V-method casting process for nodular cast iron casting

A technology of ductile iron and casting process, applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problem of large shrinkage porosity and shrinkage porosity, reduce shrinkage porosity and shrinkage porosity, improve dimensional accuracy, and reduce graphite. The effect of the expansion force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

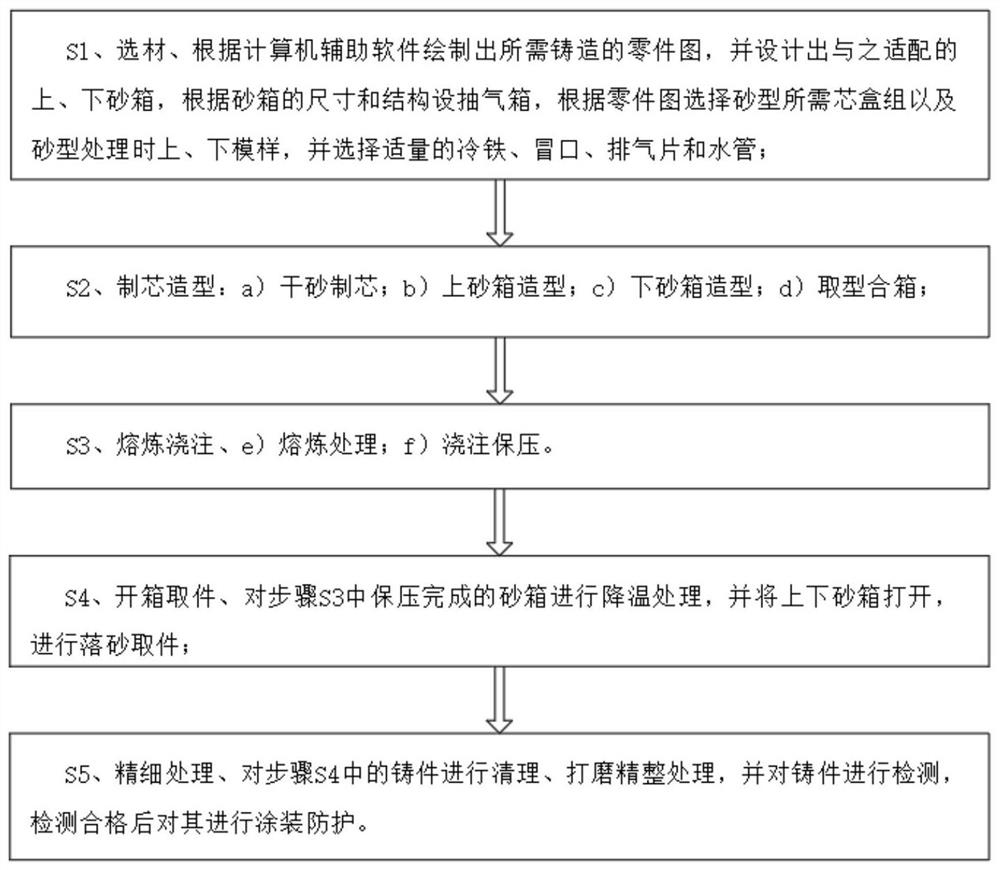

[0039] refer to Figure 1-5 , a ductile iron casting V method casting process, comprising the following steps:

[0040] S1, material selection

[0041] According to the computer-aided software, draw the parts diagram to be cast, and design the upper and lower sand boxes to match it, set up the air extraction box according to the size and structure of the sand box, select the core box group required for the sand mold according to the parts diagram and When sand molding is processed, the upper and lower shapes are selected, and the appropriate amount of cold iron, riser, exhaust sheet and water pipe should be selected.

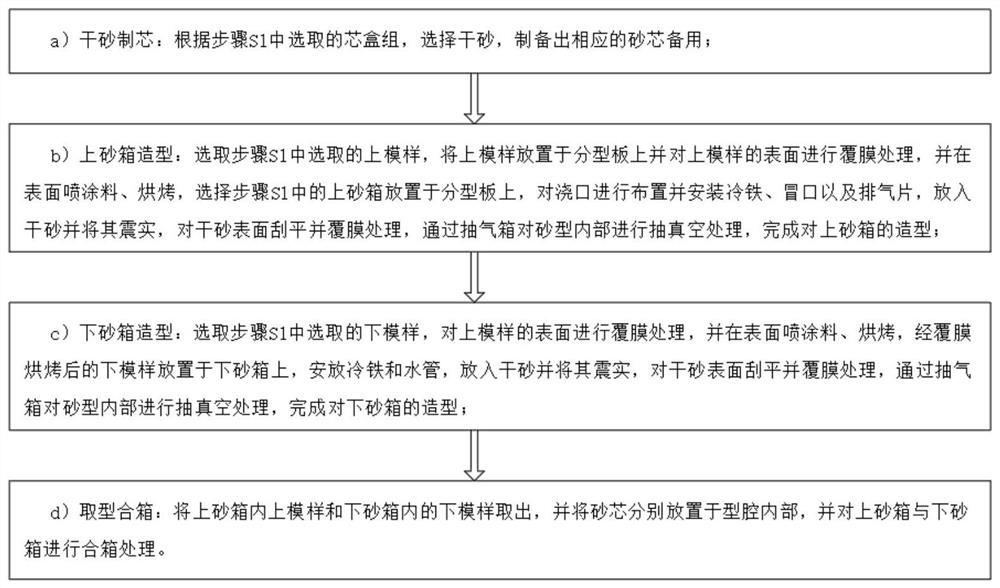

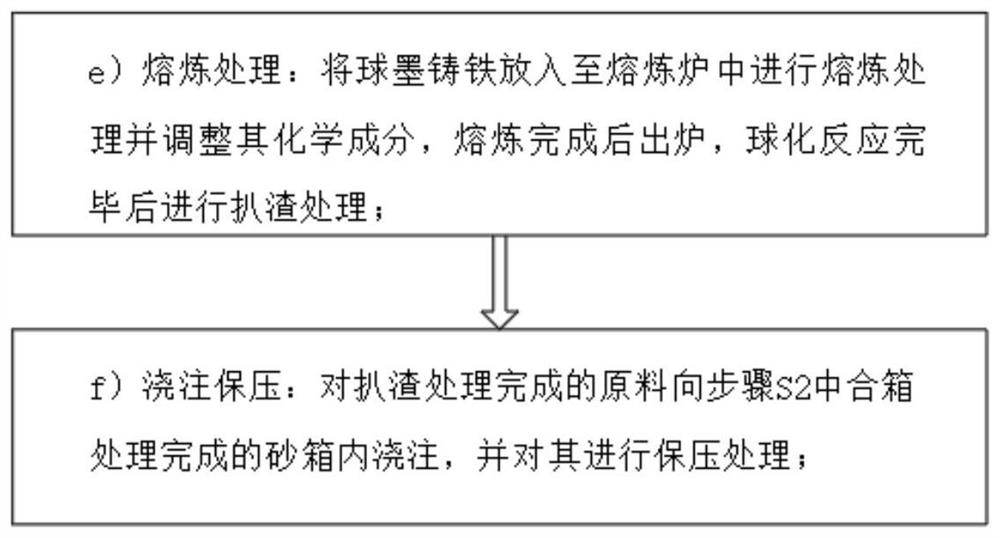

[0042] S2, core mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com