Processing method of long-narrow composite material molding part assembling mould

A composite material and combined mold technology, applied in the field of machining, can solve problems such as contact difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

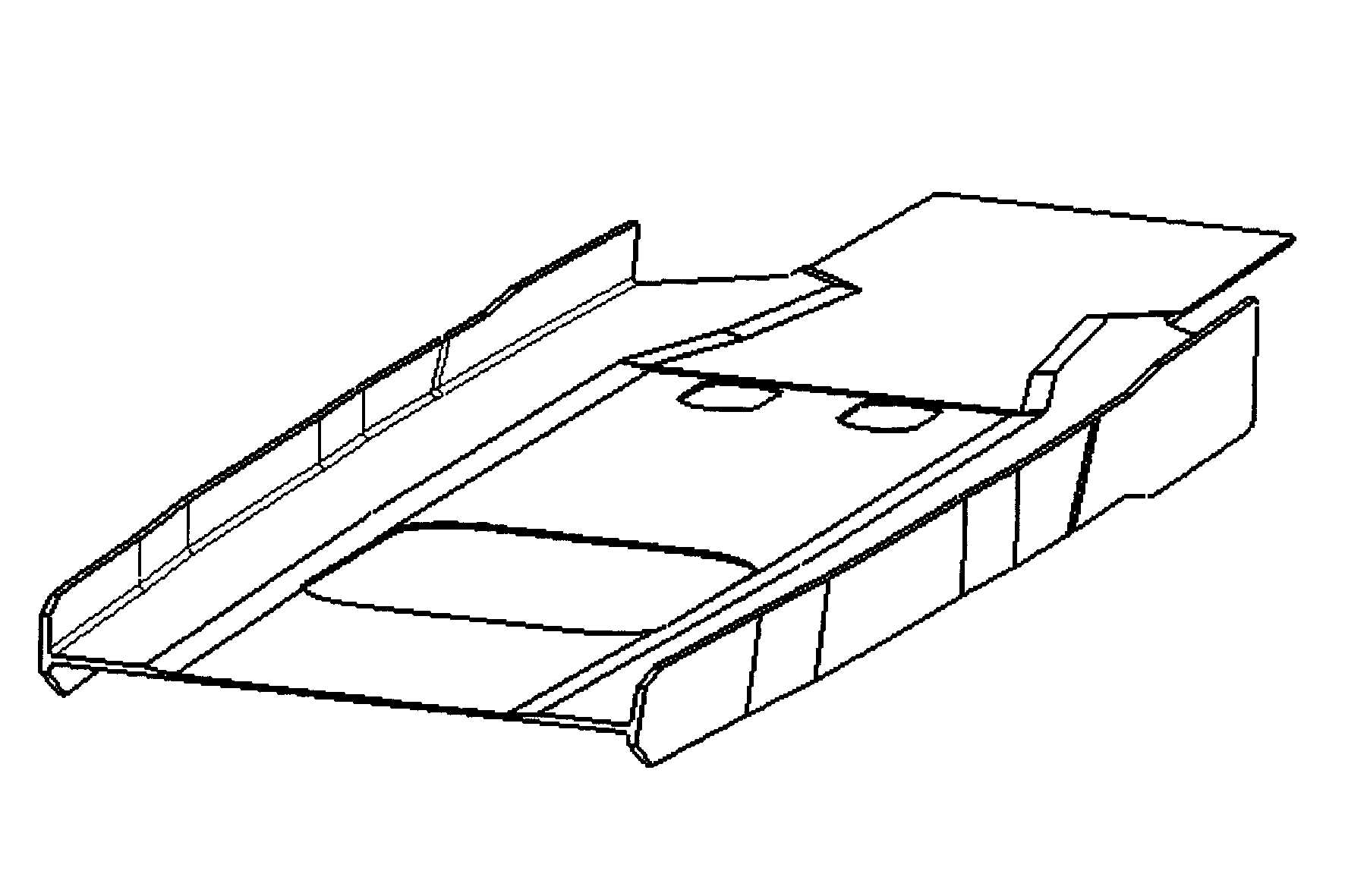

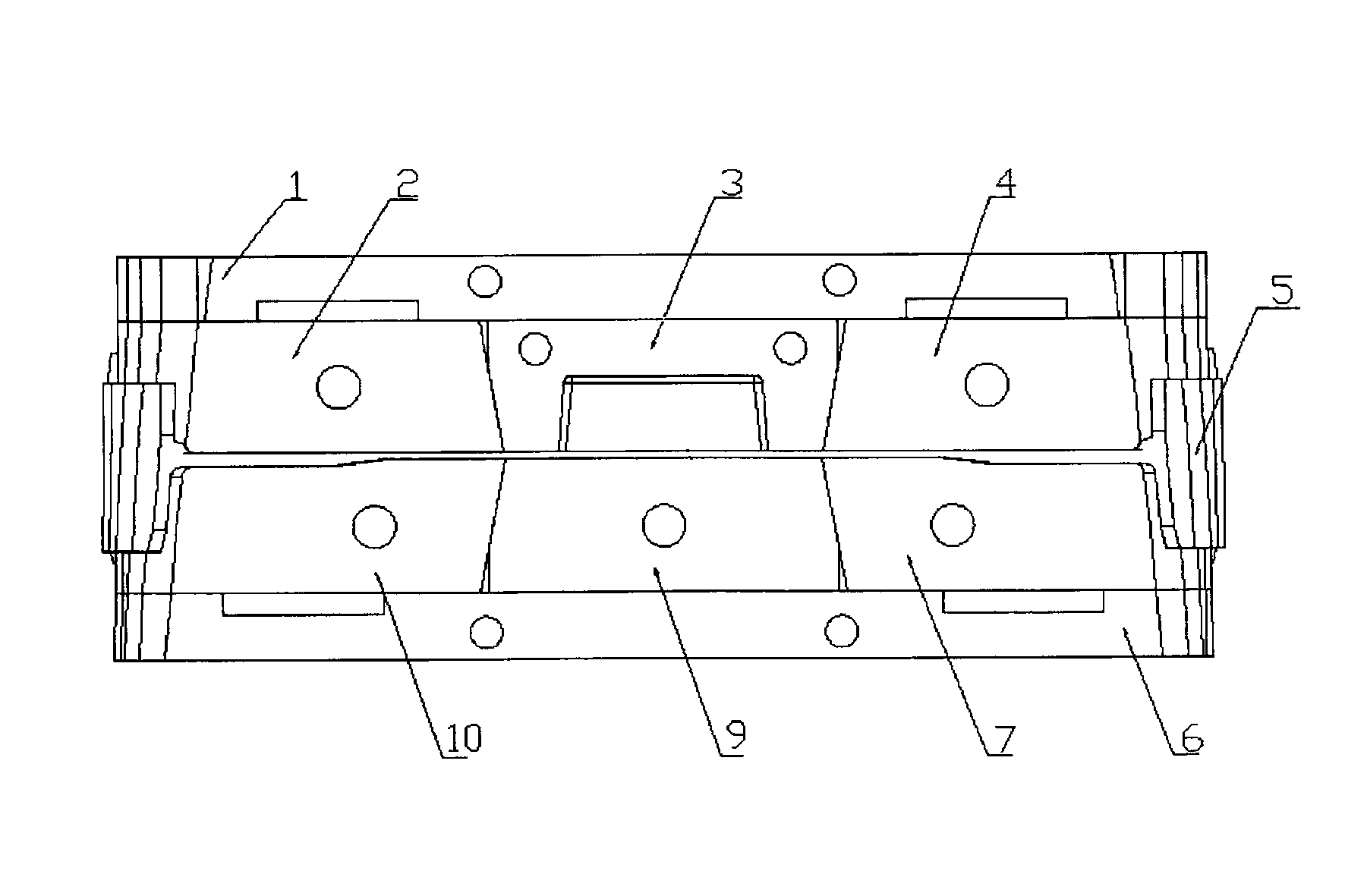

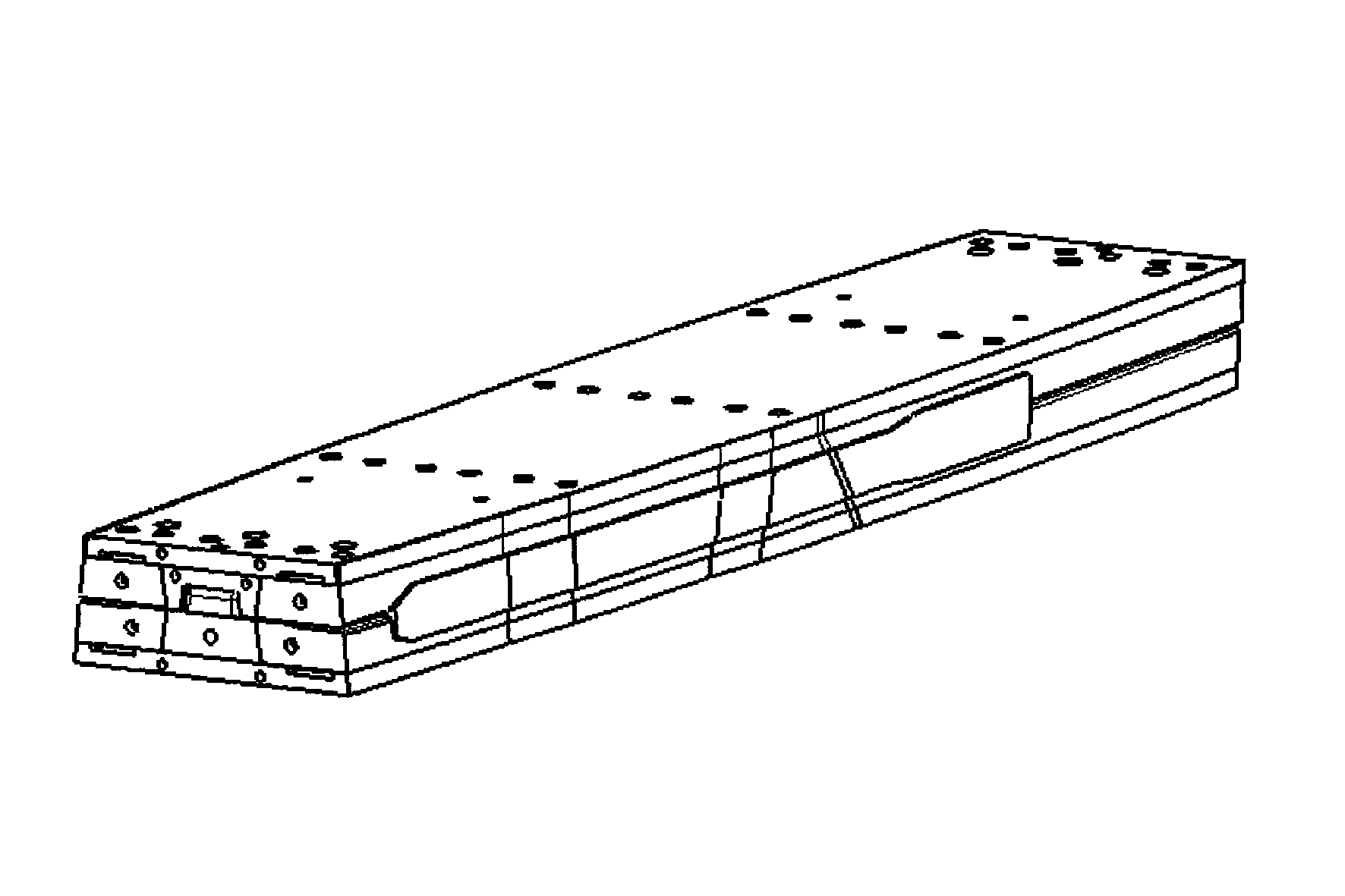

[0021] Such as figure 2 and image 3 As shown, the structure of the combination mold for long and narrow composite material molding parts is as follows: the lower long and narrow splint I7, the lower long and narrow splint II9 and the lower long and narrow splint III10 are respectively placed above the lower bottom plate 6, and the lower long and narrow splint The cross-section in the width direction of II9 is a trapezoidal structure with a narrow top and a wide bottom. One side of the lower long and narrow splint I7 and one side of the lower long and narrow splint III10 are respectively closely matched with the side of the lower long and narrow splint II9; Place the upper long and narrow splint Ⅰ2, the upper long and narrow splint Ⅱ3 and the upper long and narrow splint Ⅲ4. One side of the long and narrow splint III4 is closely matched with the side of the lower long and narrow splint II9; The combined profiles of the narrow splint I2, the upper long narrow splint II3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com