Pipe die powder for centrifugally casting nodular cast iron pipe and preparation process thereof

A technology of ductile iron pipe and centrifugal casting, which is applied in the field of ductile iron pipe manufacturing, can solve the problems of increased casting defects of ductile iron pipes, low product yield, unreasonable particle size, etc., and achieve improved product quality, simple production process, and production efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

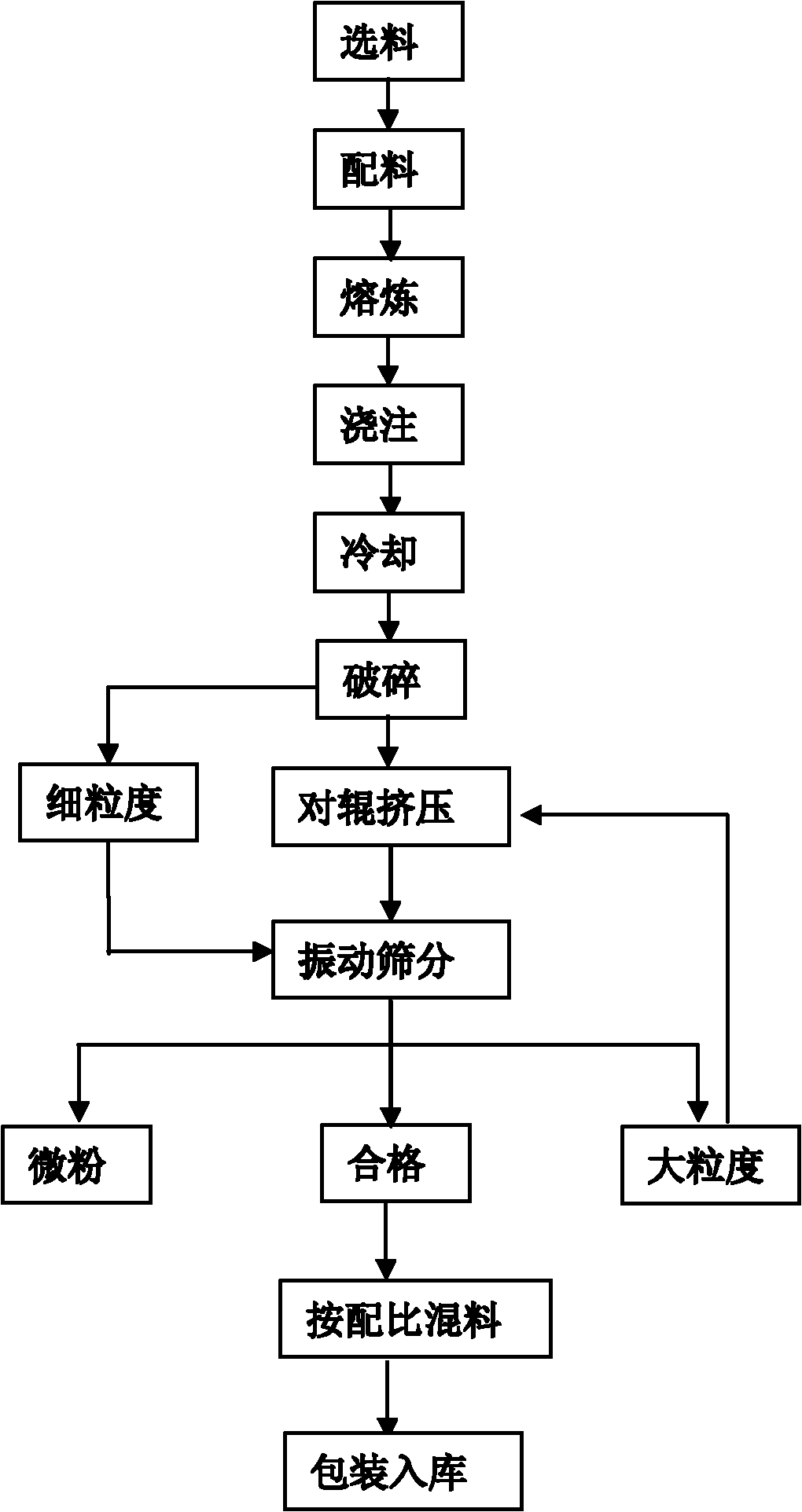

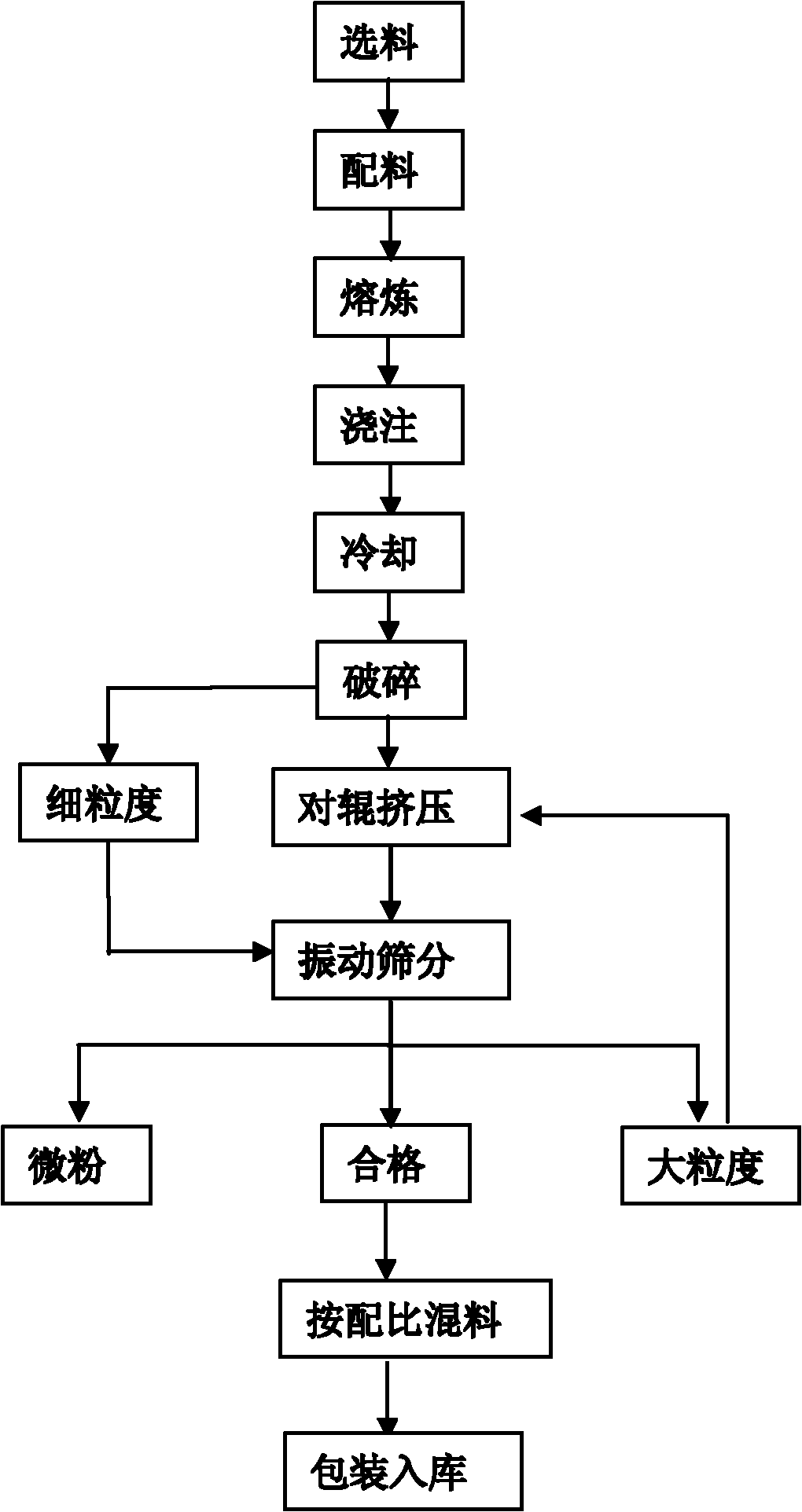

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0029] As shown in the accompanying drawings, the pipe mold powder preparation process of the present invention adopts a fusion method, and its specific steps are: batching, smelting, pouring, cooling, crushing, powder making, mixing according to particle size distribution, and vacuum packaging.

[0030] Further, scrap steel, ferrosilicon, silicon calcium, silicon barium, ferromanganese, pure magnesium ingot and pure aluminum ingot are used as raw materials in the batching step, and the batching is designed according to the composition content of the pipe mold powder with reference to the burning loss rate; intermediate frequency is used for melting Induction electric furnace, according to the order of steel scrap, ferrosilicon and calcium silicon, add ferromanganese, metal magnesium and metal aluminum before pouring; in the pouring step, after the alloy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com