High-quality wear resisting ball and preparation process thereof

A preparation process and technology of wear-resistant balls, applied in the field of wear-resistant balls, can solve problems such as low hardness and easy corrosion, and achieve the effects of uniform distribution, improved quality, and fine graphite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

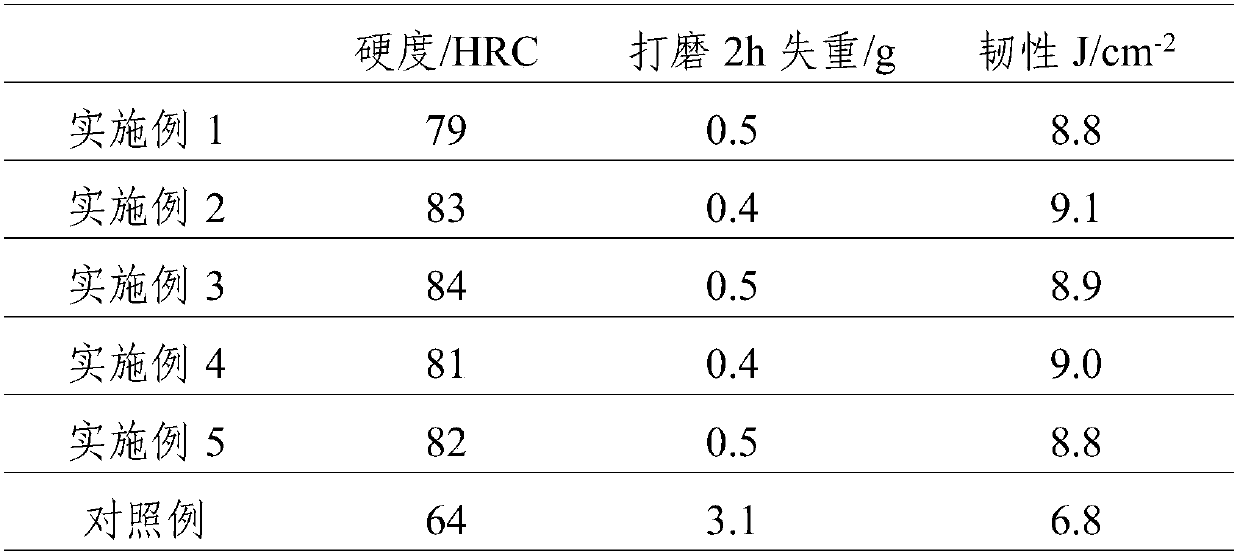

Examples

Embodiment 1

[0023] A high-quality wear-resistant ball, composed of the following elements: C: 2.6%, Si: 2.4%, Mn: 0.4%, Cr: 2.0%, Nd: 0.003%, Te: 0.01%, Cu: 0.05% , B: 0.005%, Zn: 0.1%, Sr: 0.04%, P≤0.05%, S≤0.05%, the balance is Fe;

[0024] The preparation process of the high-quality wear-resistant ball includes the following steps:

[0025] (1) Add pig iron, steel scrap, ferromanganese, ferrochrome, ferro-nd, sodium tellurate, brass, borax, ferro-zinc, ferro-strontium, recarburizer to the intermediate frequency induction furnace in turn, heat and smelt to obtain molten iron, and then carry out Static slag removal;

[0026] (2) Put yttrium-based heavy rare earth ferrosilicon alloy, ferrosilicon magnesium ingot, iron filings, barium, and calcium into the crusher for crushing and screening, then mix with light rare earth magnesium spheroidizer, and finally cold press to form composite balls spheroidizing agent, adjust the temperature of the molten iron to 1400°C, and add the obtained co...

Embodiment 2

[0031] A high-quality wear-resistant ball, composed of the following elements: C: 3.5%, Si: 1.5%, Mn: 0.9%, Cr: 1.5%, Nd: 0.01%, Te: 0.005%, Cu: 0.1% , B: 0.001%, Zn: 0.5%, Sr: 0.01%, P≤0.05%, S≤0.05%, and the balance is Fe.

[0032] The preparation process of the high-quality wear-resistant ball includes the following steps:

[0033] (1) Add pig iron, steel scrap, ferromanganese, ferrochrome, ferro-nd, sodium tellurate, brass, borax, ferro-zinc, ferro-strontium, recarburizer to the intermediate frequency induction furnace in turn, heat and smelt to obtain molten iron, and then carry out Static slag removal;

[0034] (2) Put yttrium-based heavy rare earth ferrosilicon alloy, ferrosilicon magnesium ingot, iron filings, barium, and calcium into the crusher for crushing and screening, then mix with light rare earth magnesium spheroidizer, and finally cold press to form composite balls spheroidizing agent, adjust the temperature of molten iron to 1430°C, and add the obtained com...

Embodiment 3

[0039] A high-quality wear-resistant ball, composed of the following elements: C: 2.7%, Si: 2.0%, Mn: 0.5%, Cr: 1.9%, Nd: 0.005%, Te: 0.008%, Cu: 0.07% , B: 0.004%, Zn: 0.2%, Sr: 0.03%, P≤0.05%, S≤0.05%, and the balance is Fe.

[0040] The preparation process of the high-quality wear-resistant ball includes the following steps:

[0041] (1) Add pig iron, steel scrap, ferromanganese, ferrochrome, ferro-nd, sodium tellurate, brass, borax, ferro-zinc, ferro-strontium, recarburizer to the intermediate frequency induction furnace in turn, heat and smelt to obtain molten iron, and then carry out Static slag removal;

[0042] (2) Put yttrium-based heavy rare earth ferrosilicon alloy, ferrosilicon magnesium ingot, iron filings, barium, and calcium into the crusher for crushing and screening, then mix with light rare earth magnesium spheroidizer, and finally cold press to form composite balls spheroidizing agent, adjust the temperature of molten iron to 1410°C, and add the obtained com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com