Method and product for preparing copper-based shape memory alloy with arbitrary shape in situ by laser

A memory alloy, arbitrary shape technology, applied in the field of copper-based shape memory alloy preparation, can solve the problems of low alloy density, slow cooling rate, poor mechanical properties, etc., achieve uniform and dense composition, reduce the formation of pores, improve Density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for directly preparing Cu-13.5Al-4Ni-0.5Ti copper-based shape memory alloy of arbitrary shape from alloyed powder, comprising the following steps:

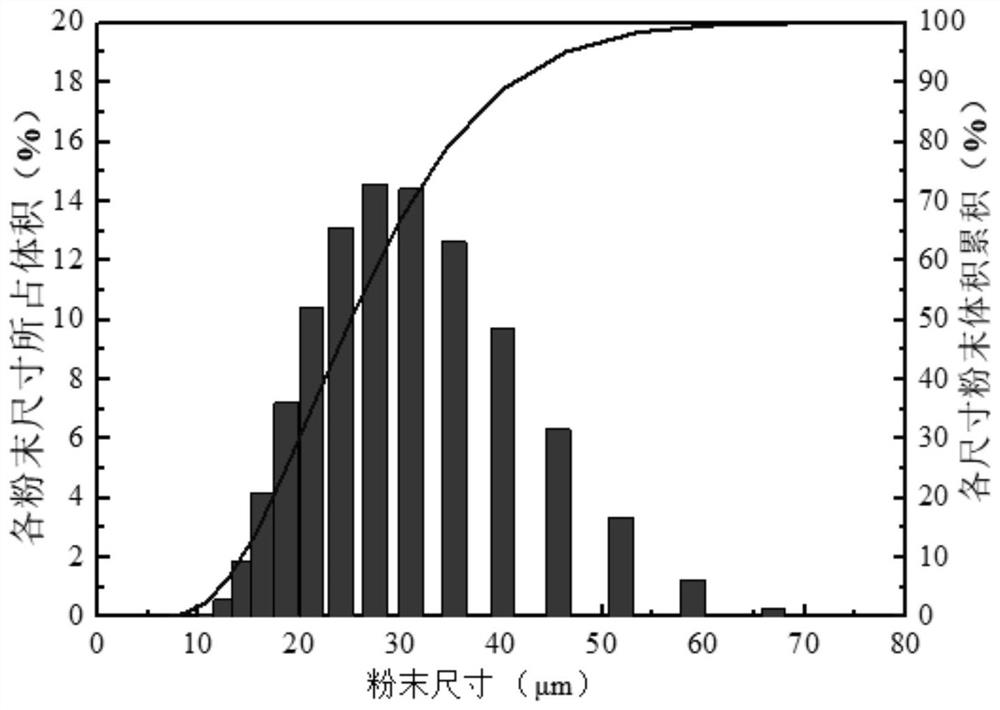

[0043] (1) Put the high-purity alloy of each element (i.e. Cu, Al, Ni, Ti) in the alloy into the vacuum melting furnace according to the mass ratio for melting, and repeat the melting three times to obtain the original ingot, and place the ingot in the vacuum melting furnace While melting at medium and high temperature, argon gas is introduced to form an impact on the melt, and the melt is dispersed by the impact to form small droplets, and after cooling, the required alloying powder raw material is formed. The particle size of the powder is 19.5-46.7 μm, and the average particle size is 30.5 μm. ;

[0044] (2) The prepared alloyed powder is used as the raw material, and a continuous YAG laser is used as the energy source. The laser spot diameter is 80 μm. The scanning mode of the laser is to rotate 67° between lay...

Embodiment 2

[0049] A method for directly preparing Cu-25.5Zn-4Al-0.6Mn copper-based shape memory alloy of arbitrary shape from alloyed powder, comprising the following steps:

[0050] (1) Put the high-purity alloy of each element (i.e. Cu, Zn, Al, Mn) in the alloy into the vacuum melting furnace according to the mass ratio for melting, and repeat the melting three times to obtain the original ingot, and place the ingot in the vacuum melting furnace While melting at medium and high temperature, argon gas is introduced to form an impact on the melt, and the melt is dispersed by the impact to form small droplets, and the required alloying powder raw material is formed after cooling. The powder particle size is 13.6-71.5 μm, and the average particle size is 34.4 μm. ;

[0051] (2) The prepared alloyed powder is used as the raw material, and a continuous fiber laser is used as the energy source. The laser spot diameter is 60 μm. The scanning mode of the laser is to rotate 67° between layers, a...

Embodiment 3

[0056] A method for directly preparing Cu-13Al-4Ni-2Mn-0.5Ti copper-based shape memory alloy of arbitrary shape from alloyed powder, comprising the following steps:

[0057] (1) Put the high-purity alloy of each element (i.e. Cu, Al, Ni, Mn, Ti) in the alloy into a vacuum melting furnace according to the mass ratio for melting, and repeat the melting three times to obtain the original ingot, and place the ingot in a vacuum While melting at high temperature in the melting furnace, argon gas is introduced to form an impact on the melt. The melt is dispersed by the impact to form small droplets, and after cooling, the required alloying powder raw material is formed. The powder particle size is 7.94-49.3μm, and the average particle size 23.6μm;

[0058] (2) The prepared alloyed powder is used as the raw material, and a continuous fiber laser is used as the energy source. The laser spot diameter is 70 μm. The scanning mode of the laser is to rotate 67° between layers, and the brass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com