Energy-saving gap sealing type hydraulic cylinder and detection equipment applying same

A sealed, energy-saving technology, applied in the field of hydraulic cylinders, can solve the problems of increased energy consumption of hydraulic pumping stations, expansion and deformation of cylinder side walls, and reduced pressure difference of pistons, so as to reduce hydraulic leakage, reduce expansion deformation, The effect of reducing the gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

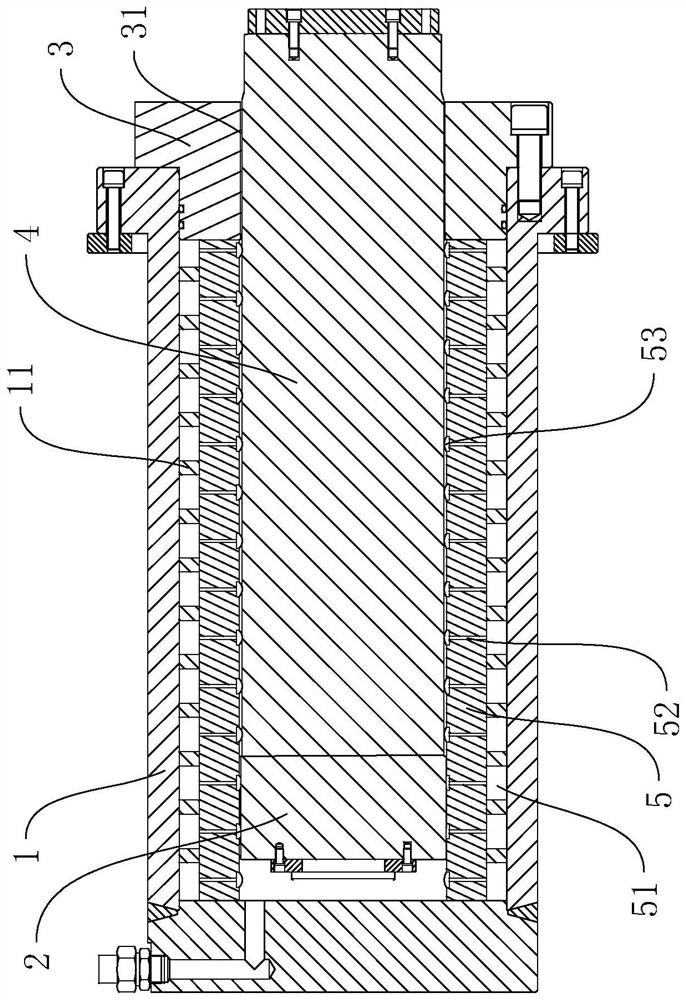

[0046] Embodiment 1 of the present application discloses an energy-saving gap-sealed hydraulic cylinder. refer to figure 1 The energy-saving gap-sealed hydraulic cylinder includes a cylinder 1, a cylinder head 3, a piston 2 and a piston rod 4. A bushing 5 is coaxially distributed inside the cylinder 1, and an annular cavity 51 is formed between the cylinder 1 and the bushing 5. , the bushing 5 is provided with a balanced pressure structure, the balanced pressure structure is used to increase the inner pressure of the annular chamber 51 and make it close to the hydraulic pressure in the bushing 5, so as to reduce the deformation of the bushing 5, so that the piston 2 can be connected with the bushing 5. The inner wall is closely matched to reduce the gap, so as to reduce the pressure difference between the two sides of the piston 2 caused by liquid leakage, and play an energy-saving role.

[0047] The cylinder barrel 1 is cylindrical, and the cylinder head 3 is circular. The cyl...

Embodiment 2

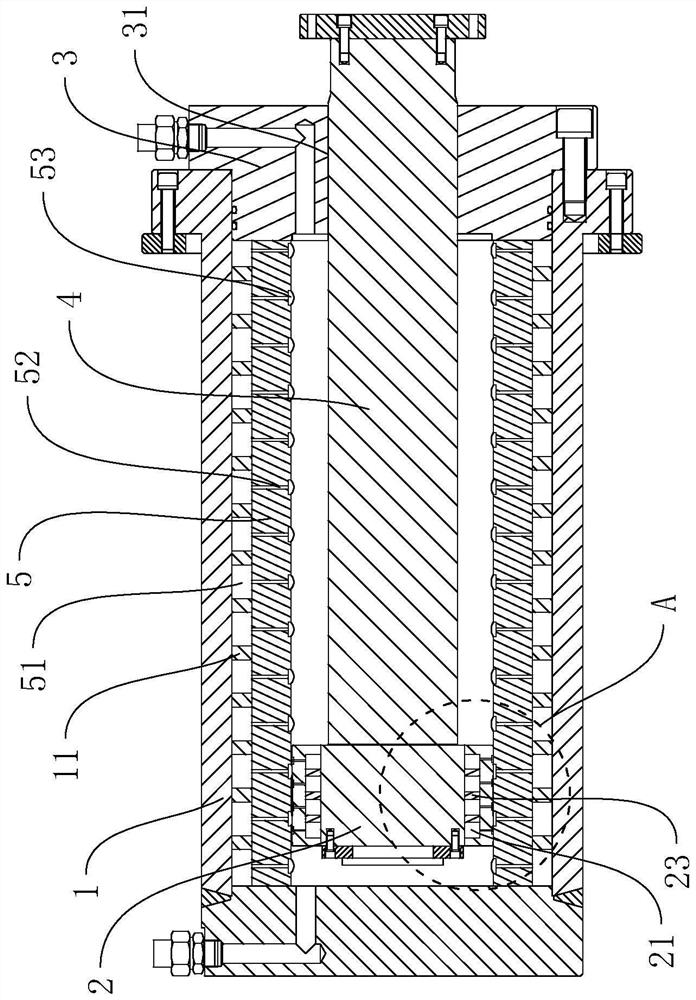

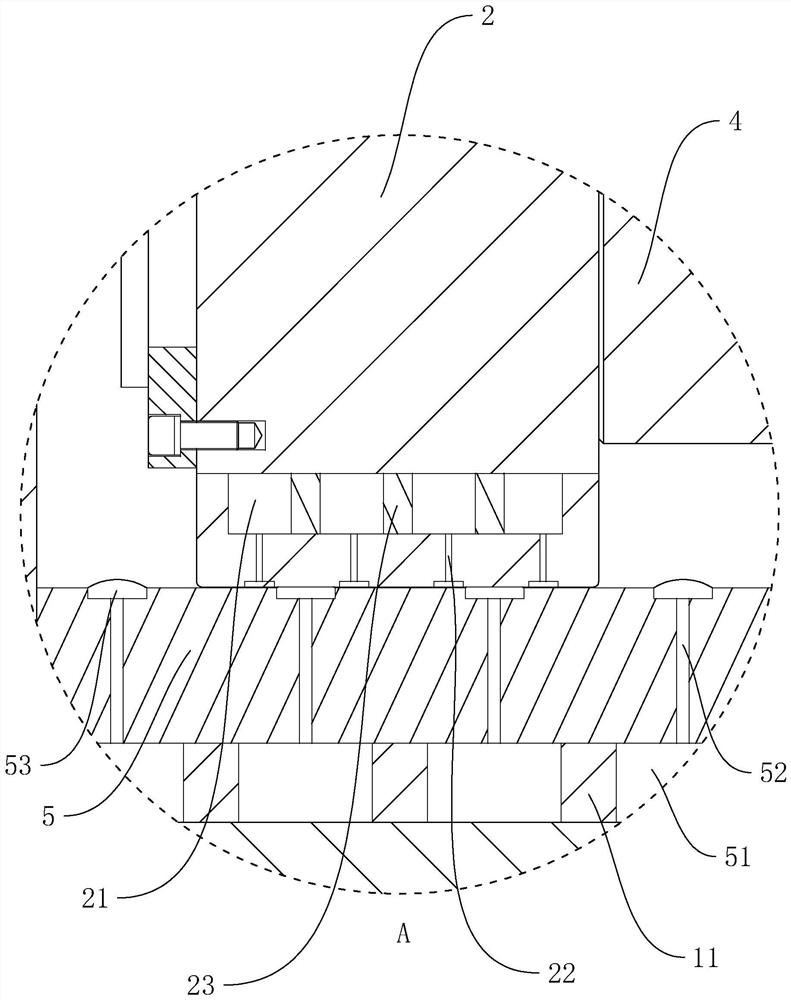

[0054] Embodiment 2 of the present application discloses an energy-saving gap-sealed hydraulic cylinder, referring to figure 2 , image 3 , the difference from Embodiment 1 is that this embodiment adopts a two-way hydraulic cylinder, the bottom end of the cylinder barrel 1 and the cylinder head 3 are provided with passages for the liquid to enter and exit, and the diameter of the piston 2 is greater than the diameter of the piston rod 4, so that the lining A chamber for liquid circulation is formed between the sleeve 5 and the piston rod 4 , and the expansion and contraction of the piston rod 4 can be realized by adjusting the hydraulic pressure of the liquid on both sides of the piston 2 .

[0055] There is a circular balance chamber 21 inside the piston 2. The central axis of the balance chamber 21 coincides with the central axis of the piston 2. There are multiple balance chambers 21 arranged axially along the piston 2. Between the multiple balance chambers 21 There is a ...

Embodiment 3

[0060] Embodiment 3 of the present application discloses a testing device, which includes a machine body on which the above-mentioned energy-saving gap-sealed hydraulic cylinder is installed. The testing equipment includes a hydraulic press, a force standard machine, etc., and is used to measure parameters such as product pressure resistance, quality, and torque. .

[0061] The implementation principle of Embodiment 3 of the present application is: the force input / output of the above-mentioned hydraulic cylinder is more accurate than that of rubber-sealed hydraulic cylinders and ordinary gap-sealed hydraulic cylinders, so as to improve the detection accuracy of the detection equipment and reduce the detection equipment. energy consumption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com