Novel ceramic conical assembly equipped with annular spring

A ring spring and ceramic technology, which is applied in clamping/spring connection, X-ray tube parts, electrical components, etc., can solve the problems of new ceramic cone components and other problems, and achieve the effect of avoiding high temperature baking and avoiding failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in detail below in conjunction with the accompanying drawings.

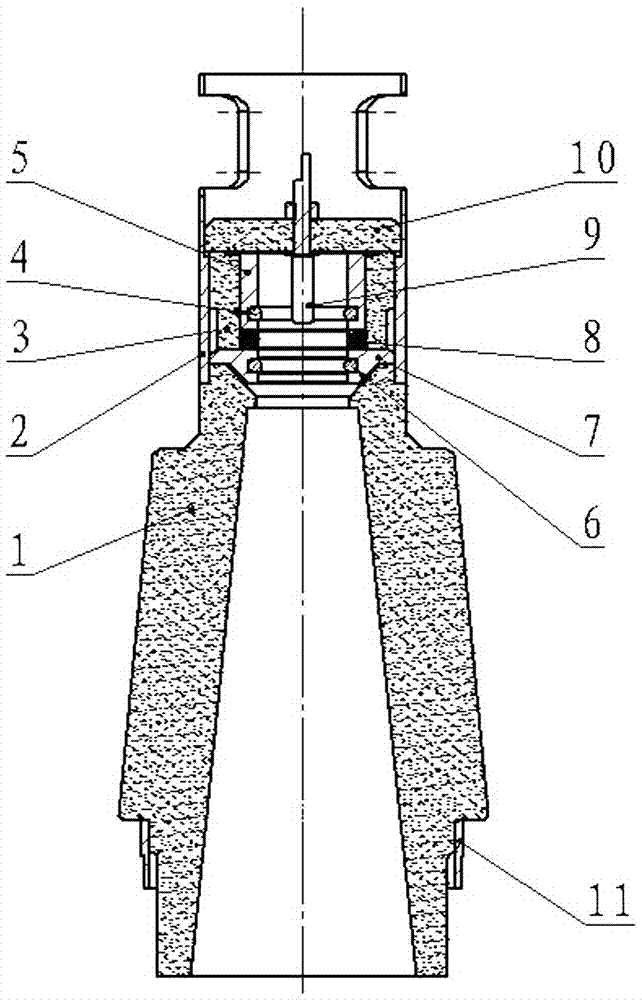

[0009] A new type of ceramic cone assembly equipped with a ring spring, such as figure 1 As shown, a ceramic cone 1 is arranged on the upper part of the ceramic cone assembly, a sealing sleeve 2 is arranged on the upper part of the ceramic cone 1, and an outer ceramic ring 3 is connected inside the sealing sleeve 2, and a large focal point is installed inside the outer ceramic ring 3. The conductive ring 5 is equipped with an annular spring 4 inside the large focal point conductive ring 5, and the inside of the sealing sleeve 2 is also provided with a common point conductive ring 7, and the inside of the common point conductive ring 7 is equipped with an annular spring 6, and the outer ceramic ring 3 An insulating ceramic ring 8 is arranged in the middle of the common point conductive ring 7, a fixed porcelain plate 10 is installed on the top of the outer ceramic rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com