Spheroidizing device and working method thereof

A technology of spheroidizing and weighing devices, which is applied in the direction of manufacturing tools, metal processing equipment, casting molten material containers, etc., can solve the problems of poor heat preservation effect, splashing of molten iron, waste, etc., to improve heat preservation effect and spheroidization effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

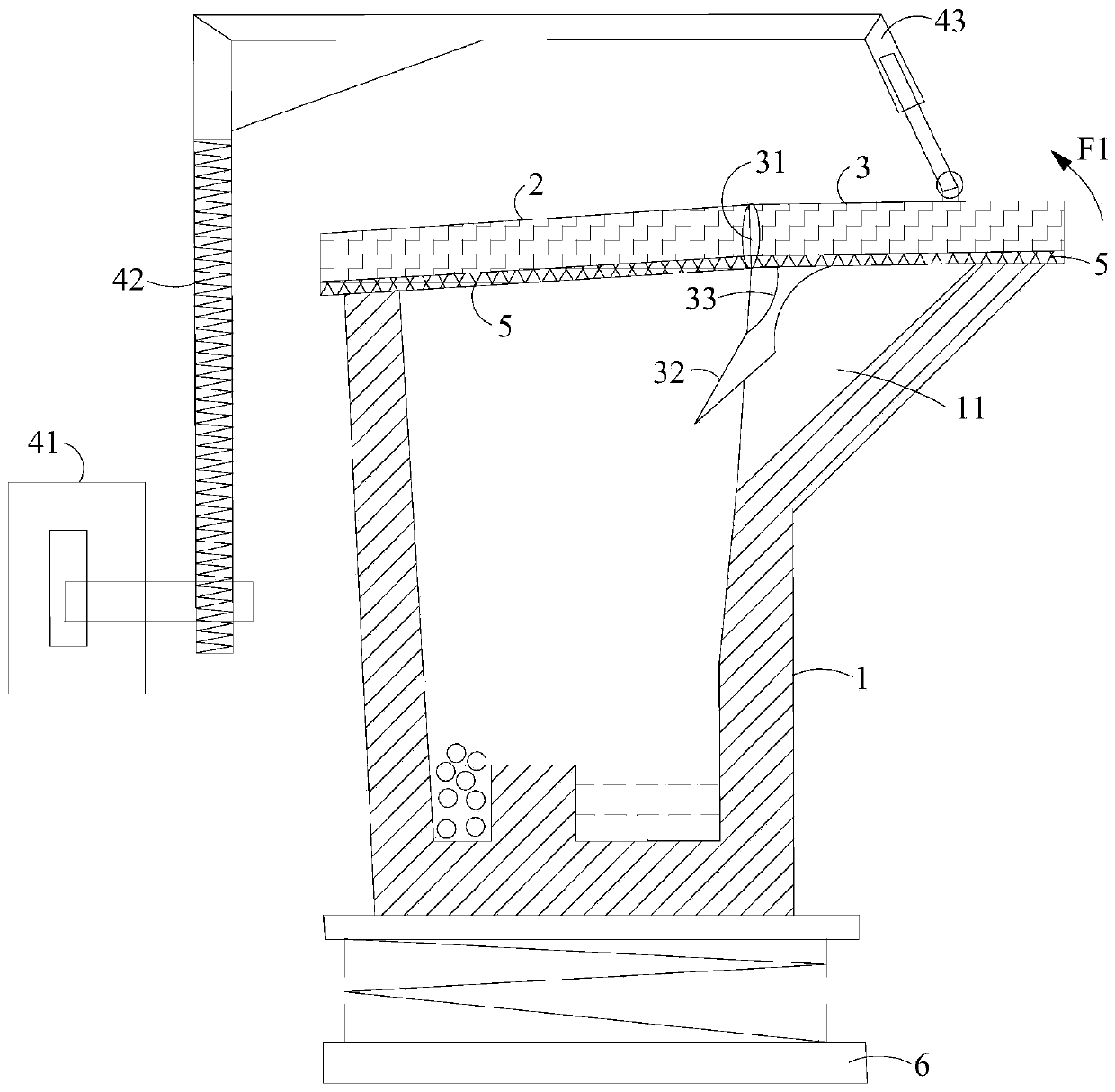

[0041] figure 1 It is a structural diagram of the spheroidizing device of the present invention.

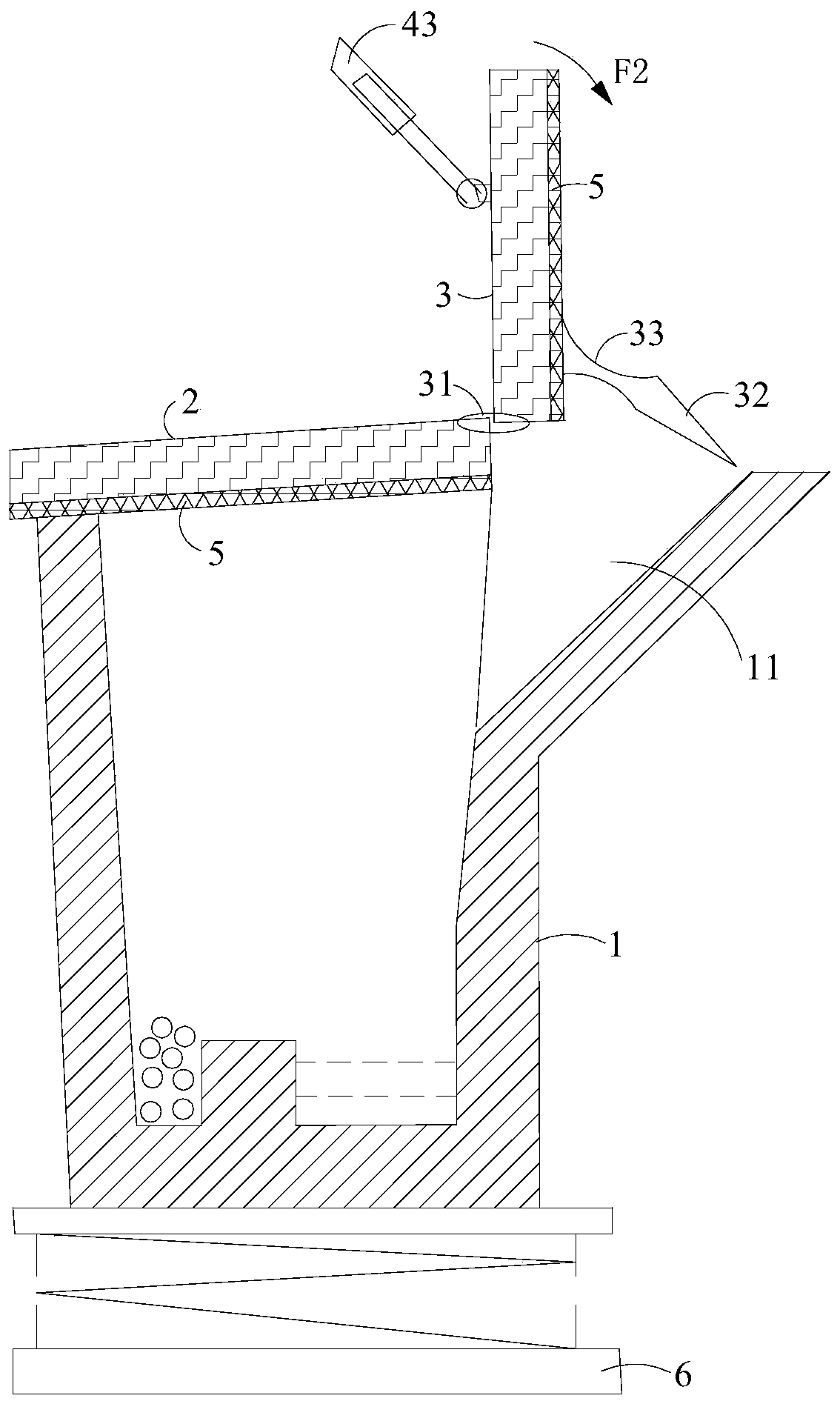

[0042] figure 2 It is the opening state diagram of the cap of the present invention.

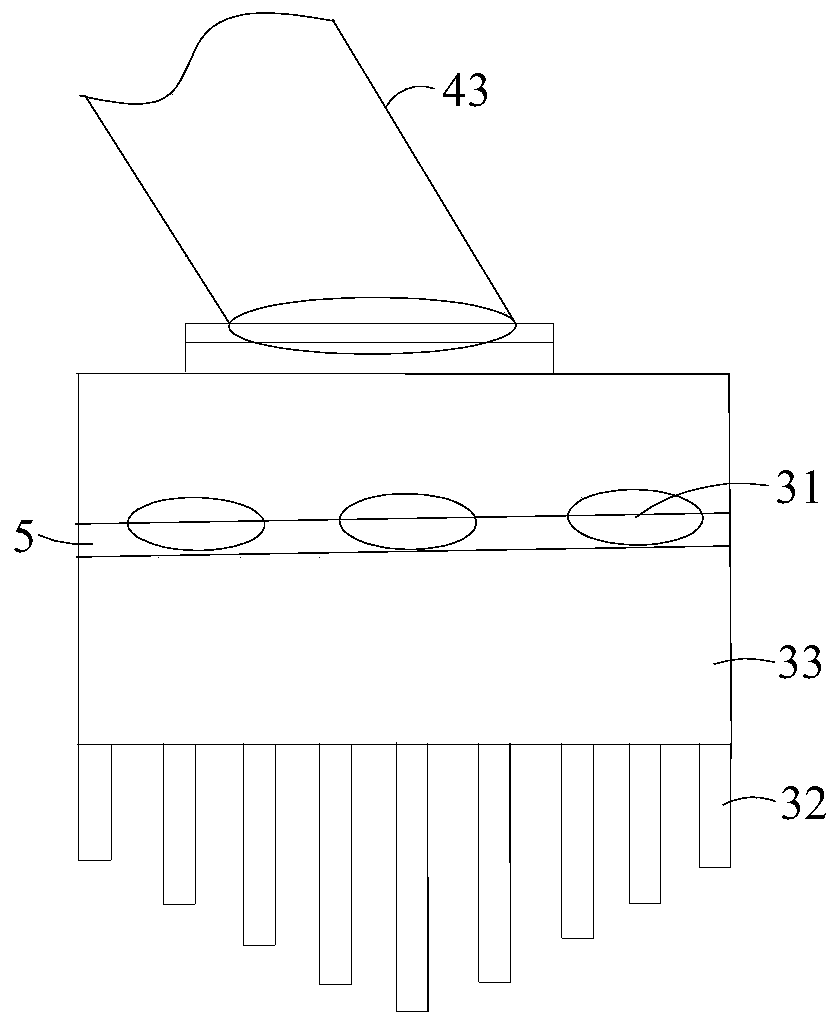

[0043] Such as figure 1 and figure 2 As shown, this embodiment provides a spheroidizing device, which includes a bag body 1, and the top cover of the bag body 1 and the inlet and outlet are respectively covered with a spheroidizing bag.

[0044] Wherein, the top cover of the spheroidizing bag includes: a cover body 2 covering the top of the bag body 1, a cap 3 covering the inlet and outlet 11 of the bag body 1, and a driving mechanism 4 suitable for driving the movement of the cap 3 , to open the inlet and outlet 11 of the bag body 1, so that molten iron can enter or flow out of the bag body 1 when pouring.

[0045] The top cover of the spheroidizing ladle of this embodiment is suitable for automatically opening the cap through a driving mechanism, so that molten iron enters or pours out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com