Fireproof silicone rubber material and preparation method thereof

A technology of silicone rubber and methyl silicone rubber, which is applied in the field of fireproof and refractory silicone rubber materials and its preparation, can solve the problems of high manufacturing cost, cumbersome processing technology, and complicated cable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

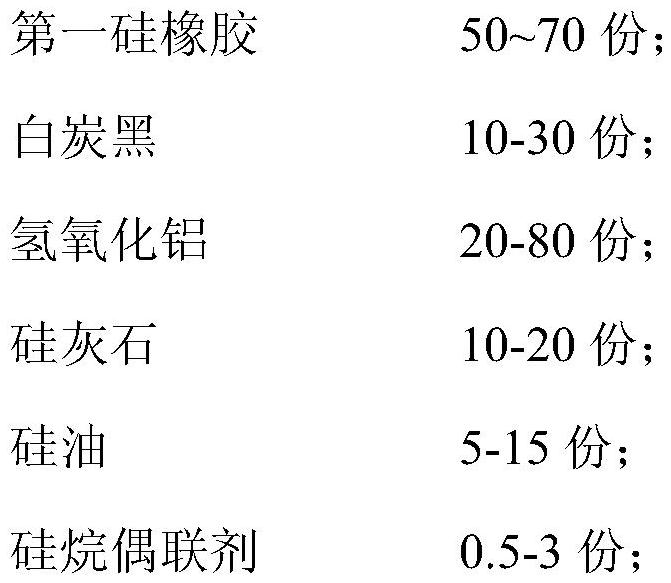

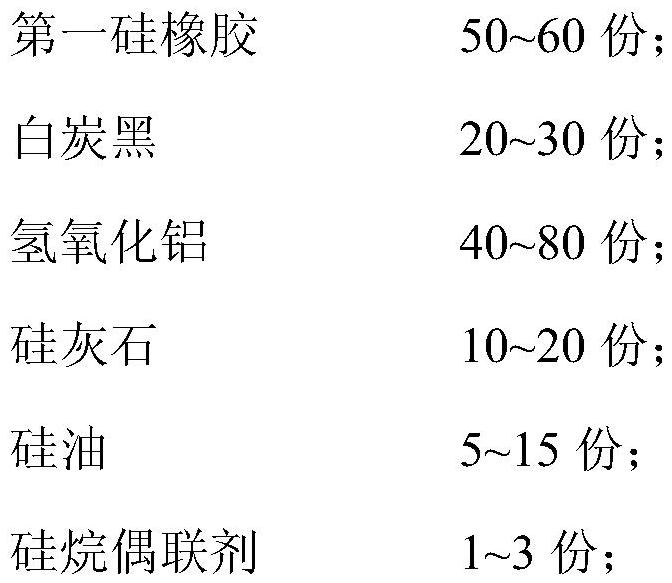

[0055] As a preferred embodiment, the raw materials of the fireproof and refractory silicone rubber material include the following components in parts by weight:

[0056] The raw materials of the A component include the following components in parts by weight:

[0057]

[0058] The raw materials of the B component include the following components in parts by weight:

[0059] 40-50 parts of the second silicone rubber;

[0060] 1-5 parts of magnesium oxide;

[0061] 20-30 parts of boric acid.

[0062] Another aspect of the present invention provides a method for preparing the fireproof and refractory silicone rubber material described in the first aspect of the present invention, the preparation method comprising: mixing the first silicone rubber, white carbon black, aluminum hydroxide, wollastonite, silicone oil, silane The joint agent is mixed to obtain the A component; the second silicone rubber, magnesium oxide, and boric acid are mixed to obtain the B component; and t...

Embodiment 1

[0082] Add 60 parts of the first silicone rubber 110-0 into the first kneader, knead for 10 minutes, then add 20 parts of white carbon black SJ-34, 50 parts of aluminum hydroxide, 20 parts of wollastonite 1250, 1.6 parts of even Joint agent A171, 8 parts of hydroxy silicone oil QLS-203, each addition needs to be kneaded for 15 minutes. It is -0.08Mpa; get the base glue A and cool it down.

[0083] Add 40 parts of the second silicone rubber 110-0 into the second kneader, knead for 10 minutes, then add 20 parts of boric acid and 3 parts of magnesium oxide in 3 times, and knead for 10 minutes each time. After forming a group, the base rubber B is obtained .

[0084] The base rubber A and the base rubber B are thoroughly mixed in a kneader to obtain the fire-resistant and refractory silicone rubber material described in this patent. Add 1.5 parts of vulcanizing agent Shuang24 into the fireproof and refractory silicone rubber material on the open mill, mix evenly, and make firepr...

Embodiment 2

[0086] Add 60 parts of the first silicone rubber 110-0 into the first kneader, knead for 10 minutes, then add 30 parts of white carbon black SJ-34, 50 parts of aluminum hydroxide, 20 parts of wollastonite 1250, 2 parts of even Joint agent A171, 10 parts of hydroxy silicone oil QLS-203, kneading for 15 minutes each time, after forming a lump; continue kneading and heat up to 130°C for vacuum heat treatment, the kneading temperature in the kneader is 160°C, the time is 1h, the vacuum degree It is -0.08Mpa; get the base glue A and cool it down.

[0087] Add 40 parts of the second silicone rubber 110-0 into the second kneader, knead for 10 minutes, then add 20 parts of boric acid and 3 parts of magnesium oxide in 3 times, and knead for 10 minutes each time. After forming a group, the base rubber B is obtained .

[0088] The base rubber A and the base rubber B are thoroughly mixed in a kneader to obtain the fire-resistant and refractory silicone rubber material described in this p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com