A kind of thixotropic forming method for pipe parts with shoulders

A technology of thixotropic forming and tubes, applied in the direction of forming tools, furnace types, furnaces, etc., can solve the problems of long production cycle, poor mechanical properties, low material utilization rate, etc., and achieve high production efficiency, good performance, and improved The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

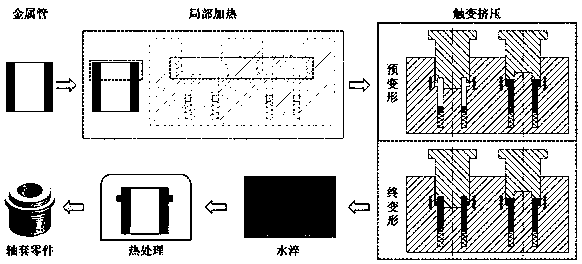

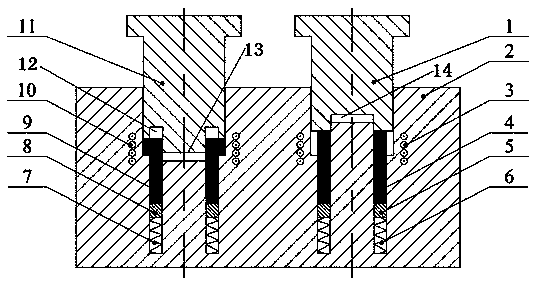

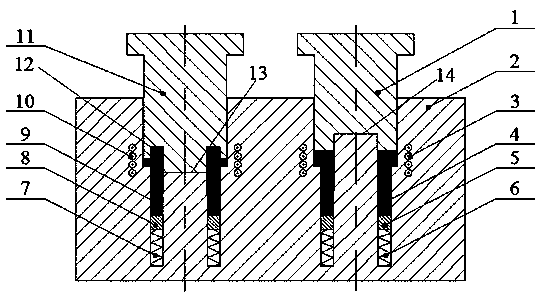

[0035] A kind of method for thixotropic forming of a copper alloy tube with shoulders described in this embodiment, the technological process is as follows figure 1 As shown, the mold structure is as Figure 2-3 As shown, the specific steps are as follows:

[0036] (1) The material of this example is ZCuSn10P1 copper alloy, and the measured solidus temperature of ZCuSn10P1 copper alloy is 876.1°C, and the liquidus temperature is 1024.2°C.

[0037] (2) Locally heat an extruded ZCuSn10P1 copper alloy tube with an inner diameter of 20mm, a wall thickness of 10mm, and a height of 50mm. The heating height is 10mm, and the heating temperature is 886°C and kept for 5 minutes; at the same time, the cavity of the concave mold is preheated to 420°C.

[0038] (3) Put the heated ZCuSn10P1 copper alloy tube into the pre-deformation cavity of the preheated die, and then drive the pre-deformation punch 1 to extrude the metal tube at a movement speed of 8mm / s, and hold the pressure for 3s af...

Embodiment 2

[0044] A kind of thixotropy forming method of 7075 aluminum alloy pipe with shoulders described in this embodiment, the preparation process is as follows figure 1 As shown, the specific steps are as follows:

[0045] (1) The material of this example is 7075 aluminum alloy, and the measured solid-liquidus temperature range of 7075 aluminum alloy is 540-638°C.

[0046] (2) Partially heat the 7075 aluminum alloy tube with an inner diameter of 20mm, a wall thickness of 10mm, and a height of 50mm prepared by spinning. The heating height is 10mm, and the heating temperature is 545°C and kept for 10 minutes; at the same time, the concave mold cavity is preheated to 360°C.

[0047] (3) Put the heated 7075 aluminum alloy tube into the pre-deformation cavity of the preheating die, and then drive the pre-deformation punch 1 to extrude the metal tube at a movement speed of 10mm / s, and hold the pressure for 6s after extrusion.

[0048] (4) Take out the pre-deformed 7075 aluminum alloy tub...

Embodiment 3

[0052] A kind of shoulder AZ91D magnesium alloy tube thixotropic forming method described in this embodiment, the preparation process is as follows figure 1 As shown, the specific steps are as follows:

[0053] (1) The material of this example is AZ91D magnesium alloy, and the measured solid-liquidus temperature range of AZ91D magnesium alloy is 470-595°C.

[0054] (2) Locally heat the drawn AZ91D magnesium alloy tube with an inner diameter of 20mm, a wall thickness of 10mm, and a height of 50mm. The heating height is 10mm, and the heating temperature is 478°C and kept for 8 minutes; at the same time, the concave mold cavity is preheated to 300°C.

[0055] (3) Put the heated AZ91D magnesium alloy tube into the pre-deformation cavity of the preheated die, and then drive the pre-deformation punch 1 to extrude the metal tube at a movement speed of 12mm / s, and hold the pressure for 10s after extrusion.

[0056] (4) Take out the pre-deformed AZ91D magnesium alloy tube and put it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solidus temperature | aaaaa | aaaaa |

| liquidus temperature | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com