Fuel cell and process for the production thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

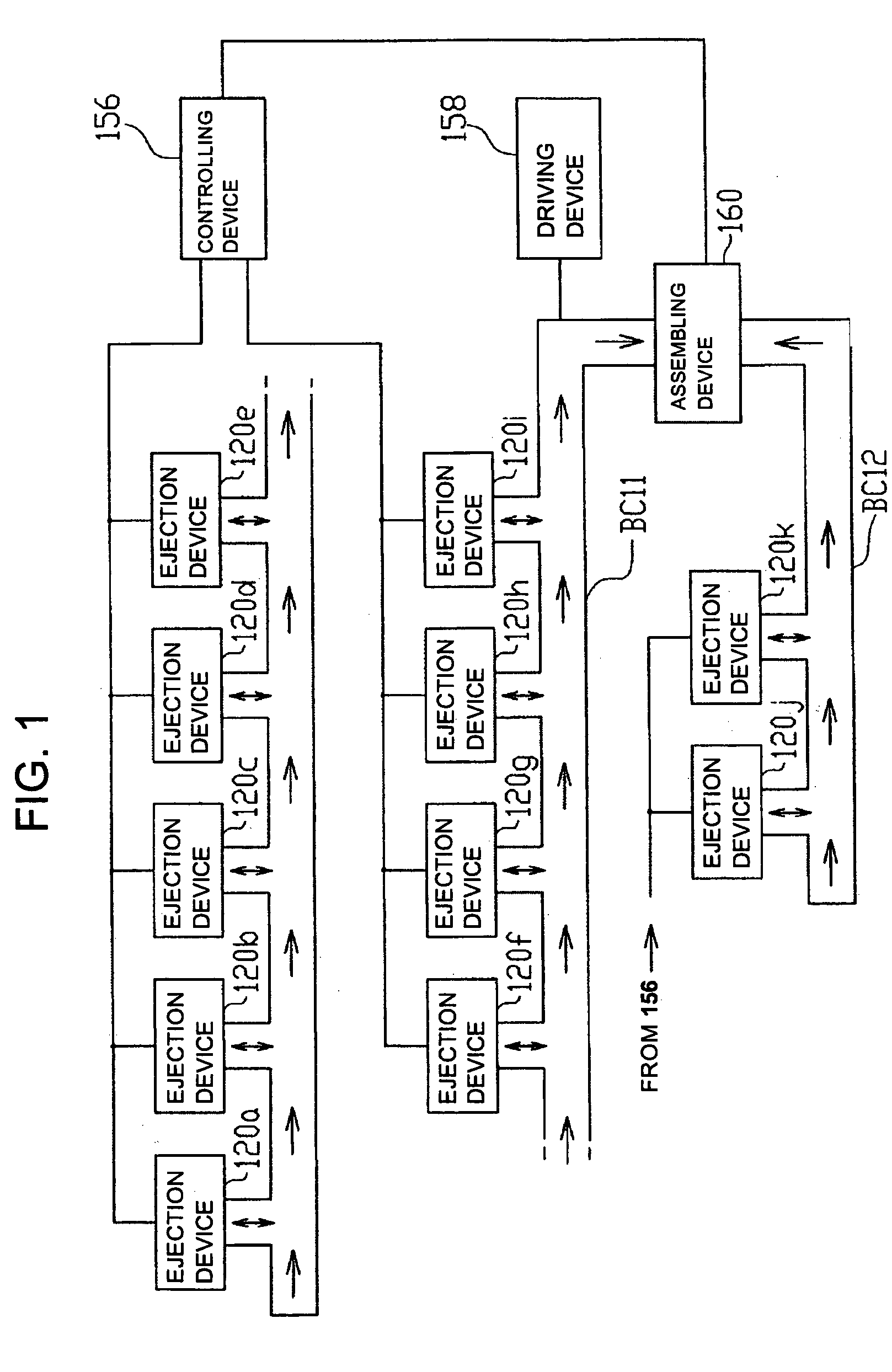

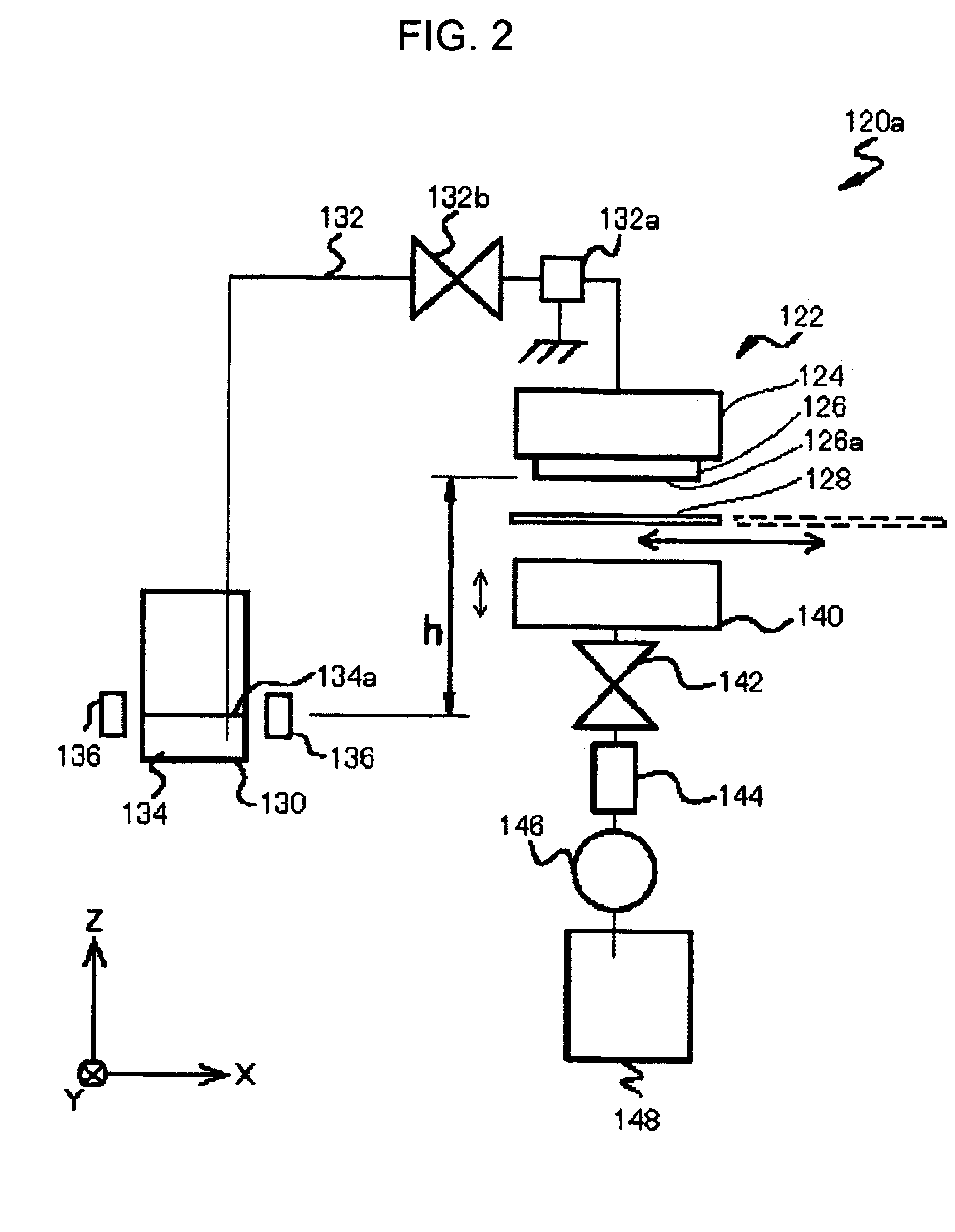

[0083]Processes for the production of a fuel cell according to embodiments of implementation of the invention will be described hereinafter. FIG. 1 is a diagram illustrating the configuration of an exemplary fuel cell production line for executing the process for the production of a fuel cell according to implementation of the invention. As shown in FIG. 1, the fuel cell production line is formed by ejection devices 120a to 120k used in various steps, a belt conveyor BCl 1 connecting the ejection devices 120a to 120i to each other, a belt conveyor BC12 connecting the ejection devices 120j and 120k to each other, a driving device 158 for driving the belt conveyors BC 11 and BC 12, an assembling device 160 for assembling a fuel cell and a controlling device 156 for controlling the entire fuel cell production line.

[0084]The ejection devices 120a to 120i are arranged at a predetermined interval in a line along the belt conveyor BC11. The ejection devices 120j and 120k are arranged at a ...

second embodiment

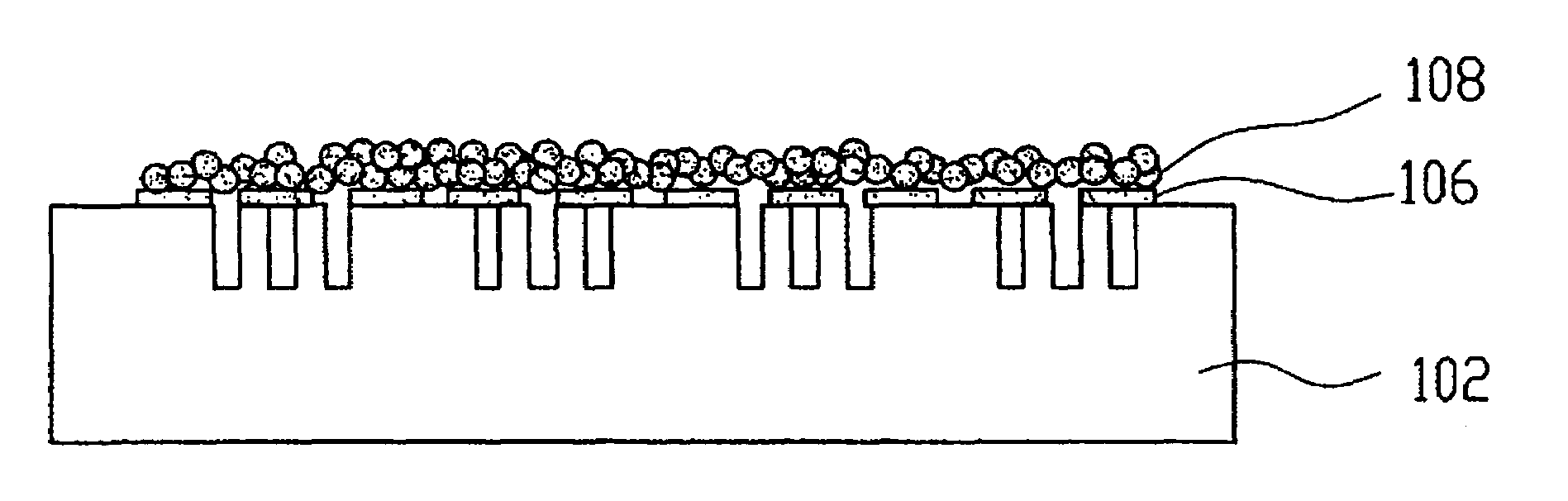

[0126]In accordance with the process for the production of a fuel cell according to implementation of the invention, a gas flow path the opening width of which is smaller than the particle diameter of particulate carbon constituting the gas diffusion layer is formed using an ink jet type ejection device. That is, a negative-working resist and a positive-working resist are ejected onto the substrate at the respective predetermined positions to form a sacrifice layer from which only the positive-working resist is then removed to form a gas flow path having a trapezoidal section. Accordingly, the particulate carbon constituting the gas diffusion layer enters in the gas flow path, making it possible to prevent the clogging of the gas flow path.

[0127]Further, a gas flow path having a trapezoidal section, i.e., gas flow path the opening width of which is smaller than the particle diameter of particulate carbon constituting the gas diffusion layer and the bottom width of which is greater t...

third embodiment

[0135]A process for the production of a fuel cell using gas flow path forming devices 214a and 214b and ejection devices 220a to 220g according to implementation of the invention will be described hereinafter in connection with the flow chart of FIG. 18 and other attached drawings.

[0136]Firstly, a gas flow path for supplying a reactive gas is formed in the substrate (Step S20). That is, a rectangular flat substrate 202 made of, e.g., silicon (first substrate) as shown in FIG. 19(a) is conveyed to the ejection device 214a by the belt conveyor BC21. The surface of the substrate 202 which has been conveyed by the belt conveyor BC21 is then coated with a resin 204, e.g., photo-setting or thermosetting resin (see FIG. 19(b)). Actually, the surface of the substrate 202 is coated with an uncured low viscosity resin 204, e.g., resin 204 having a viscosity of about 20 mPa·s.

[0137]Subsequently, a gas flow path forming mold which has been previously prepared is pressed against the resin 204 so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com