Electrode plate and battery

An electrode sheet and battery technology, which is applied to secondary batteries, non-aqueous electrolyte battery electrodes, circuits, etc., can solve the problems of small expansion space of wound electrode sheets, easy deformation of cells, and low storage capacity of cells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

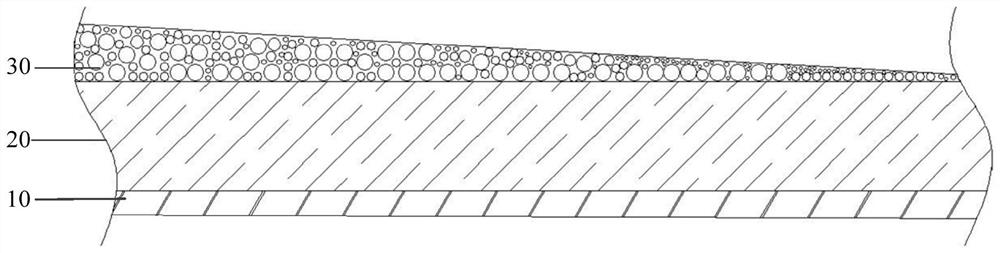

[0044] In this embodiment, the electrode sheet is a negative electrode sheet. The active material layer 20 is at least one of graphite, silicon, silicon oxide, and silicon carbon. The current collector 10 is copper foil. The bump layer 30 is composed of organic conductive particles and a binder, and the organic particles include at least one of conductive carbon black, polyethylene, polypropylene, polyacetylene, polypropylene, and polystyrene; the binder The binder is sodium carboxymethyl cellulose, polystyrene butadiene rubber, polyacrylic acid, styrene butadiene rubber SBR, nitrile rubber, butadiene rubber, modified styrene butadiene rubber, sodium polyacrylate PAANa, water-based polyacrylonitrile copolymer at least one of .

[0045] Furthermore, said A=5um, B=1um, and C=0.2um. Wherein, A represents the thickness of the protruding point layer 30 near the end of the tab 40, B represents the thickness of the protruding point layer 30 away from the end of the tab 40, and C r...

Embodiment 2

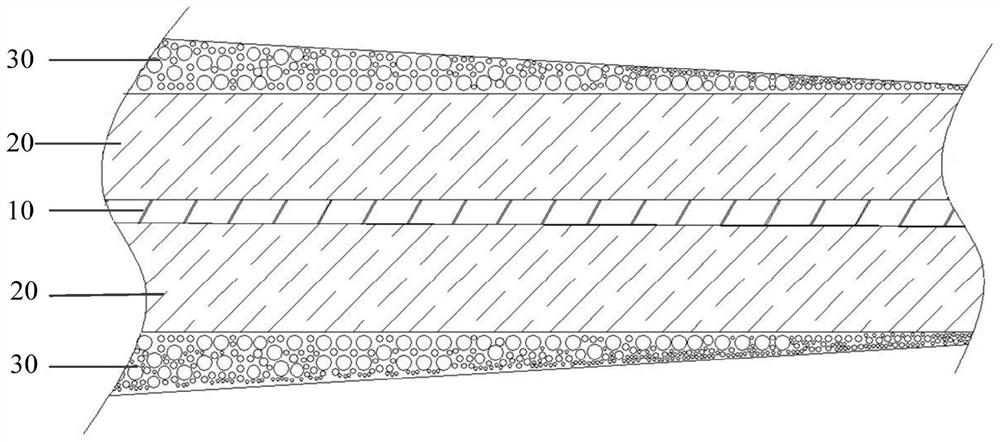

[0054] In this embodiment, the electrode sheet is a positive electrode sheet. The active material layer 20 is at least one of lithium cobalt oxide and lithium nickel cobalt manganese oxide. The current collector 10 is aluminum foil. The bump layer 30 is composed of organic conductive particles and a binder, and the organic particles include at least one of conductive carbon black, polyethylene, polypropylene, polyacetylene, polypropylene, and polystyrene; the binder The binder is polyvinyl difluoride.

[0055] Furthermore, said A=5um, B=1um, and C=0.2um. Wherein, A represents the thickness of the first end of the protruding point layer, B represents the thickness of the second end of the protruding point layer, and the first end of the protruding point layer is close to the first end of the current collector Set, the second end of the protruding point layer is set away from the first end of the current collector.

[0056] The preparation method of the negative electrode sh...

Embodiment 3

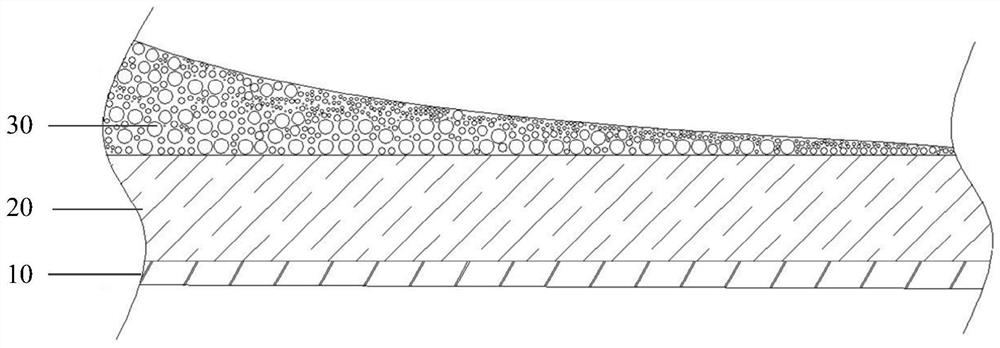

[0064] The electrode sheet in this embodiment is basically the same as the electrode sheet provided in Example 1, and the battery in this example is basically the same as the battery provided in Example 1. The difference is that in this example, the A=7um , B=1um, C=0.2um.

[0065] A cycle test was performed on the battery provided in Example 3. At 25°C, the battery was charged to the rated voltage at a rate of 1C and then discharged at a rate of 1C. Both charge and discharge were cut off at a rate of 0.05C, and the number of cycles was 600 times. The test results are shown in the table below, where the liquid retention capacity is determined by measuring the weight of the battery before liquid injection and after two seals:

[0066] Liquid retention (g) Energy density (Wh / L) Capacity retention Is the cycle battery deformed? 5.67 758 86.9% Undeformed

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com