Metal liquid integrative performance on-line intelligent checking system

A comprehensive performance and detection system technology, applied in the field of online intelligent detection system for comprehensive performance of molten metal, can solve the problems of identification, small detection range, few parameters, and inability to detect gray iron molten iron at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Before the online detection system of comprehensive performance of molten metal of the present invention is described in detail, the reasons for the technical defects of the existing online detection system are first analyzed theoretically, and thus the characteristics and excellent effects of the present invention can be better understood mechanism.

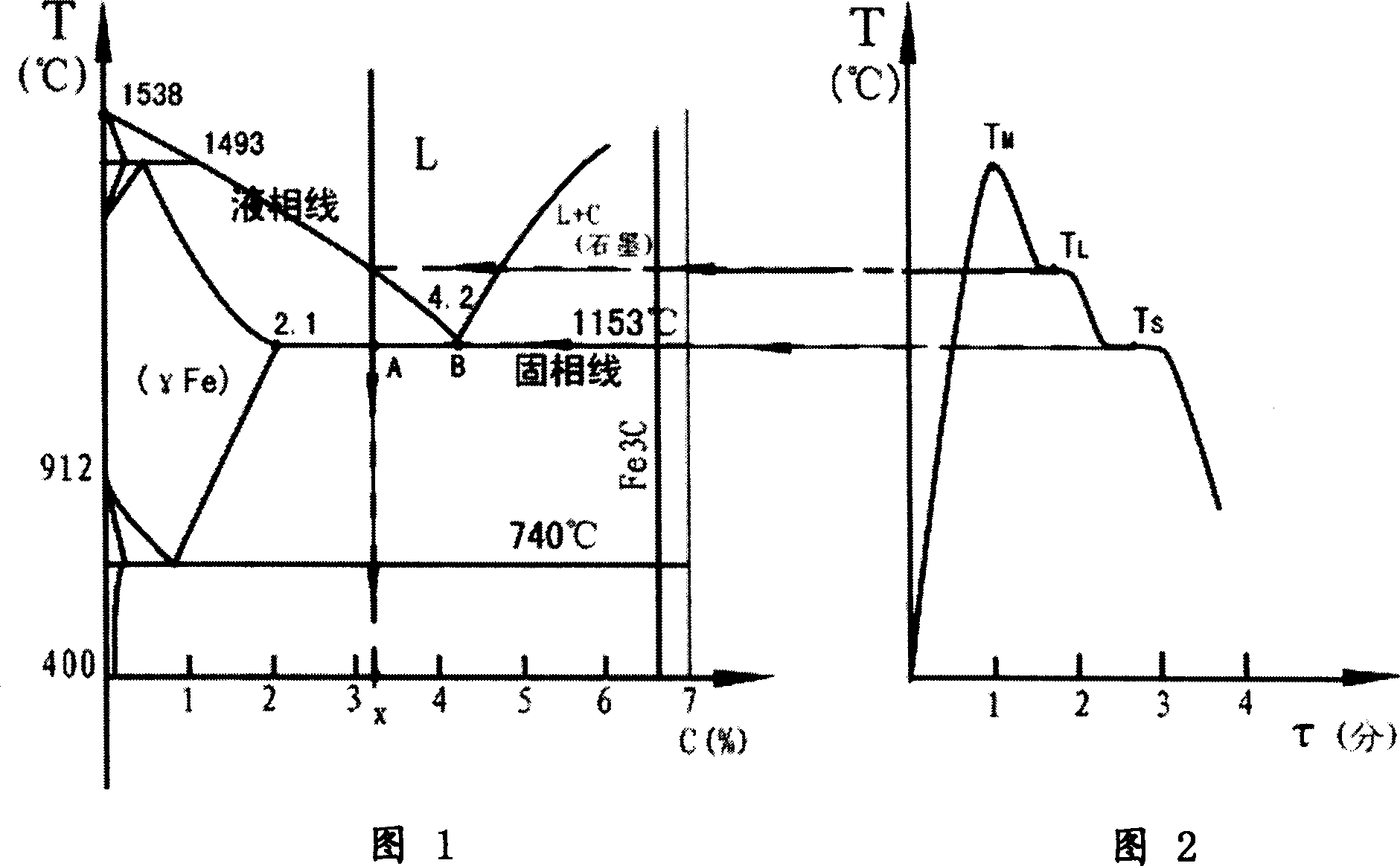

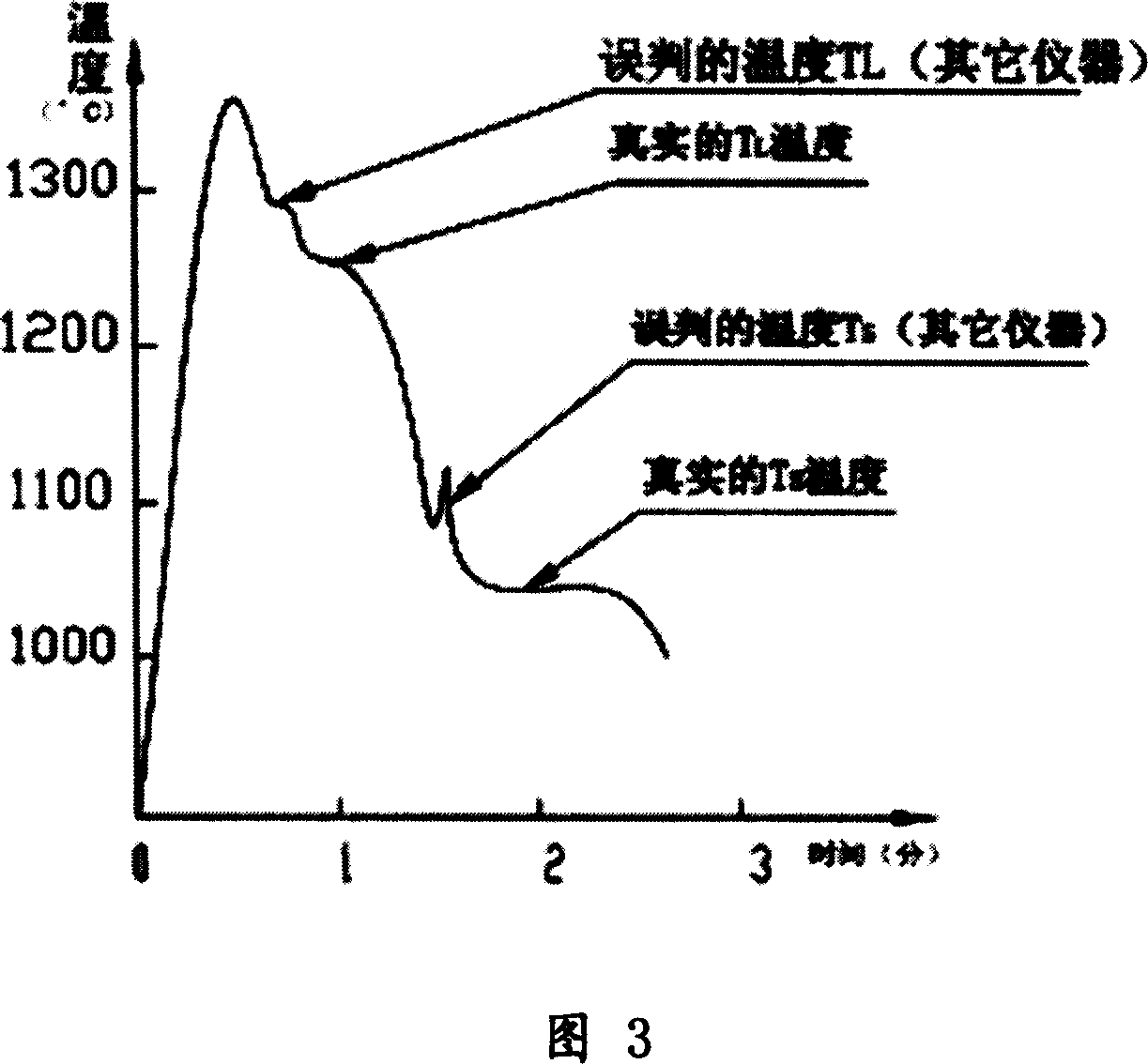

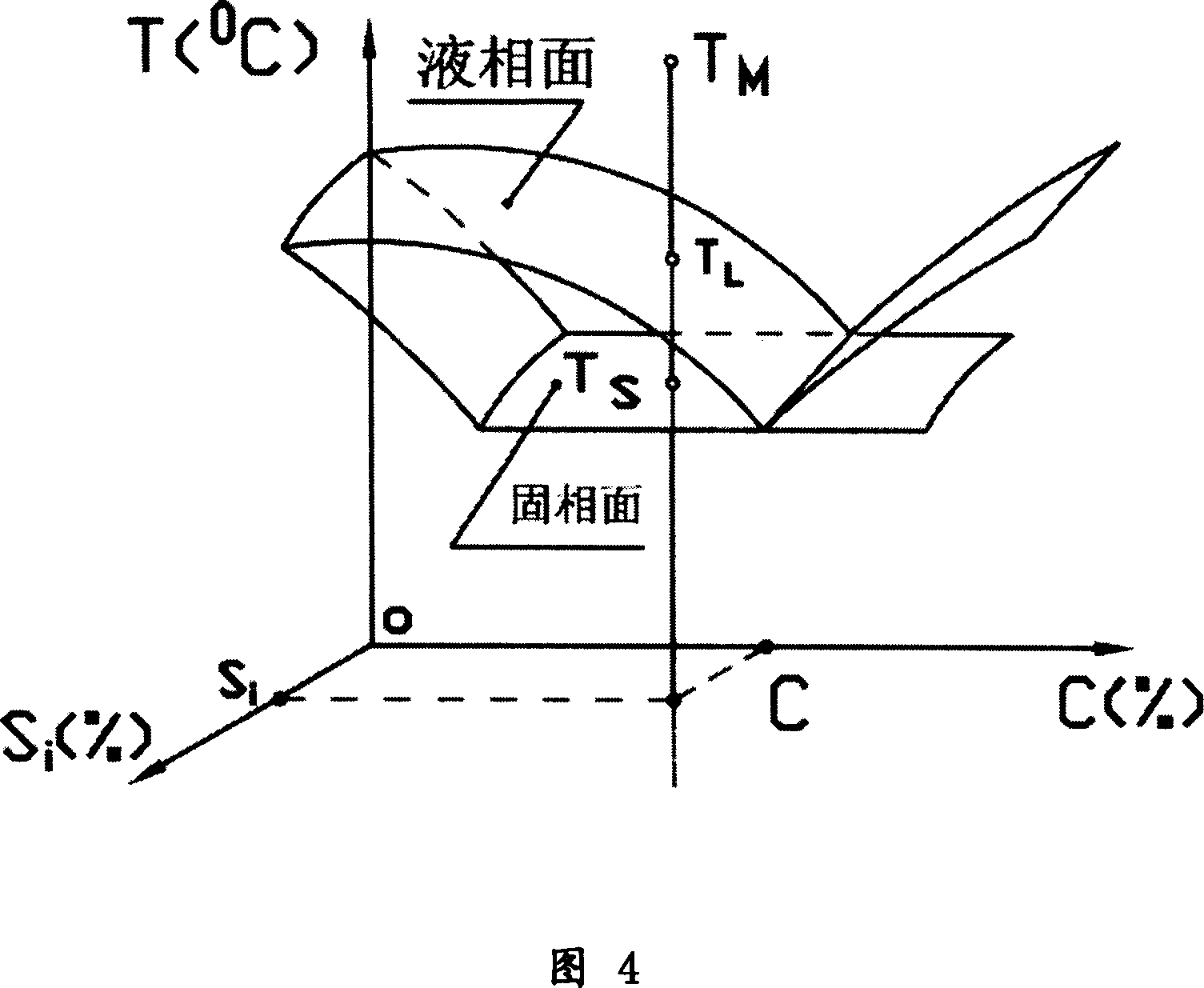

[0022] The thermal analysis method is to use the latent heat of crystallization released by the state change of each phase during the solidification of the alloy to be different, thereby forming an inflection point or a plateau on the cooling curve, thereby inverting the chemical composition of the alloy.

[0023] The existing on-line detection system only adopts the thermal analysis method, and takes the binary ideal state, that is, the molten metal or cast iron is regarded as an iron-carbon binary alloy in an ideal state, so it can only measure the carbon equivalent C EL , carbon C and a few chemical components; the Fe-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com