Air static pressure high-speed motorized spindle based on titanium-aluminum alloy mandrel

A high-speed motorized spindle, air static pressure technology, applied in metal processing equipment, metal processing mechanical parts, maintenance and safety accessories, etc., can solve the problem of limit speed limit, large steel spindle mass, low resonance frequency, etc., to reduce The effect of generating heat, improving bearing capacity and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

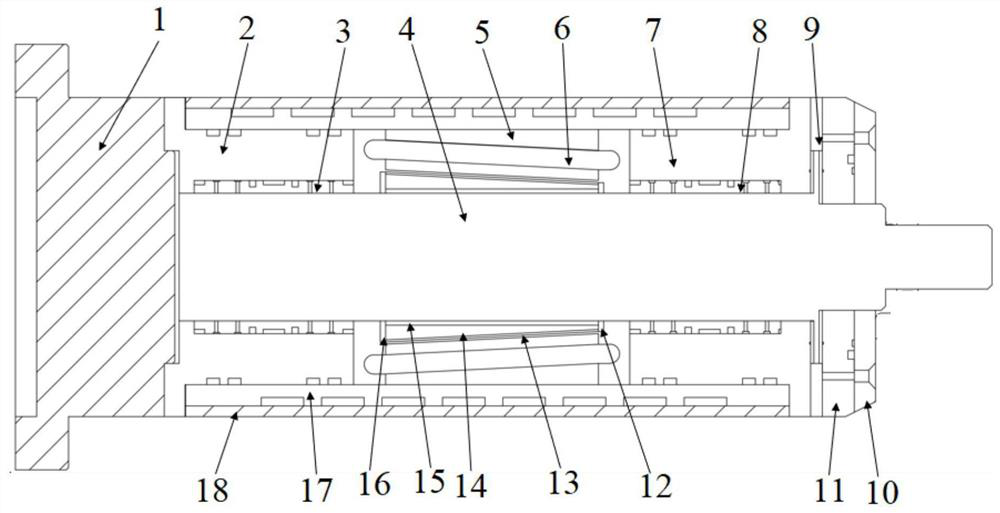

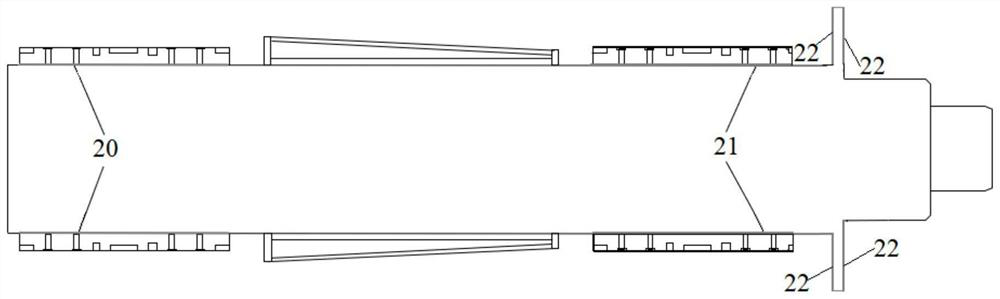

[0045] Such as Figure 1-Figure 2 As shown, this embodiment provides an aerostatic high-speed electric spindle based on a titanium-aluminum alloy mandrel, including a base 1, a housing 18, a mandrel 4, an axial air bearing 11, a support assembly, a cooling assembly, and a wedge motor assembly .

[0046] Specifically, the mandrel 4 is disposed on the base 1 , and the axial air bearing 11 is sleeved on the mandrel 4 and disposed at an end of the mandrel 4 away from the base 1 .

[0047] Titanium-aluminum alloy has low density, high specific strength and elastic modulus, the comprehensive performance index is better than traditional materials, and the toughness is higher than ordinary ceramic materials. Therefore, the choice of titanium-aluminum alloy as the material of the spindle can meet the requirements of the high speed of the spindle, and greatly improve the performance of the electric spindle of the machine tool. The mandrel 4 in this embodiment is made of titanium-alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com