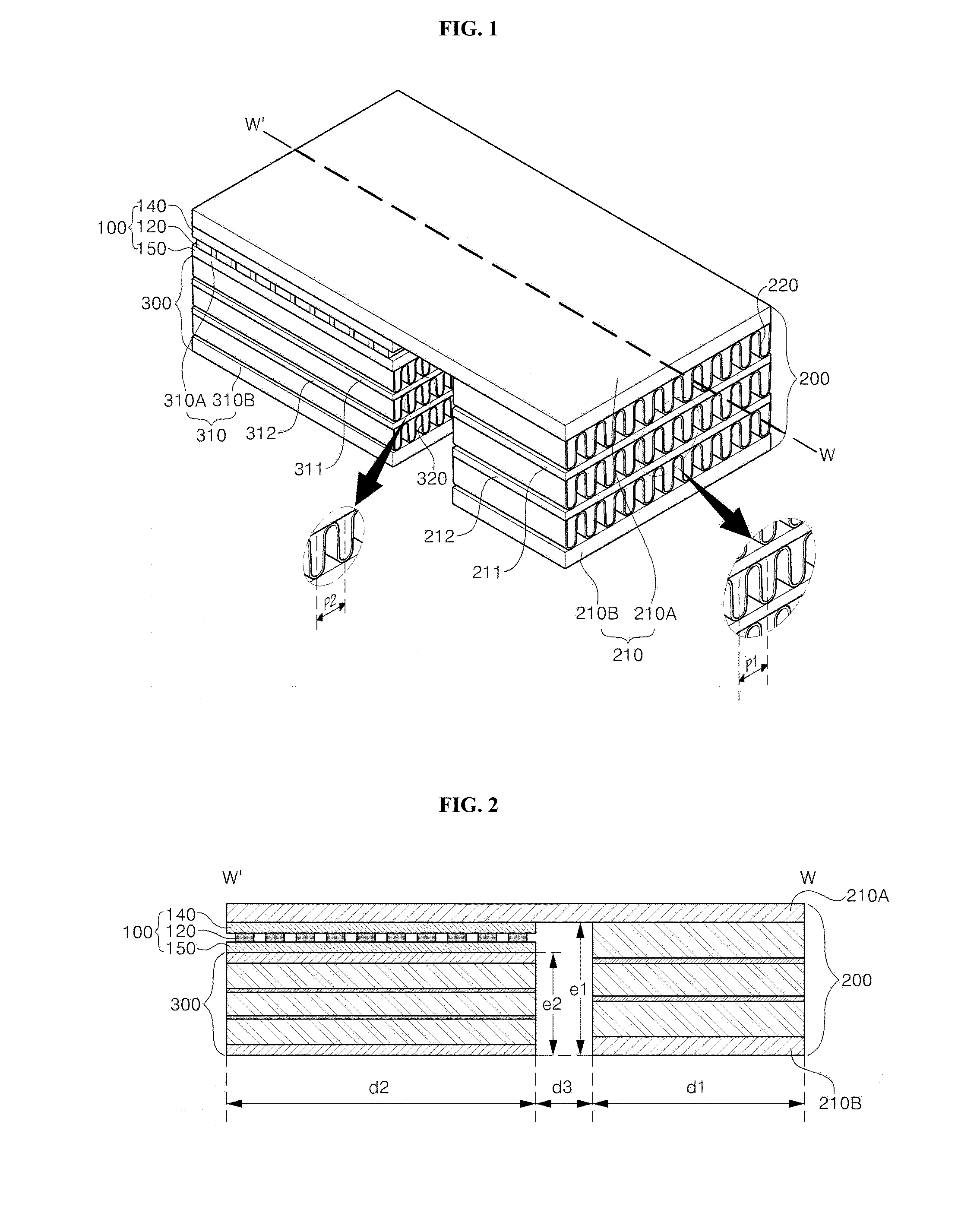

Heat exchanger

ActiveCN104884891AInhibit bias currentLower the liquid levelHeat storage plantsEvaporators/condensersEngineeringPhase change

A heat exchanger (10) for exchanging heat between a refrigerant that experiences a phase change during heat exchange and another heating medium, wherein the heat exchanger (10) is provided with a refrigerant header (50), a plurality of flat multi-hole tubes (40), and a plurality of flat tubes (20). The refrigerant header (50) has the refrigerant flowing through the interior thereof. The flat multi-hole tubes (40) extend in a direction that intersects the longitudinal direction of the refrigerant header (50). The flat multi-hole tubes (40) have formed in the interior thereof a plurality of refrigerant flow paths through which the refrigerant flows. The flat tubes (20) are stacked alternately with the plurality of multi-hole tubes (40). The flat tubes (20) have the other heating medium flowing through the interior thereof. Furthermore, the refrigerant header (50) is disposed so as to extend along the horizontal direction.

Owner:DAIKIN IND LTD

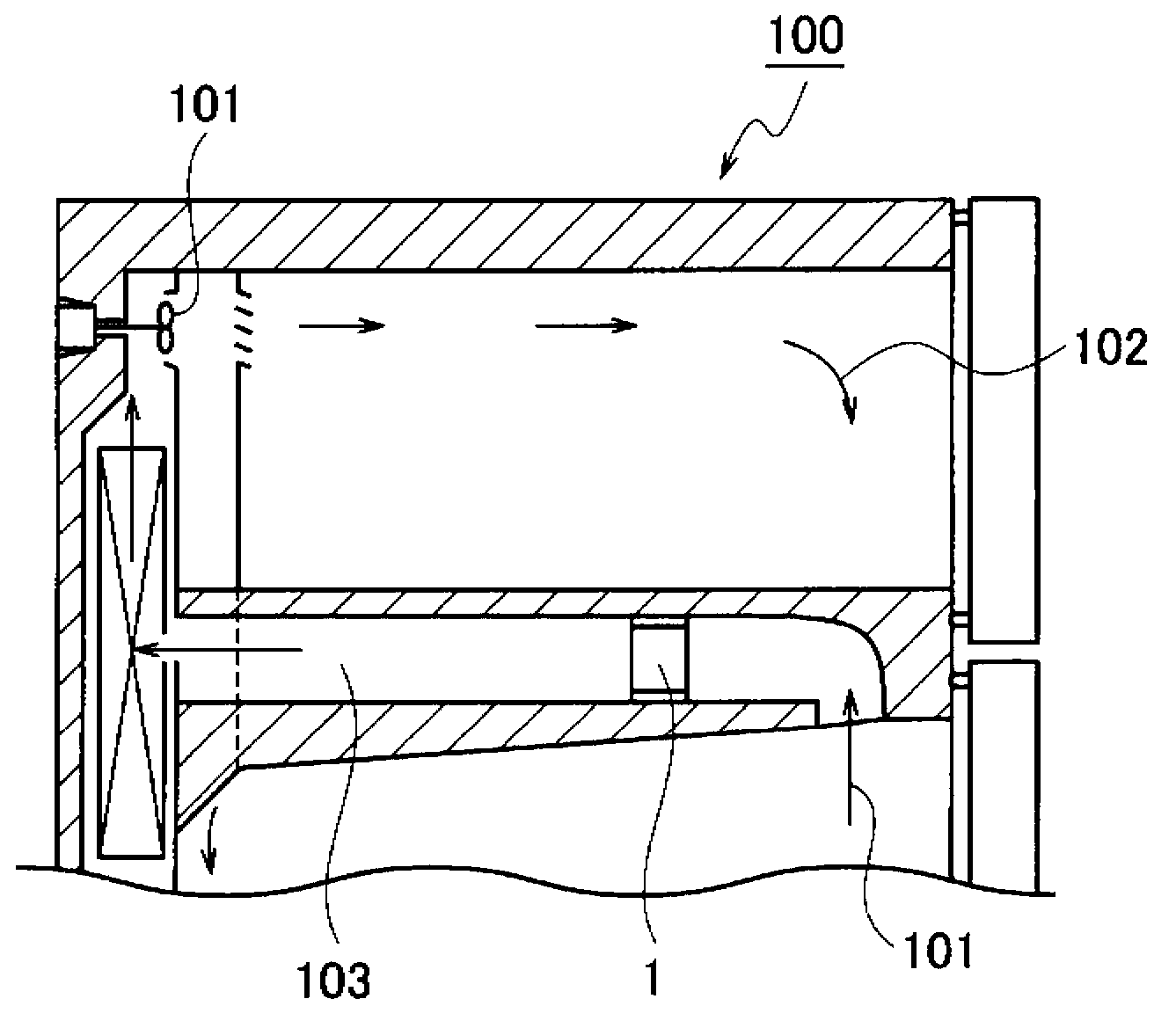

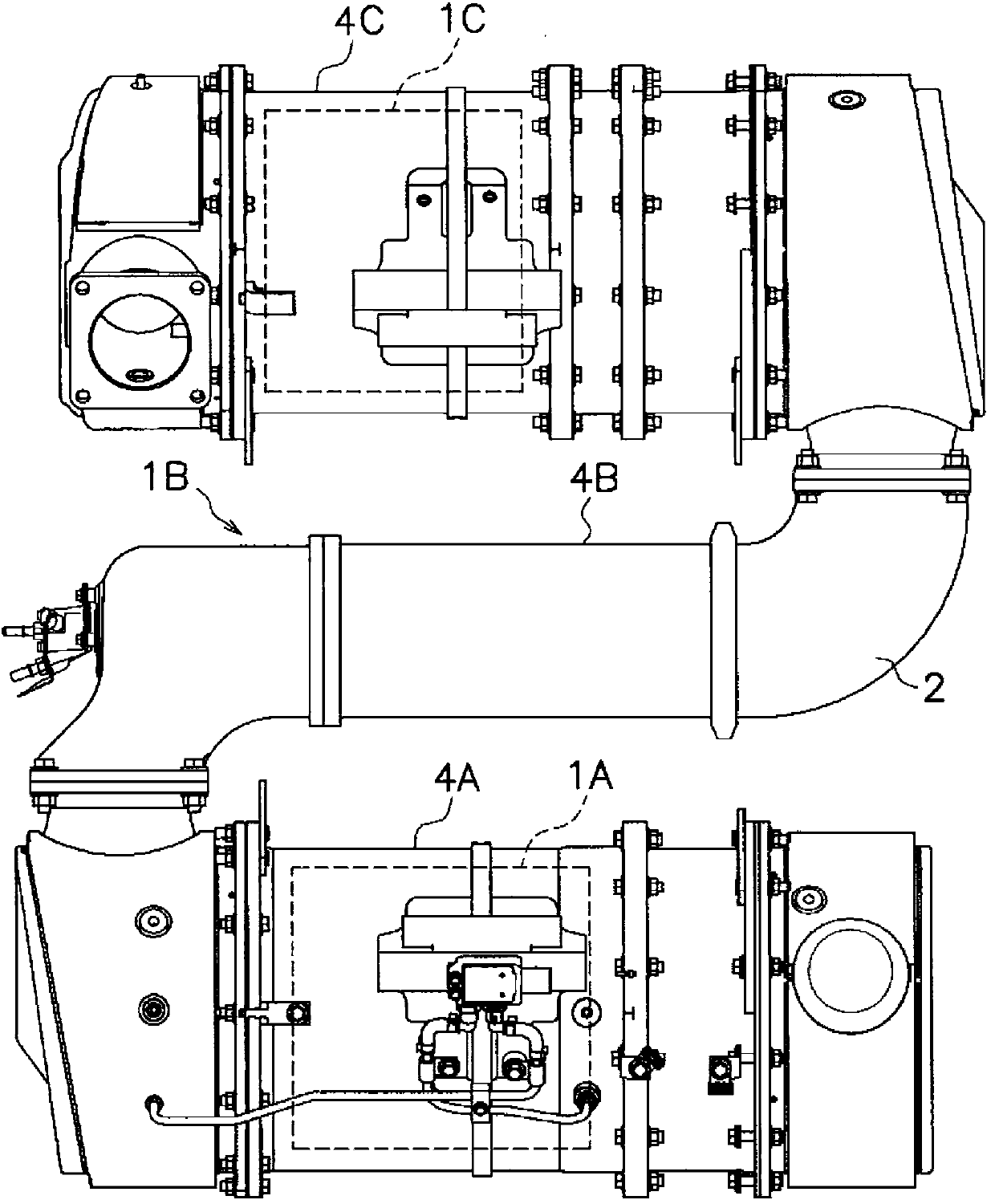

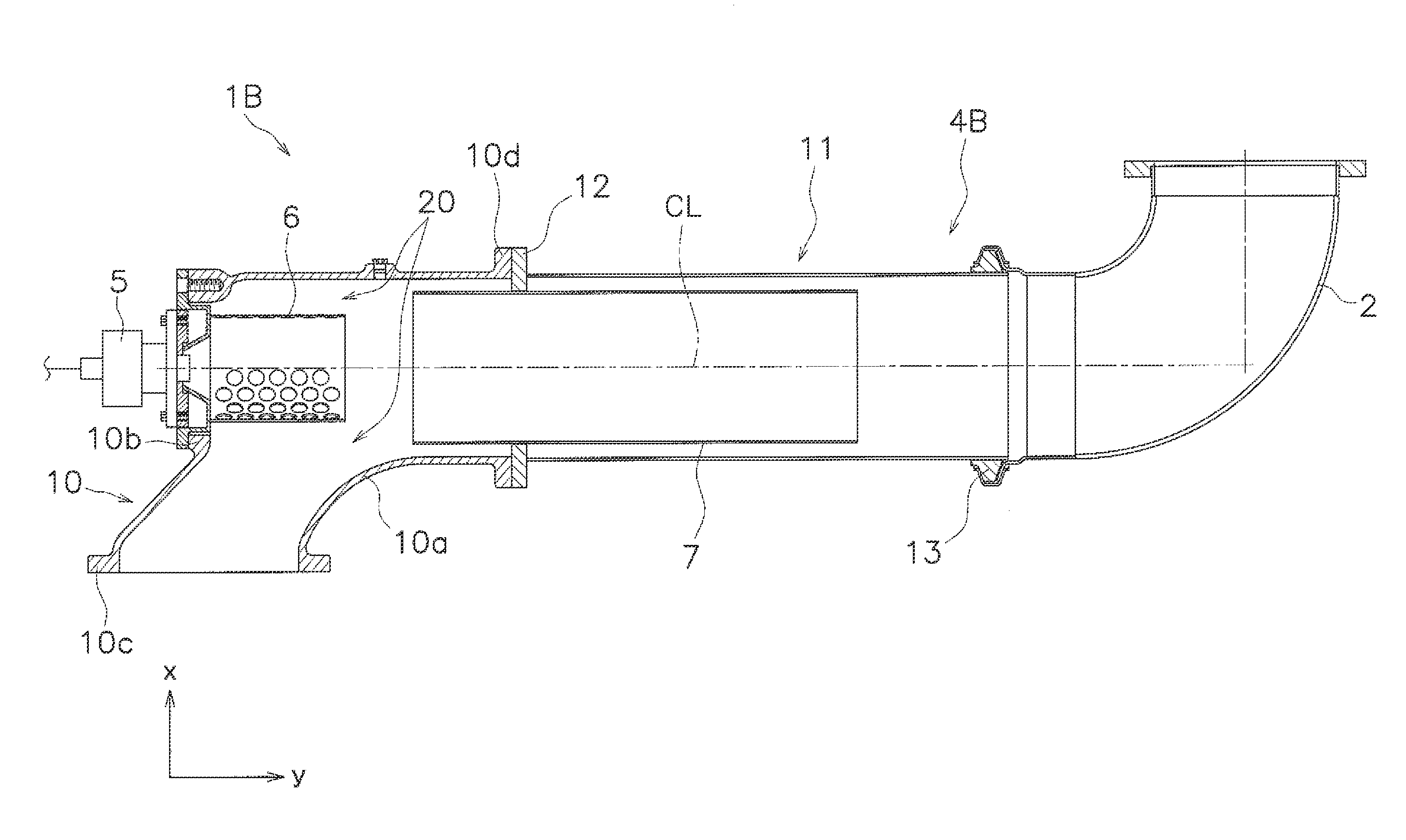

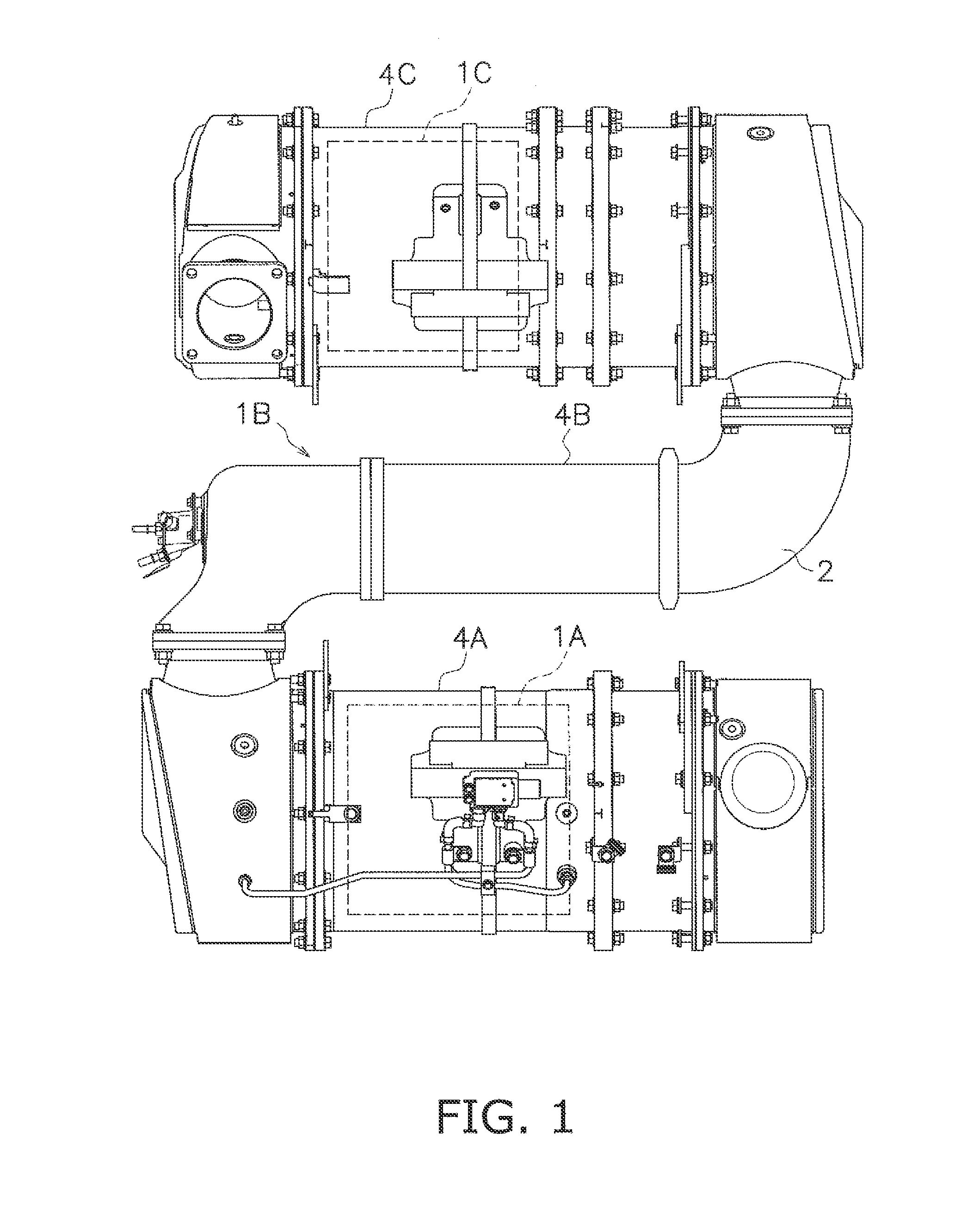

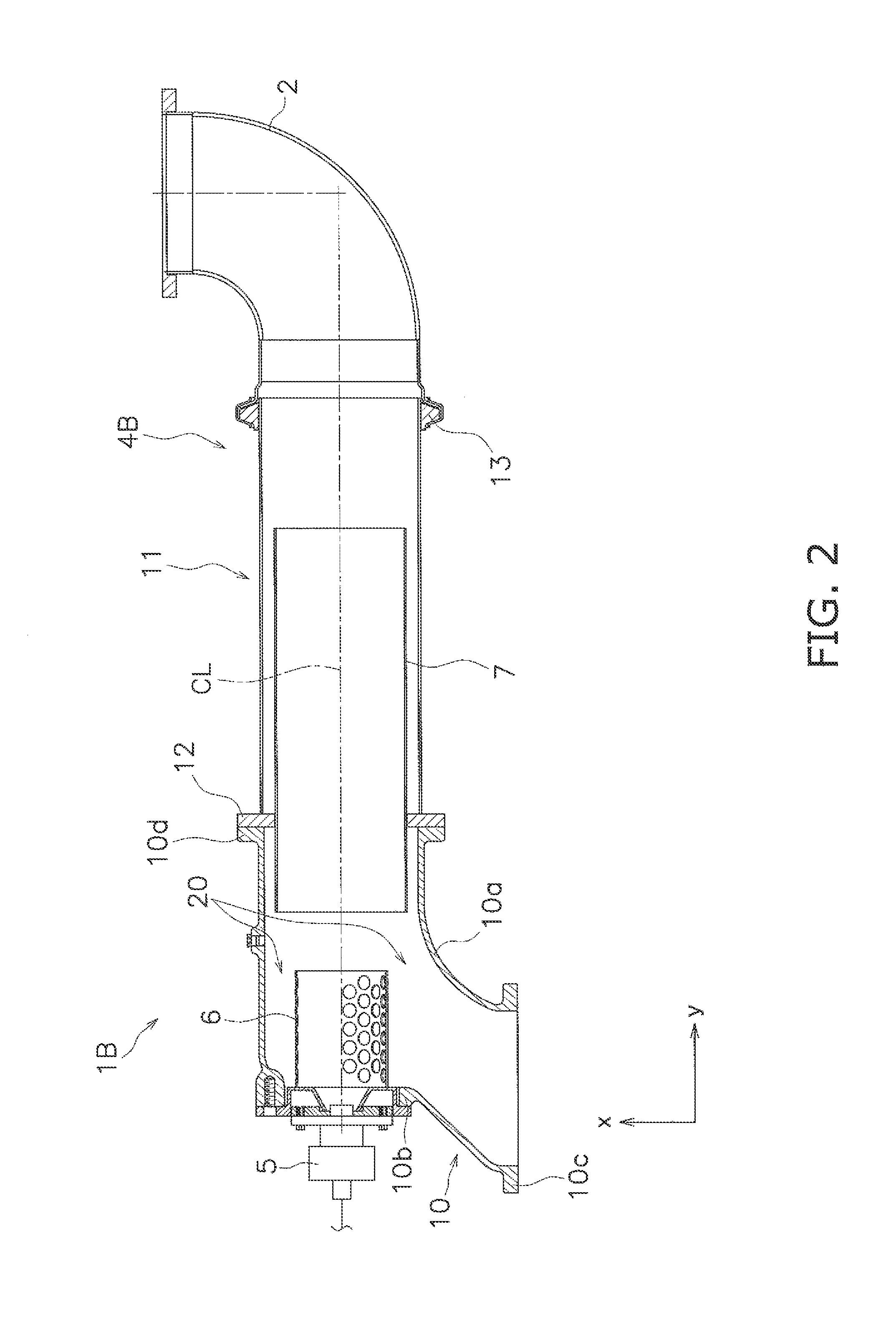

Reducing agent aqueous solution mixing device and exhaust gas after-reatment device

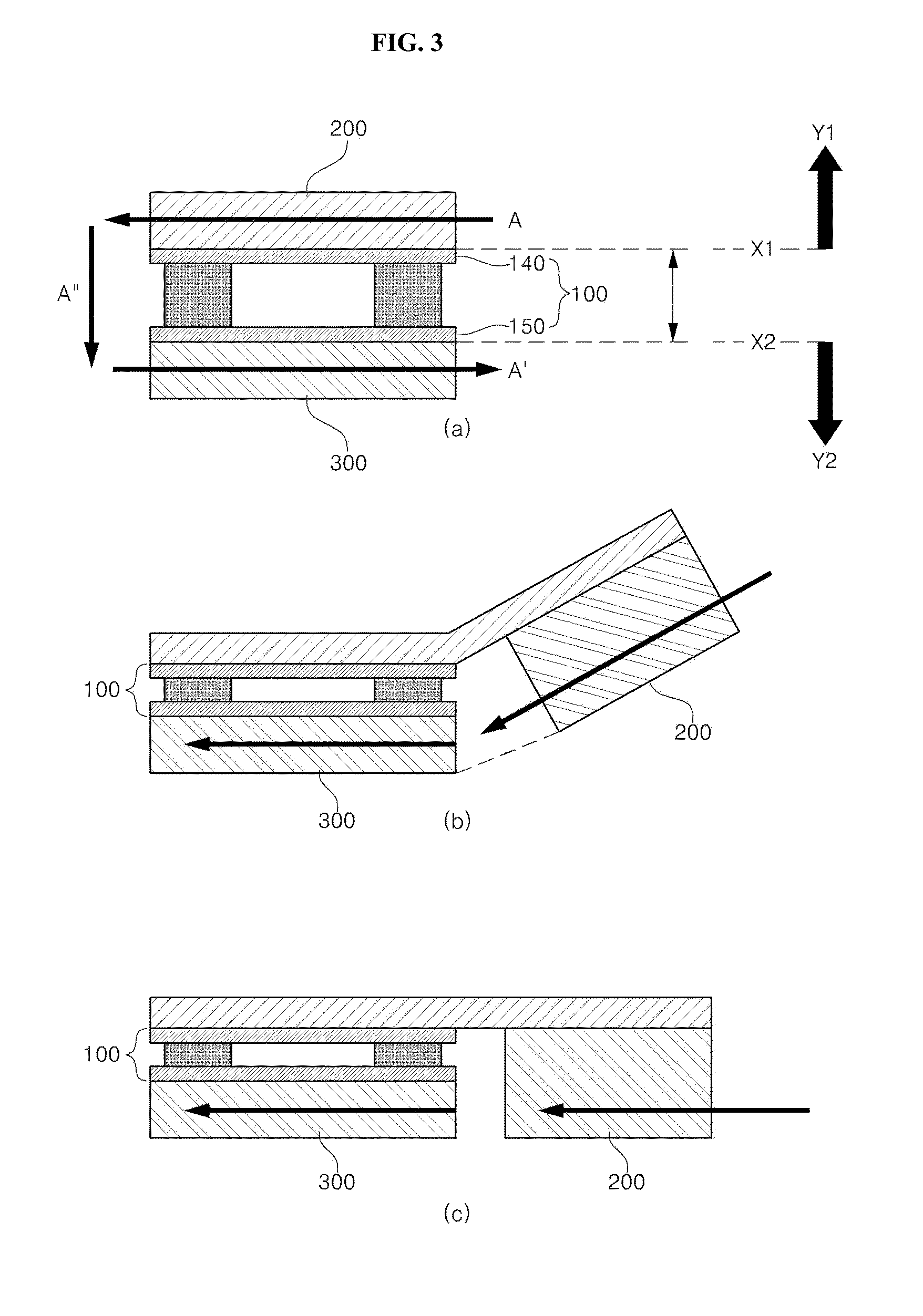

ActiveCN103282616ASuppress back pressureReduce flow path resistanceInternal combustion piston enginesFlow mixersEnvironmental engineeringAqueous solution

The present invention suppresses adhesion of a urea aqueous solution to an interior wall of an exhaust pipe and reduces flow resistance inside the exhaust pipe, in a urea aqueous solution mixing device. This urea aqueous solution mixing device is provided with an exhaust pipe (4B), an injector (5), a mixing pipe (6), an interior pipe (7), and a flow unit (20). The exhaust pipe (4B) has an elbow part (10) with a curved section, and a straight part (11). The injector (5) injects the urea aqueous solution, and is provided in the elbow part (10). The mixing pipe (6) is positioned so as to cover the area around the urea aqueous solution injected by the injector (5), and has an exit part formed between the interior walls of the exhaust pipe (4B) with an interval interposed therebetween, and a plurality of openings (6a) formed in the outer-peripheral surface thereof. The interior pipe (7) allows exhaust gas to flow through the interior and outer-peripheral sections thereof, and is positioned in the straight part (11) of the exhaust pipe (4B). The flow unit (20) guides exhaust gas into the interior pipe (7), and is formed between the exit part of the mixing pipe (6) and the interior walls of the exhaust pipe (4B).

Owner:KOMATSU LTD

Waste liquid collecting method, liquid injecting apparatus and cartridge set

A printer includes a recording head and a maintenance mechanism for sucking an ink in the recording head. A plurality of cartridges to be attached to the printer includes a first housing portion for storing an ink to be supplied to the recording head and a second housing portion for storing a waste ink discharged from the maintenance mechanism. In a first one of the cartridges, the flow path resistance of a cartridge side flow path from a waste ink introducing portion to an air communicating hole for discharging air in a waste ink reservoir portion to an outside through the waste ink reservoir portion is lower than the flow path resistance of each of the cartridge side flow paths of the other cartridges (FIG. 14).

Owner:SEIKO EPSON CORP

Reducing agent aqueous solution mixing device and exhaust gas post-treatment device

ActiveUS8916100B2Reduce flow path resistanceInhibition of attachmentCombination devicesInternal combustion piston enginesEngineeringAqueous solution

A reducing agent aqueous solution mixing device includes an exhaust pipe, an injector, a mixing pipe, an inner pipe and a flow section. The exhaust pipe includes an elbow part and a linear part. The injector is disposed in the elbow part and injects a reducing agent aqueous solution. The mixing pipe receives the reducing agent aqueous solution injected from the injector, and includes an outlet portion formed spaced apart from an inner wall of the exhaust pipe, and a plurality of openings formed on the outer peripheral surface thereof. The inner pipe is disposed in the linear part and allows the exhaust gas to flow through the inside and the outer periphery thereof. The flow section is formed between the outlet portion of the mixing pipe and the inner wall of the exhaust pipe to direct the exhaust gas to the inner pipe.

Owner:KOMATSU LTD

Tank flow path structure

InactiveUS7926506B2High trafficPrevent outflowValve members for absorbing fluid energyVenting valvesFuel tankEngineering

Owner:TOYODA GOSEI CO LTD

Photocatalyst deodorization device

ActiveCN102985116BReduce flow path resistanceMaximum absorptionGas treatmentPhysical/chemical process catalystsGlass fiberFiber

Disclosed is a long-life photocatalyst deodorization device (1) which effectively excites photocatalysts over the entire surface of a photocatalyst sheet and is capable of maintaining deodorization performance over a long period. Substrates (5 and 7) upon which vent holes (4) have been provided are disposed in parallel, and upon at least one substrate (5) of the two substrates, LEDs (3) are mounted. Between the two substrates, photocatalyst sheets (6) constituted by woven glass fiber material (6A) carrying photocatalyst particles (6B) and a frame (6C) supporting the material are disposed. The photocatalyst sheets and the two substrates are fixed to a housing (8), whereupon emitting surfaces of the LED light sources for exciting the photocatalysts and the photocatalyst sheets are disposed in parallel. Air fed from the vent holes is caused to pass through the photocatalyst sheets. The photocatalyst sheets are constituted by bundling glass fibers and weaving the fibers in a crisscross manner so as to have a predetermined aperture ratio such that ventilation is possible under low wind speed. The photocatalyst particles are mechanically held in contact between the glass fibers of the photocatalyst sheets.

Owner:TOSHIBA LIGHTING & TECH CORP

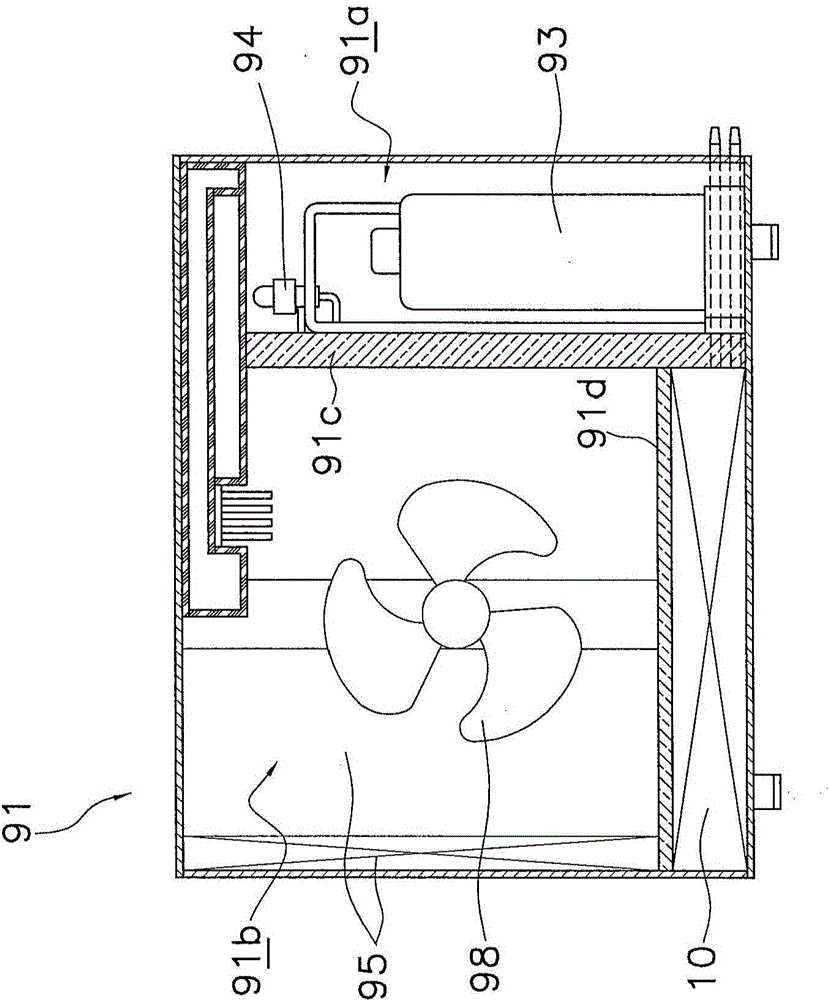

Heat conversion device

ActiveUS20150233613A1Reduce power consumptionImprove efficiencyMachines using electric/magnetic effectsAir conditioning systemsAir velocityAir volume

Provided is a heat conversion device including a thermoelectric element, the heat conversion device capable of implementing a heat conversion function of high efficiency in spite of low power consumption by disposing a heat absorption module and a heat emission module in a horizontal direction in a structure of a heat exchange device to which a thermoelectric module is applied, and by implementing a heat conversion effect for air while maintaining a desired air volume and air velocity without flow path resistance.

Owner:LG INNOTEK CO LTD

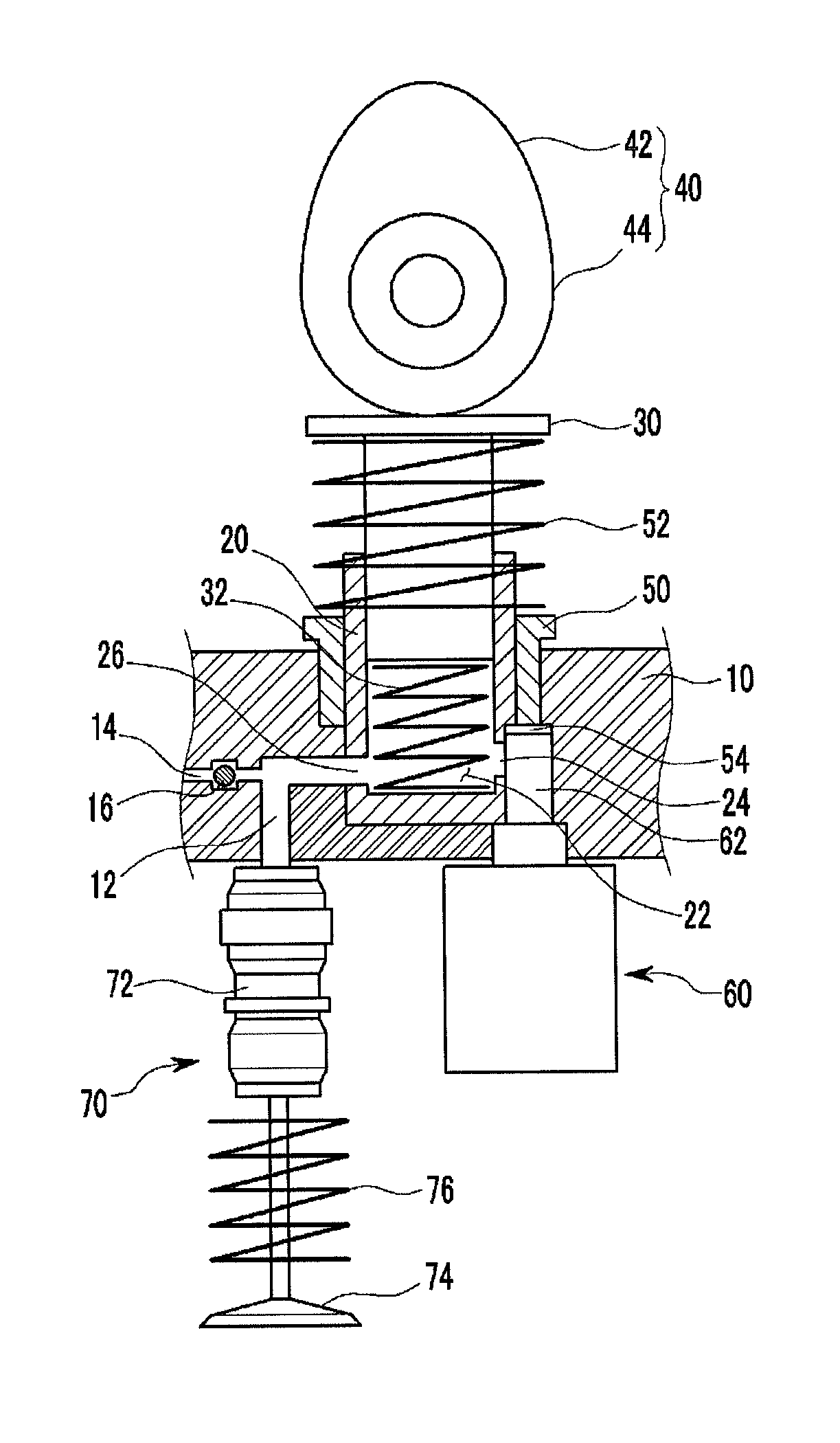

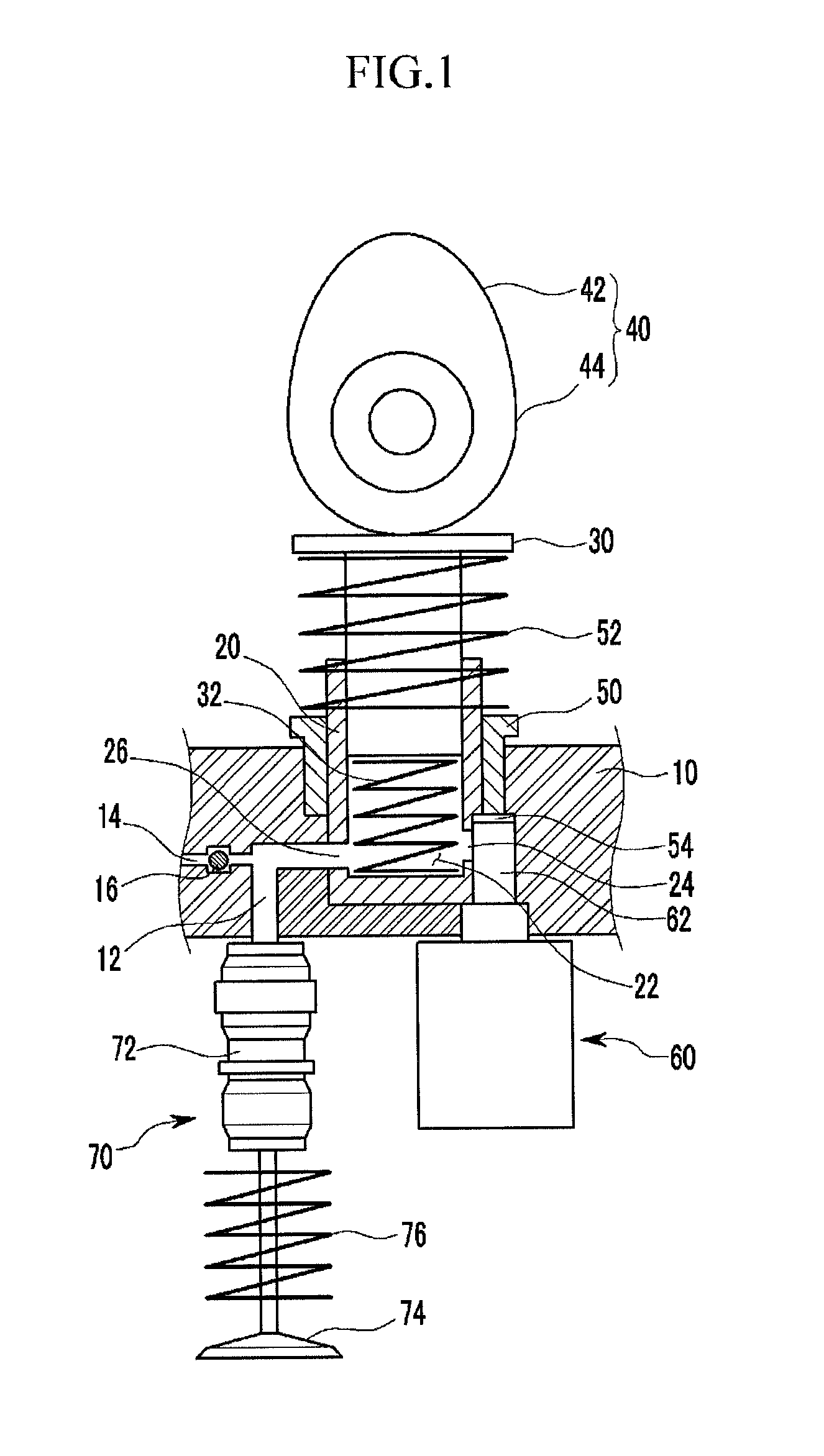

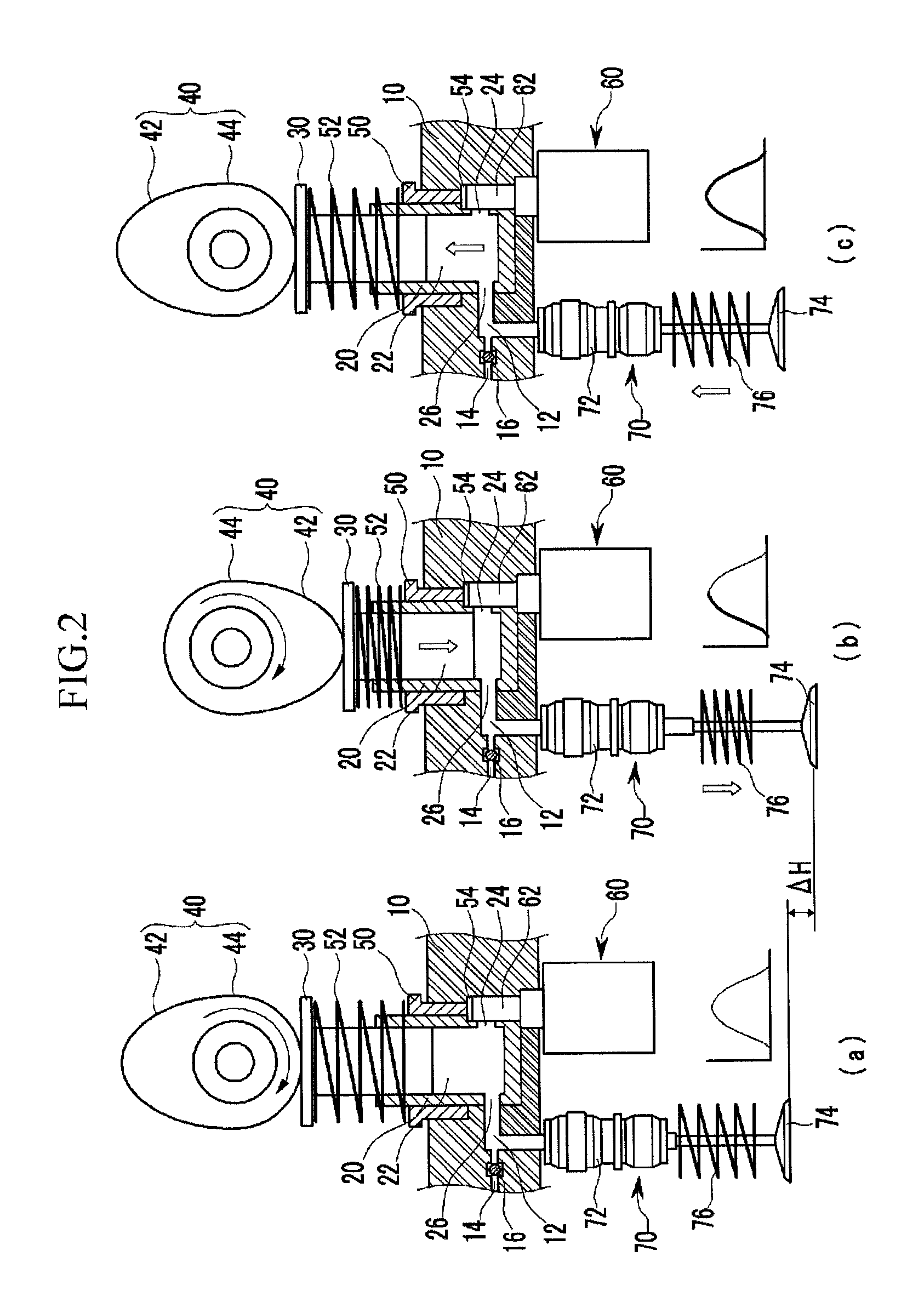

Electro-hydraulic variable valve lift apparatus

ActiveUS8899195B2Simplified oil circuitReduce flow path resistanceMachines/enginesLubrication pressure controlReciprocating motionPump chamber

An electro-hydraulic variable valve lift apparatus may include an hydraulic pump body installed in an engine, a piston provided to reciprocate within the hydraulic pump body and forming an hydraulic pump chamber together with the hydraulic pump body, an hydraulic pump cam disposed to be in contact with the piston and enabling the piston to reciprocate according to a rotation thereof, a retainer provided to be slidable along the piston between the piston and the engine and forming a retainer chamber with the engine, a retainer spring elastically supporting the retainer, an oil control valve allowing the hydraulic pump chamber and the retainer chamber to selectively communicate with each other, a valve opening and closing unit communicating with the hydraulic pump chamber and opened or closed according to oil pressure supplied from the hydraulic pump chamber.

Owner:HYUNDAI MOTOR CO LTD

Valve and manufacturing method for valve

ActiveUS10458552B2High accuracyInhibit functionDiaphragm valvesOperating means/releasing devices for valvesValve seat

A valve includes a valve seat having a hole configured as a flow path, a valve body configured to open / close the flow path due to relative movement with respect to the valve seat, an opening member having a first surface fixed to one of the valve seat and the valve body, a second surface configured to separate away and abut the other one of the valve seat and the valve body, a third surface which intersects the first and second surfaces, and an opening penetrating the first and second surfaces, a fixing member that fixes the first surface to the one of the valve seat and the valve body, and an inclined portion, which makes an interval between the one of the valve seat and the valve body and the first surface long in a direction from the opening to the third surface.

Owner:SEIKO EPSON CORP

Check valve and receptacle structure

ActiveUS10030783B2Simple structureReduce total pressure lossVessel mounting detailsContainer filling methodsEngineeringCheck valve

In order to reduce a pressure loss in a check valve and simplify a manufacturing process, a check valve (10) configured to be disposed in piping of fluid is provided, which includes a valve housing (31) including a valve element (52) and a valve seat (54) therein, a casing (20) that is configured to place the valve housing therein, in which a casing flow path (60) is provided between the casing and the valve housing to make a flow of the fluid in an axial direction of the valve housing. In the valve housing, a communicating hole (38) and sealing portion (34) are formed. The communicating hole that is formed through the valve housing in a thickness direction thereof introduces the fluid, which flows through between the valve element and the valve seat at the open position of the check valve, into the casing flow path. The sealing portion that is provided on an outer surface of the valve housing upstream of the communicating hole in a flow direction of the fluid in the casing flow path, is configured to come into contact with an inner surface of the casing to seal the casing flow path and position the valve housing in a radial direction perpendicular to the axial direction relative to the casing.

Owner:TOYOTA JIDOSHA KK +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com