Residual quantity-reducing member

一种残量、部件的技术,应用在残量减少部件领域,能够解决无法内容物排出量稳定化、内装袋排出量无法稳定化、无法稳定地获得混合比等问题,达到减少残存量、形状简单、排出量稳定的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

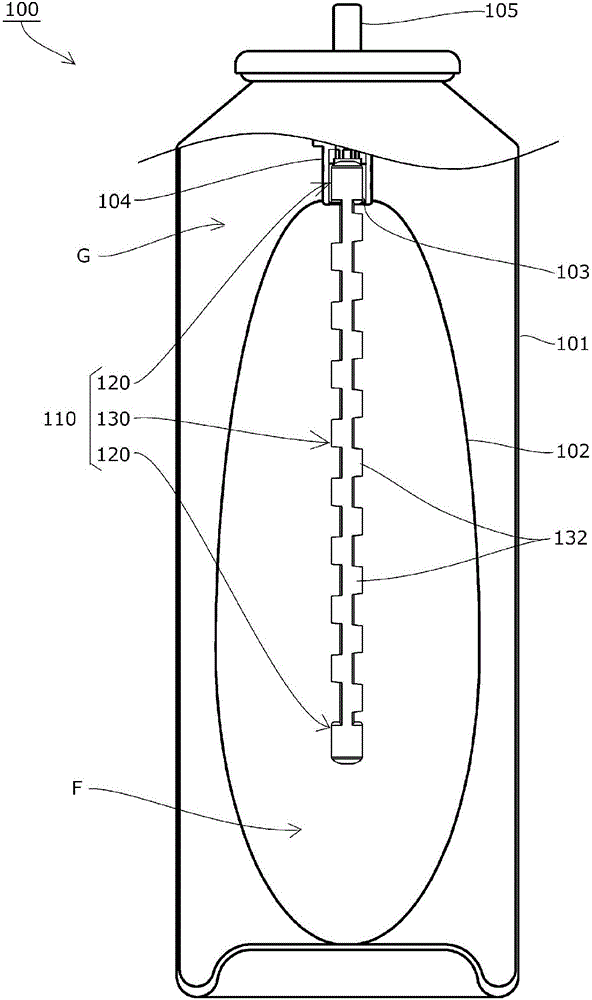

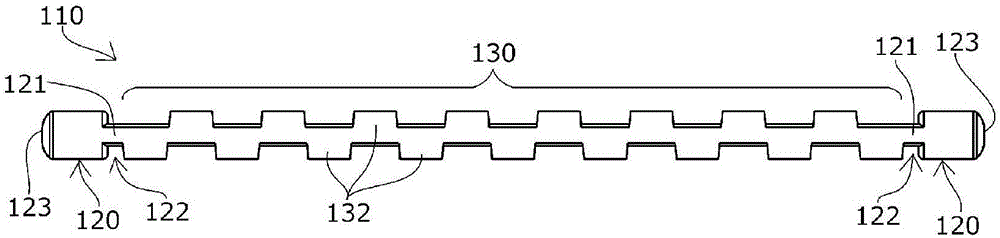

[0062] The remaining amount reducing member 110 according to the first embodiment of the present invention is inserted into the inflow port 103 of the aerosol container 100 similar to the above-mentioned known aerosol container 500 instead of the known dipping tube 511 .

[0063] That is, if figure 1 As shown, the inside of the outer tank 101 of the aerosol container 100 is provided with an inner bag 102 containing the contents F, and the inner bag 102 is provided with a spout 104, and the top of the inner bag 102 has a rod 105, and the inner bag 102 There is an inflow port 103 in the inner opening.

[0064] The space between the outer tank 101 and the inner bag 102 of the aerosol container 100 is filled with a pressurized fluid G such as nitrogen gas, and when the lever 105 is pressed, the contents contained in the inner bag 102 flow in from the inflow port 103, and are discharged from the inner bag 102. The front end of the rod 105 is discharged to the outside.

[0065] F...

Embodiment 2

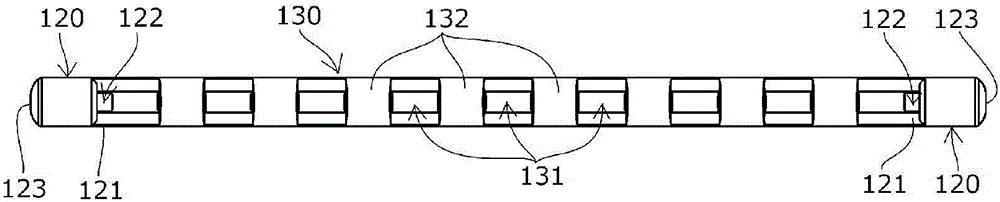

[0092] The remaining amount reducing member 210 of the second embodiment of the present invention is as Figure 9 to Figure 12 As shown, in addition to the structure of the remaining amount reducing member 110 of the first embodiment described above, two outer surface grooves 238 extending in the longitudinal direction are provided on the arcuate surface 233 at the arc of the adjacent grooved block 232 . A position where the surface 233 does not overlap in the longitudinal direction (The same structure as that of the first embodiment is shown with reference numerals corresponding to No. 200, and description of the structure is omitted.).

[0093] Outer surface groove 238 such as Figure 12 As shown in (b), two arcuate surfaces 233 of each grooved block 232 are provided so as to extend in the longitudinal direction.

[0094] In this embodiment, it is formed at the position and cross-sectional shape at the maximum that does not overlap with the arcuate surface 233d of the adjac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com