Nodulizer Companion

A technology of nodulizer and partner, which is applied in the field of nodulizer partner, can solve the problems of fast nodularization decline, few balls, and failure, and achieve the effects of improving anti-decay ability, increasing purification of molten iron, and increasing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

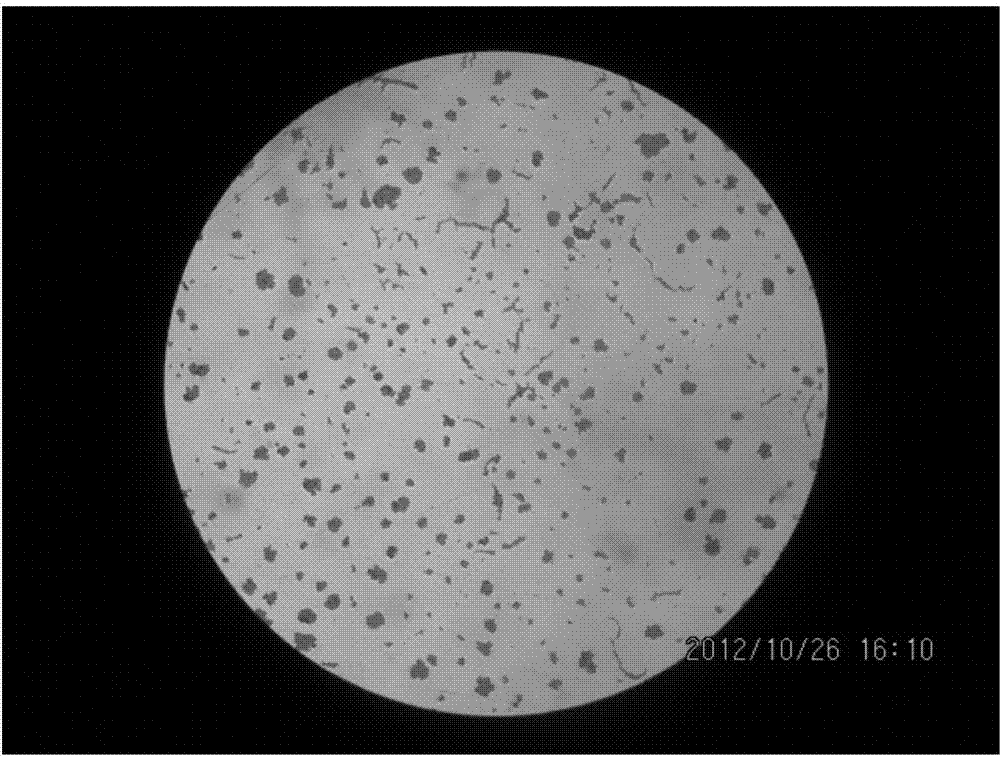

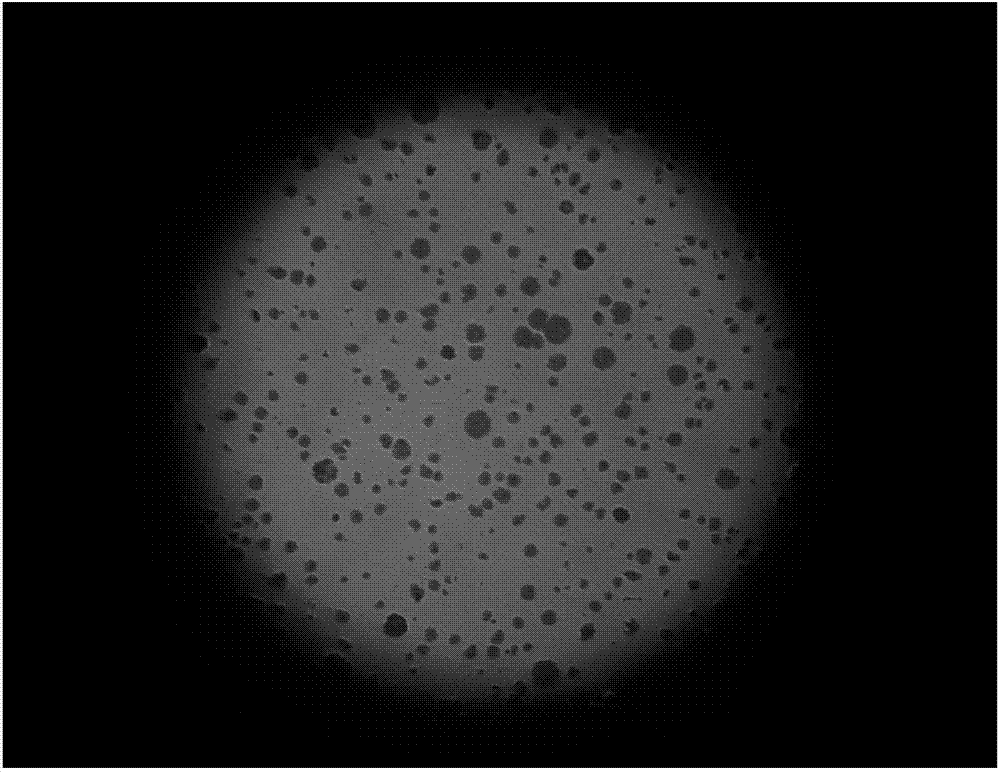

Image

Examples

Embodiment Construction

[0021] Nodulizer Companion and Preparation

[0022] Table 1 shows the composition of the nodulizer partners (Example 1, Example 2, Example 3) obtained by adopting the technical scheme of the present invention.

[0023] Table 1 Nodulizer Companion Components and parts by weight

[0024] Implementation

the form

Ba

Bi

Sb

La

Ce

Si

Fe

example 1

mixture

12

11

0

13

8

42

12

Example 2

mixture

11

6

10

14

9

40

9

Example 3

mixture

13

8

5

15

7

44

15

[0025] Example 1 is relatively suitable for small and medium ductile iron castings with a wall thickness of less than 40mm, and Example 2 is relatively suitable for large ductile iron castings with a wall thickness greater than 40mm.

[0026] Preparation method: select raw materials from metal bismuth, metal antimony, silicon barium, silicon element, lanthanum silicon, cerium si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com