Method for spheroidizing inoculation treatment of large-scale wind power casting

A technology of spheroidizing inoculation and wind power, which is applied in the field of spheroidizing inoculation of large-scale wind power castings to achieve the effects of saving production costs, improving inoculation effect and efficiency, and reducing operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

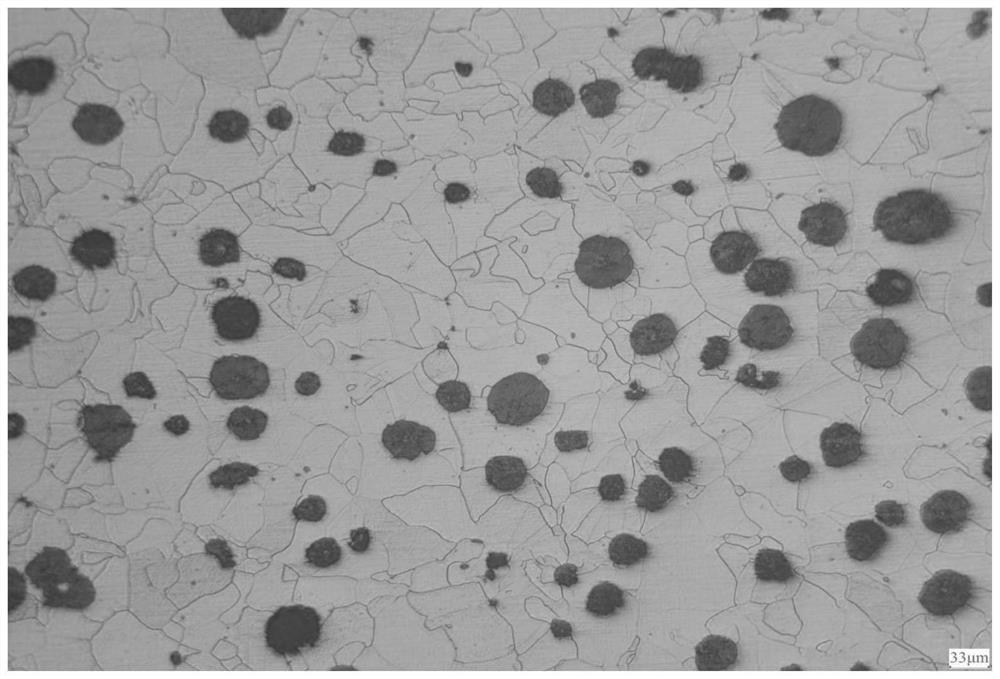

Image

Examples

Embodiment 1

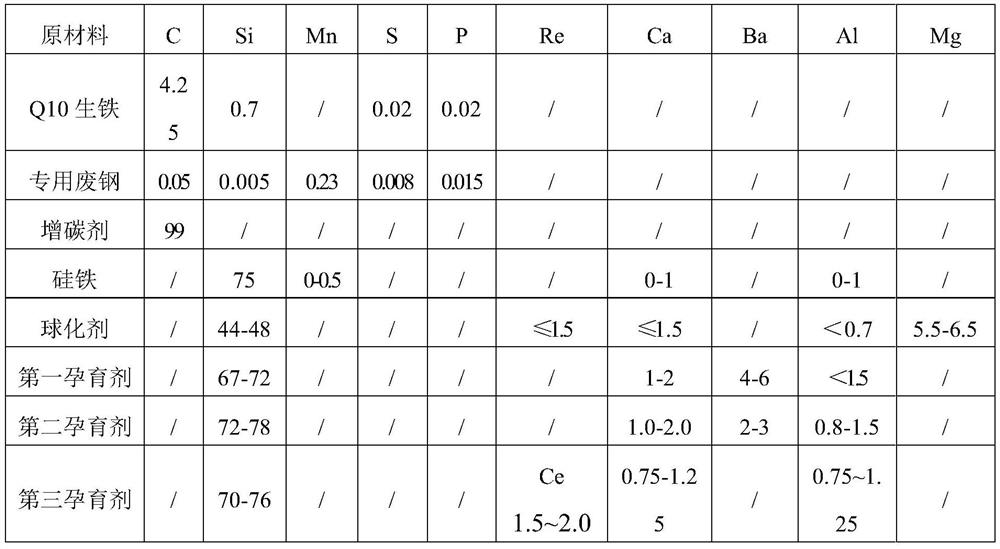

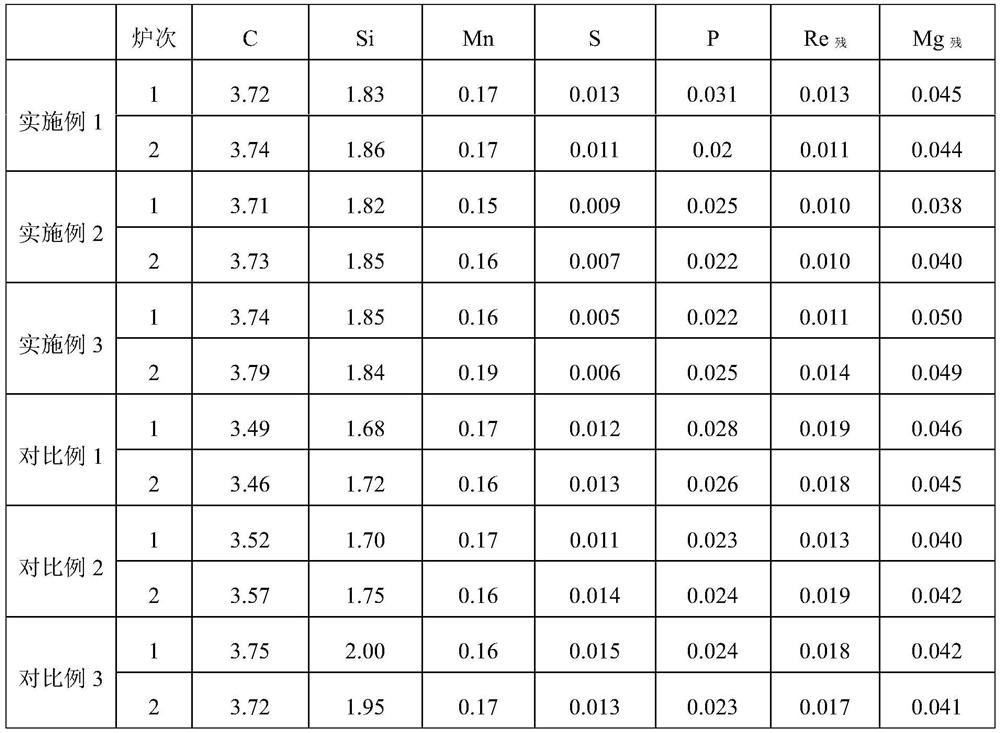

[0027] The method for spheroidizing inoculation treatment of castings for wind power in this embodiment includes the following steps:

[0028] S1. Charge selection: use 70wt% Q10 pig iron and 30wt% special scrap steel as raw materials, then add 1wt% recarburizer and 0.54wt% 75 ferrosilicon;

[0029] S2, the charge in step S1 is placed in a smelting furnace for smelting, and the molten iron temperature is controlled to be 1500±20°C;

[0030] S3, spheroidizing inoculation treatment: set a spheroidizing embedding chamber on the bottom side of the ladle, first place 1.4wt% spheroidizing agent and 0.006wt% antimony alloy in the spheroidizing process. At the bottom of the embedding chamber, add the inoculant slow-release ball A, and cover the silicon steel sheet; a circle of first bosses is arranged on the inner side wall of the middle part of the ladle, and a number of first bosses are placed on the first bosses. Inoculant sustained-release ball B; a circle of second bosses is arr...

Embodiment 2

[0036] The method for spheroidizing inoculation treatment of castings for wind power in this embodiment includes the following steps:

[0037] S1. Charge selection: use 60wt% Q10 pig iron and 40wt% scrap steel as raw materials, then add 1.45wt% recarburizer and 0.48wt% 75 ferrosilicon; the components of the Q10 pig iron, scrap steel, recarburizer, and 75 ferrosilicon are the same as The same in embodiment 1;

[0038] S2, the charge in step S1 is placed in a smelting furnace for smelting, and the molten iron temperature is controlled to be 1500±20°C;

[0039] S3, spheroidizing inoculation treatment: a spheroidizing embedding chamber is set on the bottom side of the ladle, firstly adding 0.6wt% of the first spheroidizer, 0.6wt% of the second spheroidizer, 0.6wt% of the molten iron in step S2, 0.002wt% antimony alloy was placed at the bottom of the spheroidized embedding chamber, then inoculant slow-release ball A was added, and a silicon steel sheet was covered; 10 first protru...

Embodiment 3

[0042] The method for spheroidizing inoculation treatment of castings for wind power in this embodiment includes the following steps:

[0043] S1. Charge selection: use 80wt% Q10 pig iron and 20wt% scrap steel as raw materials, then add 0.59wt% recarburizer and 0.45wt% 75 ferrosilicon; the components of the Q10 pig iron, scrap steel, recarburizer, and 75 ferrosilicon are The same in embodiment 1;

[0044] S2, the charge in step S1 is placed in a smelting furnace for smelting, and the molten iron temperature is controlled to be 1500±20°C;

[0045] S3, spheroidizing inoculation treatment: set a spheroidizing embedment chamber on the bottom side of the ladle, first add 0.75wt% of the first spheroidizer, 0.75wt% of the second spheroidizer and 0.75wt% of the molten iron in step S2. 0.008wt% antimony alloy is placed at the bottom of the spheroidized embedding chamber, and then an inoculant slow-release ball A is added to cover the silicon steel sheet; a first boss is arranged on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com