Stator assembly and motor with the stator assembly

A stator and component technology, which is applied in the field of stator components and motors having the stator components, can solve the problems such as the threat of performance stability of permanent magnet magnetic poles, the restriction of heat transfer rate in the heat-producing link of the motor, and the large loss of resistance along the path and in local areas. Achieve the effect of reducing expansion deformation, preventing air gap from narrowing, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

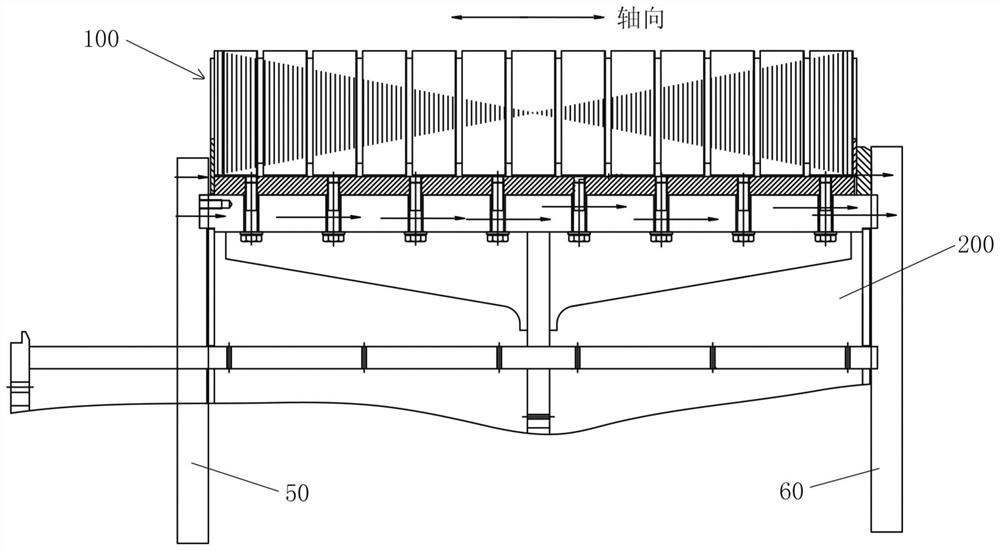

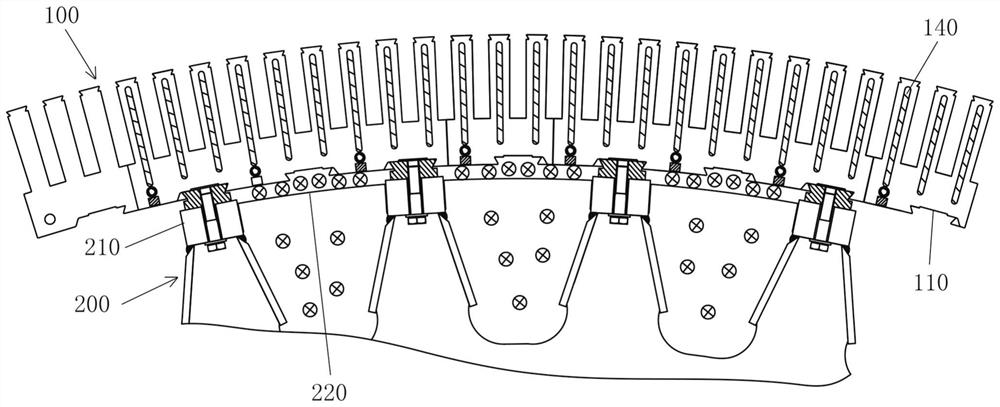

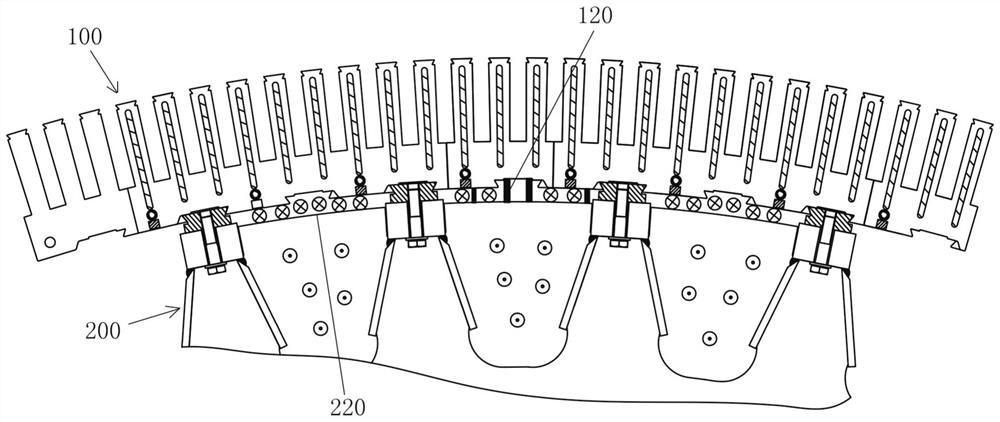

[0029] Hereinafter, the embodiment of the present invention will be described in detail with reference to the drawings by taking the inner stator of the motor as an example.

[0030] Such as figure 1 with figure 2 As shown, in order to reduce eddy current loss and other losses, the stator core 100 of the motor is made of ferromagnetic conductor thin sheets with large resistivity and small hysteresis loop area, which are punched and insulated, and then laminated. In the prior art, when manufacturing the stator core, a plurality of fan-shaped silicon steel sheets are usually spliced along the circumferential direction and stacked along the axial direction, and the support column 210 of the stator bracket 200 is combined with the dovetail groove 110 by fasteners, so that the The silicon steel sheet is fixed on the supporting shroud 220 of the stator bracket along the circumferential direction, and the axial ends are clamped by the tooth pressure plate 140 , thereby forming a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com