Patents

Literature

43results about How to "Prevent spheroidization" patented technology

Efficacy Topic

Property

Owner

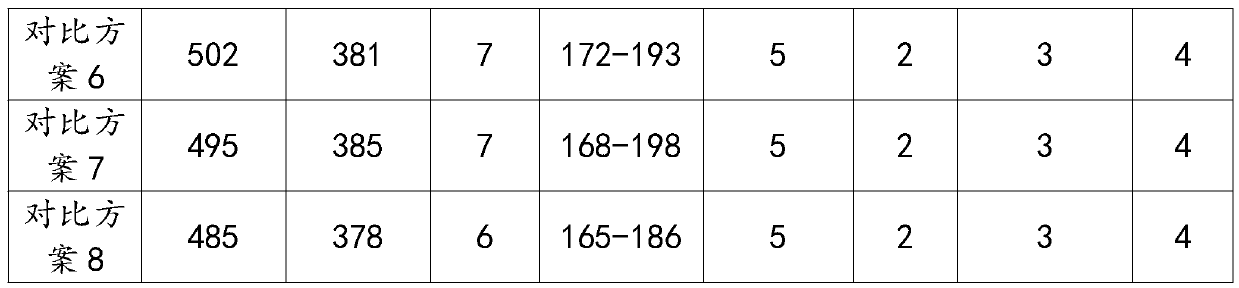

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for casting thin-shell nodular-cast-iron turbocharger

The invention relates to a method for casting a thin-shell nodular-cast-iron turbocharger, in particular to a method for casting the thin-shell nodular-cast-iron turbocharger and the like products, which is characterized by comprising the following steps of: process method design, three-dimensional model design of the casting process, mold-filling / solidifying simulation, analysis treatment for a simulated result, selection of mold materials, mold assembling simulation, molding, core making, mold assembling, molten iron melting, spheroidizing inoculation, and pouring. The process method provided by the invention is unique, which can solve the problem of shrinkage porosity because the partially overlarge part of an inner cavity cannot be fed by a riser, and can ensure the dimensional accuracy of air cavity, water cavity and oil cavity which are intersected one another in the inner cavity of the casting shell.

Owner:KOCEL EQUIP +1

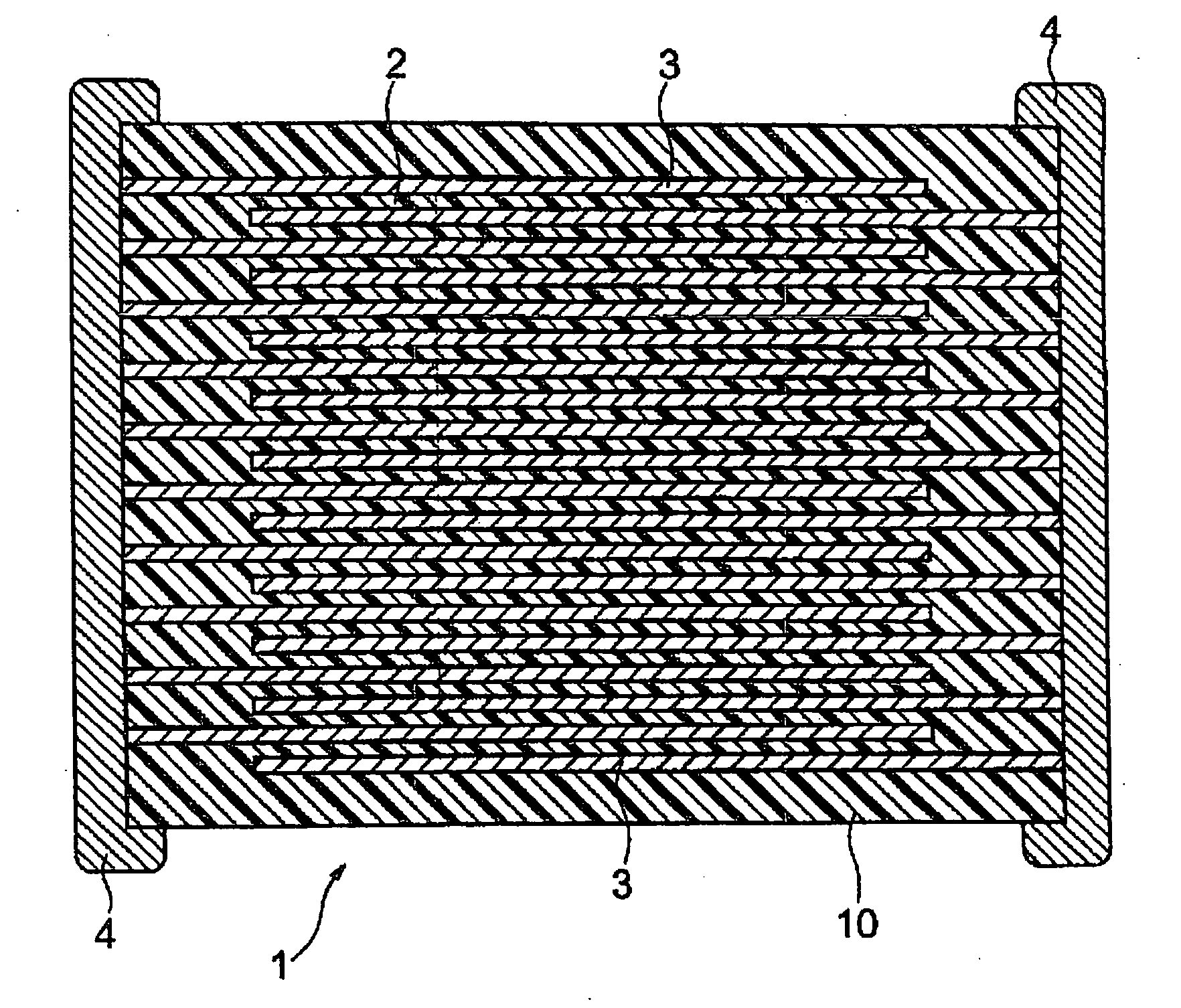

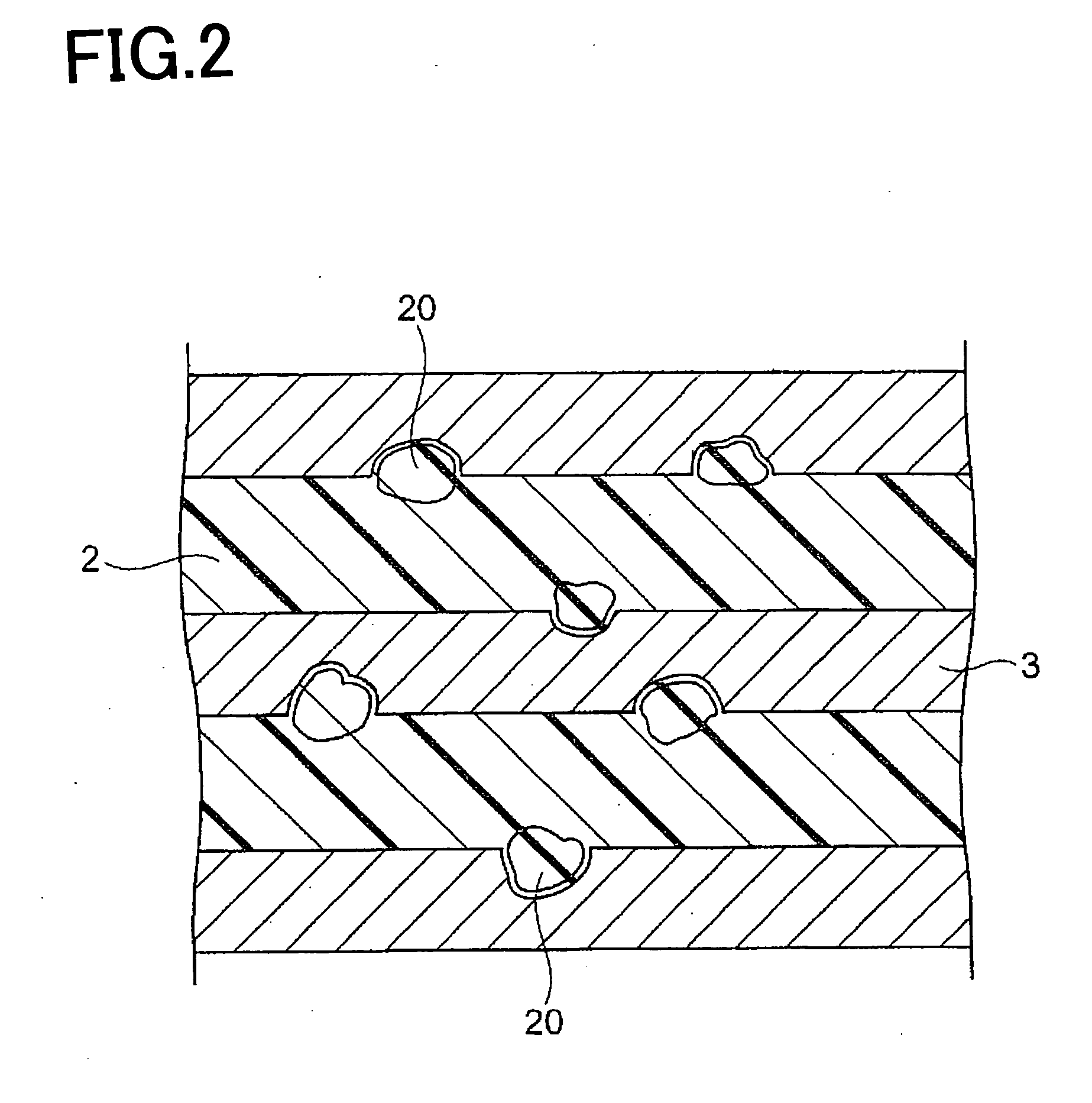

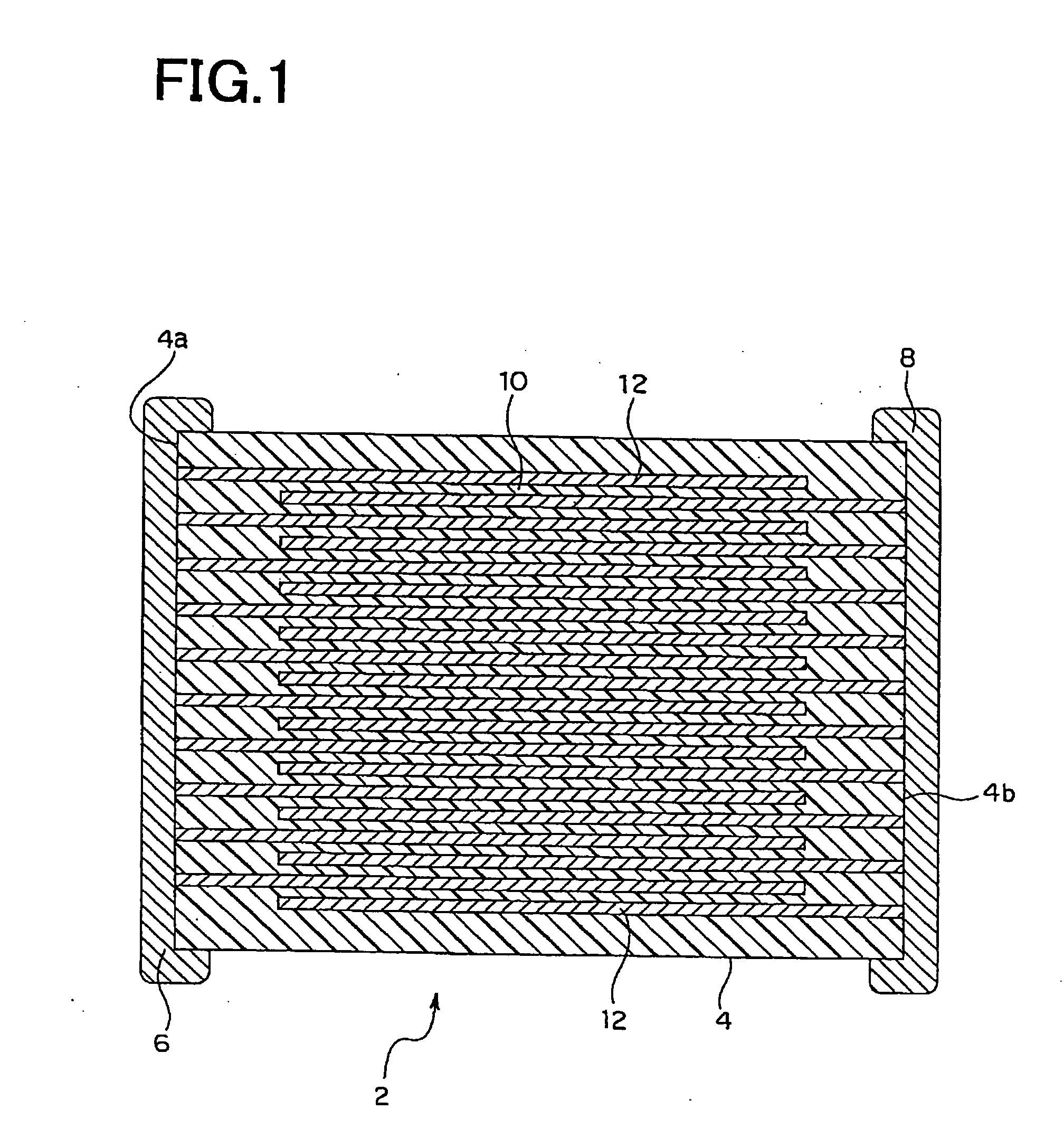

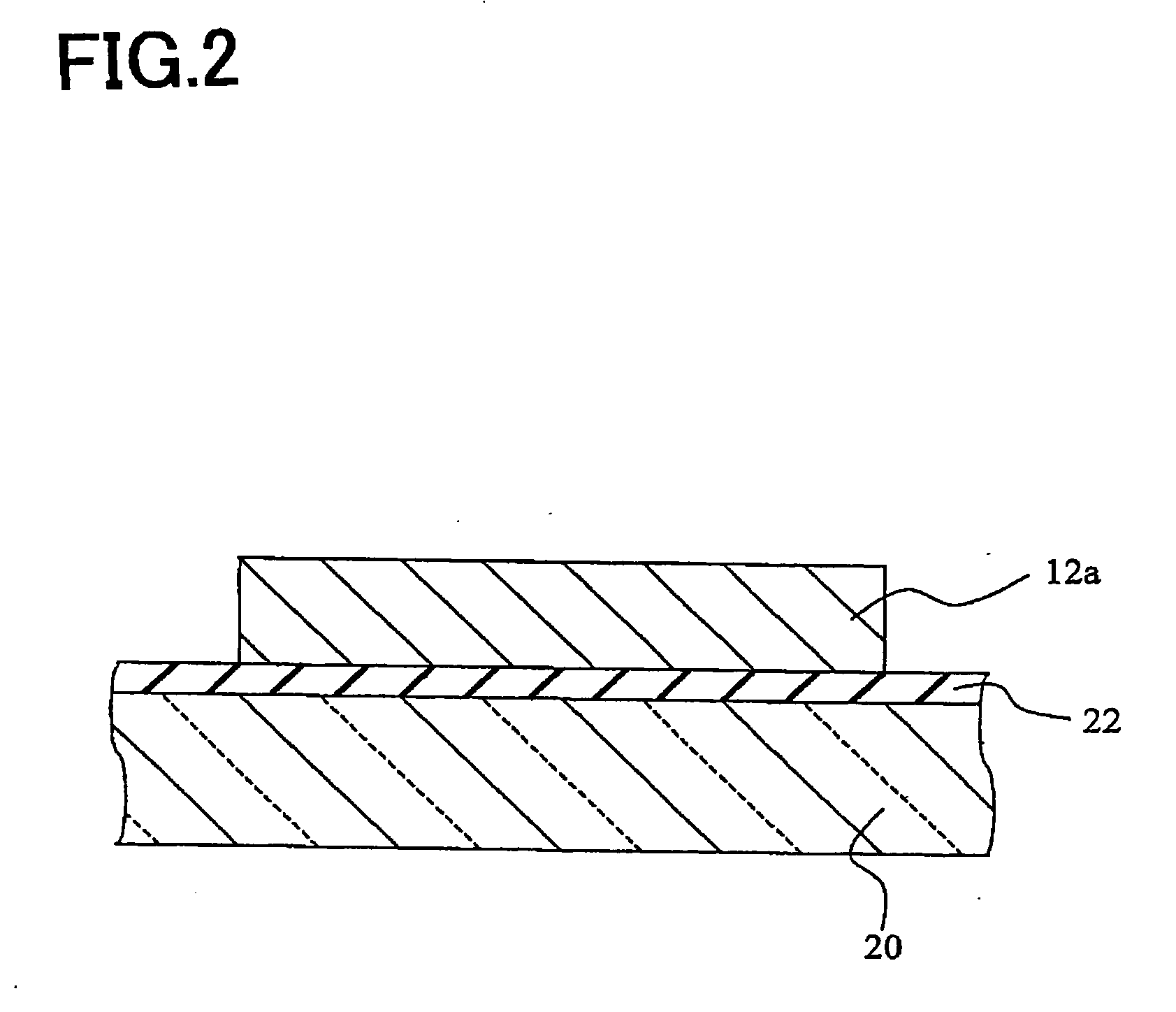

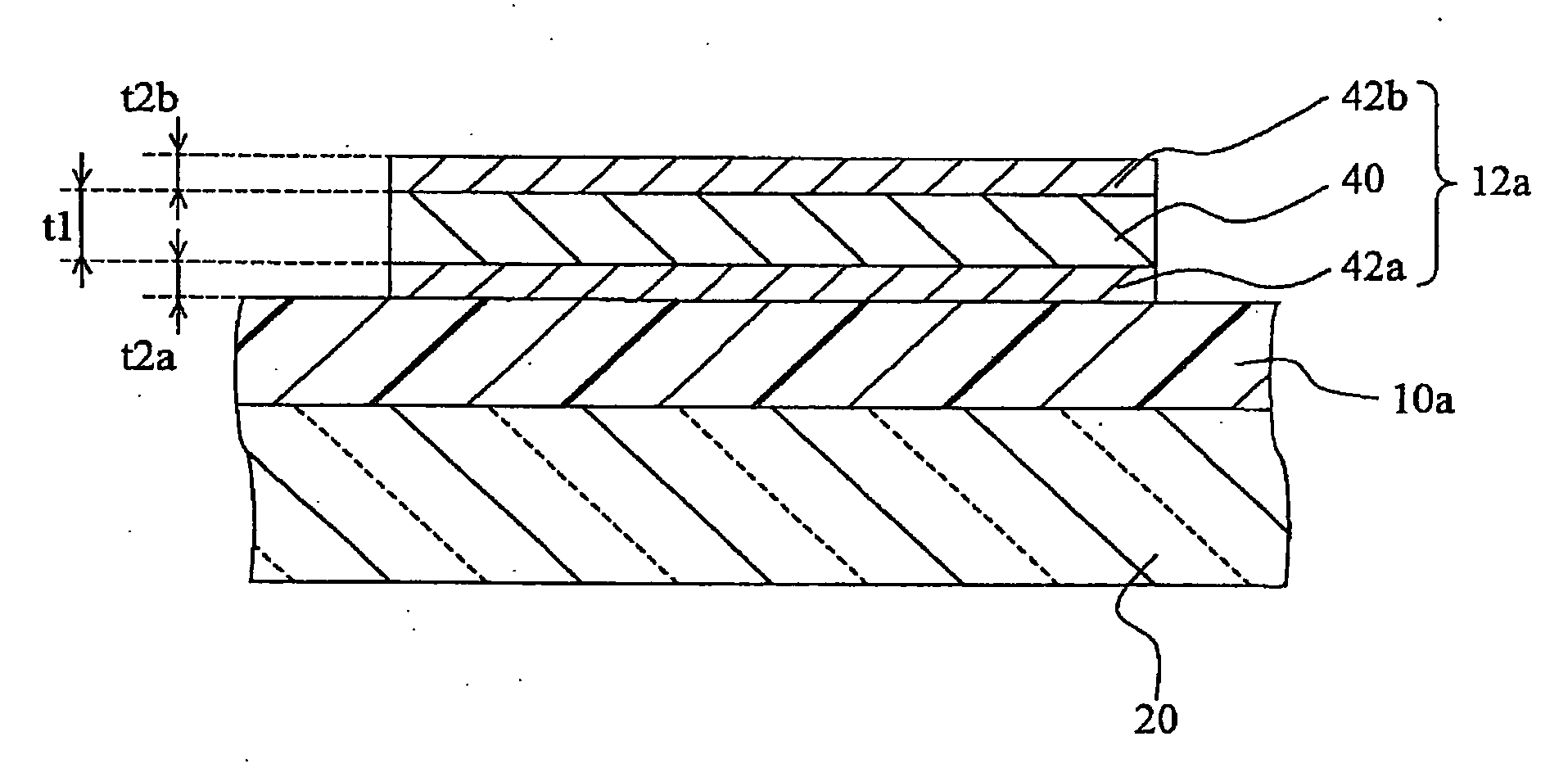

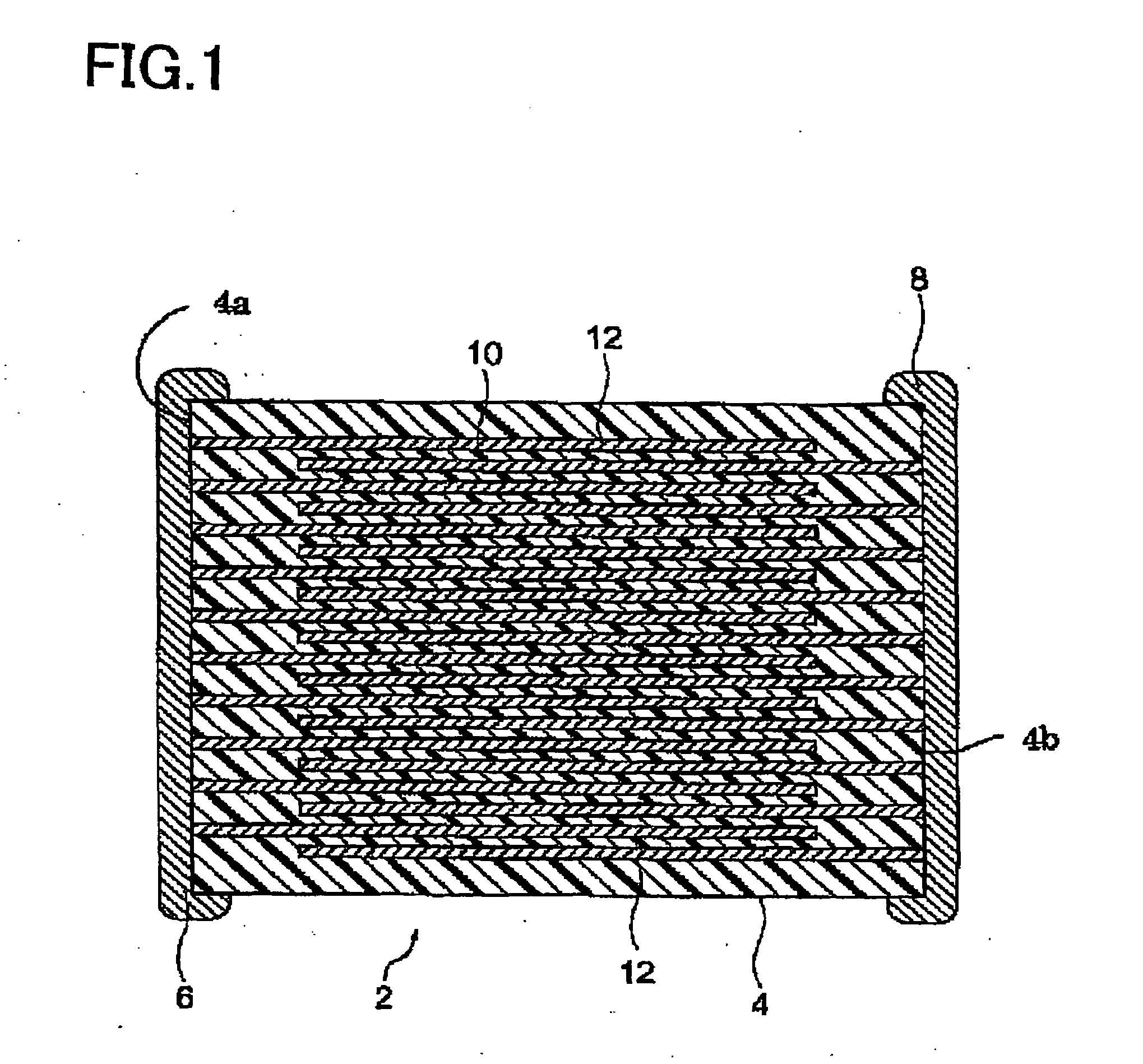

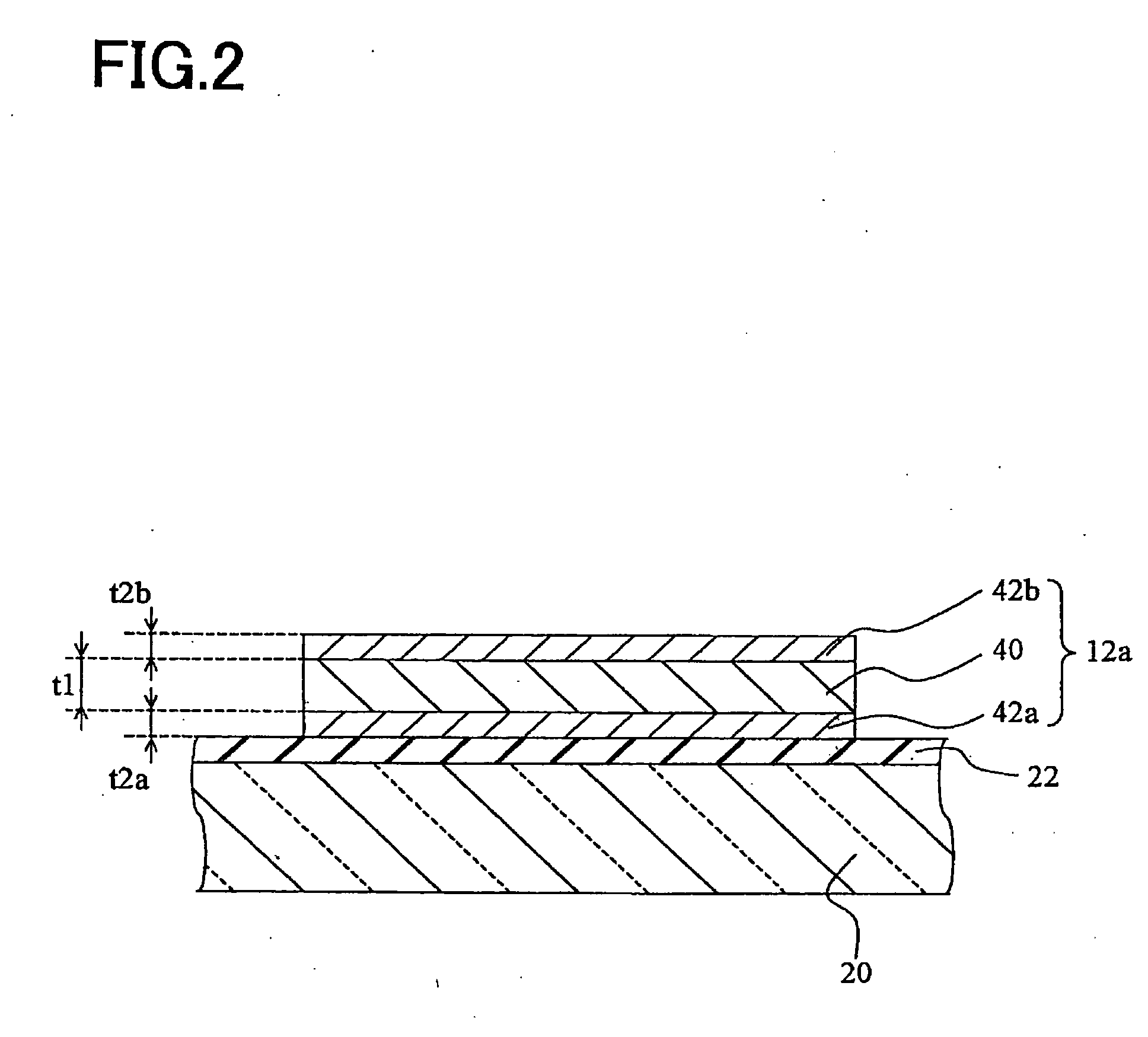

Production method of multilayer ceramic electronic device

InactiveUS20070074806A1Prevent spheroidizationAvoid crackingFixed capacitor dielectricStacked capacitorsCapacitanceMetallurgy

By a production method for producing a multilayer ceramic electronic device including dielectric layers and internal electrode layers comprising the steps of forming a green sheet to be said dielectric layer after firing, forming a pre-fired electrode layer to be said internal electrode layer after firing in a predetermined pattern on said green sheet by using a conductive material paste, forming a green chip by successively stacking said green sheets and said pre-fired electrode layers, and firing said green chip: wherein the conductive material paste for forming said pre-fired electrode layer is composed at least of conductive material particles, a first common material composed of ceramic powder and a second common material composed of ceramic powder having a larger average particle diameter than that of said first common material; an average particle diameter of said first common material is 1 / 20 to ½ of an average particle diameter of said conductive material particles; and the average particle diameter of said second common material is 1 / 10 to ½ of an average thickness of said internal electrode layers after firing; a multilayer ceramic electronic device, such as a multilayer ceramic capacitor, wherein arising of cracks is effectively prevented, having a low short-circuit defect rate, a low voltage resistance defect rate and high capacitance is produced.

Owner:TDK CORPARATION

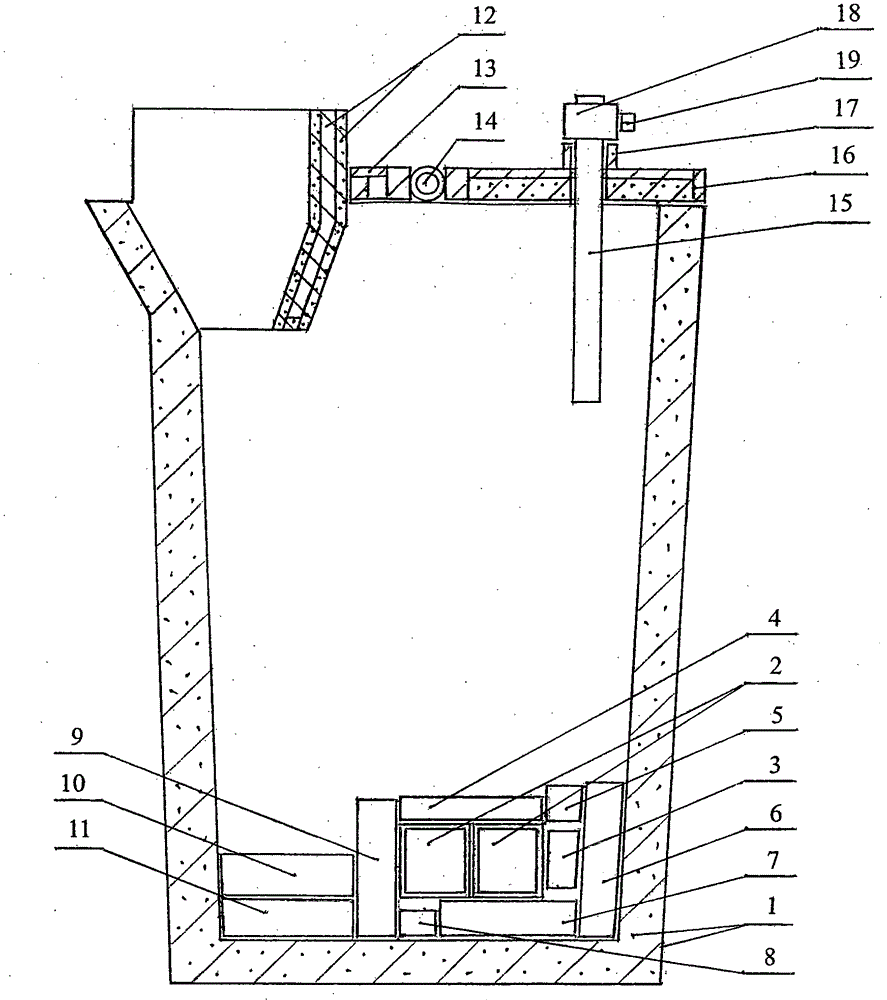

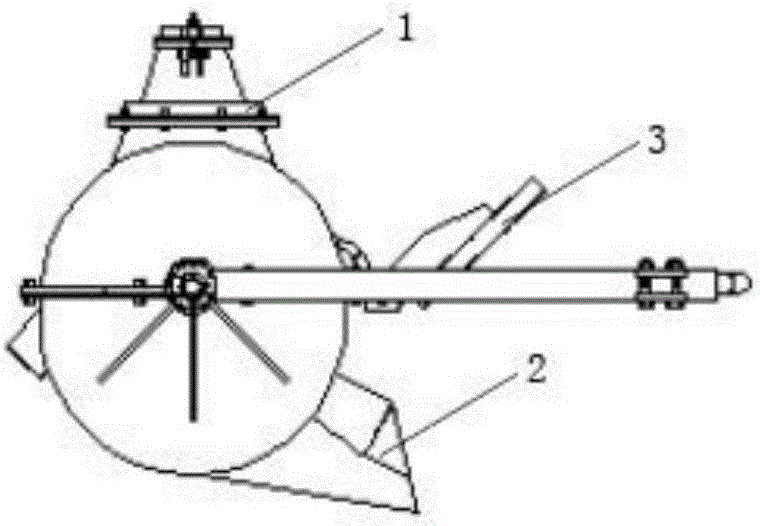

Smelting for ultra-large thick-wall spheroidal cast iron element and on site metamorphism treatment method thereof

The invention relates to a process of melting and field modification treatment of melting ductile iron castings, in particular to a process of melting and field modification treatment of super large ductile iron castings with thick walls, which is characterized in that the invention includes the steps of selecting melting devices, feeding to melt, heat preservation, spheroidization, inoculation and pouring. The processing method of the invention is unique and simple, thereby successfully and effectively resolving the melting of a small-tonnage electric induction furnace on large-tonnage molten iron and the modification treatment of large-tonnage spheroidal graphite cast-iron, which also solves the problems of inner decline of casings with inner walls, graphite segregation of the thick walls and the like.

Owner:KOCEL EQUIP

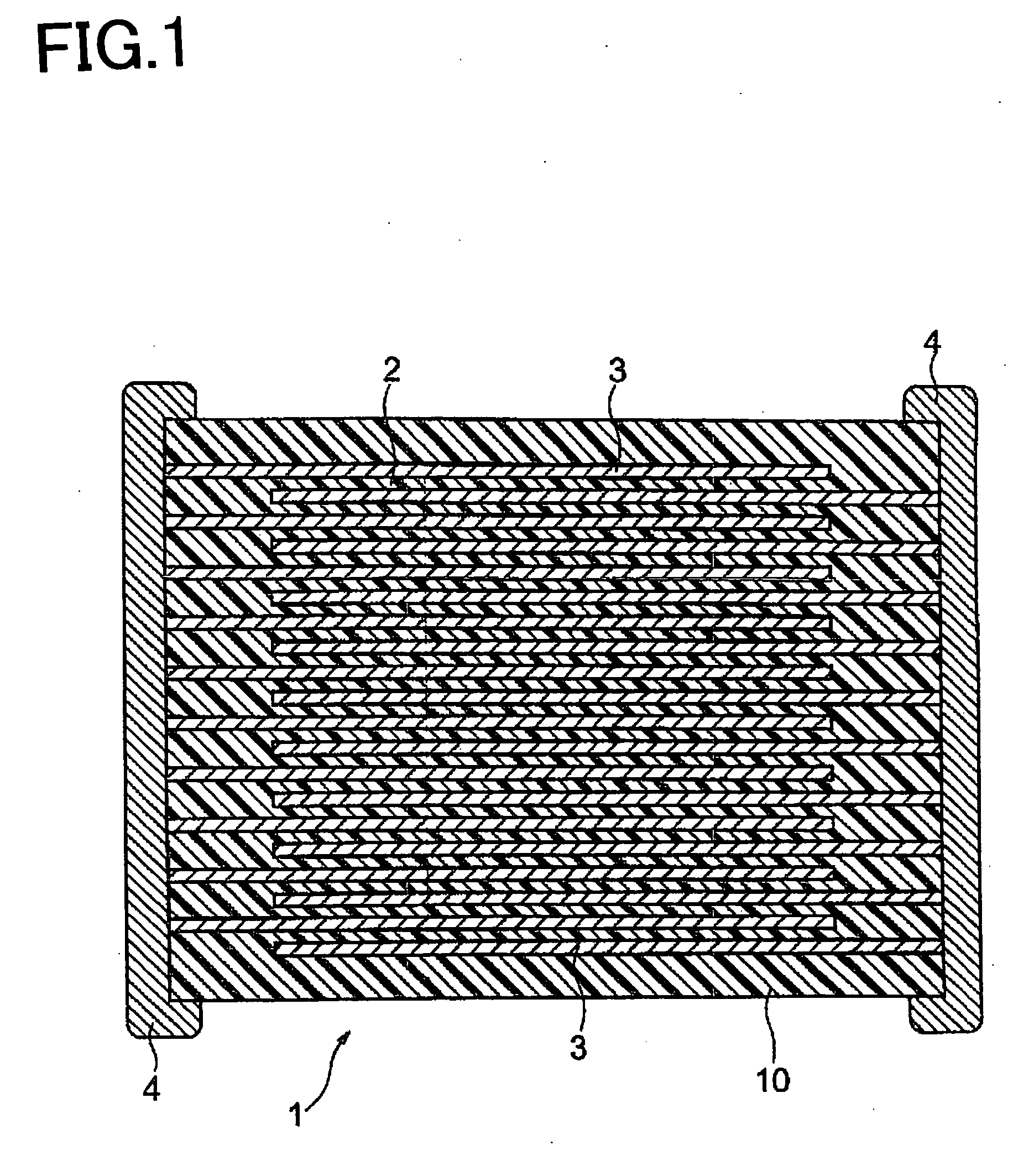

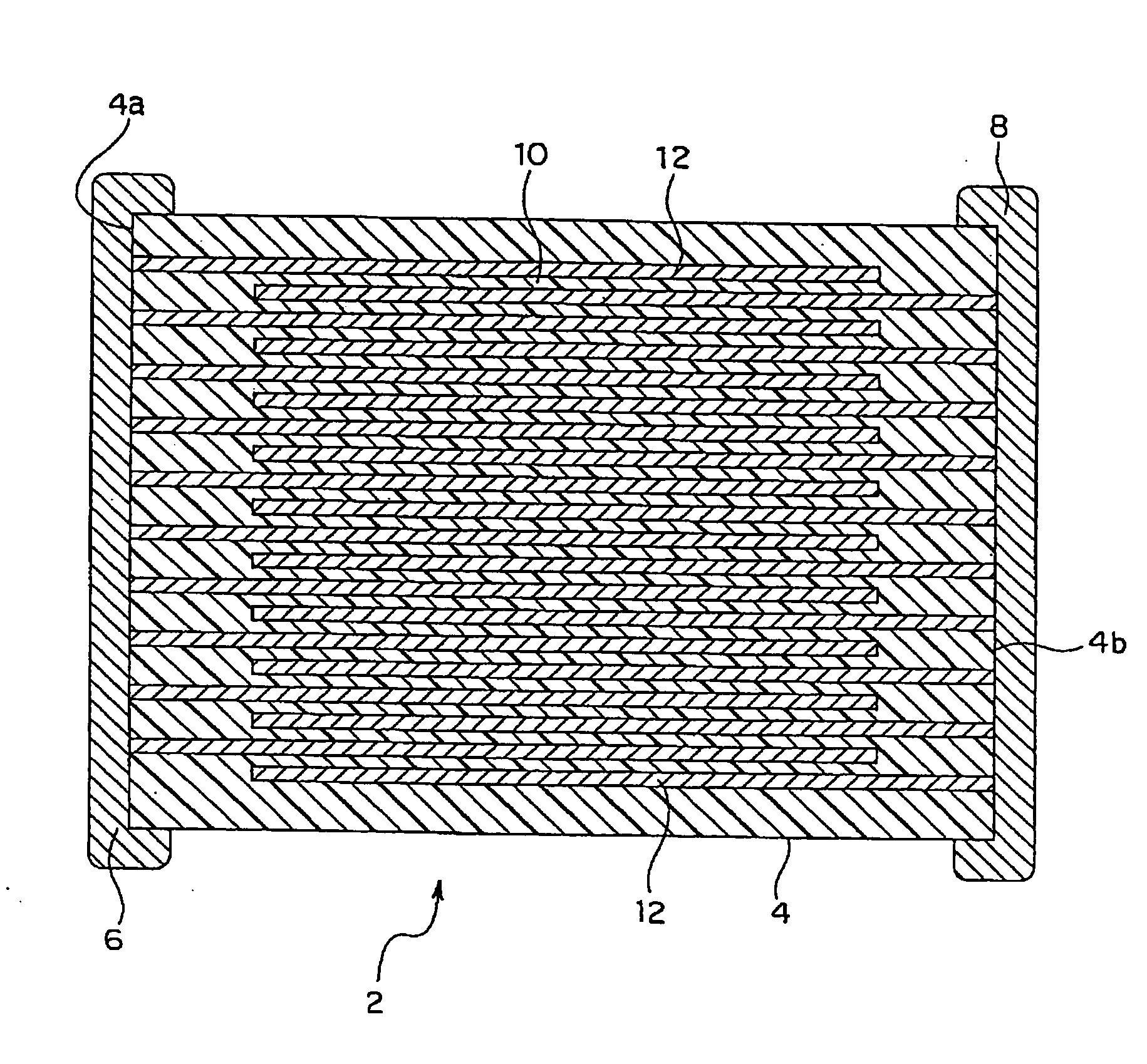

Electronic Device, Multilayer Ceramic Capacitor and the Production Method Thereof

InactiveUS20090122462A1Curb recessionAvoid grain growthFixed capacitor electrodesFixed capacitor dielectricCapacitanceCeramic capacitor

An electronic device, such as a multilayer ceramic capacitor, and a method for producing the electronic device having an internal electrode layer and a dielectric layer, comprising a step of forming a pre-fired internal electrode thin film including a conductive component and a dielectric component, a step of stacking green sheets to be dielectric layers after firing and the internal electrode thin films, and a step of firing a multilayer body of the green sheets and the internal electrode thin films are provided: by which grain growth of conductive particles in a firing step can be suppressed, spheroidizing in the internal electrode layers and breaking of electrodes can be effectively prevented, and a decline of the capacitance can be effectively suppressed even when a thickness of each internal electrode layer is made thinner.

Owner:TDK CORPARATION

Electronic Device, Multilayer Ceramic Capacitor and the Production Method Thereof

InactiveUS20080137264A1Increase capacitanceAvoid breakingFixed capacitor electrodesElectrolytic capacitorsCapacitanceCeramic capacitor

An electronic device, such as a multilayer ceramic capacitor, capable of suppressing grain growth of metal particles in a firing step, effectively preventing spheroidizing of internal electrode layers and breaking of electrodes and effectively suppressing a decline of a capacitance, and the production method are provided: wherein the production method of an electronic device including internal electrode layers and dielectric layers comprises the steps of forming a pre-fired internal electrode thin film having a dielectric thin film and a metal thin film; stacking green sheets to be dielectric layers after firing and the internal electrode thin films; and firing a multilayer body of said green sheets and said internal electrode thin films.

Owner:TDK CORPARATION

Spheroidizing method of nodular cast iron

InactiveCN103433471ASolve the problem of moving up after meltingAdjust the amount added at any timeMelt-holding vesselsRare-earth elementFerrosilicon

The invention relates to a spheroidizing method for producing nodular cast iron. According to the spheroidizing method, a melted whole rare earth ferrosilicon magnesium alloy spheroidizing agent containing not more than 20% of Mg, not more than 70% of Si and not more than 3% of RE is put into a reaction chamber built in the spheroidizing ladle and carrying out an inter-ladle pouring process, wherein the addition amount of the spheroidizing agent is only 0.4%-0.8% of the weight of the melted iron to be processed; the spheroidizing reaction time is controlled accurately, the temperature of the melted iron in the spheroidizing and pouring processes is less reduced, absorption rates of Mg, RE and Si after spheroidization are high, the addition amount of the spheroidizing agent is only one third of that of the traditional process, and thus the spheroidizing cost can be reduced by 50%; the production environment in the production and use processes of the spheroidizing agent is improved, and the product quality is improved. Compared with the traditional rare earth ferrosilicon magnesium alloy spheroidizing agent with rare earth element RE of 2-8%, the use amount of the rare-earth element RE is reduced by 50-75% by using the spheroidizing method for producing nodular cast iron for spheroidization.

Owner:TIANJIN WANLU LTD CO OF SCI & TECH +2

Spheroidizing method

InactiveCN102690985APrevent the problem of moving up after meltingAvoid lostMelt-holding vesselsRare-earth elementBrick

The invention relates to a spheroidizing method for producing spheroidal graphite cast iron, and the method comprises the following steps: injecting rare earth magnesium silicon iron inoculant alloy fluid containing less than or equal to 20% of Mg, less than or equal to 65% of Si and less than or equal to 3% of RE into a square steel pipe for solidifying and cooling; fixing the whole rare earth magnesium silicon iron inoculant of the outer lining square steel pipe in a spheroidizing bag by using refractory bricks and wedge-type chocks at the bottom of the spheroidizing bag covered, and then carrying out spheroidizing by utilizing a bag injecting method. The time for controlling spheroidizing is accurate, the molten iron cooling is less in the spheroidizing and casting process, the absorption rate of Mg, RE and Si after the spheroidizing is high, degradated spheroidization is avoided 15min after spheroidizing, the environment for producing and using a spheroidizing agent is improved, the production cost is remarkably reduced and the quality of the product is improved. Compared with the traditional magnesium silicon iron spheroidizing agent with the rare-earth element RE content of 2-8%, the spheroidizing method can be used for reducing the use amount of the rare-earth element RE by 50-75%.

Owner:TIANJIN WANLU LTD CO OF SCI & TECH +2

Nodulizing method

The invention relates to a nodulizing method for producing nodular cast iron, which comprises the following steps: injecting a fused rare-earth (RE) magnesium silicon iron nodulizer alloy liquid, which contains at most 20% of Mg, at most 65% of Si and at most 3% of RE, into a rectangular steel tube, solidifying, and cooling; and fixing the integral RE magnesium silicon iron nodulizer of the outer lining rectangular steel tube into the nodulizing ladle by using refractory bricks and wedged blocks on the bottom in the cladded nodulizing ladle, and nodulizing by a ladle-in process. The nodulizing reaction time is controlled precisely, the temperature drop in the nodulizing process and casting process is low, the absorptivity of Mg, RE and Si after nodulization is high, and no degraded nodulization appears within 15 minutes after the nodulizing reaction finishes, thereby improving the production environment in the nodulizer manufacturing process and use process, obviously lowering the production cost and improving the product quality. Compared with the traditional rare-earth magnesium silicon iron nodulizer with the RE content of 2-8%, the nodulizing technique provided by the invention lowers the consumption of the RE by 50-75%.

Owner:TIANJIN WANLU LTD CO OF SCI & TECH +2

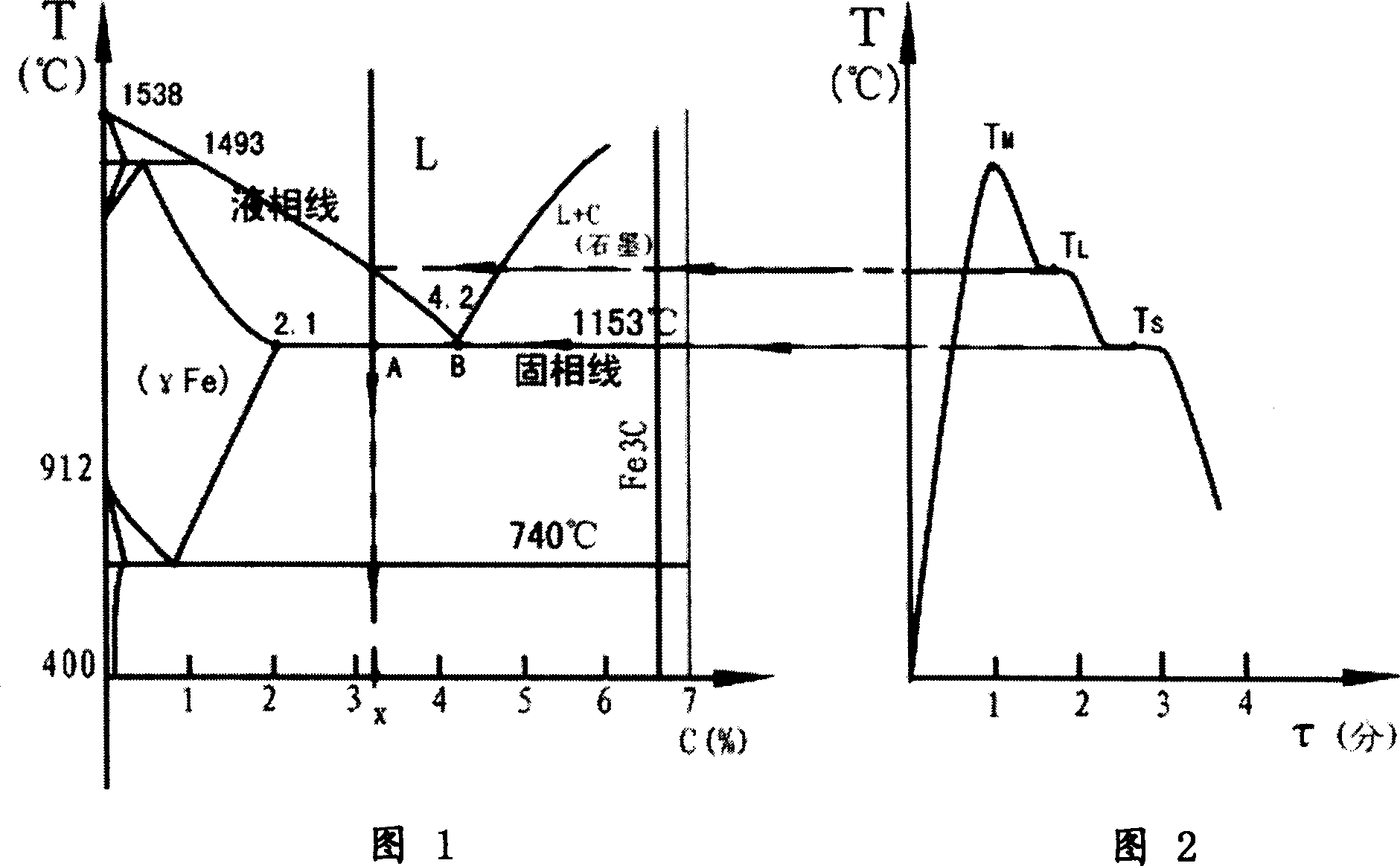

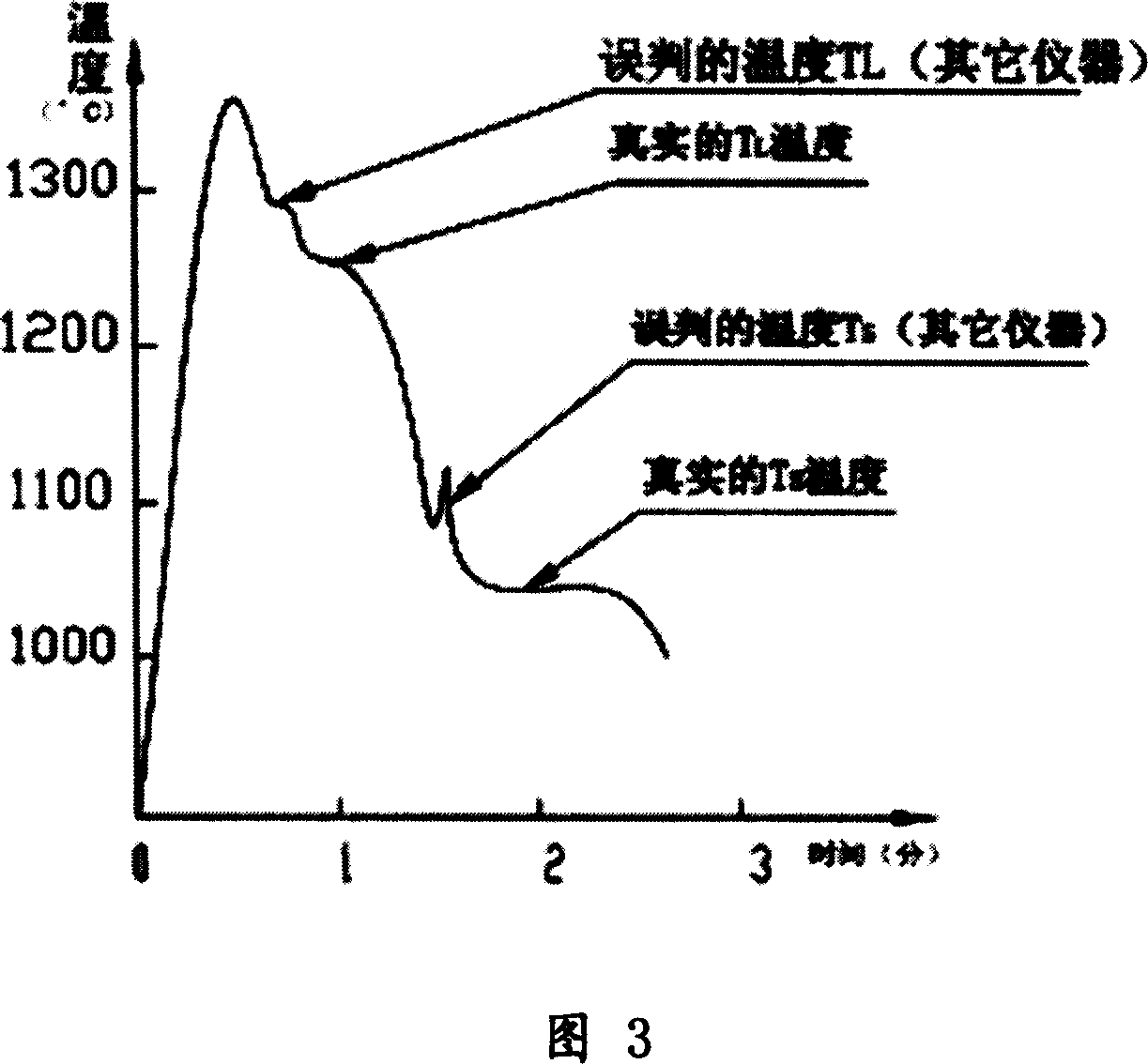

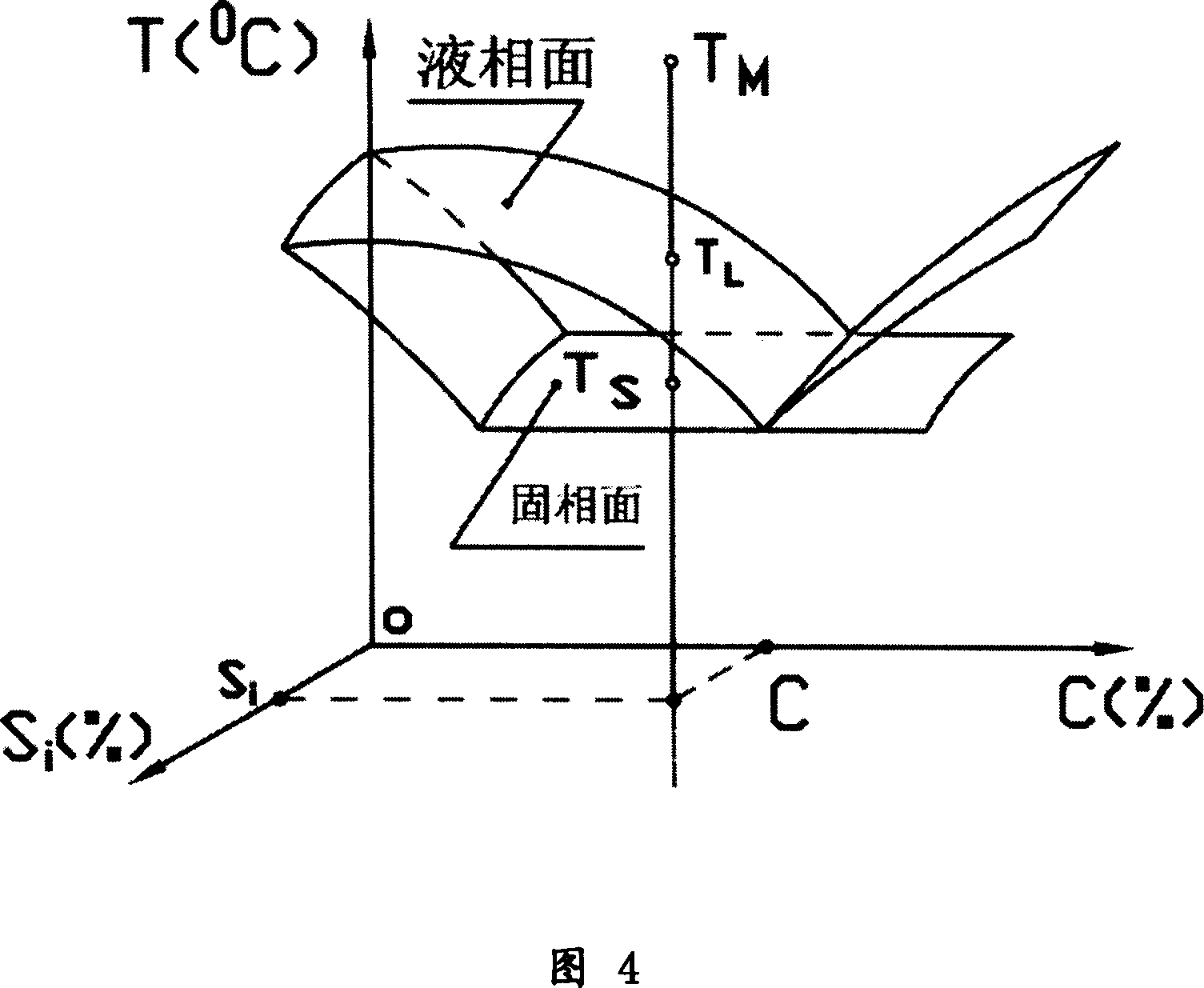

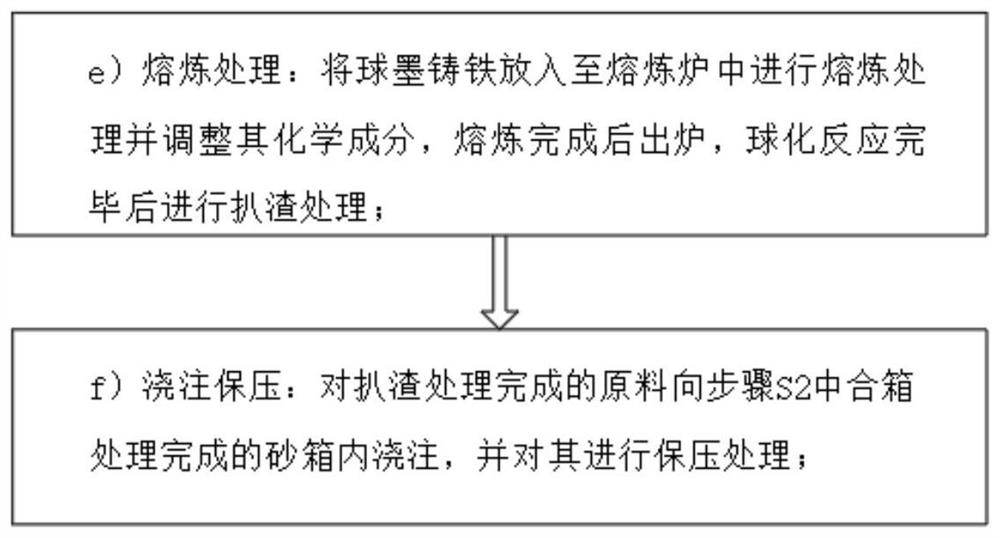

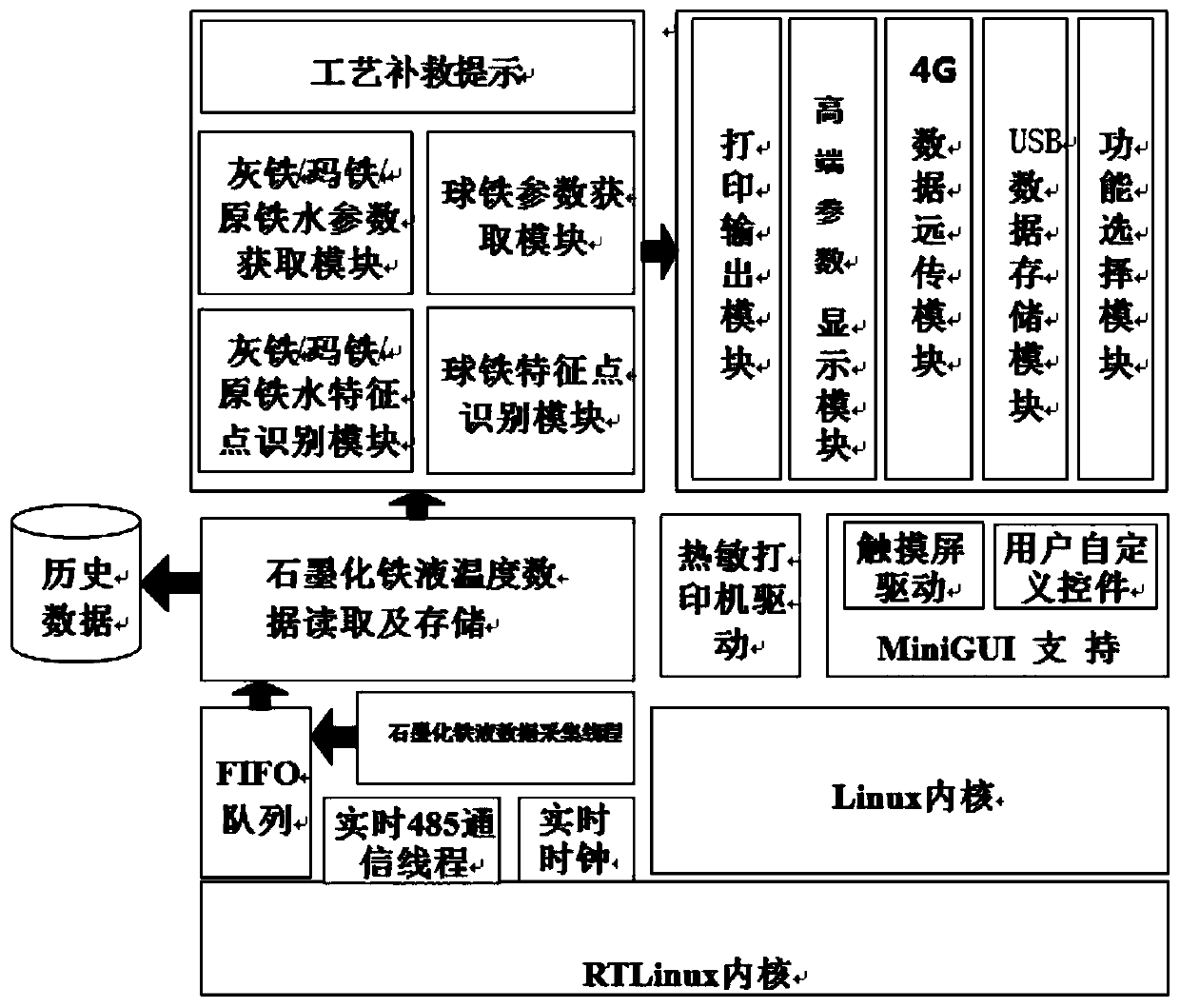

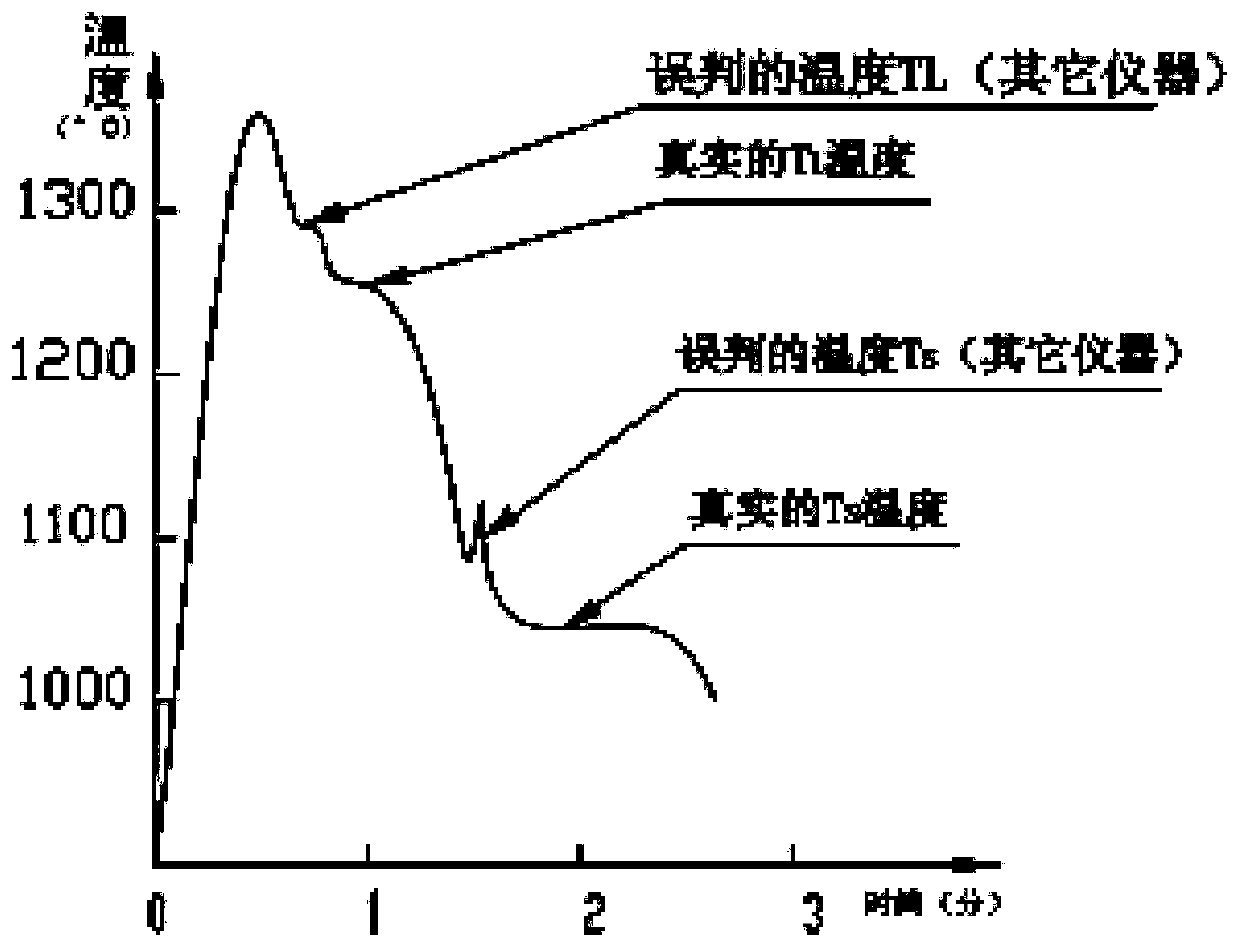

Metal liquid integrative performance on-line intelligent checking system

InactiveCN101055261ASalvage Crafting TipsPrevent spheroidizationMaterial heat developmentInvestigating phase/state changeInternational standardDisplay device

The invention relates to an on-line detection system for molten metal integration property, which includes a signal collection device for generating electric signal correlated with molten metal temperature change, a data processing main frame, a thermoemf combination measuring interface device for carrying amplification and analog / digital conversion of the electric signal, which is convenient for processing digital signal by the data processing main frame, and a data output device including a data remote transmission device, a storage device, a display device and a printing device. The detection system is adapted for eighteen kinds of designation molten iron and nineteen kinds of key parameter fast detection prescribed by national standard and international standard, and has high detection accuracy and good stability.

Owner:合肥双发信息系统技术有限公司

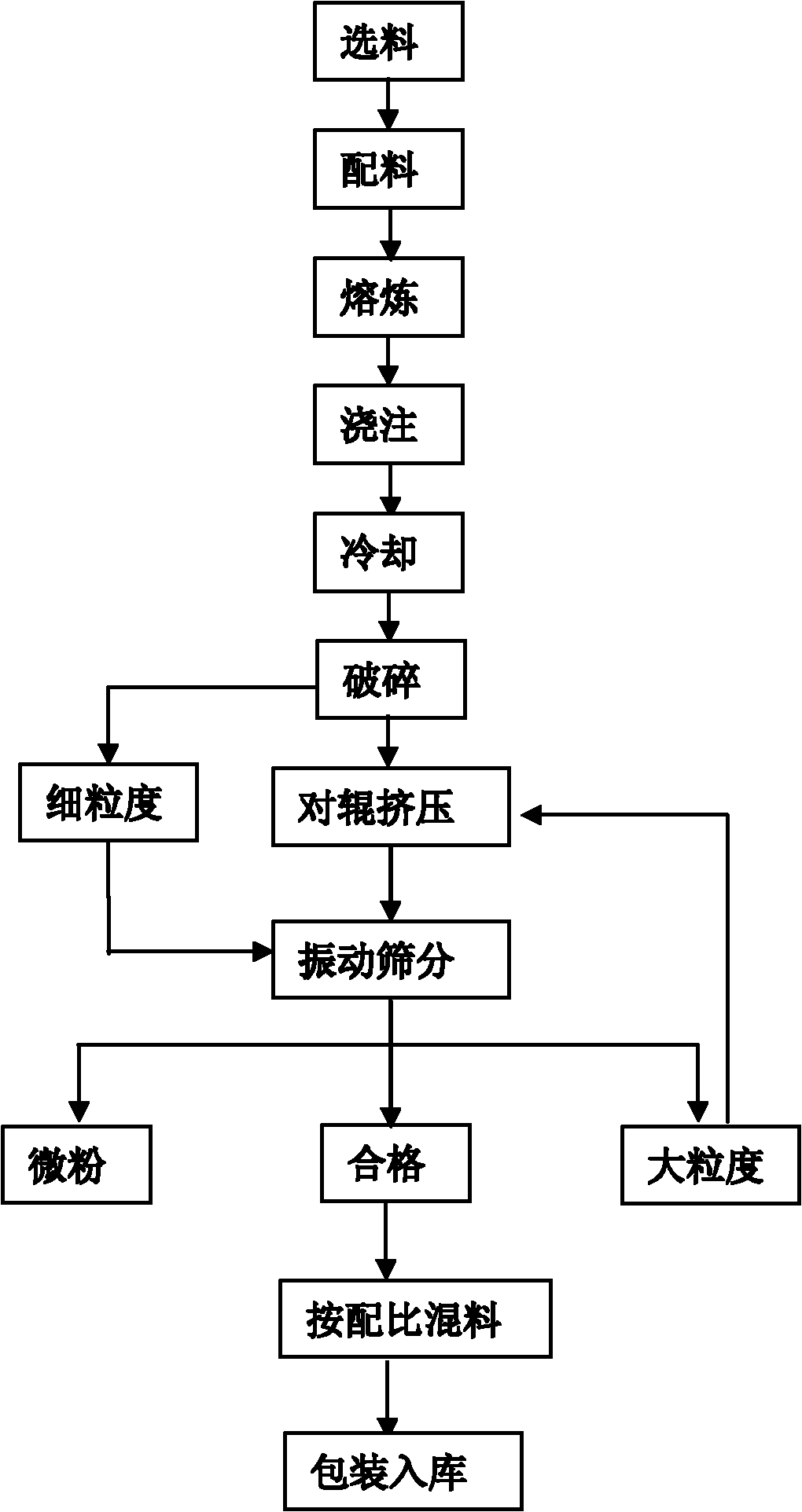

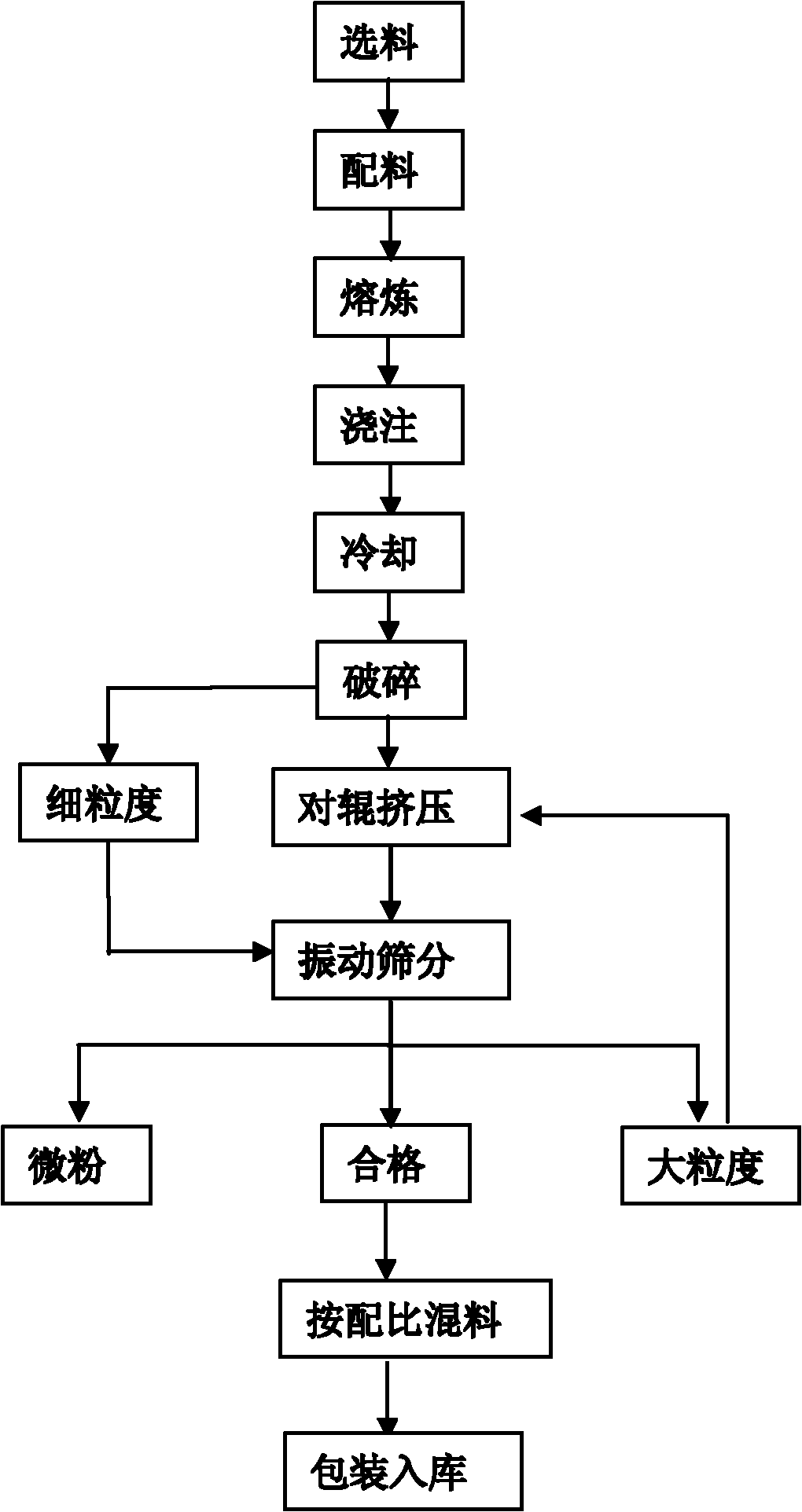

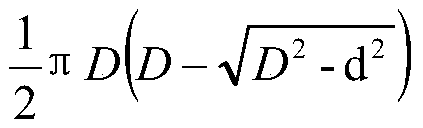

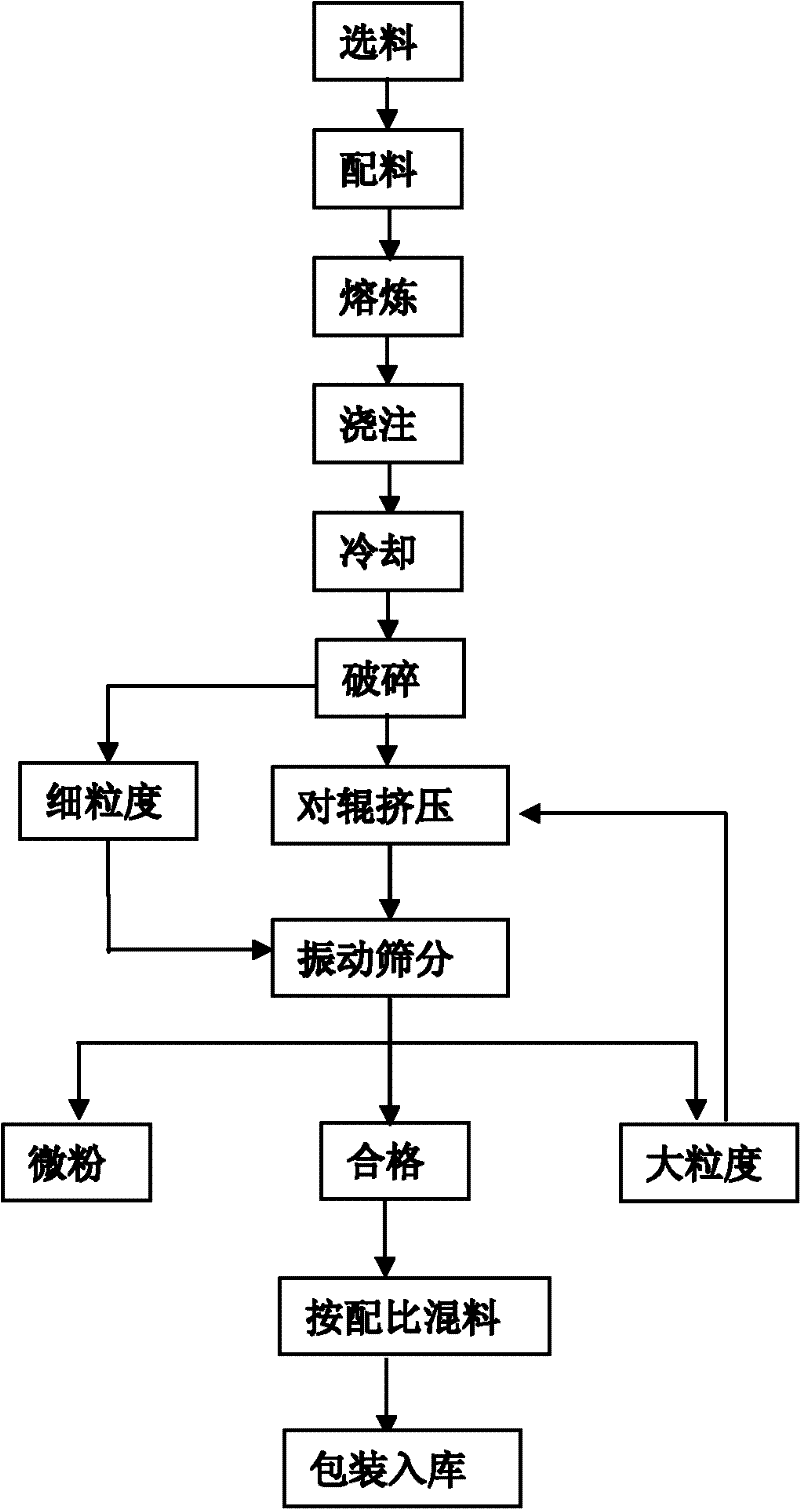

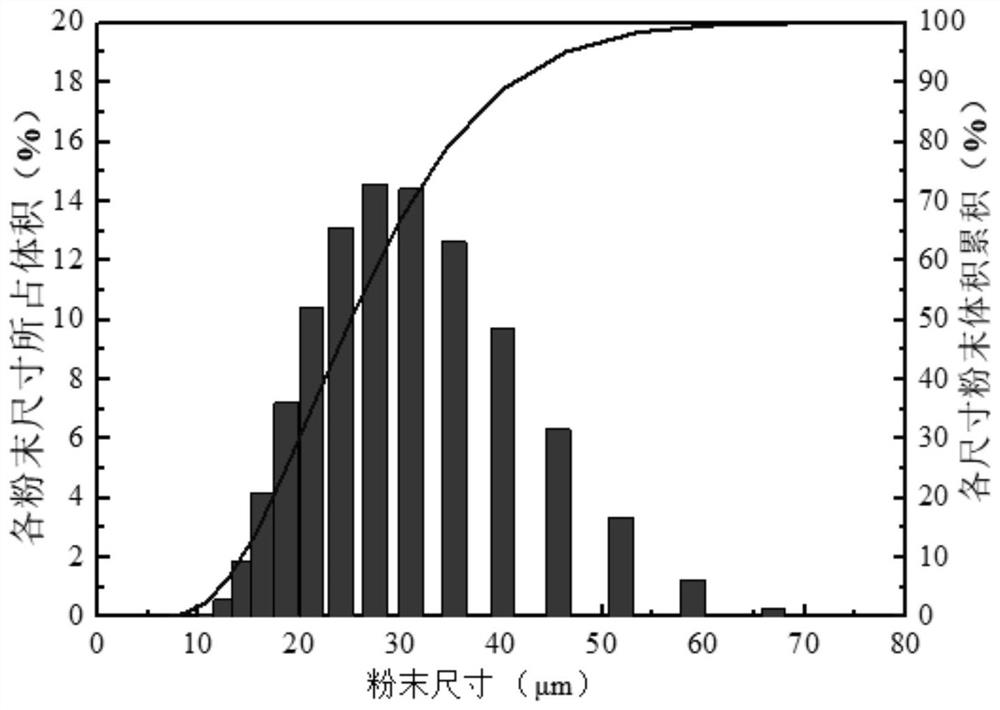

Pipe die powder for centrifugally casting nodular cast iron pipe and preparation process thereof

The invention discloses pipe die powder for centrifugally casting a nodular cast iron pipe and a preparation process thereof. The pipe die powder comprises the following components in percent by mass: 60-65 percent of Si, 1.5-2.0 percent of Ca, 2.0-3.0 percent of Ba, 1.4-1.6 percent of Mn, 1.0-1.5 percent of Mg, 1.0-2.0 percent of Zr, 0.7-1.5 percent of Al and the balance of Fe; and the granularities of pipe die powder comprise less than 1.5 percent of 80 mu, 25-30 percent of 100-120 mu, 40-50 percent of 140-180 mu, 25-30 percent of 200-300 mu and less than 2.5 percent of more than 300 mu. The preparation process comprises the following steps of: preparing, melting, pouring, cooling, crushing, milling, proportioning granularities and packaging in vacuum. The pipe die powder has the advantages of uniform components, consistent melting points and reasonable granulometric class, and is beneficial to the prolonging of the service life of a pipe die of the nodular cast iron pipe, the reduction of a series of casting defects of cockles, poor nodulizing, surface cracks and the like of the nodular cast iron pipe, the improvement of the quality of the nodular cast iron pipe and the yield, and the lowering of the production cost.

Owner:YUZHOU HENGLILAI ALLOY CO LTD

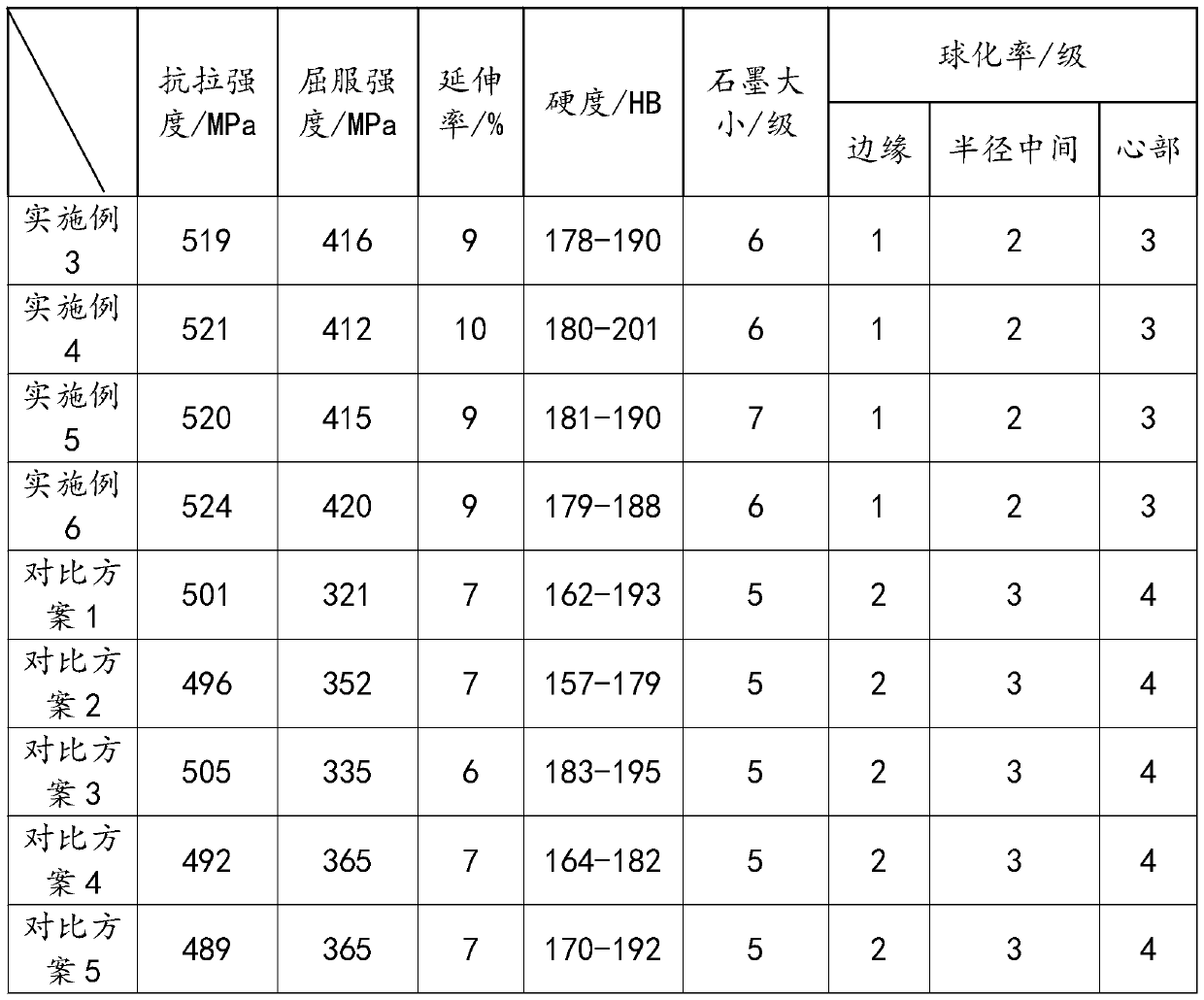

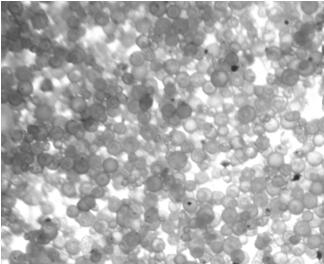

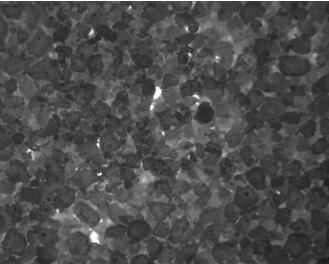

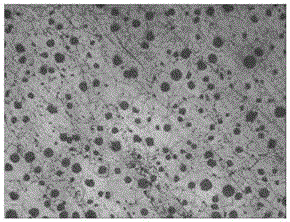

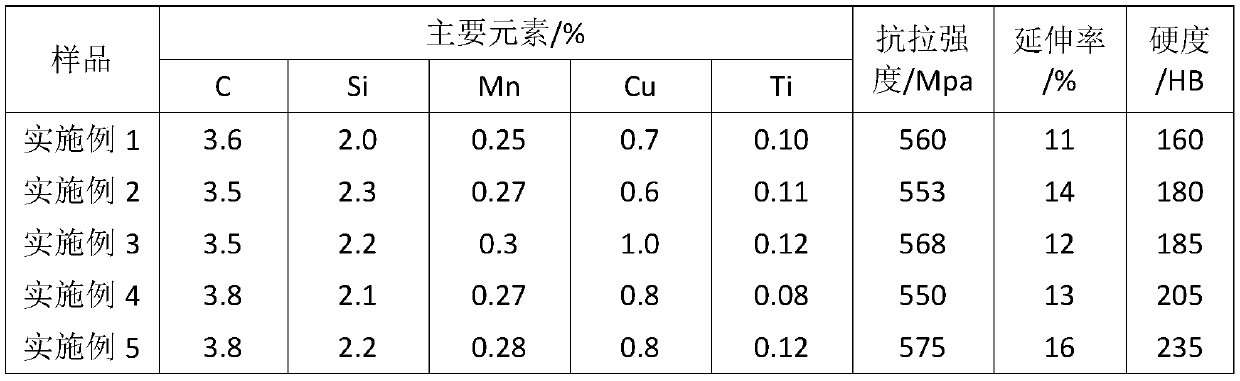

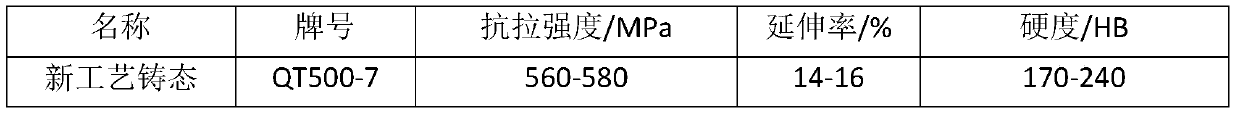

Large-section high-strength high-toughness spheroidal graphite cast iron profile and preparation method thereof

InactiveCN109837454AGenetic reductionReduce the influence of heredityProcess efficiency improvementGas emission reductionLiquid coreSulfur

The invention belongs to the technical field of cast iron materials and casting metallurgy, and particularly relates to a large-section high-strength high-toughness spheroidal graphite cast iron profile and a preparation method thereof. The large-section high-strength high-toughness spheroidal graphite cast iron profile is prepared from the following elements in percentage by mass: 3.45-3.55% of carbon, 2.60-2.70% of silicon, 0.30-0.40% of manganese, 0.04-0.06% of magnesium, 0.025-0.06% of phosphorus, 0.008-0.015% of sulfur, and the balance of iron. The problems that when a large-section spheroidal graphite cast iron profile is produced, spherification and inoculation in a liquid core of the profile are faded, graphite is gathered and combined, the number of graphite crystal nuclei is small, the graphite is distorted, consequently, the overall spheroidization rate of the profile is low, spherulitic graphite is thick and big, the graphite is distorted, casting performance is reduced, and in the severe case, a casting is even scrapped are solved, and the advantage of high practicability is achieved.

Owner:HANDAN HENGGONG METALLURGICAL MACHINERY CO LTD

Lithium battery spherical positive electrode material with lithium fluoride coating layer and preparation method

InactiveCN113178573AImprove cycle performanceImprove thixotropySecondary cellsPositive electrodesLithium-ion batteryMaterials science

The invention relates to the technical field of lithium ion batteries, in particular to a lithium battery spherical positive electrode material with a lithium fluoride coating layer and a preparation method. The preparation method comprises the following steps of stirring a mixed solution formed by nickel sulfate, cobalt sulfate and manganese sulfate until the complete reaction is completed, and washing and drying solids to obtain NCM precursor powder; heating and stirring the NCM precursor powder, lithium carbonate and magnesium lithium silicate, pre-sintering at 200-300 DEG C, sintering in a fluidized bed, back-blowing the powder by hydrogen fluoride and argon, and filtering to obtain the lithium battery spherical positive electrode material with the lithium fluoride coating layer. According to the present invention, the problems of poor spheroidization control and transition metal element dissolution of the lithium battery positive electrode material in the prior art are solved. The lithium battery spherical positive electrode material with the lithium fluoride coating layer prepared by the preparation method has better spheroidized morphology, and the lithium fluoride serves as the coating layer, so that the cycle performance of the battery can be effectively improved.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

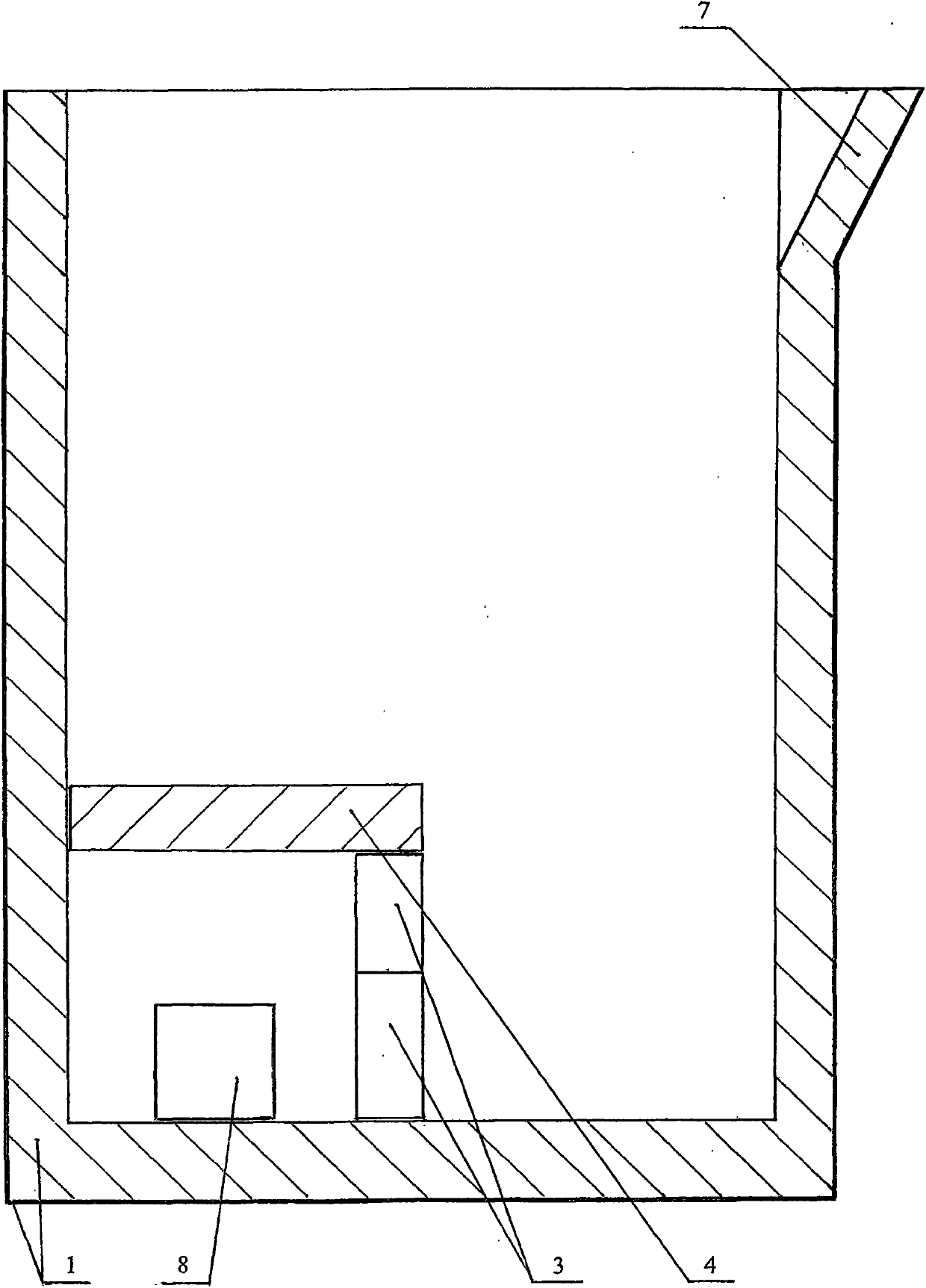

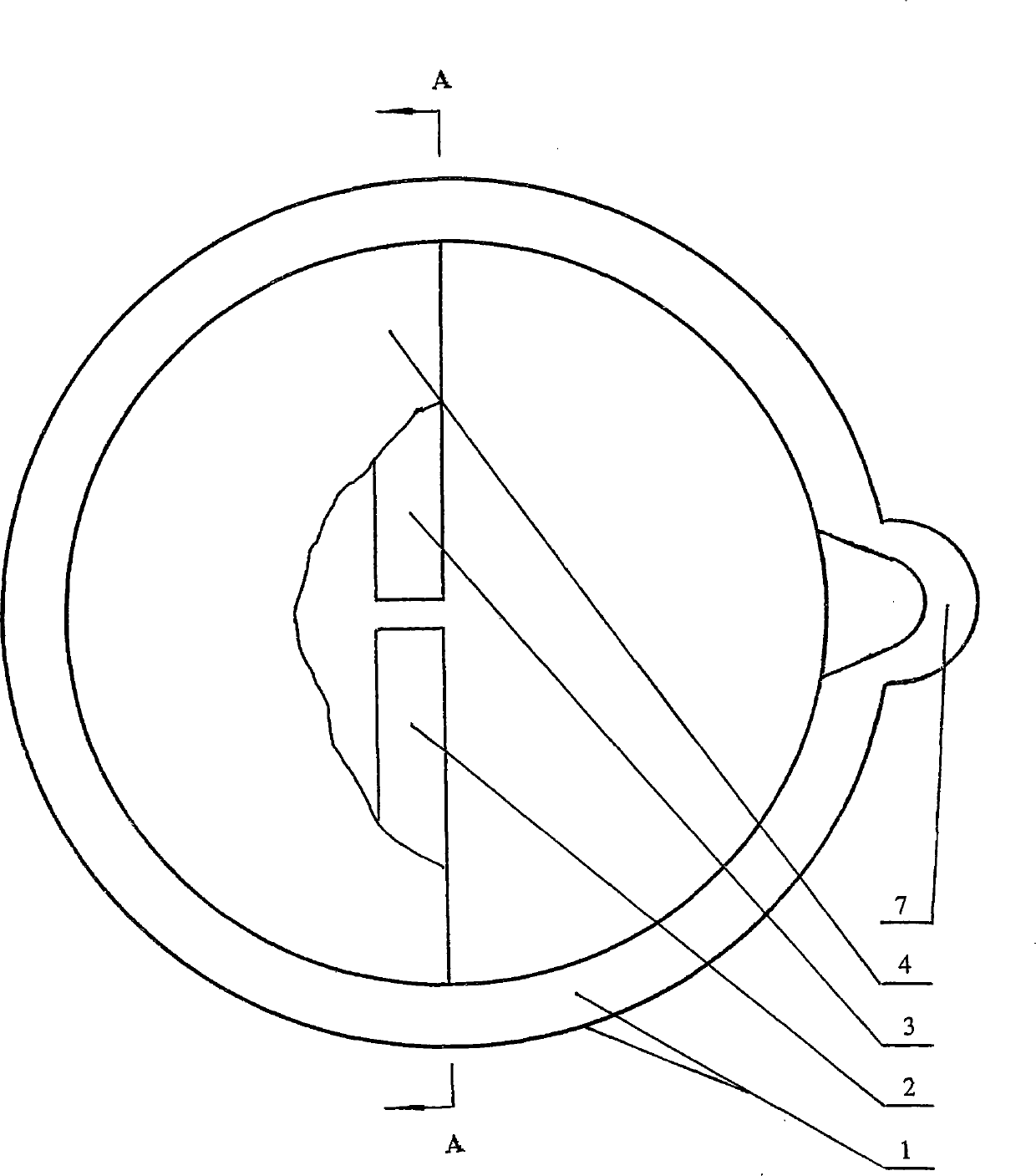

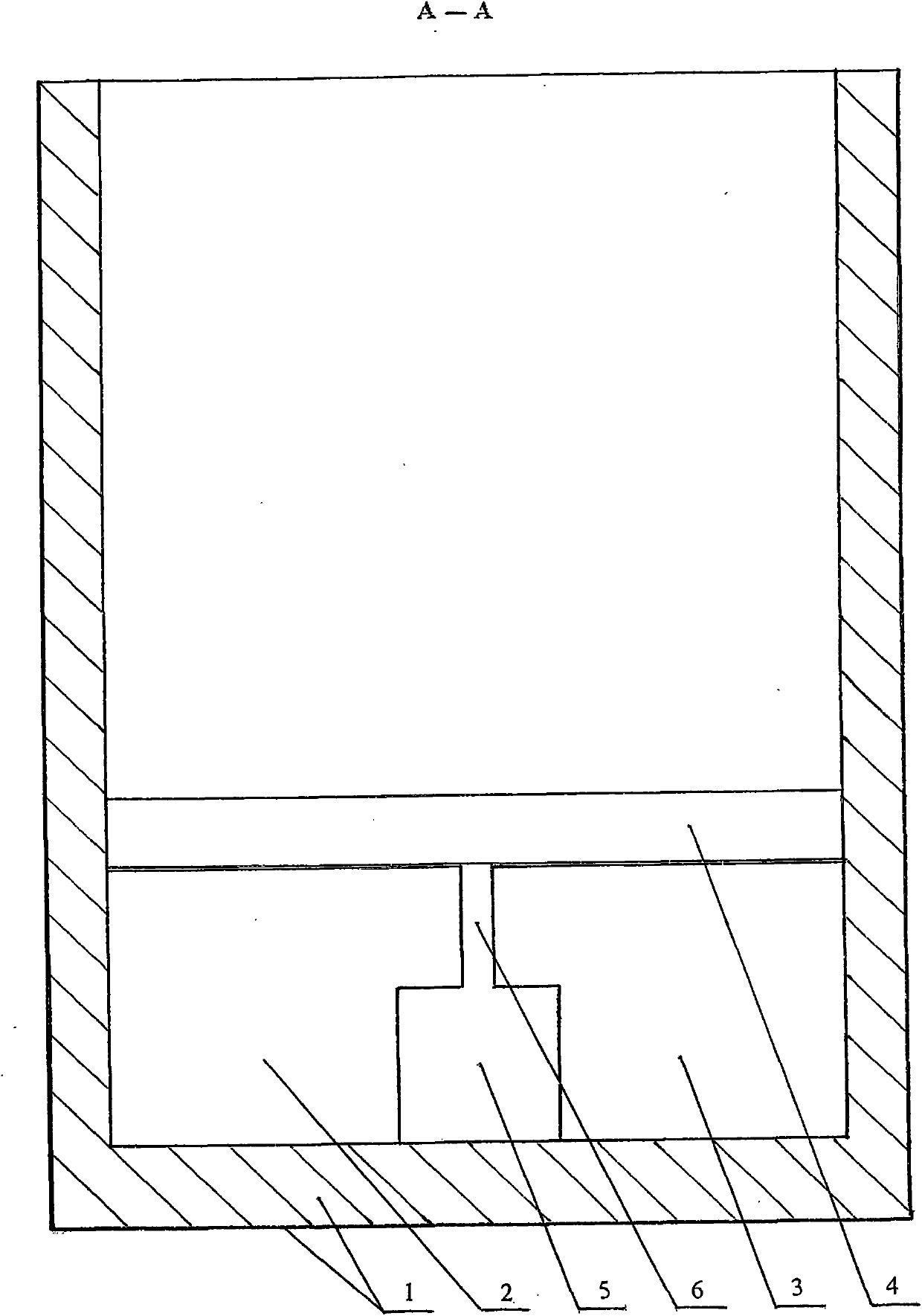

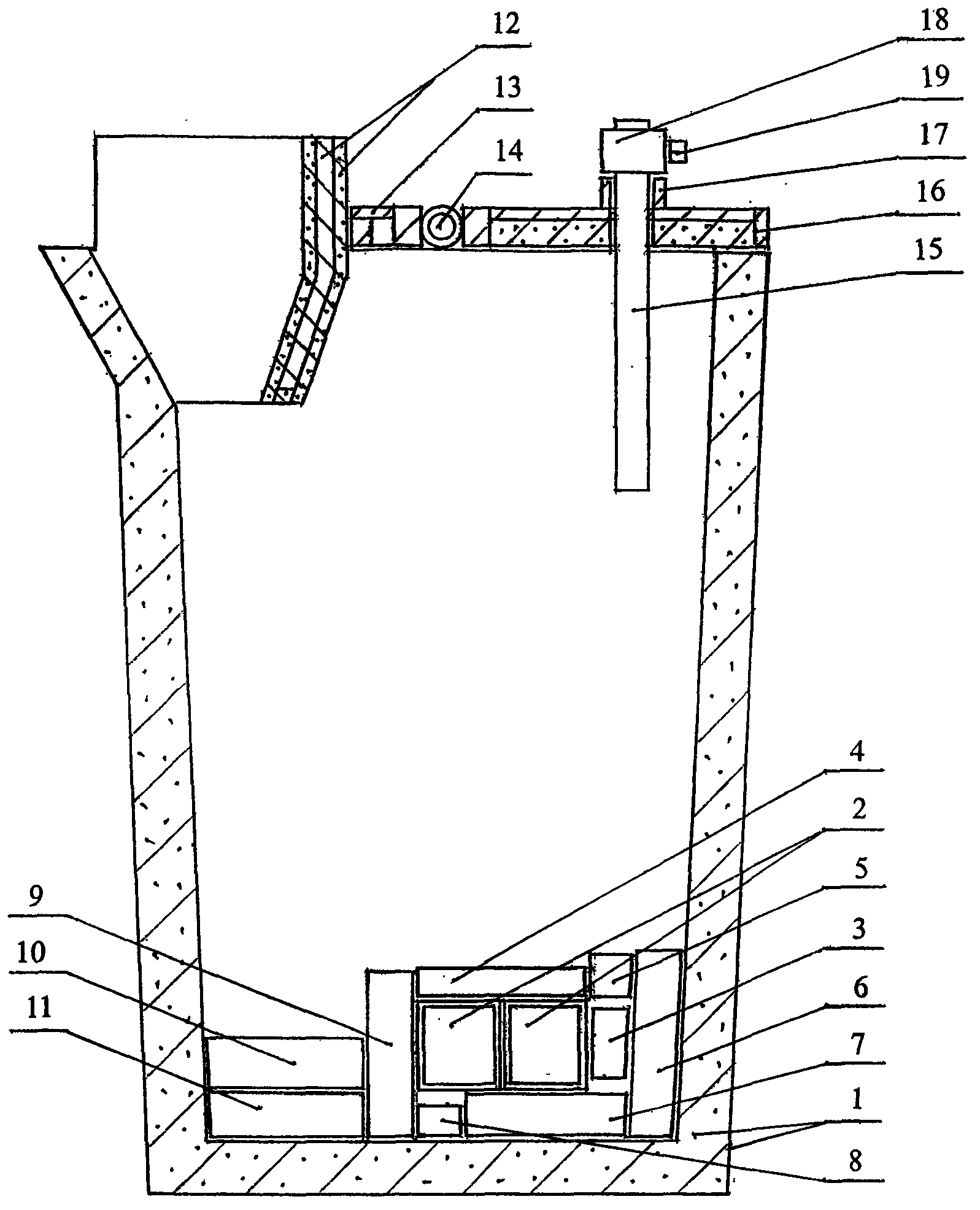

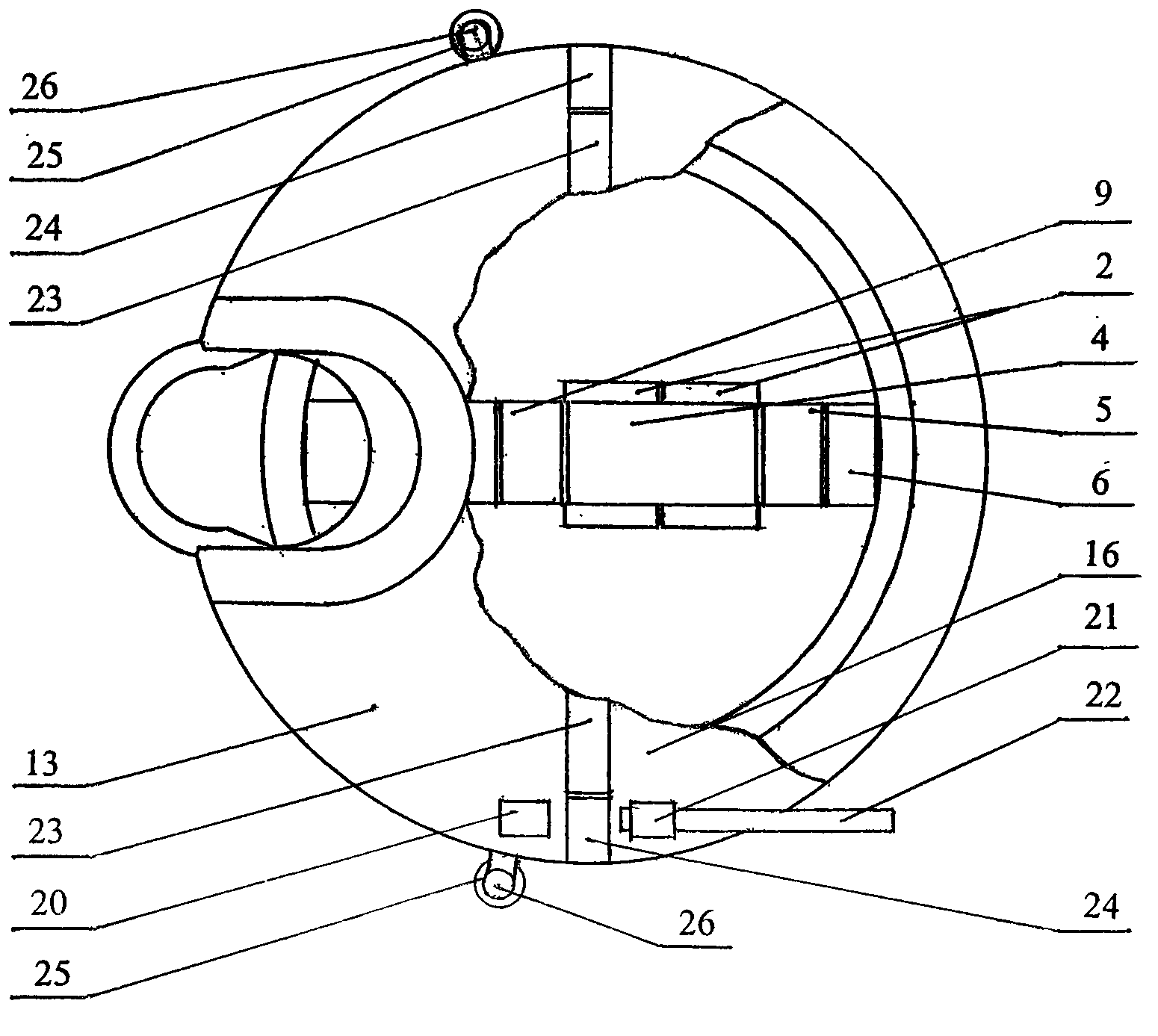

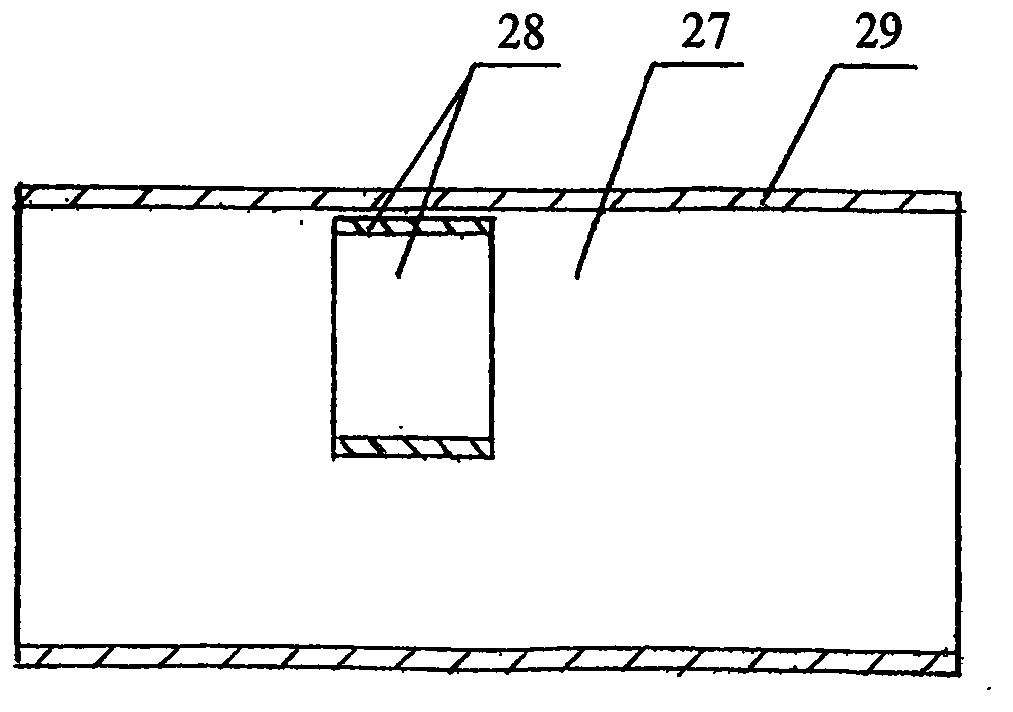

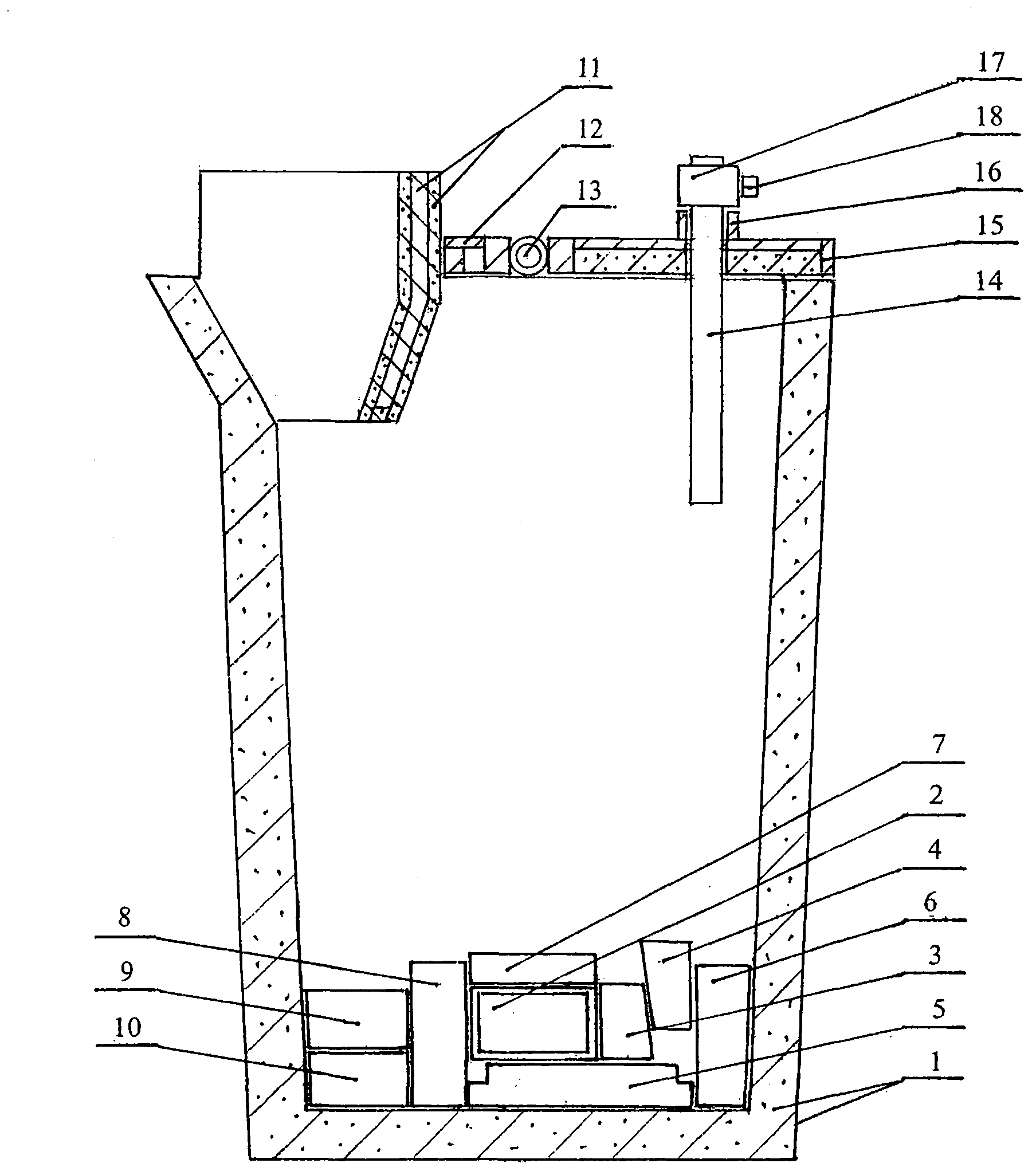

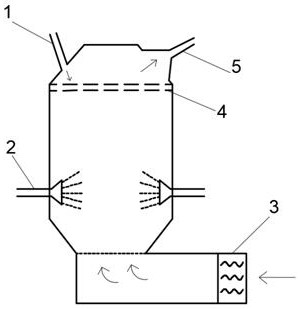

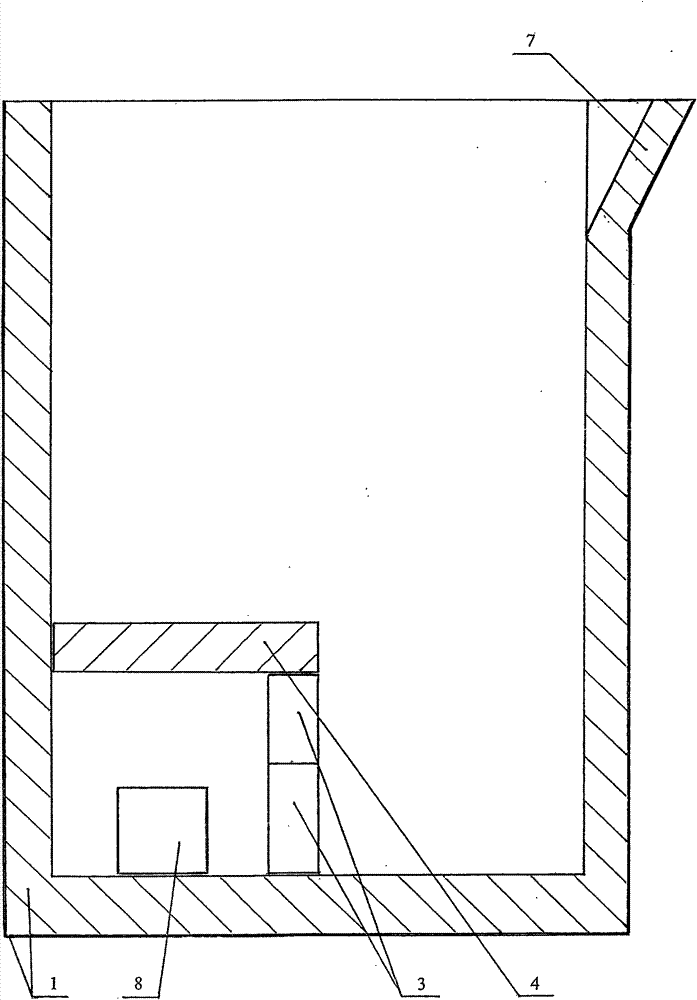

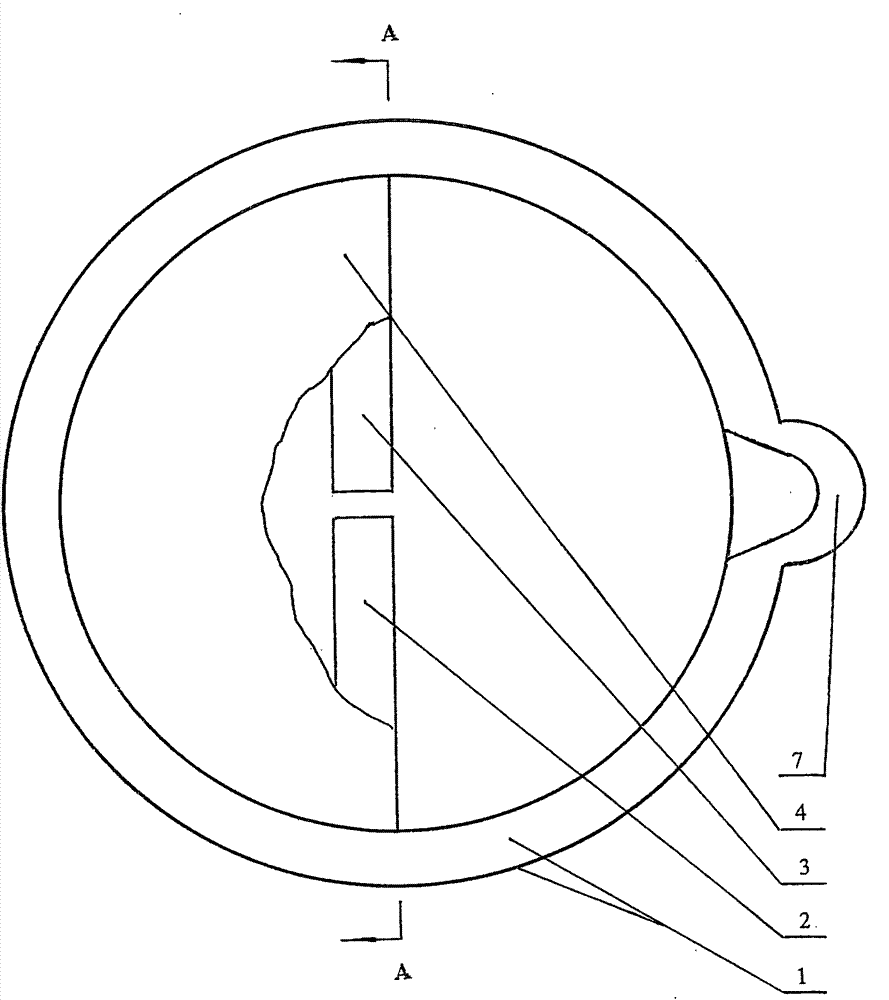

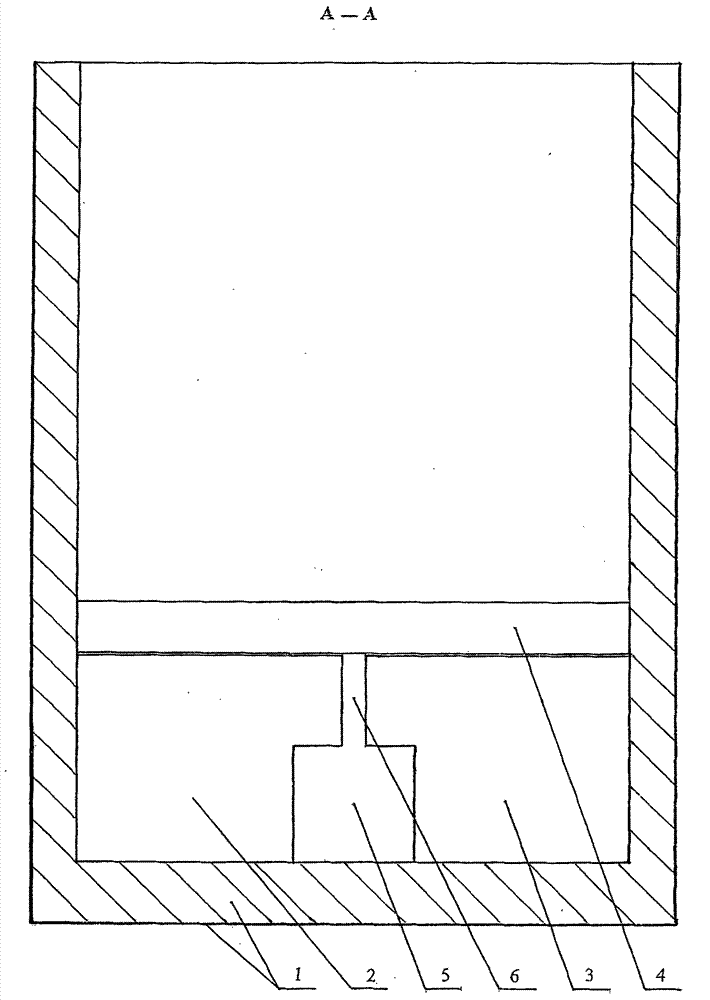

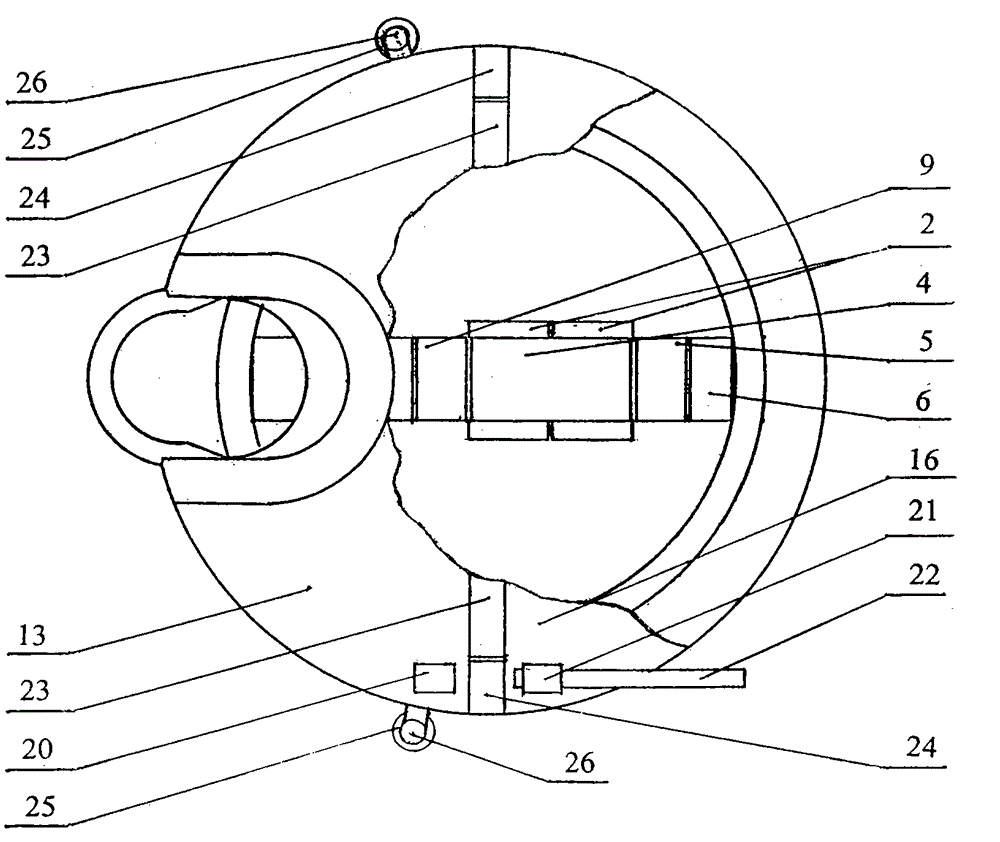

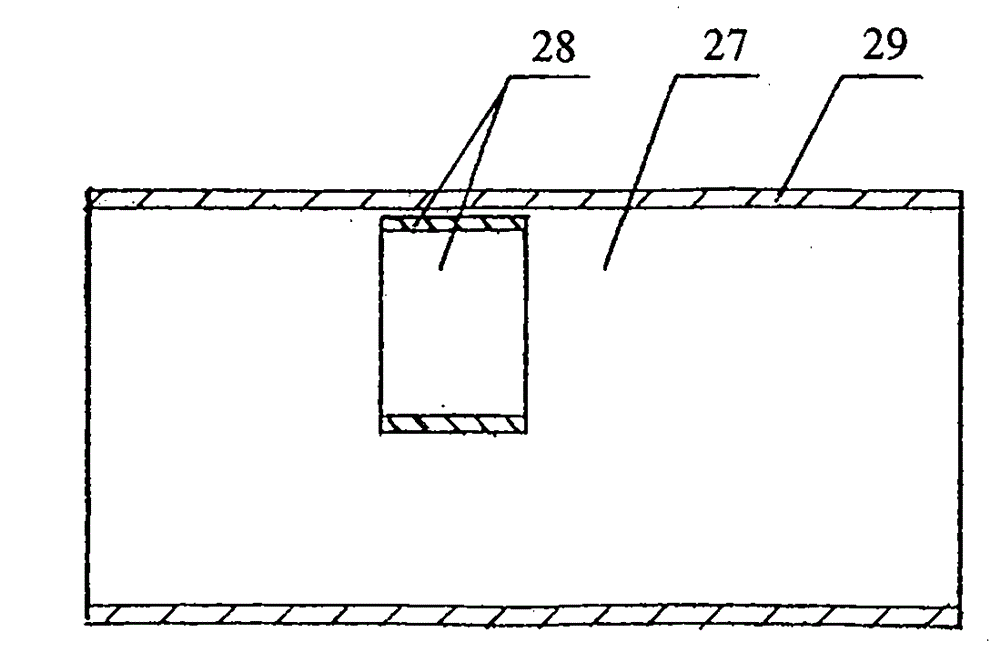

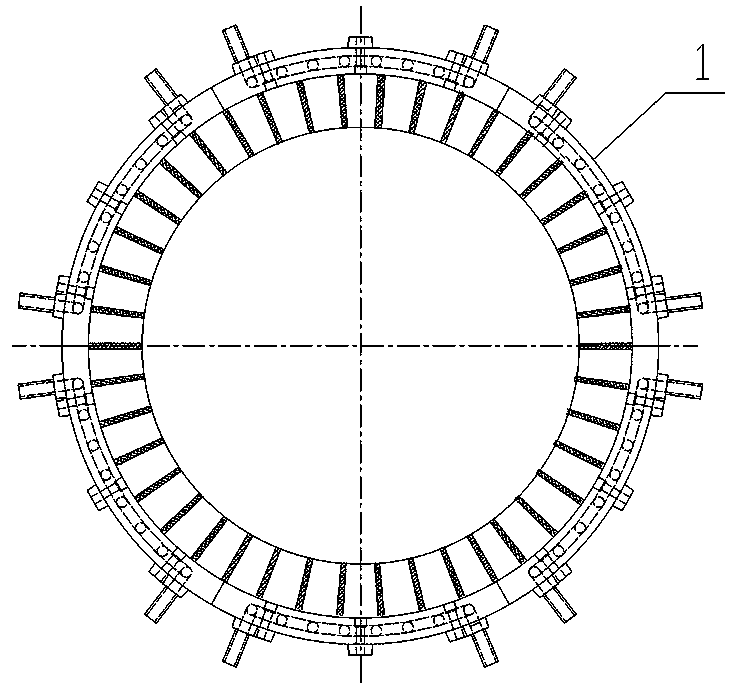

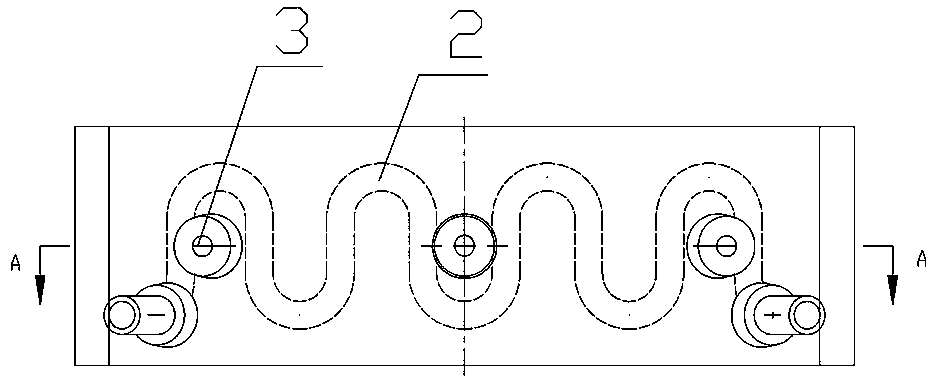

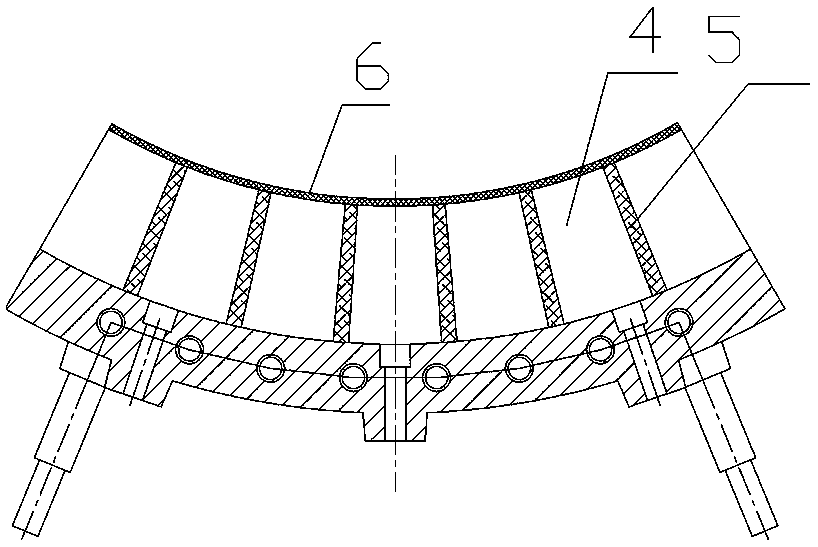

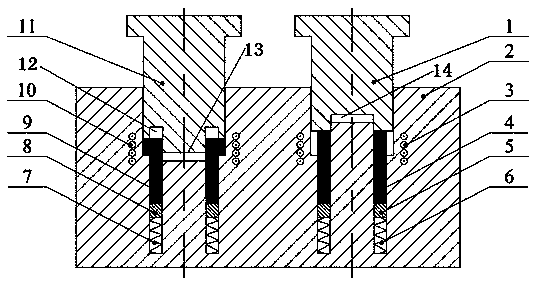

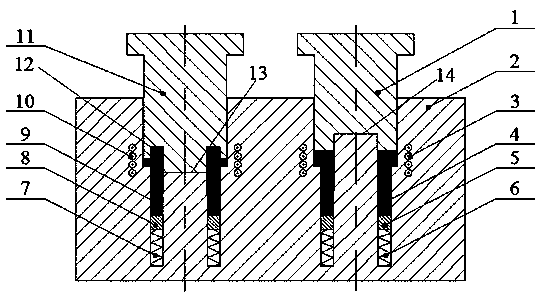

Balling processing method of nodular cast iron

ActiveCN103874771ASolve the problem of moving up after meltingAdjust the amount added at any timeFerrosiliconRare earth

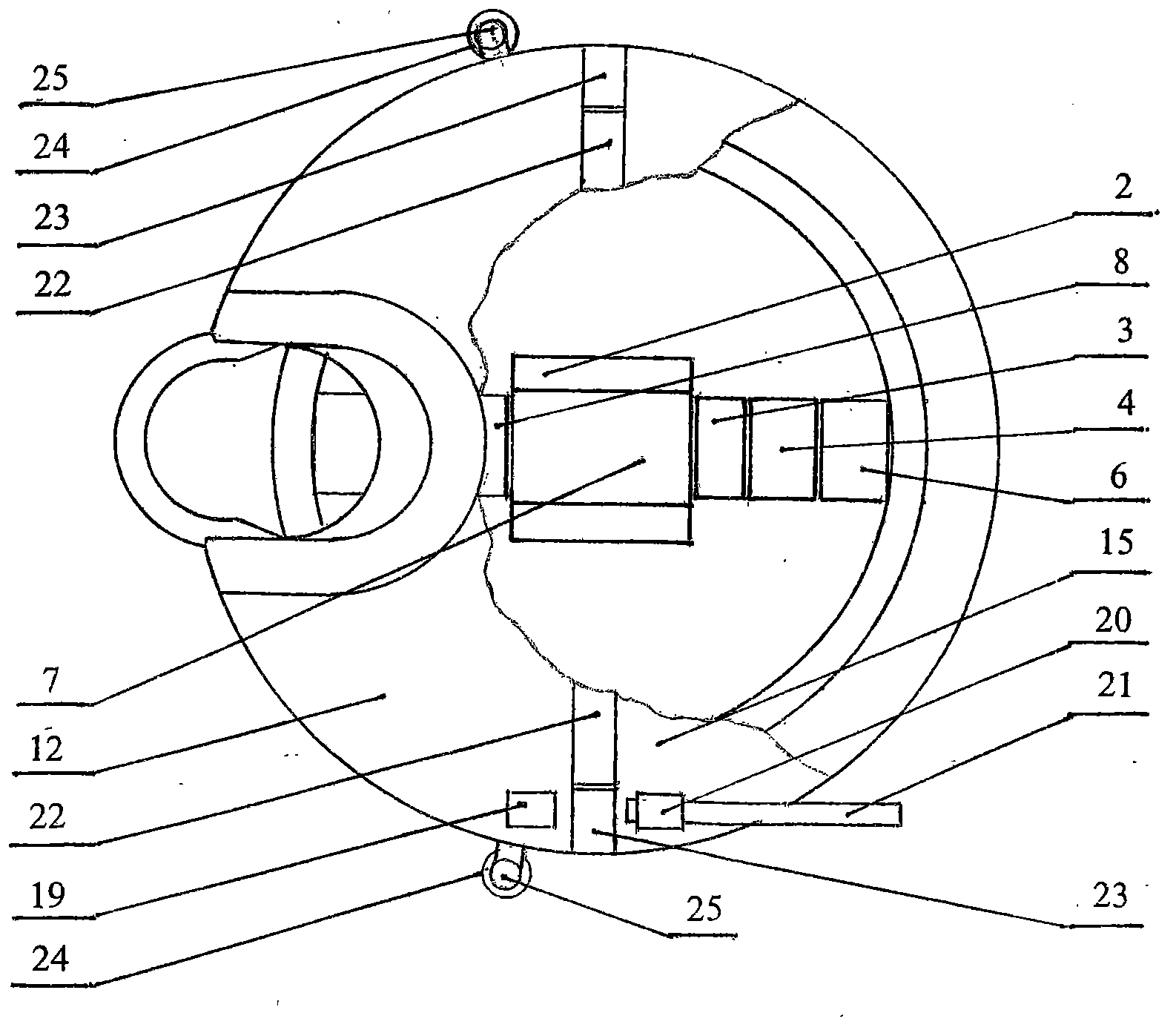

Disclosed is a balling processing method of nodular cast iron. A left vertical baffle plate (2) and a right vertical baffle plate (3) are laid at the bottom part of a balling processing bag (1). A semicircular reaction chamber upper cover plate (4) is horizontally laid on the top parts of the left vertical baffle plate (2) and the right vertical baffle plate (3). A vertical surface of the reaction chamber is provided with one or more reaction chamber material feed ports (5). The upper end of one reaction chamber material feed ports (5) is provided with a pressure reducing groove (6). The upper end of the pressure reducing groove (6) is at the same level as the semicircular reaction chamber upper cover plate (4). The finished balling processing bag is dried and then used for balling processing. The steps of balling processing are as follows: the required no-lining steel pipe overall rare earth magnesium ferrosilicon nodulizer (8) or low silicon or silicon-free nodulizer is put into the reaction chamber of the balling processing bag (1); the Ferrosilicon inoculants is put into the reaction chamber of the balling processing bag (1) and stacked at the material feed ports (5); melted iron flows into the balling processing bag (1) to carry out the balling reaction; and when the balling reaction is completed, the dross is removed, and the melted iron is coated by compound inoculants.

Owner:杭州合大铸造有限公司

Smelting method for cylinder cover of marine diesel engine

The invention relates to the technical field of marine diesel engines, and particularly relates to a smelting method for the cylinder cover of a marine diesel engine. The smelting method comprises the following steps of: proportioning, smelting original molten iron, performing spheroidization treatment, performing primary inoculation treatment, performing secondary inoculation treatment, and pouring. During smelting, a certain amount (about 0.25%) of Mn is added, so as to ensure that the content of pearlites meets technical requirements while ensuring the strength of castings; 1.3-1.8% of T-1 type spheroidizing agent is used for performing inoculation twice, and stream inoculation is performed during the secondary inoculation, so that the spheroidization rate can be increased, the spheroidization degeneration of the castings can be prevented, and the inoculation effect can be ensured; and moreover, the T-1 type spheroidizing agent is a heavy-rare-earth ferrite type spheroidizing agent capable of effectively stabilizing ferrite, ensuring the low content of rare earth, and greatly reducing the shrinkage trend of the castings.

Owner:CRRC QISHUYAN CO LTD

Spheroidizing method

The invention relates to a spheroidizing method for producing spheroidal graphite cast iron, and the method comprises the following steps: injecting melted rare earth magnesium silicon iron nodulizer alloy fluid containing less than or equal to 20% of Mg, less than or equal to 65% of Si and less than or equal to 3% of RE into a square steel pipe for cooling and solidification; fixing the whole rare earth magnesium silicon iron nodulizer of the outer lining square steel pipe in a spheroidizing bag by using refractory bricks and wedge-type chocks at the bottom of the spheroidizing bag covered, and then carrying out spheroidizing by utilizing a bag injecting method. The time for controlling spheroidizing is accurate, the molten iron cooling is less in the spheroidizing and casting process, the absorption rate of Mg, RE and Si after the spheroidizing is high, degradated spheroidization is prevented 15min after spheroidizing, the environment for producing and using a nodulizer is improved, the production cost is remarkably reduced and the quality of the product is improved. Compared with the conventional rare earth magnesium silicon iron nodulizer containing the rare-earth element RE of 2-8%, the spheroidizing method can be used for reducing the use amount of the rare-earth element RE by 50-75%.

Owner:深圳市嘉能新型环保建材有限公司

Pure magnesium spheroidizing technology of lost foam ductile cast iron

ActiveCN106636870APrevent defects such as cold insulation wrinkle skinAvoid stickingSulfurFerrosilicon

The invention discloses a pure magnesium spheroidizing technology of lost foam ductile cast iron. The pure magnesium spheroidizing technology comprises the steps that a spheroidizing agent is placed into a lip-pour ladle reaction chamber, a cover of the reaction chamber is closed, and a conventional nucleating agent, ferrosilicon, is added into a lip-pour ladle; after molten iron in a heat-insulated furnace is subjected to deslagging, molten iron is added into the lip-pour ladle, and the temperature of molten iron is controlled to be 1520 DEG C to 1560 DEG C; then, the lip-pour ladle is overturned, and molten iron and the spheroidizing agent react for 60 s to 70 s; and pouring is carried out while stream inoculation is achieved, wherein the addition amount of the stream nucleating agent is 0.08% to 0.15% of the weight of molten iron; the spheroidizing agent is a mixture of pure magnesium ingots and calcium chloride; and the weight ratio of molten iron to the pure magnesium ingots to calcium chloride to ferrosilicon is 1000 to (1.4 to 2.0) to (0.2 to 0.5) to (4 to 8). According to the pure magnesium spheroidizing technology of lost foam ductile cast iron, the spheroidizing problem of high-sulfur high-silicon molten iron can be effectively solved, the spheroidizing grade is high, a required matrix structure can be obtained, the problems that the spheroidizing effect is poor, the quality of castings is not stable, and the rejection rate is high are solved, the technology does not require lip-pour ladle nucleating, the procedures can be decreased, and the labor intensity is reduced.

Owner:桃江新兴管件有限责任公司

Manufacturing method of ultra-large-section low-temperature high-toughness ferrite spheroidal graphite iron casting

ActiveCN108866427AMeet technical requirementsShorten the setting timeFoundry mouldsFoundry coresNuclear powerDuctile iron

The invention discloses a manufacturing method of an ultra-large-section low-temperature high-toughness ferrite spheroidal graphite iron casting. The spheroidal graphite iron casting is more than 50 tons in weight, is 400mm or more in wall thickness, and is prepared from the following components: 3.6 to 3.7 percent of C, 0.9 to 1.0 percent of Si<original>, 1.9 to 2.0 percent of Si<final>, less than or equal to 0.1 percent of Mn, less than or equal to 0.03 percent of P, less than or equal to 0.01 percent of S, 0.03 to 0.08 percent of Mg, 0.01 to 0.02 percent of RE, 0.6 to 0.8 percent of Ni and0.003 to 0.005 percent of Sb. During manufacturing, the technical measures of ''high-temperature pure base iron melt, water-cooled metal mold, cold iron, spheroidizing agent 5800, compound strengthening inoculation, alloying and low-temperature box beating'' are adopted, so that the prepared ultra-large-section low-temperature high-toughness ferrite spheroidal graphite iron casting can meet the quality standard of a spheroidal graphite iron casting of which the license number is QT400-18, and can meet the technical requirements of ultra-large-section spheroidal graphite iron castings applied to wind power, nuclear power and the like.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

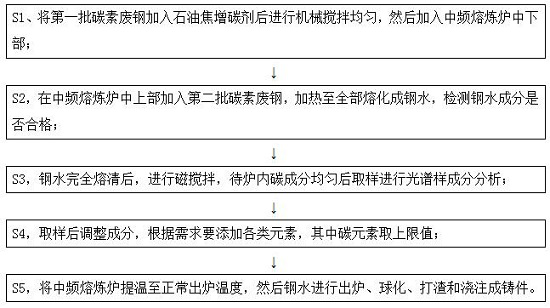

Method for eliminating casting shrinkage cavity defect by using petroleum coke carburant

InactiveCN113913584APrevent floatingPrevent spheroidizationProcess efficiency improvementGraphiteGraphitic carbon

The invention discloses a method for eliminating a casting shrinkage cavity defect by using a petroleum coke carburant. The method comprises the following steps that a first batch of carbon steel scrap is added into the petroleum coke carburant for being mechanically stirred uniformly, and then added into the middle-lower part of a medium-frequency smelting furnace; a second batch of carbon steel scrap is added into the middle-upper part of the medium-frequency smelting furnace, and heating is carried out until the carbon steel scrap is completely molten into molten steel; after the molten steel is completely melted down, magnetic stirring is carried out, and after carbon components in the furnace are uniform, sampling is carried out for spectrum sample component analysis; and the components are adjusted after sampling, and various elements are added according to requirements. The petroleum coke is added at the initial stage of the smelting furnace, so that the dissolving speed of the petroleum coke can be guaranteed, graphite carbon is effectively prevented from forming graphite floating in a casting, spheroidizing recession of graphite is effectively prevented, graphitizing expansion in a matrix is fully exerted, shrinkage porosity and shrinkage cavity defects of a hot spot part in the casting are effectively prevented, raw material waste is reduced, and the production cost is reduced.

Owner:临清市金光机械制造有限公司

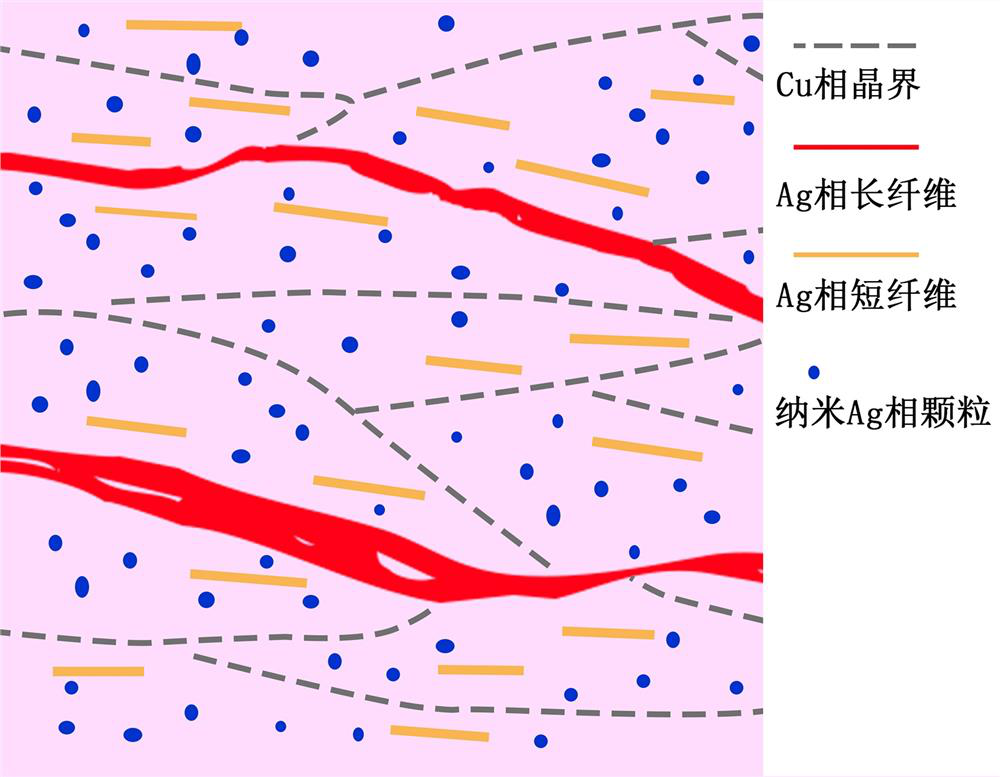

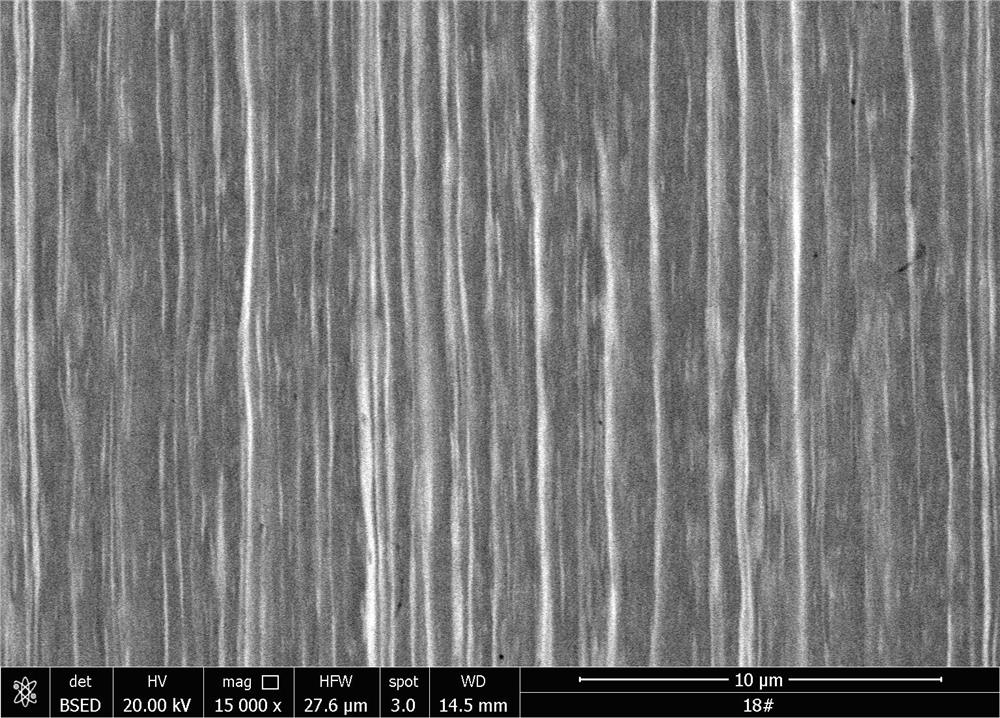

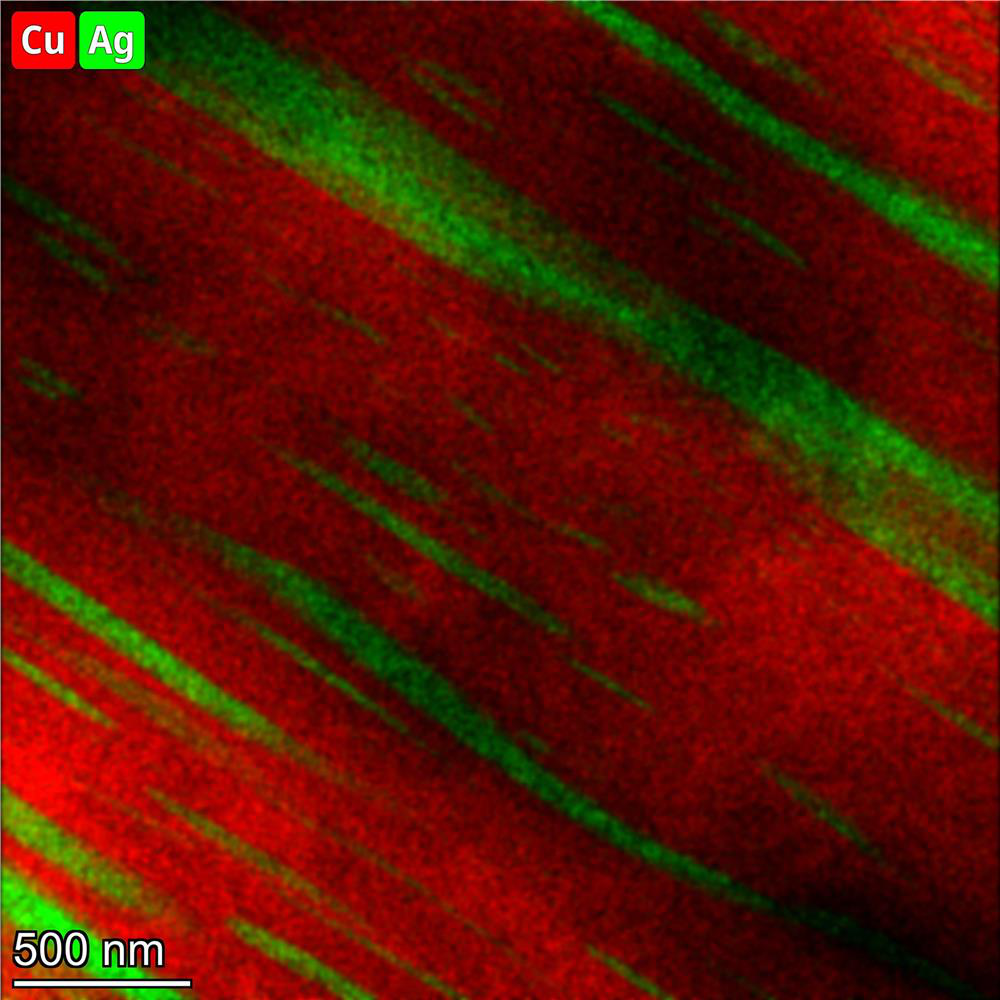

Preparation method of copper-silver alloy wire

ActiveCN114561566AProtective substrateImprove conductivityFurnace typesHeat treatment furnacesWire rodRare-earth element

The invention discloses a preparation method of a copper-silver alloy wire. A copper-silver alloy comprises the following components in percentage by weight: 18-26% of Ag, 0.02-0.25% of La, a mass ratio of Sc to La being 0.5-1.5, and the balance of Cu. And drawing for a plurality of passes to obtain a wire rod finished product. According to the copper-silver alloy wire, only two rare earth elements Sc and La are added, the mass ratio of Sc to La is controlled to be 0.5-1.5, and after the strengthening treatment process, the copper-silver alloy wire with the room temperature tensile strength reaching 1050-1520 MPa, the electric conductivity reaching 75-87% IACS and the electrical resistivity lower than 1.982-2.30 mu omega.cm can be obtained; when the environment temperature is-196 DEG C, the low-temperature tensile strength of the alloy is 1450-1860 MPa, the low-temperature resistivity is 0.70-0.87 mu omega.cm, and the comprehensive performance is excellent.

Owner:JIANGXI UNIV OF SCI & TECH

Si-Al-La nucleating agent for preventing shrinkage of ductile iron casting and preparation technique thereof

The invention discloses an Si-Al-La nucleating agent for preventing shrinkage of a ductile iron casting. The Si-Al-La nucleating agent comprises the following components in percentage by mass: 70-75%of Si, 3.2-4.5% of Al, 2.0-2.4% of La, 0.8-1.5% of Ca and the balance of Fe. By adopting the Si-Al-La nucleating agent, the problems that a riser cannot be arranged or a feeding distance is overlargeand the like for high-performance thin-walled small workpieces with complicated structures and shapes or certain parts because of geometrical position and technological limits can be effectively solved; shrinkage of the ductile iron casting can be prevented by the Si-Al-La nucleating agent; product quality is improved; the use range is wide; the limit is low; and meanwhile the cost is lowered.

Owner:南京浦江合金材料股份有限公司

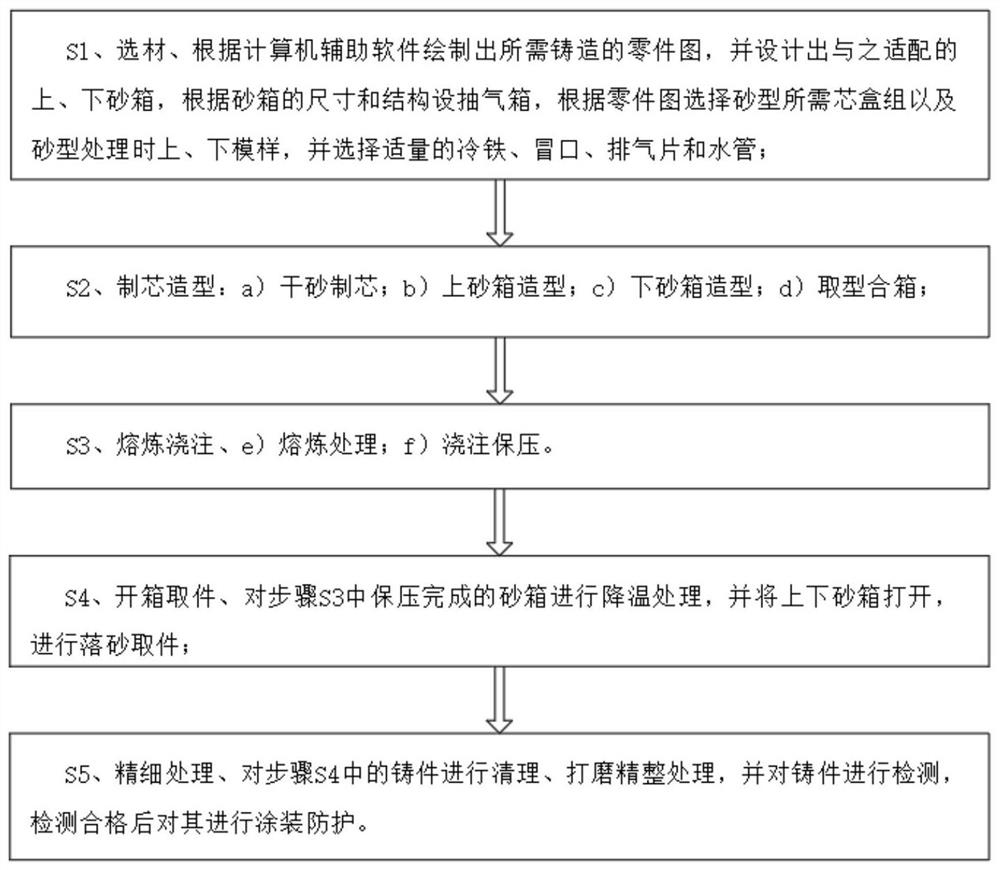

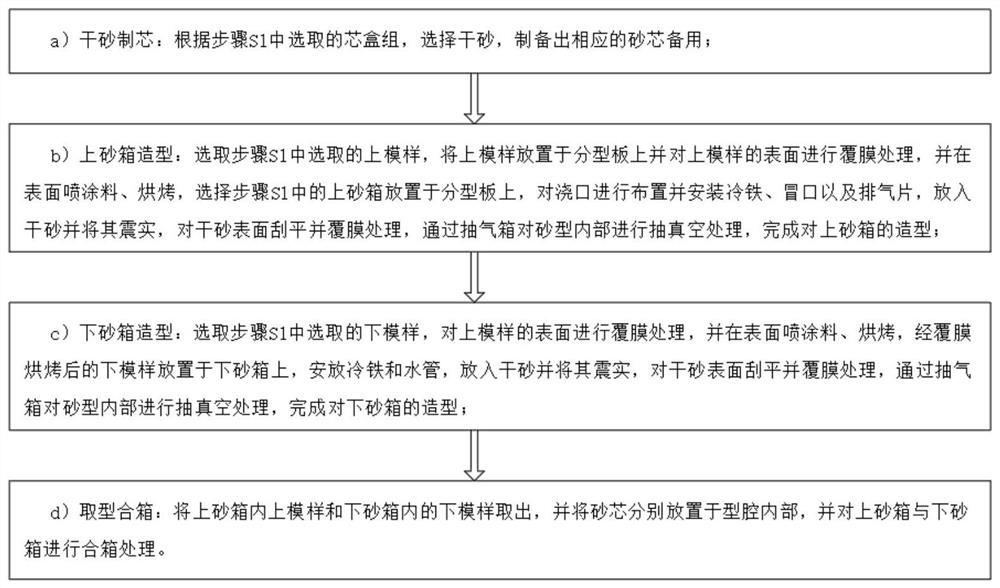

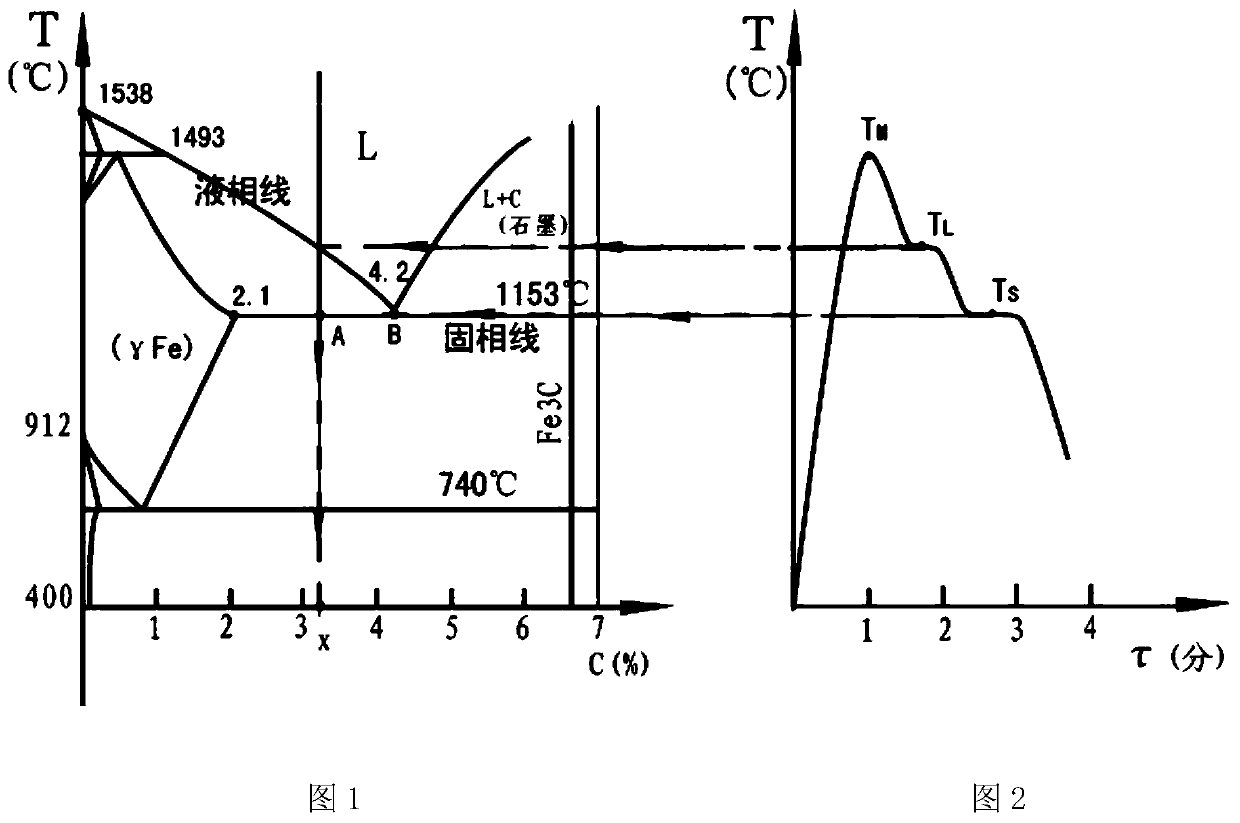

V-method casting process for nodular cast iron casting

The invention belongs to the technical field of spheroidal graphite cast iron casting processing, particularly relates to a V-method casting process for a spheroidal graphite cast iron casting, and provides the following scheme aiming at the problem that the shrinkage porosity tendency of a shrinkage cavity is relatively large when a thick and large-section casting is subjected to casting processing: S1, material selection; s2, core making and modeling; s3, smelting and pouring; s4, opening the box and taking the package; s5, fine processing; according to the method, the thick and large-section ductile iron casting is cast through V-method negative pressure, during casting of the casting, by controlling the sand mold, the compactness, the number of sprues, the number of dead heads and the number of chilling blocks and selecting the proper pouring temperature, the graphitization expansion force of the casting in the solidification casting process can effectively avoid shrinkage cavity and shrinkage porosity defects, and the casting quality is improved. The negative pressure pipe is pressurized at the thick and large part of the casting, so that the cooling speed is accelerated to prevent spheroidizing recession, and meanwhile, the graphitization expansion force is reduced, so that the phenomena of shrinkage cavities and shrinkage porosity of the casting are greatly reduced.

Owner:山东宇信铸业有限公司

Intelligent detector for molten iron with comprehensive performances such as elastic modulus elongation, tensile yield strength and the like

PendingCN109870552ASalvage Crafting TipsPrevent spheroidizationTesting metalsDisplay deviceEngineering

The invention relates to an intelligent detector for molten iron with comprehensive performances such as elastic modulus elongation, tensile yield strength and the like. The detector comprises a signal acquisition device, a thermoelectric force joint metering interface device, a data processing host and data output equipment; the signal acquisition device is used for generating an electric signalrelated to the temperature change of the graphite-state molten iron; the thermoelectric force joint metering interface device is used for carrying out amplification and analog / digital conversion on the electric signal, so that the data processing host can process a digital signal; and the data output equipment comprises a data remote transmission device, a storage device, a display device and a printing device. The intelligent detector is suitable for rapid detection of 22 types of molten iron and 20 key parameters specified in national standards and international standards, and is high in detection precision and high in stability.

Owner:HEFEI UNIV OF TECH +1

Heat-resistant sphere and production process thereof

The invention relates to a heat-resistant sphere which is prepared from the following components in percentage by weight: 3.00-4.20% of C, 1.8-3.0% of Si, 0.2-1.2 of Mn, 2.0-4.0% of Ni, 0.3-1.0% of Mo, less than or equal to 0.07% of P, less than or equal to 0.02% of S and the balance of Fe. According to the heat-resistant sphere provided by the invention, the fatigue resistance of the material is guaranteed by adding Ni and Mo elements; and moreover, the cold cracking tendency is reduced, the safety coefficient is improved, and the service life is prolonged. The preparation process is further improved, for example, the content of S is strictly controlled, and S is removed in a ladle by using industrial sodium carbonate; a metal-stream inoculation treatment method is adopted; a unique high-medium annealing treatment process and the like are adopted, and the tensile strength, yield strength, ductility and hardness HS of the prepared heat-resistant sphere are greatly improved.

Owner:TOYO GRINDING BALL MAANSHAN

Hot pressing former oil cylinder and preparation method thereof

The invention discloses a hot pressing former oil cylinder and a preparation method thereof, and belongs to the technical field of hot pressing former oil cylinder preparation. A bottom pouring systemis used for pouring; cold iron is arranged on the inner hole surface of a hot pressing former oil cylinder and on the bottom surface of a flat plate; under a synergistic effect of various process parameters, such casting defects as casting working surface air holes, hole shrinkage, looseness, cracks and slag and sand inclusion in the hot pressing former oil cylinder are effectively solved, the comprehensive mechanical capacity and the yield of hot pressing former oil cylinder castings are improved, and the production cost is reduced; and meanwhile, on selection of modeling sand, scrubbing rawsand with an SiO2 content of higher than 90% and a particle size of 50-100 meshes is adopted as the modeling sand, and furan resins are used as adhesives, so that the pollution emission in the casting production process is reduced.

Owner:CHENGDU AERONAUTIC POLYTECHNIC

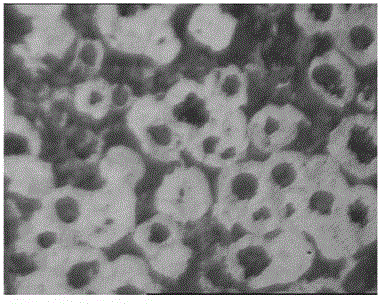

Silicon-bismuth as-cast pearlitic ductile iron inoculant

InactiveCN101381793AIncrease pearlite volumeImprove mechanical propertiesInvestment materialDuctile iron

The invention relates to an auxiliary material in metal smelting, in particular to a nucleating agent for silicon-bismuth casting state pearlite nodular cast iron. The auxiliary material comprises the following compositions in weight portion: 70 to 90 portions of silicon, 5 to 15 portions of FesiMg8Re7, 3 to 7 portions of bismuth and 3 to 7 portions of a fluxing agent. The auxiliary material has the advantages that the auxiliary material obviously improves the amount of pearlite of casting state nodular cast iron, has good spheroidization and small chilling tendency, solves the problem of degradated spheroidization of the nodular cast iron and needs no heat treatment for graphite distortion and obtains a novel nodular cast iron which has fine and round graphite balls and high comprehensive mechanical performance in the casting state.

Owner:胡德民

Pipe die powder for centrifugally casting nodular cast iron pipe and preparation process thereof

The invention discloses pipe die powder for centrifugally casting a nodular cast iron pipe and a preparation process thereof. The pipe die powder comprises the following components in percent by mass: 60-65 percent of Si, 1.5-2.0 percent of Ca, 2.0-3.0 percent of Ba, 1.4-1.6 percent of Mn, 1.0-1.5 percent of Mg, 1.0-2.0 percent of Zr, 0.7-1.5 percent of Al and the balance of Fe; and the granularities of pipe die powder comprise less than 1.5 percent of 80 mu, 25-30 percent of 100-120 mu, 40-50 percent of 140-180 mu, 25-30 percent of 200-300 mu and less than 2.5 percent of more than 300 mu. The preparation process comprises the following steps of: preparing, melting, pouring, cooling, crushing, milling, proportioning granularities and packaging in vacuum. The pipe die powder has the advantages of uniform components, consistent melting points and reasonable granulometric class, and is beneficial to the prolonging of the service life of a pipe die of the nodular cast iron pipe, the reduction of a series of casting defects of cockles, poor nodulizing, surface cracks and the like of the nodular cast iron pipe, the improvement of the quality of the nodular cast iron pipe and the yield, and the lowering of the production cost.

Owner:YUZHOU HENGLILAI ALLOY CO LTD

High Strength Gas Cylinder Head and Its Production Technology

ActiveCN108715974BImprove organizationQuality improvementFurnace typesHeat treatment furnacesGas cylinderDuctile iron

The invention discloses a high-strength fuel gas cylinder cover and a production technology thereof. The production technology comprises the following steps that step (1), furnace burdening is prepared, low-S nodular cast iron pig iron and pure carbon waste steel are selected, a medium-frequency induction electric furnace is adopted for smelting, wherein the smelting temperature is controlled to be 1500-1550 DEG C, argon is blown into molten iron, the blowing depth is 20-40% at the depth of the furnace, the blowing time is 5-8 minutes, and then the molten iron is discharged; step (2), spheroidizing and first inoculation treatment are carried out, and a pour over method is adopted; step (3), pouring and a second inoculation treatment are carried out, the pouring temperature of the molten iron is not lower than 1400 DEG C, the second inoculation is carried out by adopting a second nucleating agent during the pouring, and the second inoculation is a metal-stream instantaneous inoculation;step (4), after the pouring is completed, the waste heat of a casting is used for carrying out heat treatment until the room temperature is reached. The technology is reasonable in design, the heat treatment process of the technology is omitted, so that the production cost is reduced, environmental pollution is reduced; and the mechanical property of the fuel gas cylinder cover obtained by the technology is improved correspondingly.

Owner:宁波力古机械制造有限公司

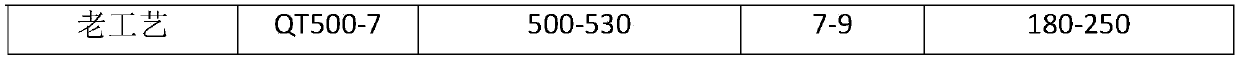

A kind of thixotropic forming method for pipe parts with shoulders

ActiveCN109092958BReduce transfer stepsShorten the manufacturing cycleShaping toolsFurnace typesSemi solidHeat conservation

The invention discloses a contact forming method of a pipe with a shoulder, and belongs to the field of semi-solid forming. The method comprises the following steps that firstly, a metal pipe is conducted local induction heating to a solidus temperature or above, and heat preservation is carried out; and then the metal pipe is put into a preheated progressive mold to carry out first pass extrusiondeformation and pressure maintaining is carried out; then the metal pipe is rapidly taken out, and put into the preheated progressive mold to carry out second pass extrusion deformation and pressuremaintaining is carried out so as to obtain a pipe part with the shoulder; then rapid water quenching is carried out on the pipe part with the shoulder, and finally T6 heat treatment is carried out. According to the method, progressive mold two-step local contact extrusion forming is adopted to prepare the pipe part with the shoulder, the mold is simple in structure, production efficiency is high,cost is low, product quality is high, a material utilization rate is high, and mechanization and automatic production are realized conveniently.

Owner:KUNMING UNIV OF SCI & TECH

Electron beam selective melting forming method for pure tungsten metal parts

ActiveCN107914014BPrevent spheroidizationAvoid droplet spheroidizationAdditive manufacturing apparatusIncreasing energy efficiencyElectron bunchesTungsten

The invention discloses a method for electron beam selective melting and forming of pure tungsten metal parts. In the method, a three-dimensional model of the pure tungsten metal part is firstly established by software and sliced to obtain slice data, and then according to the slice data of the three-dimensional model Electron beams are used to melt tungsten powder into selected areas to obtain pure tungsten metal parts. The invention uses electron beams to melt tungsten powder into shape, which improves the energy of the heat source, ensures complete melting of tungsten powder with high melting point, avoids spheroidization during the melting process of tungsten powder, and separates the forming bottom plate and tungsten powder before scanning the melting selection area. The high-temperature preheating treatment of the powder reduces the temperature gradient during the forming process of pure tungsten metal parts, slows down the cooling rate of the micro-melt pool, avoids the spheroidization of tungsten powder droplets caused by rapid cooling, and reduces the spheroidization of pure tungsten metal parts. Cracking greatly improves the forming quality of pure tungsten metal parts and increases the density of pure tungsten metal parts.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Method and product for preparing copper-based shape memory alloy with arbitrary shape in situ by laser

ActiveCN109365810BSolve processing difficultiesUniform compositionAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing technologyShape-memory alloy

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com