Nodular cast iron and preparation method thereof

A technology for ductile iron and molten iron, applied in the field of ductile iron and its preparation, can solve the problems of limiting the application of ductile iron and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

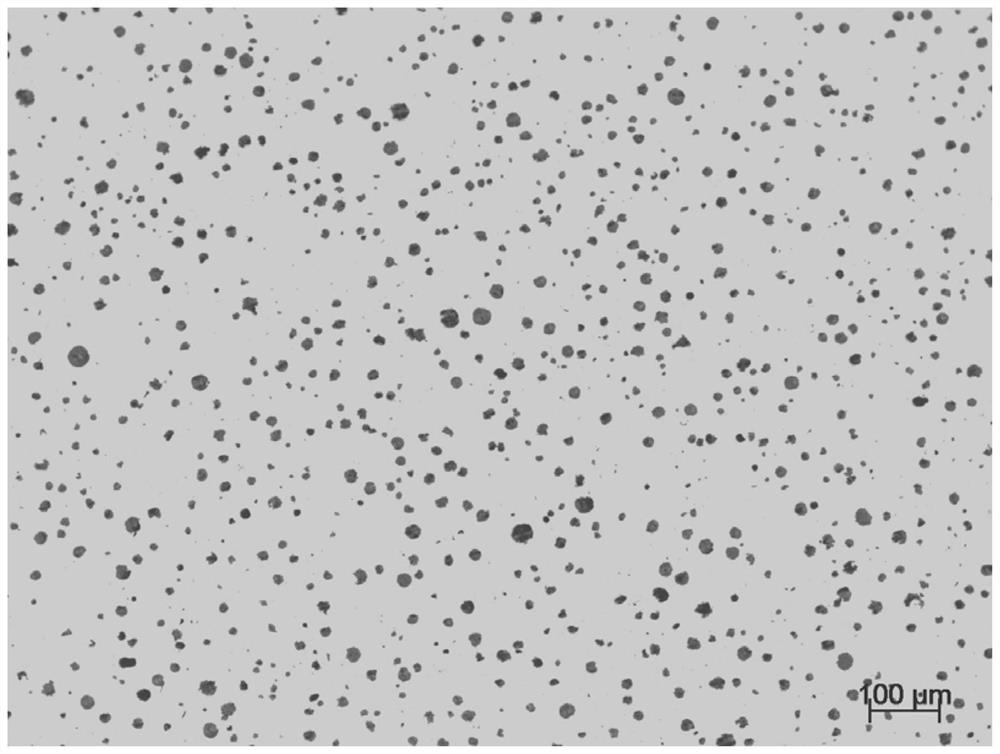

Image

Examples

preparation example Construction

[0039] An embodiment of the present invention also provides a method for preparing nodular cast iron, including the following steps S10-S40.

[0040] Step S10, providing raw materials for preparation and smelting into raw molten iron.

[0041] Step S20, performing desulfurization treatment on the original molten iron obtained in step S10 to obtain desulfurized molten iron.

[0042] Step S30, the desulfurized molten iron obtained in step S20 is spheroidized under the action of a rare earth ferrosilicon-magnesium alloy spheroidizer and a ferrosilicon inoculant; the molten iron after spheroidization is obtained; the quality of the ferrosilicon inoculant is 0.5wt% to 0.7wt% of the mass of molten iron; the mass of the rare earth silicon-iron-magnesium alloy nodulizer is 1.1wt% to 1.2wt% of the mass of the original molten iron;

[0043] The molten iron after spheroidization includes the following components: 3.5wt% to 3.9wt% C, 2.5wt% to 2.8wt% Si, 0.7wt% to 0.85wt% Cu, 0.001wt% to...

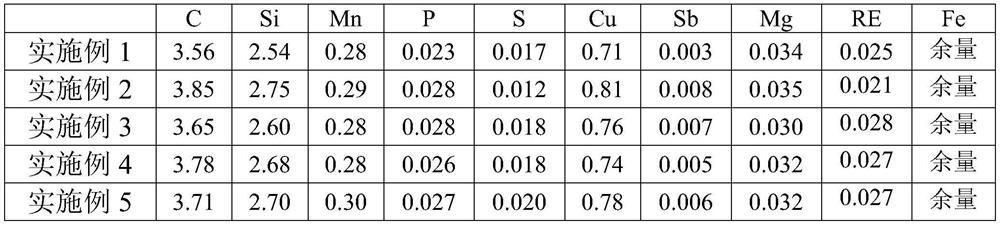

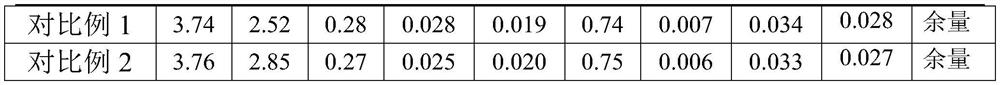

Embodiment 1

[0075] (1) Equipped raw materials: provide iron materials including high-purity pig iron, scrap steel and returned iron, antimony (grade SB-3), electrolytic copper, rare earth silicon-iron-magnesium alloy, 75SiFe. The raw materials are then smelted into raw molten iron, the composition of which is shown in Table 1.

[0076] (2) Desulfurization process: First, heat the desulfurization ladle thoroughly until the temperature inside the ladle is higher than 800°C, pour the original molten iron, hang the desulfurization stirring device, cover the mouth of the ladle, and cover it tightly. Then add a deep desulfurization agent (CaO-based desulfurization powder) from the feeding hole of the desulfurization stirring device, stir for 5 minutes, then lift the desulfurization stirring device, remove the slag on the liquid surface of the molten iron, and use the pouring spectrum analysis test block to analyze the sulfur content , the sulfur content of the molten iron is controlled to be le...

Embodiment 2

[0083] Example 2 is basically the same as Example 1, except that the composition of the original molten iron is different, as shown in Table 1. The composition of the prepared nodular cast iron is shown in Table 3.

[0084] Other processing parameters are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com