High thermal conductivity lubricating oil and preparation method thereof

A technology of lubricating oil and high thermal conductivity, applied in the field of lubricating oil, can solve the problems of inability to improve lubricity, anti-wear and anti-wear performance, decline in processing and use performance, and limit the application of graphene, so as to improve thermal conductivity and thermal conductivity. , The effect of reducing the coefficient of friction, reducing the coefficient of friction and the amount of wear of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

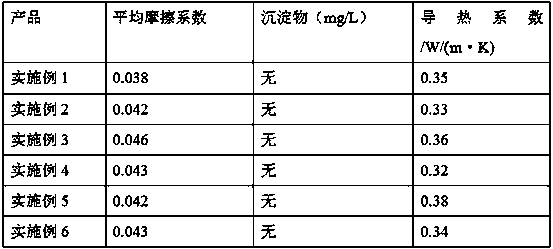

Examples

Embodiment 1

[0026] A high thermal conductivity lubricating oil, comprising the following raw materials in parts by weight: 120 parts of PAO base oil, 1.5 parts of modified graphene, 0.3 part of yttrium oxide, 0.5 part of boron nitride, 2 parts of polyethylene glycol dehydroabietic acid ester , 1.2 parts of succinate sulfonated hydrogenated castor oil, 1.5 parts of oleic acid diethanolamide borate, 1 part of defoamer, 1 part of lubricant and 0.8 part of 1010 antioxidant. The defoamer is composed of polyether-modified polysiloxane and polyoxyethylene polyoxypropanolamine ether with a mass ratio of 1:3. The lubricant is composed of castor oil polyoxyethylene ether and pentaerythritol palmitate with a mass ratio of 1:1.

[0027] The modified graphene is obtained through the following modification steps of graphene oxide:

[0028] (1) Add graphene oxide, ethanol and ethylene bisstearamide at a ratio of 1g:8mL:0.5mL into an ultrasonic reactor, and stir ultrasonically at room temperature for 1....

Embodiment 2

[0033] A high thermal conductivity lubricating oil, comprising the following raw materials in parts by weight: 150 parts of PAO base oil, 2.5 parts of modified graphene, 0.1 part of yttrium oxide, 0.3 part of boron nitride, and 2 parts of polyethylene glycol dehydroabietic acid ester , 1.5 parts of succinate sulfonated hydrogenated castor oil, 1 part of oleic acid diethanolamide borate, 1.2 parts of antifoaming agent, 1.2 parts of lubricant and 1.2 parts of 1076 antioxidant. The defoamer is composed of polyether-modified polysiloxane and polyoxyethylene polyoxypropanolamine ether with a mass ratio of 1:3. The lubricant is composed of castor oil polyoxyethylene ether and pentaerythritol palmitate with a mass ratio of 1:2.

[0034] The modified graphene is obtained through the following modification steps of graphene oxide:

[0035] (1) Add graphene oxide, ethanol and ethylene bisstearamide at a ratio of 1g:5mL:0.3mL into an ultrasonic reactor, and ultrasonically stir for 2 hou...

Embodiment 3

[0040] A high thermal conductivity lubricating oil, comprising the following raw materials in parts by weight: 100 parts of 500SN base oil, 1.5 parts of modified graphene, 0.5 parts of yttrium oxide, 0.2 parts of boron nitride, and 1.5 parts of polyethylene glycol dehydroabietic acid ester , 1 part of succinate sulfonated hydrogenated castor oil, 1.5 parts of oleic acid diethanolamide borate, 1 part of antifoaming agent, 1.5 parts of lubricant and 1 part of 1076 antioxidant. The defoamer is composed of polyether-modified polysiloxane and polyoxyethylene polyoxypropanolamine ether with a mass ratio of 1:4. The lubricant is composed of castor oil polyoxyethylene ether and pentaerythritol palmitate with a mass ratio of 1:1.

[0041] The modified graphene is obtained through the following modification steps of graphene oxide:

[0042] (1) Add graphene oxide, ethanol and ethylene bisstearamide at a ratio of 1g:10mL:0.5mL into an ultrasonic reactor, and stir ultrasonically at room te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com