Tunnel structure for expansible stratum

A tunnel structure and expansibility technology, which is applied in the field of traffic engineering, can solve problems such as large deformation of the tunnel base, difficult maintenance, cracking, etc., and achieve the effects of reducing expansion deformation, improving bearing capacity, and optimizing drainage system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in combination with specific embodiments.

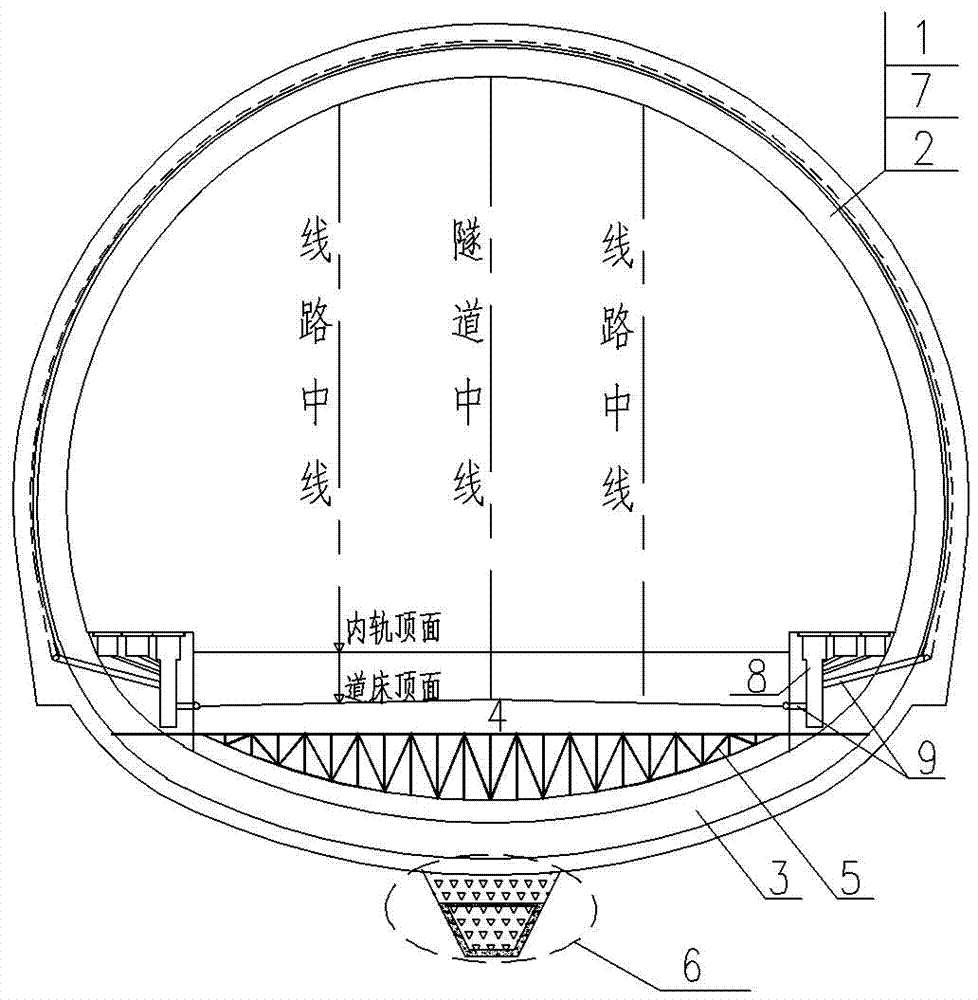

[0022] The invention relates to a tunnel structure for expansive formations, which comprises a steel frame shotcrete primary support 1, a reinforced concrete arch wall lining 2, an inverted arch 3 and an inverted arch filling 4. A waterproof layer 7 is arranged between the shotcrete primary support 1 of the steel frame and the lining 2 of the reinforced concrete arch wall.

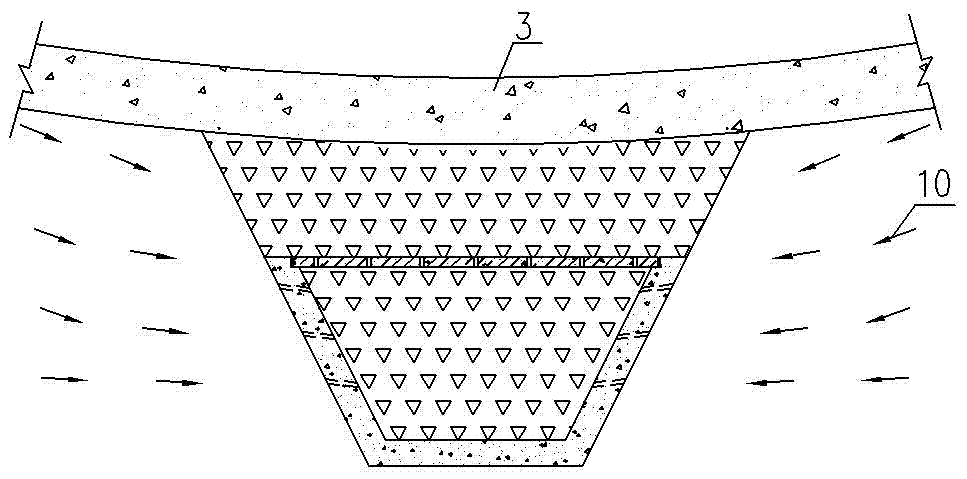

[0023] The present invention cancels the central ditch provided in the inverted arch filling 4, and a central seepage ditch 6 is arranged below the inverted arch 3. The central seepage ditch 6 is arranged along the longitudinal length of the tunnel, and the top surface of the ditch body is provided with a prefabricated reinforced concrete cover plate, and a water seepage layer is provided in the ditch body and above the prefabricated reinforced concrete cover plate, and a water seepage layer is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com