Wheel hub of wind turbine generator system (WTGS)

A hub and wind power technology, applied in the field of wind turbines, can solve the problems affecting the use effect of the hub, the influence of the appearance quality of castings, and the inequality of cold iron, so as to ensure the integrity of the appearance, promote the graphitization effect, and reduce the production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Mold manufacturing: In order to achieve the wall thickness in line with the requirements of the drawings, and at the same time facilitate the controllability of the solidification process during pouring, and avoid the occurrence of shrinkage porosity and shrinkage defects, all our molds use CNC machining centers (industry conventional technology ) manufacturing, to ensure that the wall thickness tolerance of the casting is within 2mm, and there is no artificial manufacturing of new hot pitch circles;

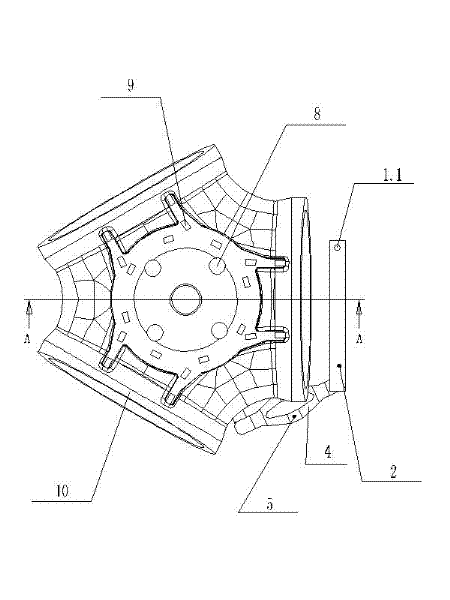

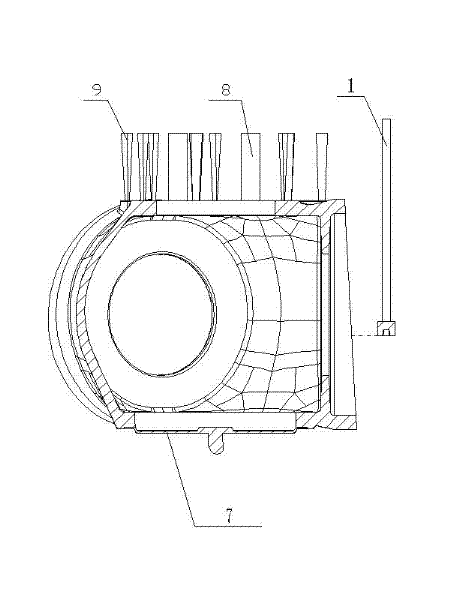

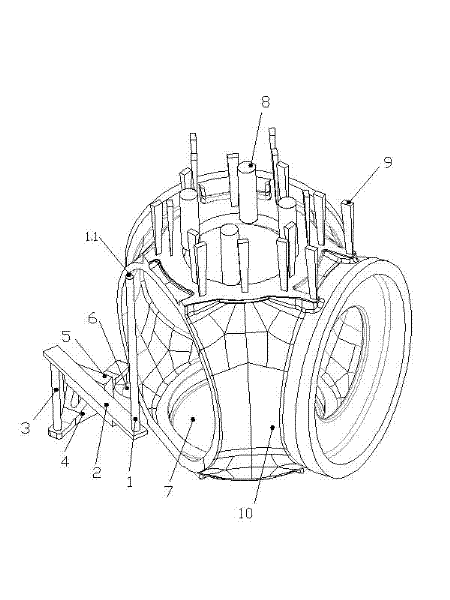

[0025] (2) Sand mold manufacturing: a fully open bottom pouring gating system is adopted, the inner runner 7 is designed as an inverted cone shape with a width of 20mm and a circle of draped seams, and the sprue 1.1 at the upper end of the upper sprue 1 is poured with quantitative package plugging At the highest point of the casting 10, place an appropriate amount of flat air outlet 9 (rectangular air outlet, used to discharge the gas in the mold), and the ratio of eac...

Embodiment 2

[0029] The chemical composition of the prepared sample is: carbon (the carbon equivalent is controlled at 4.65) 3.9%, silicon 2.3%, manganese 0.16%, phosphorus 0.015%, sulfur 0.014%, magnesium 0.05%, tin 0.08%, rare earth 0.025%, the preparation method is the same as the example 1.

Embodiment 3

[0031] The chemical composition of the prepared sample is: carbon (the carbon equivalent is controlled at 4.65) 3.85%, silicon 2.18%, manganese 0.15%, phosphorus 0.019%, sulfur 0.013%, magnesium 0.045%, tin 0.075%, rare earth content 0.02%, and the balance is iron .

[0032] The preparation method of embodiment 2-3 is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com