Plasma-arc nodulizing device and method for iron-based intermediate alloy powder

An intermediate alloy and plasma arc technology, which is applied in the ion arc spheroidization device and the field of ion arc spheroidization, can solve the problems of uneven heating, low spheroidization efficiency, and high price, so as to improve the effect and solve the disordered input of powder concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

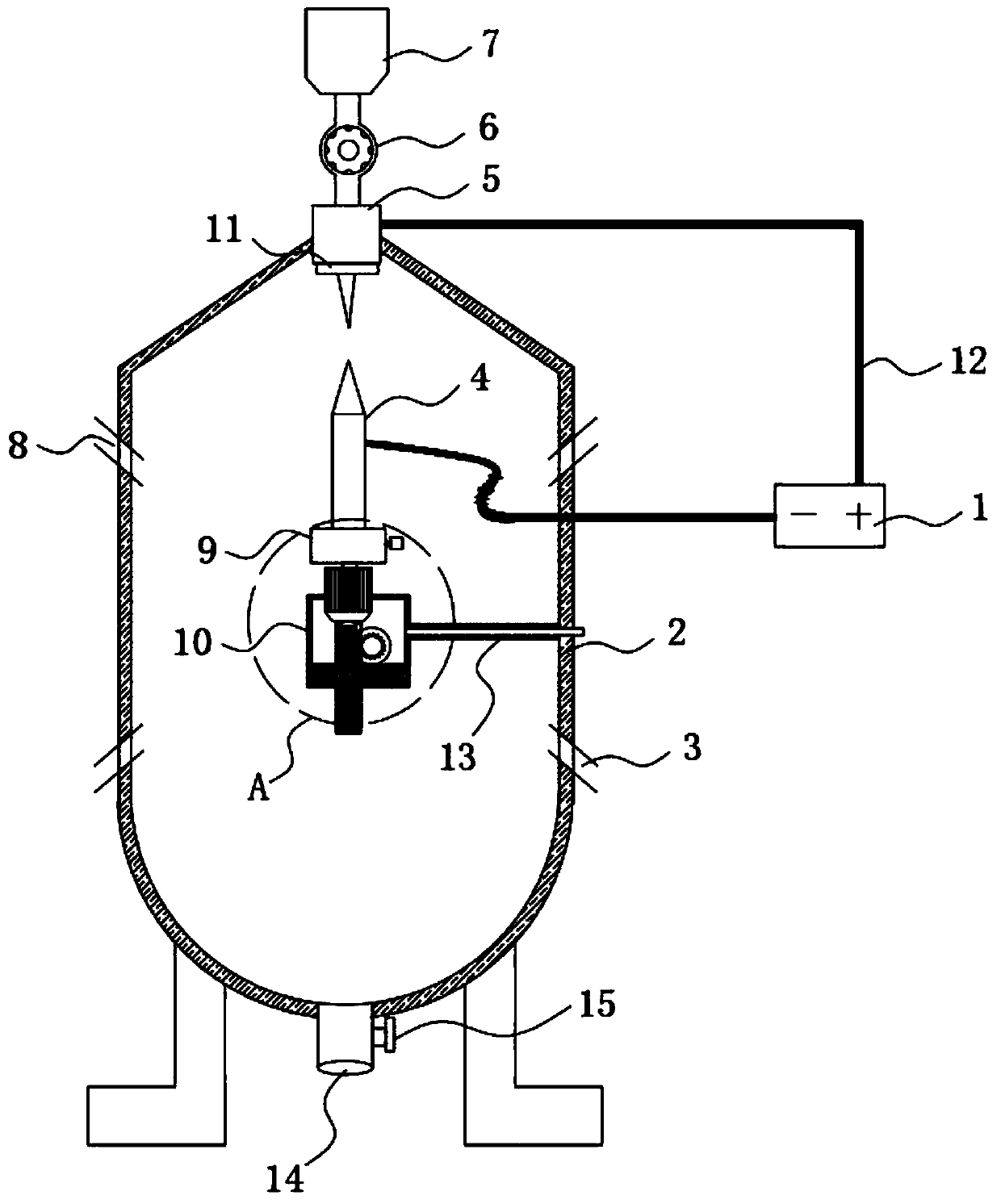

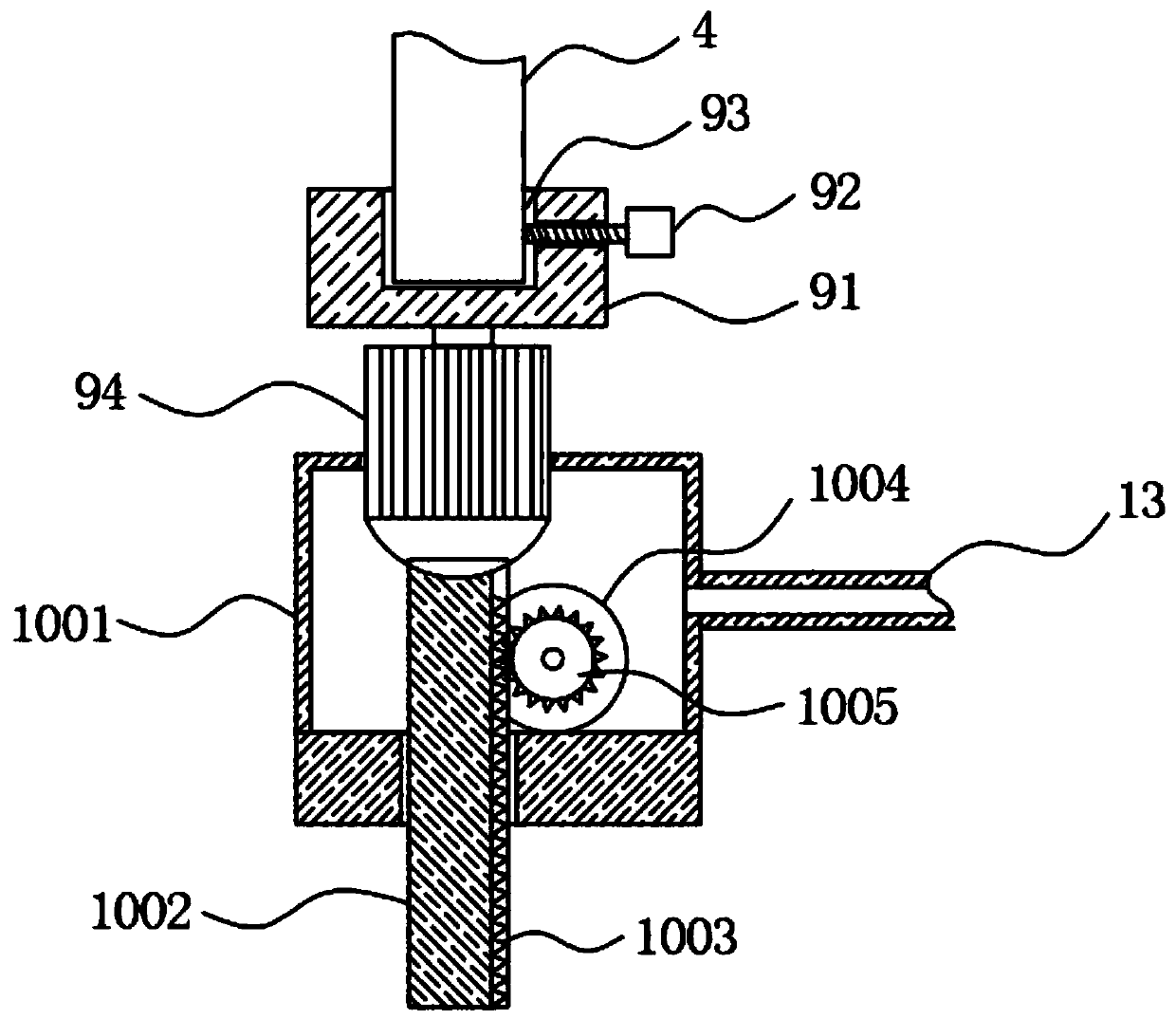

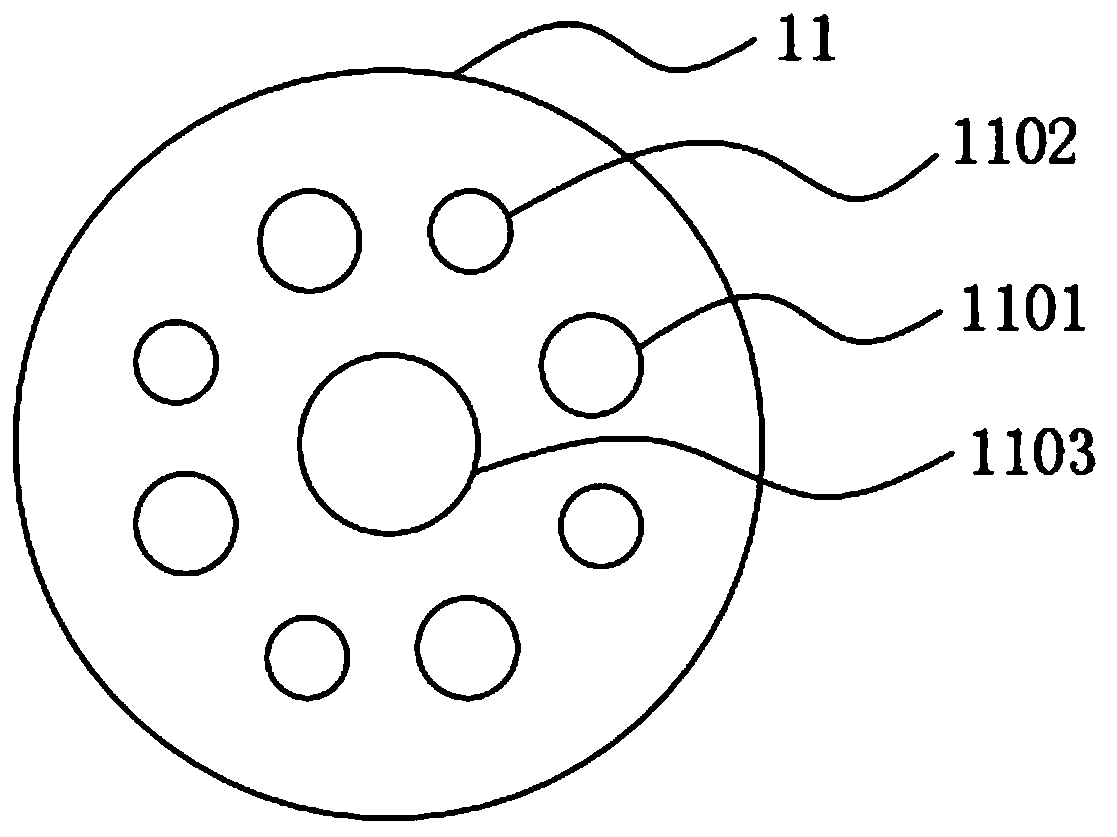

[0030] A plasma arc spheroidization device for iron-based master alloy powder, comprising an atmosphere reaction chamber 2 and a plasma arc power supply 1, a plasma arc spray gun 5 is fixedly installed on the top of the atmosphere reaction chamber 2, and the upper part of the plasma arc spray gun 5 is connected to There is a powder delivery mechanism 6, the upper end of the powder delivery mechanism 6 is connected with a powder hopper 7, the lower end of the plasma arc spray gun 5 is equipped with a porous powder dispersion outlet plate 11, and the upper side wall of the atmosphere reaction chamber 2 A cooling air inlet 8 is provided, and a cooling air outlet 3 is provided on the lower side wall of the atmosphere reaction chamber 2. The inner wall of the atmosphere reaction chamber 2 is fixedly connected with a lifting mechanism 10 through a hollow support plate 13, so that The upper end of the lifting mechanism 10 is equipped with a rotating clamping mechanism 9, and the upper...

Embodiment 2

[0042] Different from embodiment 1, the specific implementation process of embodiment 2 is as follows:

[0043] (1) Turn on the power, ignite the plasma arc, and set the current of the plasma arc power supply 1 to 85A; the plasma gas is argon, the flow rate of the plasma gas is 2L / min, and the pressure is 0.6MPa; the protective gas is argon and hydrogen according to The volume ratio is 2:1 to 4:1, and the flow rate of protective gas is 15L / min;

[0044] (2) Screen out ferroboron powder with a diameter of 180-220 mesh, put it in the powder hopper 7, and open the powder feeding gas cylinder, the flow rate of the powder feeding gas is 5L / min, turn on the power supply of the first motor 62, and the powder feeding speed 50~350g / min;

[0045] (3) The air in the atmosphere reaction chamber 2 is pumped to 0Mpa, and the cooling gas intake switch is turned on; the cooling gas is an inert gas, the temperature of the cooling gas is 5-10°C, and the flow rate of the inert gas is 85L / min; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com