Preparation method of low-magnesium nodulizer

A low-magnesium nodularizing agent and technology of nodularizing agent, applied in the field of nodular cast iron, can solve the problems of increased amount of nodularizing agent, poor nodularizing treatment and high MgO content, improve the performance of nodular iron and reduce black slag defects , The effect of strong desulfurization and deoxidation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

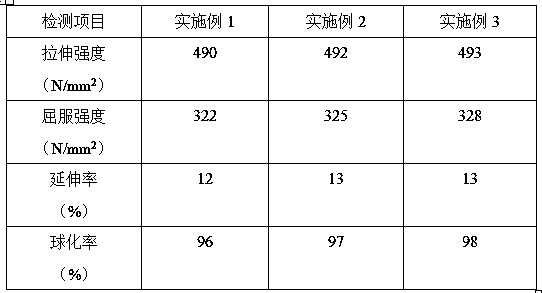

Embodiment 1

[0037] In parts by weight, weigh 40 parts of pure silicon powder, 8 parts of barium powder, 4 parts of zirconium powder, and 60 parts of iron powder, and place the pure silicon powder, barium powder, zirconium powder, and iron powder in a high-speed mixer, and Stir and mix at 1200r / min for 20min to obtain the inoculant germ powder, place the inoculant germ powder in a multifunctional melting furnace, raise the temperature from normal temperature to 1700 °C at a heating rate of 50 °C / min, and keep it for 1-2 hours to obtain Inoculant molten liquid, pour the inoculant molten liquid into a mold with a specification of 200mm×80mm×80mm while it is hot, place it in cold water to quench, take it out, and obtain the ferrosilicon alloy inoculant; and weigh them separately according to the number of parts by weight 80 parts of pure silicon powder, 8 parts of magnesium powder, 8 parts of yttrium powder, 16 parts of cerium powder, 4 parts of calcium powder, 80 parts of iron powder, 400 par...

Embodiment 2

[0039] In parts by weight, weigh 45 parts of pure silicon powder, 9 parts of barium powder, 4.5 parts of zirconium powder, and 70 parts of iron powder, and place the pure silicon powder, barium powder, zirconium powder, and iron powder in a high-speed mixer, and Stir and mix at a speed of 1400r / min for 25min to obtain the inoculant germ powder, place the inoculant germ powder in a multifunctional melting furnace, raise the temperature from normal temperature to 1750 °C at a heating rate of 50 °C / min, and keep it for 1.5 hours to obtain the inoculant Inoculant melt, pour the inoculant melt while hot into a mold with a specification of 200mm×80mm×80mm, place it in cold water to quench, take it out, and obtain the ferrosilicon alloy inoculant; then weigh 90 1 part of pure silicon powder, 9 parts of magnesium powder, 9 parts of yttrium powder, 18 parts of cerium powder, 4.5 parts of calcium powder, 90 parts of iron powder, 450 parts of absolute ethanol, pure silicon powder, magnesi...

Embodiment 3

[0041] In terms of parts by weight, weigh 50 parts of pure silicon powder, 10 parts of barium powder, 5 parts of zirconium powder, and 80 parts of iron powder, and place the pure silicon powder, barium powder, zirconium powder, and iron powder in a high-speed mixer, and Stir and mix at a speed of 1600r / min for 30min to obtain the inoculant germ powder, place the inoculant germ powder in a multifunctional melting furnace, raise the temperature from normal temperature to 1800 °C at a heating rate of 50 °C / min, and keep it for 2 hours to obtain the inoculant Molten liquid, pour the inoculant molten liquid into a mold with a specification of 200mm×80mm×80mm while it is hot, place it in cold water to quench, take it out, and obtain the ferrosilicon alloy inoculant; then weigh 100 parts by weight Pure silicon powder, 10 parts of magnesium powder, 10 parts of yttrium powder, 20 parts of cerium powder, 5 parts of calcium powder, 100 parts of iron powder, 500 parts of absolute ethanol, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com