Efficient high-frequency vibration divergent plasma powder spheroidizing device and method and application thereof

A high-frequency vibration and divergent technology, applied in the field of materials, can solve the problems of uneven heating, low spheroidization efficiency, difficulty in large-scale and batch production, etc., and achieve the effect of low cost and improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

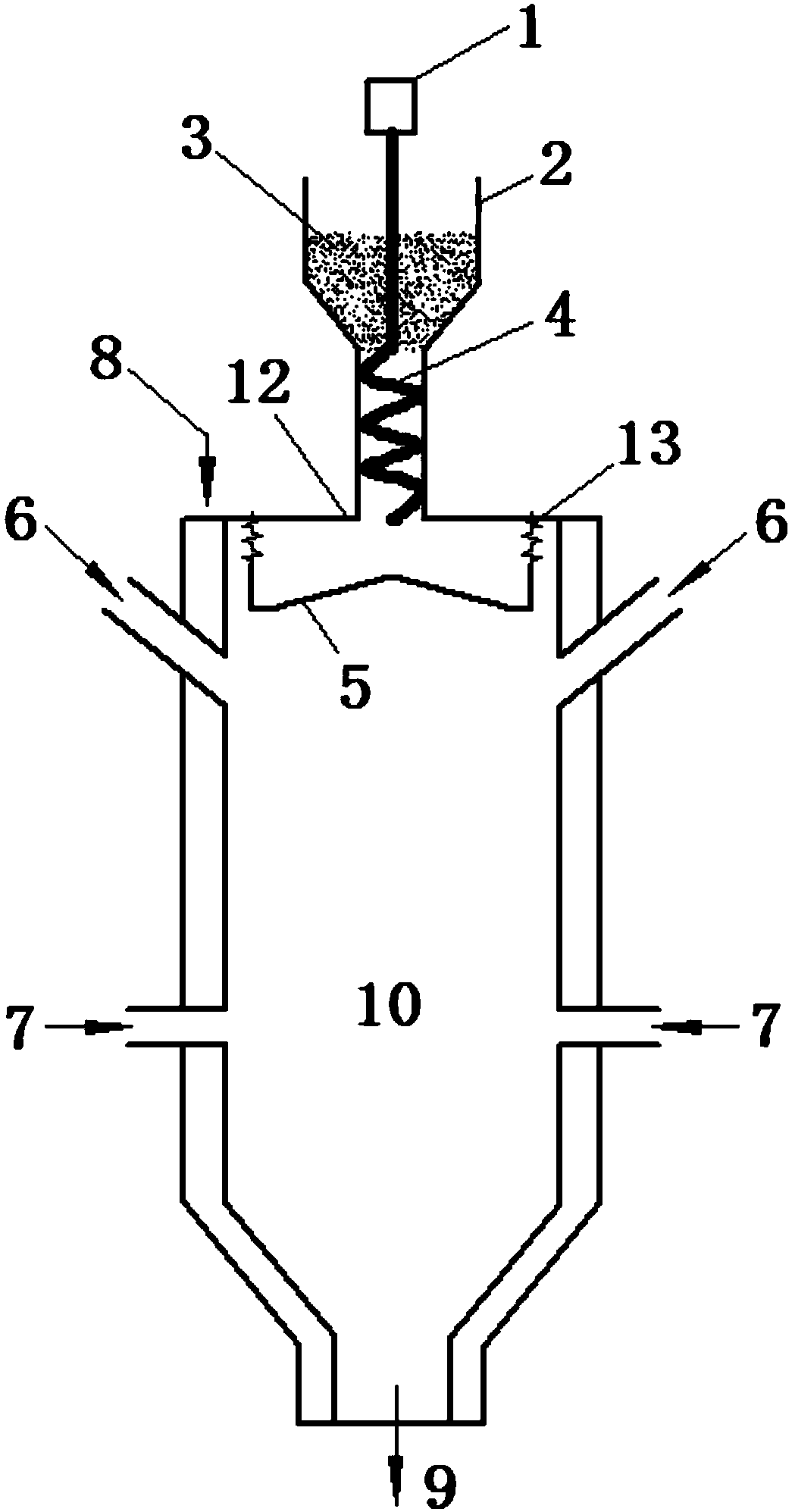

[0038] Example 1 High-efficiency high-frequency vibration divergent plasma powder spheroidization device

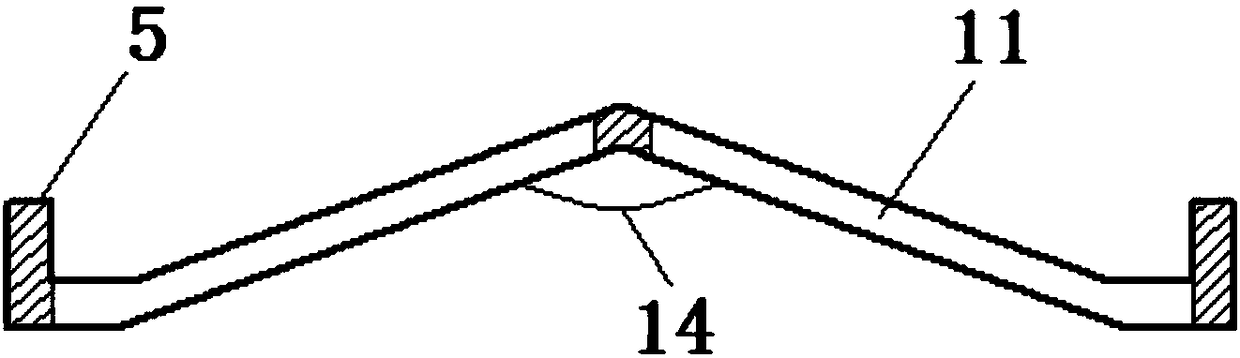

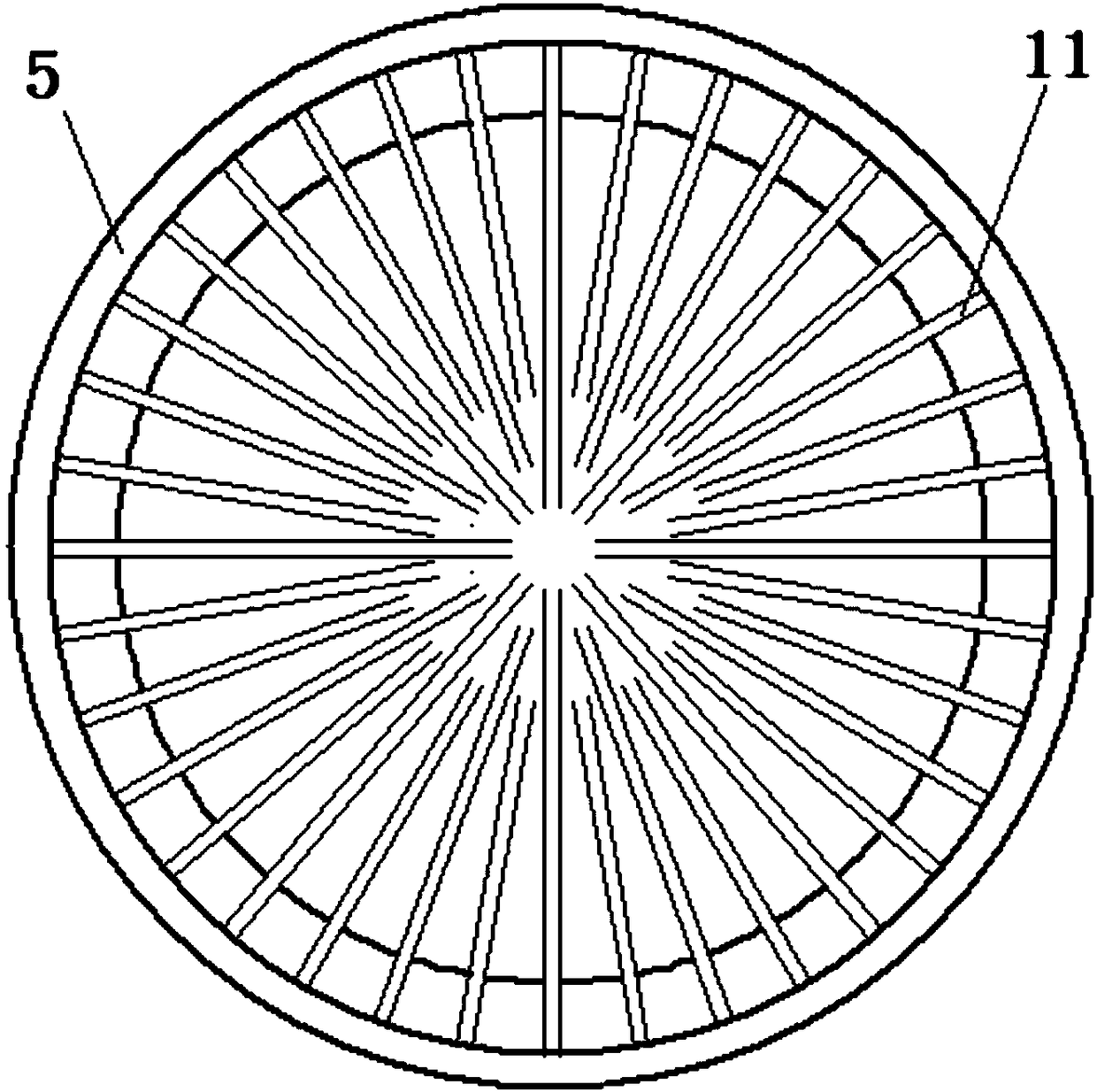

[0039] like figure 1 As shown, the high-efficiency high-frequency vibration divergent plasma powder spheroidization device of this embodiment includes a high-frequency vibration device, a powder dispersion cone 5 and a powder spheroidization device; the powder dispersion cone 5 and the high-frequency vibration device 13 pass The bolt connection is placed in the powder spheroidizing device, and the vibration frequency of the powder dispersion conical disc is the same as that of the high-frequency vibration device, wherein the high-frequency vibration device 13 includes the feeding port 2 and the conveying device from top to bottom, and the conveying device passes through the feeder Inside the feed port 2, it is set to convey powder into the powder spheroidizing device; the conveying device includes a speed-regulating motor 1 and a worm gear 4. The powder dispersing conica...

Embodiment 2

[0041] Embodiment 2 The use method of high-efficiency high-frequency vibration divergent plasma powder spheroidization device

[0042] This embodiment discloses the method of using the high-efficiency high-frequency vibration divergent plasma powder spheroidization device of embodiment 1, including the following steps:

[0043] S1. Add the powder with irregular shape to the feed port, and quantitatively transport the powder to the powder dispersion conical disk through the conveying device; the powder feeding speed is 100-1000g / min, and the powder in the powder dispersion conical disk passes through the powder dispersion cone The through-hole groove on the disk is input into the spheroidization chamber; the vibration frequency of the high-frequency vibration device is 1000-3000 Hz, and the vibration frequency of this embodiment is 2500 Hz.

[0044] S2. At the same time, the delivery pipe is fed into the plasma gas. The flow rate of the plasma gas is 2-5L / min. In this embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com