A cement-based high-performance micro-expansion filling grout

A grouting, cement-based technology, applied in the field of filling grouting and cement-based high-performance micro-expansion filling grouting, can solve the problems of poor application effect, poor adhesion of secondary lining concrete and high price, and achieve The effect of enhancing final setting strength and firmness, good material-liquid suspension stability and suitable density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

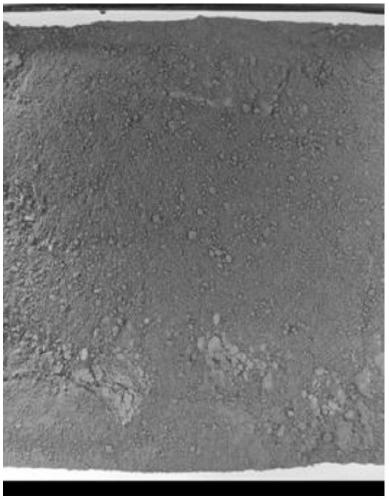

[0059] Cement-based filling grout, composed of the following parts by mass of cementitious material, weighting agent, quartz sand and composite admixture: 440 parts of P·O42.5R ordinary Portland cement, R·S·AC 42.5R sulfoaluminic acid 74 parts of salt cement, silica fume powder (specific surface area 18000m 2 / g) 40 parts, YJ-4 cementing weighting agent (magnetite) 70 parts, 30 mesh to 50 mesh coarse quartz sand 185 parts, 50 mesh to 120 mesh fine quartz sand 185 parts, water reducer 5 parts. Under the environmental conditions within the range of normal air temperature 10-30 ℃, put the above raw material components into figure 1 In the dry powder mortar mixing equipment shown, fully stir and mix for 4 minutes, and pack in double-layer sealed bags.

[0060] The properties of the prepared cement-based grout are as follows: figure 2 As shown, it is mixed with water according to the water-material ratio of 0.19, fully stirred and mixed well, and the grouting material in the wor...

Embodiment 2

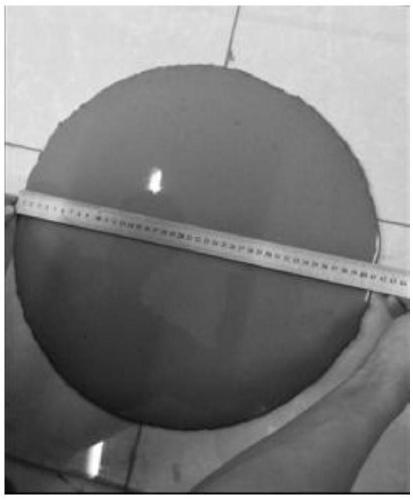

[0070] Cement-based filling grout, composed of the following parts by mass of cementitious material, weighting agent, quartz sand and composite admixture: 438 parts of 42.5R ordinary Portland cement, 75 parts of 42.5R sulfoaluminate cement, silica fume powder 40 parts, 69 parts of weighting agent, 187 parts of coarse quartz sand of 30-50 mesh, 185 parts of fine quartz sand of 50-120 mesh, 4 parts of water reducer. Under the environmental conditions within the normal temperature range of 10-30°C, put the above-mentioned raw material components into the dry powder mortar mixing equipment, fully stir and mix for 5 minutes, and pack them in double-layer sealed bags. After testing, the fluidity of the cement-based filling grouting material is 410mm, such as image 3 As shown, the results meet the requirements of technical indicators.

Embodiment 3

[0075] The cement-based filling grout consists of the following parts by mass of cementitious material, weighting agent, quartz sand and composite admixture: 440 parts of ordinary portland cement, 75 parts of sulphoaluminate cement, 40 parts of silica fume powder, weighting 70 parts of agent, 185 parts of coarse quartz sand of 30-50 mesh, 185 parts of fine quartz sand of 50-120 mesh, and 6 parts of composite admixture. Put the above raw materials into the dry powder mortar mixing equipment, fully stir and mix for 4 minutes, and pack them in double-layer sealed bags.

[0076] The cement slurry expansion rate testing instrument adopts plexiglass, and the instrument is equipped with a sealing cover to detect and analyze the cement slurry expansion rate. The cement-based filling grout prepared in this embodiment did not find bleeding in the plexiglass expansion rate test container, and its plastic expansion rate was as follows: Figure 4 As shown, the cement-based filling grout h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com