Modified graphene and application thereof in lubricating oil

A technology of graphene and lubricating oil, which is applied in the field of lubricating oil, can solve the problems of poor dispersion of graphene, achieve the effects of improving lubrication state, high thermal conductivity, and low friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

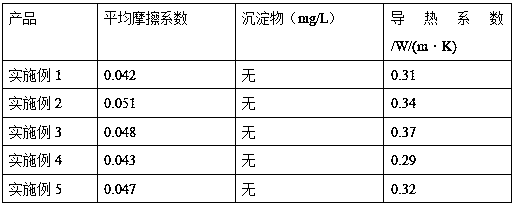

Examples

Embodiment 1

[0024] A modification method of graphene for lubricating oil, comprising the steps of:

[0025] (1) Add graphene oxide, ethanol and polyethylene glycol with a ratio of 1g:8mL:1mL into the ultrasonic reactor, and ultrasonically stir at room temperature for 1.5h to obtain a graphene dispersion;

[0026] (2) In the graphene dispersion, add a modifier consisting of coconut acid diethanolamide, octaphenyl clathrate silsesquioxane and rare earth coupling agent with a mass ratio of 2:1:1, the The addition of modifying agent is 4% of graphene weight, continues to carry out ultrasonic stirring and carries out surface modification, obtains modified mixed solution;

[0027] (3) After the modified mixed solution is filtered, the solvent is recovered and dried to obtain the modified graphene.

[0028] The application of the modified graphene in lubricating oil, the lubricating oil includes the following raw materials in parts by weight: 120 parts of PAO base oil, 1.2 parts of modified gra...

Embodiment 2

[0031] A modification method of graphene for lubricating oil, comprising the steps of:

[0032] (1) Add graphene oxide, ethanol and polyethylene glycol at a ratio of 1g:5mL:1.5mL into an ultrasonic reactor, and ultrasonically stir for 2 hours at room temperature to obtain a graphene dispersion;

[0033] (2) In the graphene dispersion, add a modifier consisting of coconut acid diethanolamide, octaphenyl clathrate silsesquioxane and rare earth coupling agent with a mass ratio of 1:1:1, the The addition of the modifier is 3% of the graphene weight, and the ultrasonic stirring is continued for surface modification to obtain a modified mixed solution;

[0034] (3) After the modified mixed solution is filtered, the solvent is recovered and dried to obtain the modified graphene.

[0035] The application of the modified graphene in lubricating oil, the lubricating oil includes the following raw materials in parts by weight: 150 parts of PAO base oil, 1.5 parts of modified graphene, 0...

Embodiment 3

[0038] A modification method of graphene for lubricating oil, comprising the steps of:

[0039] (1) Add graphene oxide, ethanol and polyethylene glycol at a ratio of 1g:10mL:0.5mL into an ultrasonic reactor, and ultrasonically stir for 1 hour at room temperature to obtain a graphene dispersion;

[0040] (2) In the graphene dispersion, add a modifier consisting of coconut acid diethanolamide, octaphenyl clathrate silsesquioxane and rare earth coupling agent with a mass ratio of 3:1:0.5, said The addition of modifying agent is 4.5% of graphene weight, continues to carry out ultrasonic stirring and carry out surface modification, obtains modified mixed solution;

[0041] (3) After the modified mixed solution is filtered, the solvent is recovered and dried to obtain the modified graphene.

[0042] The application of the modified graphene in lubricating oil, the lubricating oil includes the following raw materials in parts by weight: 100 parts of 500SN base oil, 0.5 part of modifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com