Low smoke zero halogen high-temperature (100 DEG C) and flame resistance multi-core control cable core insulation rubber

A technology for insulating rubber and control cables, applied in the field of cable insulating rubber, can solve the problems of far-flung mechanical properties, environmental resistance, poor plastic insulation properties, affecting insulation properties, etc., and achieves comprehensive rubber technical performance, good aging resistance, Easy color matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

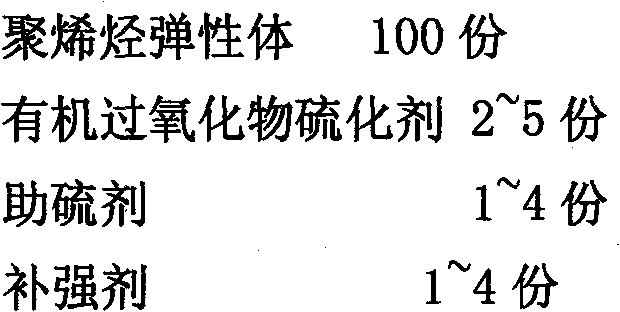

[0025] A 100°C-resistant, low-smoke, halogen-free, flame-retardant multi-core control cable core insulating rubber according to the present invention, the formula of the insulating rubber contains the following components by weight:

[0026] 100 parts of polyolefin elastomer, select POE8450, 2 parts of organic peroxide vulcanizing agent, select dicumyl peroxide DCP, 1 part of sulfur promoter is triallyl isocyanurate TAIC, 1 part of reinforcing agent Choose precipitation white carbon black. Anti-aging agent RD 1 part, light calcium carbonate 30 parts, nano clay 40 parts, zinc oxide 1 part, paraffin wax 2 parts, paraffin oil 4 parts, titanium dioxide 4 parts, stearic acid 1 part, coupling agent KH5501 parts.

[0027] The specific performance indicators of the insulating rubber obtained are as follows:

[0028] Before aging: elongation at break 275%; tensile strength 11.1N / mm 2 ;

[0029] After aging (120℃*240h) the elongation at break is 250%; the tensile strength is 10.2N / mm 2 ; Elong...

Embodiment 2

[0034] Another 100℃-resistant low-smoke halogen-free flame-retardant multi-core control cable core insulating rubber, the formula of the insulating rubber contains the following components by weight:

[0035] 100 parts of polyolefin elastomer are selected from POE8450, 5 parts of organic peroxide curing agent are selected from dicumyl peroxide DCP, 4 parts of sulfur promoter are selected from triallyl isocyanurate TAIC, 4 parts of reinforcing agent are selected Precipitation method white carbon black. Anti-aging agent RD 4 parts, light calcium carbonate 60 parts, nano clay 80 parts, zinc oxide 5 parts, paraffin wax 5 parts, paraffin oil 9 parts, titanium dioxide 9 parts, stearic acid 4 parts, coupling agent KH5504 parts.

Embodiment 3

[0037] Another 100℃-resistant low-smoke halogen-free flame-retardant multi-core control cable core insulating rubber, the formula of the insulating rubber contains the following components by weight:

[0038] 100 parts of polyolefin elastomer are selected from POE8450, 3 parts of organic peroxide curing agent is selected from dicumyl peroxide DCP, 3 parts of sulfur promoter is selected from triallyl isocyanurate TAIC, and 2 parts of reinforcing agent are selected Precipitation method white carbon black. Anti-aging agent RD 2 parts, light calcium carbonate 40 parts, nano clay 60 parts, zinc oxide 3 parts, paraffin wax 3 parts, paraffin oil 5 parts, titanium dioxide 6 parts, stearic acid 3 parts, coupling agent KH5503 parts.

[0039] The invention has comprehensive performance, excellent electrical performance, good heat resistance, aging resistance and abrasion resistance, small expansion and deformation at high temperature, is beneficial to secondary vulcanization processing, and i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com