Patents

Literature

36results about How to "Solve shrinkage defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-silicon solution-strengthening ferrite spheroidal graphite iron casting and manufacturing method thereof

InactiveCN108611551AReduce the content of trace elementsGuaranteed to beProcess efficiency improvementSlagDuctile iron

The invention relates to a high-silicon solution-strengthening ferrite spheroidal graphite iron casting, and further relates to a manufacturing method of the high-silicon solution-strengthening ferrite spheroidal graphite iron casting. The high-silicon solution-strengthening ferrite spheroidal graphite iron casting comprises the components of, by weight, 3.25%-3.35% of C, 3.70%-3.80% of Si, 0.15%of Mn or the less, 0.03% of P or the less, 0.012% of S or the less, 0.035%-0.05% of Mg, 0.004%-0.015% of Re, 0.004%-0.006% of Sb and the balance iron. The manufacturing method comprises the steps of raw material batching, smelting in a cupola, molten iron desulphurization, smelting in an electric furnace, sampling analysis and blending, tapping, spheroidization and primary inoculation treatment, slag removal, and pouring. The high-silicon solution-strengthening ferrite spheroidal graphite iron casting and the manufacturing method thereof have the advantage that the defects of shrinkage porosity and cavity generated when the QT500-14 spheroidal graphite iron casting with the wall thickness being larger than 60 mm is manufactured by high-silicon solution-strengthening ferrite spheroidal graphite cast iron can be effectively overcome.

Owner:宁波日星铸业有限公司

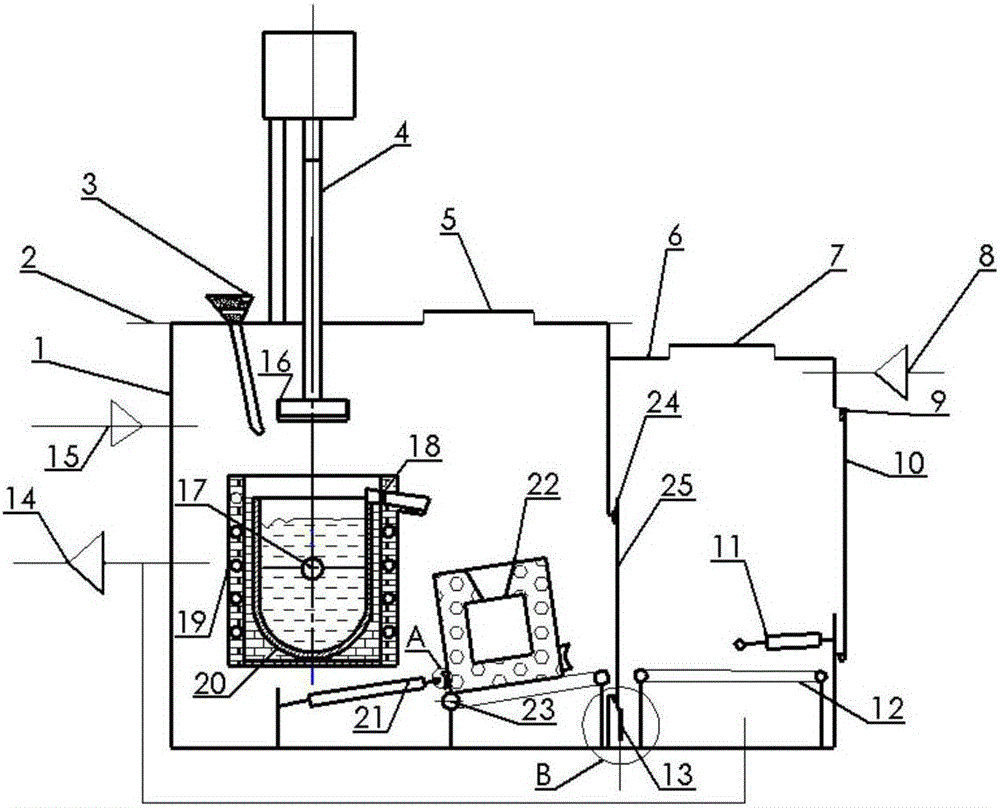

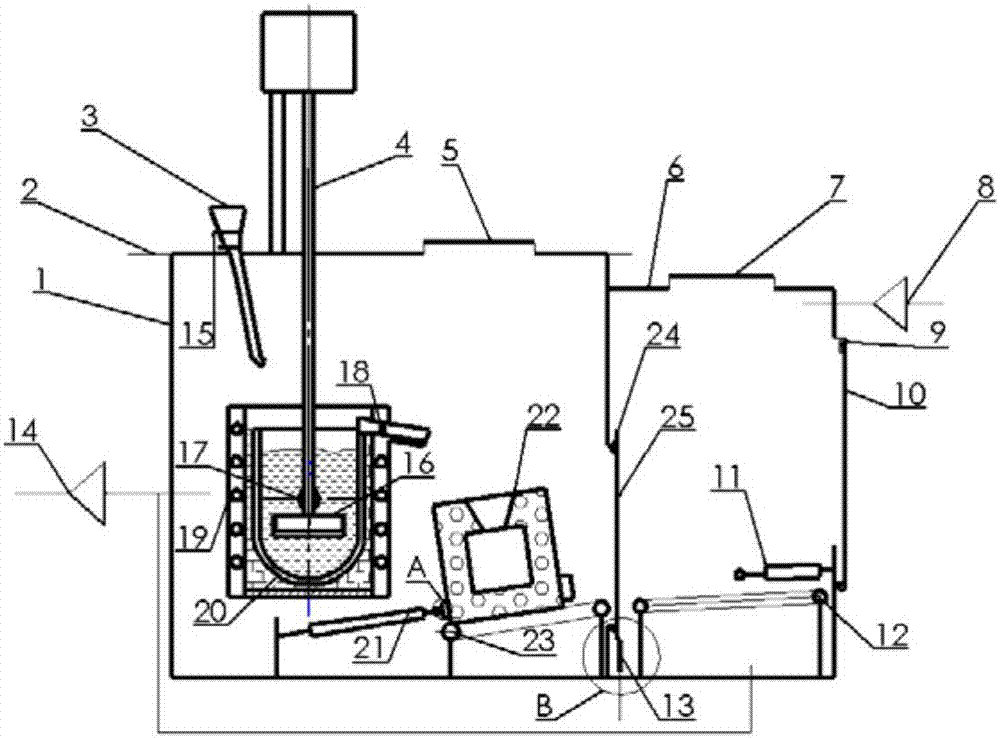

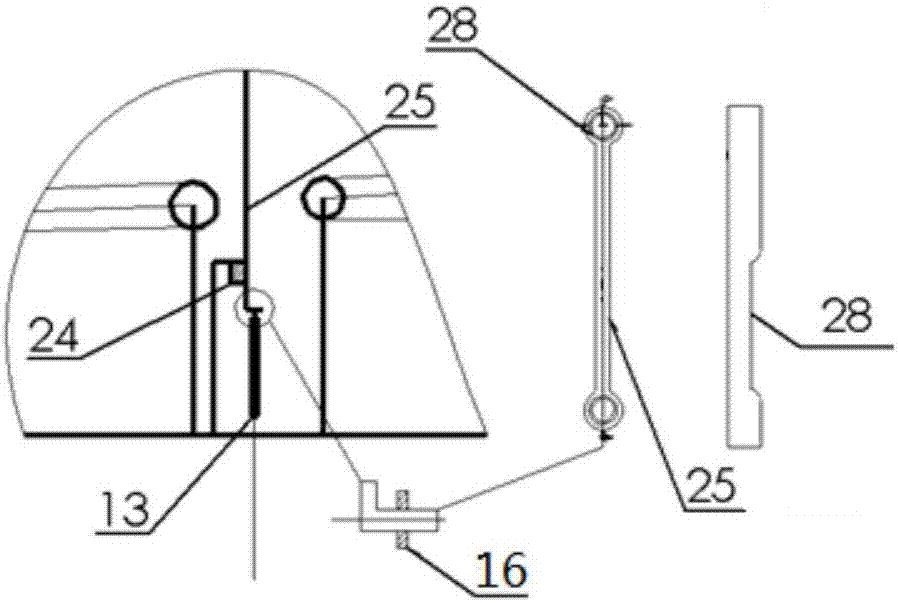

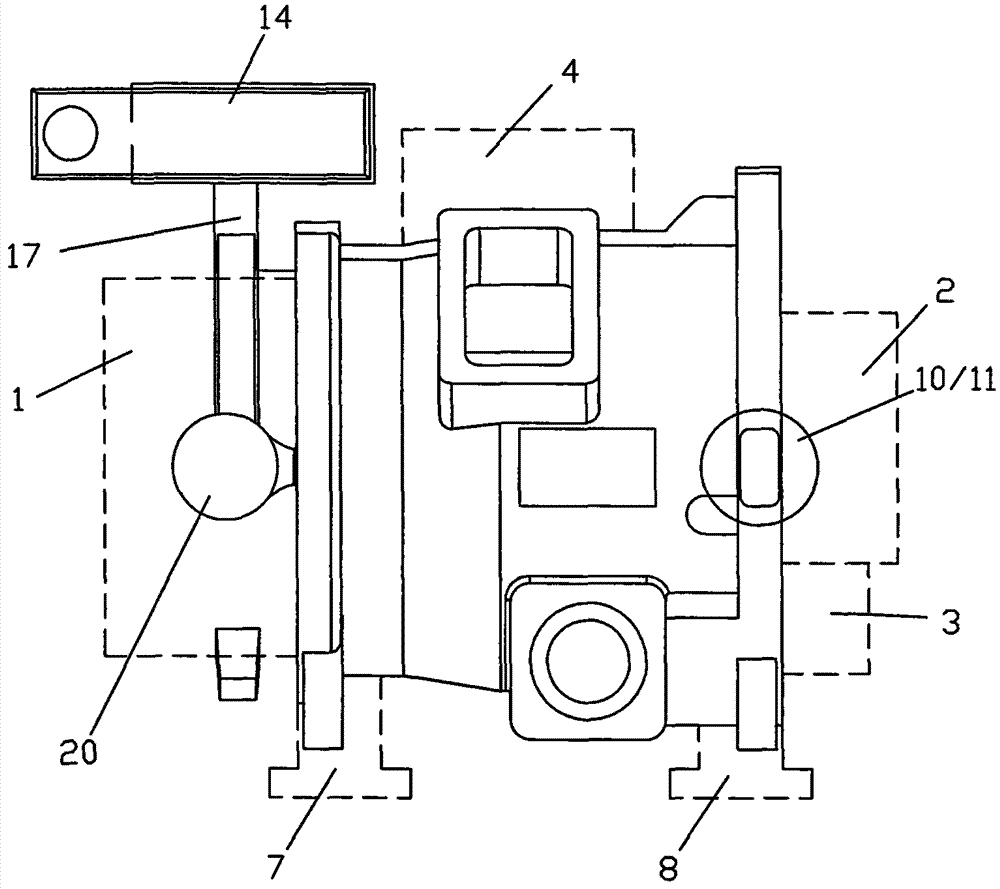

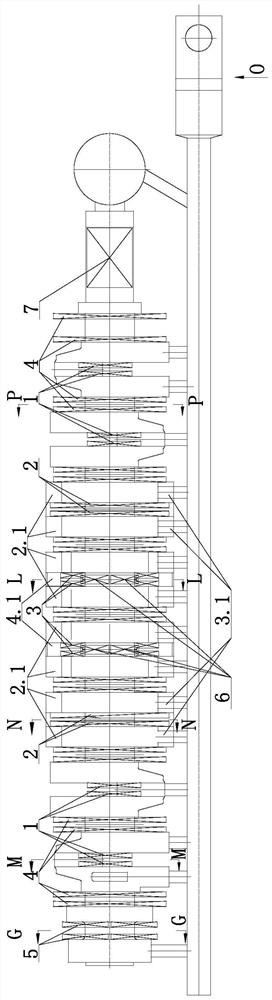

Integrated preparing and forming device for magnesium alloy thin-walled pieces

The invention relates to an integrated preparing and forming device for magnesium alloy thin-walled pieces. The forming device comprises a smelting-pouring tank and a protective atmosphere solidification tank, wherein the smelting-pouring tank and the protective atmosphere solidification tank are used for preparing a magnesium alloy. The smelting-pouring tank and the protective atmosphere solidification tank are both connected with a vacuumizing device and a protective gas injection device. By means of the integrated preparing and forming device, the magnesium alloy can be smelted under the vacuum condition, preparation is completed and pouring is conducted under the condition that the protective gas is injected, and pressurized solidification is conducted under the condition that the protective gas is injected in the protective atmosphere solidification tank. The integrated preparing and forming device is suitable for producing complex and thin-walled magnesium alloy castings, the production safety is high, the surfaces of the castings are free of oxidation defects, internal defects such as slag inclusion, shrinkage porosity and cold shut are basically solved, the structure is compact, performance is good, production requirements are met, the integrated preparing and forming device is easy to popularize, and the yield of the castings is high.

Owner:HENAN POLYTECHNIC UNIV

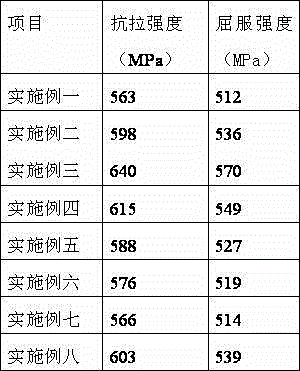

High-silicon-molybdenum vermicular graphite cast iron and production method thereof

The invention discloses high-silicon-molybdenum vermicular graphite cast iron. The high-silicon-molybdenum vermicular graphite cast iron comprises, by mass percent, 3.1%-3.4% of C, 4.3%-4.8% of Si, 0-0.3% of Mn, 0-0.07% of P, 0-0.02% of S, 0.5% to 0.75% of Mo, 0.025%-0.045% of Mg, 0.006%-0.01% of Ca, 0.04%-0.06% of Al and the balance Fe and inevitable microelements. A production method of the high-silicon-molybdenum vermicular graphite cast iron is further disclosed. Prepared materials are put into an electric furnace to be smelted. During ladle casting, a vermiculizer and a nucleating agent are added, and the performance of the cast iron can be improved. Carbide generated inside the cast iron is stable, the heat-resisting performance of the cast can be effectively improved, the creep ratio of the large-thick portion of the cast is improved to above 70%, the tensile strength is improved to 640 Mpa, the yield strength is improved to 570 Mpa, and the performance of the obtained casting is very excellent.

Owner:西峡飞龙特种铸造有限公司

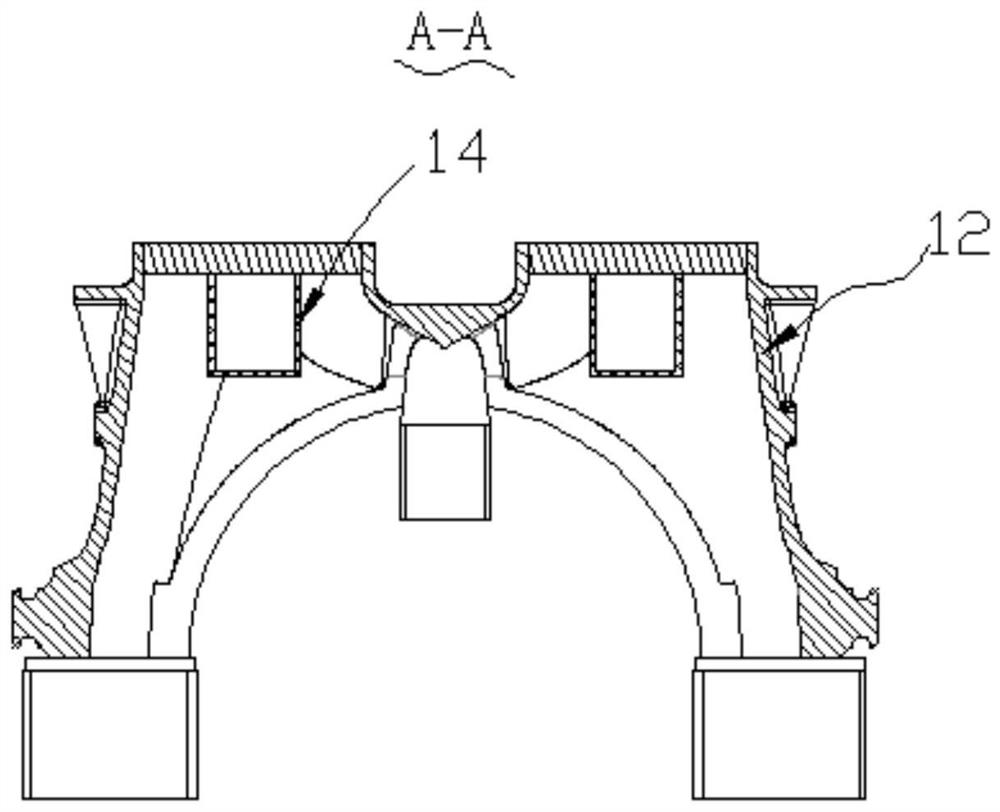

Novel casting mould structure for car brake disc

ActiveCN103567391AHarm reductionImprove impact toughnessFoundry mouldsFoundry coresWeather resistanceEngineering

The invention provides a novel high-strength casting mould structure for a car brake disc. The novel casting mould structure is formed by compounding two outer moulds and a sand core, wherein the sand core is located in the outer moulds. According to the novel casting mould structure, the strength, the toughness, the weather resistance and the processability of a rear brake disc for a car are improved. A micro-alloy vanishing ring is additionally arranged at an R angle part which easily generates inner looseness in the casting mould so as to improve the strength and the toughness of a casting. The casting is commonly molded by the sand moulds and the sand core; a casting system is arranged in the sand core; a ceramic filtering sheet, an annular liquid inlet sheet, a chilling block and a dead head of the casting system are arranged reasonably so that the defects of the casting are improved and the product quality is improved.

Owner:富士和机械工业(湖北)有限公司

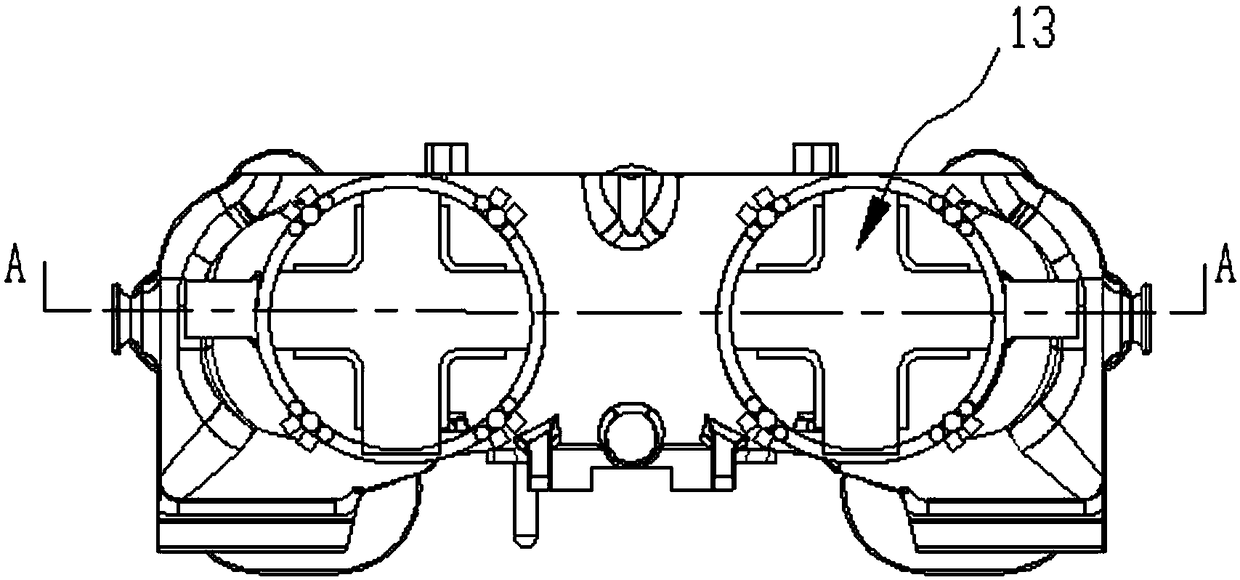

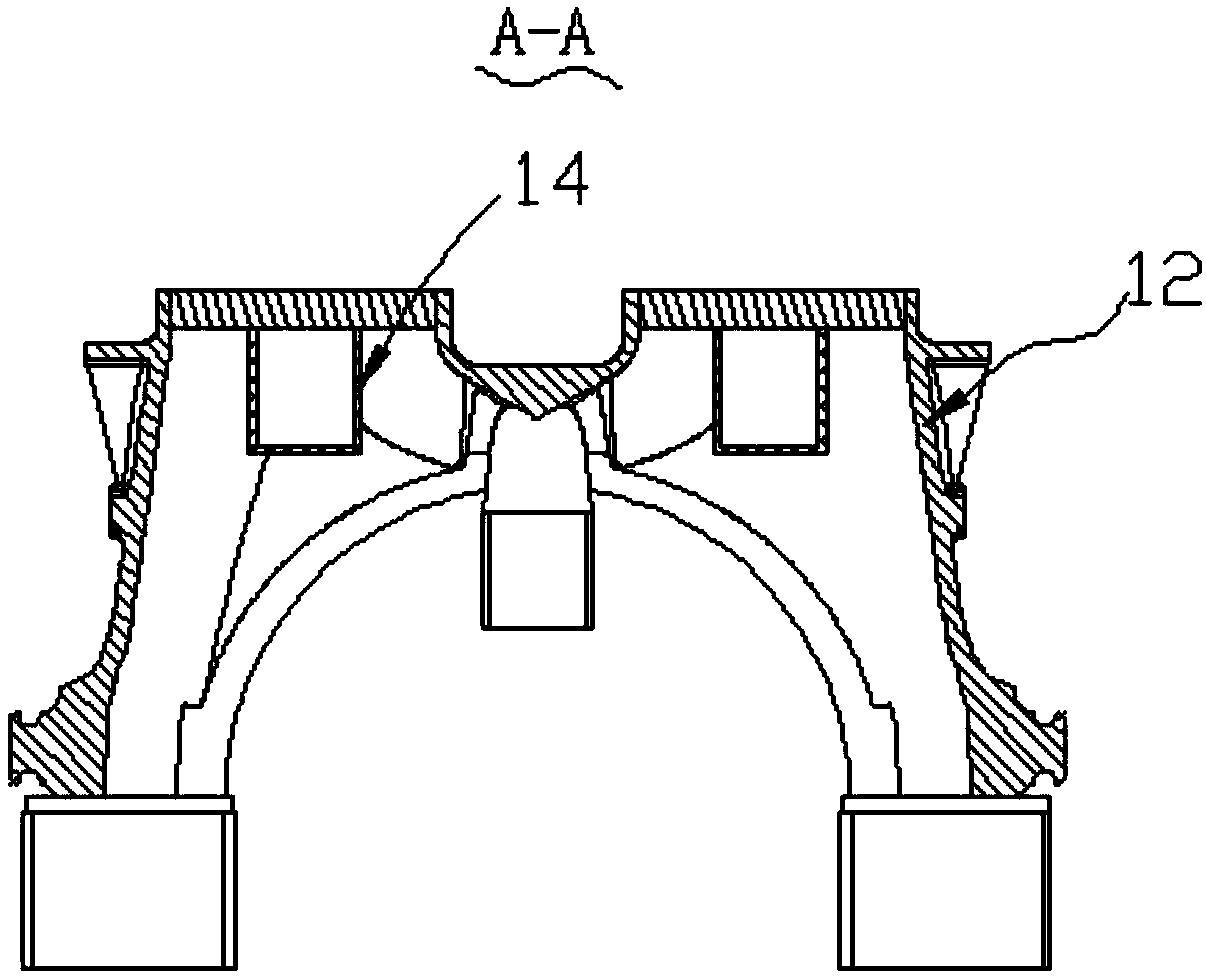

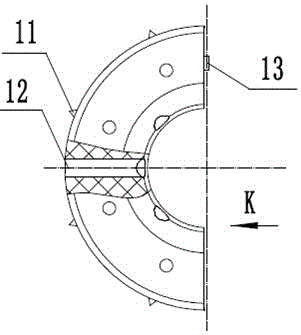

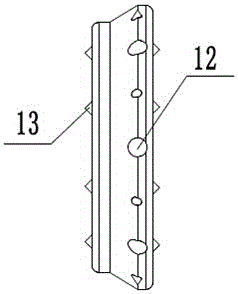

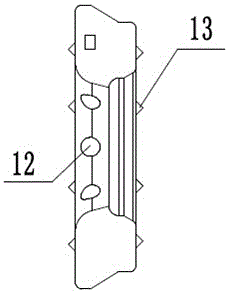

Casting method capable of preventing defects of air cylinder casting pipe orifice

ActiveCN109128046APrevent inflowSolve the problem that the gate cannot be set when the wall thickness is thinFoundry mouldsFoundry coresSlagCasting defect

The invention belongs to the field of casting and mainly relates to a casting method capable of preventing defects of an air cylinder casting pipe orifice. When the pipe orifice part is casted in theprior art, one loop of cold iron is adopted, and the casting defects such as shrinkage porosity and slag inclusion exist among the cold iron through RT ray detection; in consideration of the above problem, the invention provides a casting method capable of preventing casting defects for an air cylinder casting pipe orifice part. The casting method comprises: a casting process scheme of placing theair cylinder casting with the upward combined surface and the downward pipe orifice is selected, a crossed riser neck is arranged at the radial part of the air cylinder casting pipe orifice, a blindriser is arranged at the middle position of the crossed riser neck, and partitioned cold iron is arranged on the end face part of a crossed riser neck feeding superposed area of the air cylinder casting pipe orifice, so that the casting defects such as shrinkage porosity, slag inclusion and crack on the air cylinder casting pipe orifice part are effectively avoided, the quality of the air cylindercasting is improved, and the standard requirement for the RT ray detection first level of the air cylinder casting pipe orifice part is met.

Owner:KOCEL STEEL

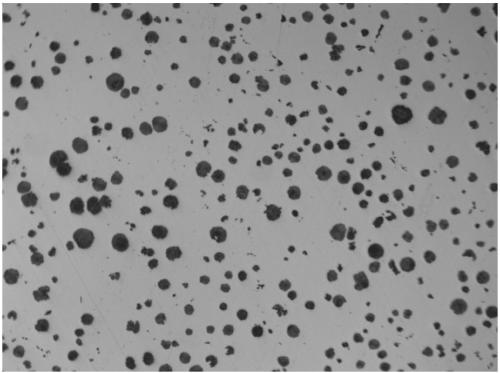

Control method for increasing number of graphite nodule by solid solution strengthening ferrite nodular cast iron with thick and large cross section

ActiveCN109402491AGuaranteed performanceGuaranteed uniformityProcess efficiency improvementPerformance indexSolid solution strengthening

The invention discloses a control method for increasing the number of graphite nodules by solid solution strengthening ferrite nodular cast iron with a thick and large cross section, which comprises the following steps: selecting materials: 50-70 percent of pig iron and 30-50 percent of scrap steel; smelting: adding the materials into an electric furnace for smelting, wherein the tapping temperature of the molten iron is 1420-1450 DEG C; spheroidizing: adding a spheroidizing agent, adding a covering agent on the spheroidizing agent, and then spheroidizing, wherein the spheroidizing temperatureis 1420-1450 DEG C; inoculating: adding a silicon-aluminum-calcium-barium type inoculant during a primary inoculation, and respectively adding the inoculant on the surface of the covering agent and the other side of a ladle dam before tapping, wherein the distribution proportion is 50 percent; adding a trace amount of alloy Sb along with the flow of the molten iron during casting, wherein the adding amount of the alloy Sb is 0.003-0.005% of the total amount of the molten iron, molding, casting and cooling: ensuring that the casting opening temperature is controlled to be <= 300 DEG C, and thecasting is obtained by air cooling after the casting is opened. The control method has the advantages of obtaining higher number of the graphite nodules, ensuring a metallographic structure and goodconsistency of performance indexes, thereby improving the quality of the castings and prolonging the service life.

Owner:宁波日星铸业有限公司

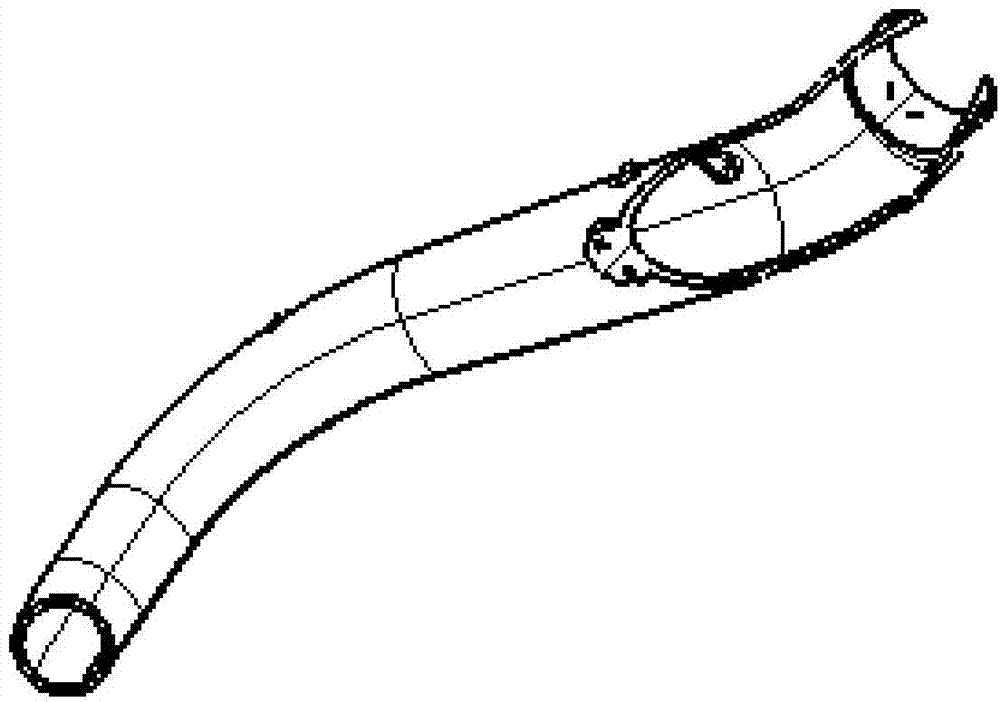

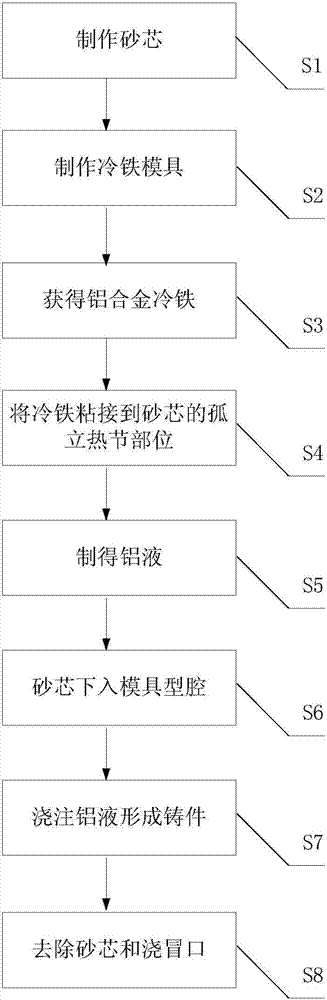

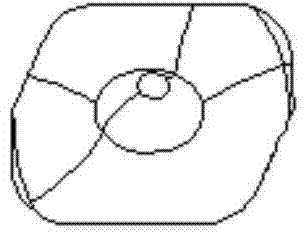

Casting method for protecting thin-wall casting from local isolated hot spot shrinkage

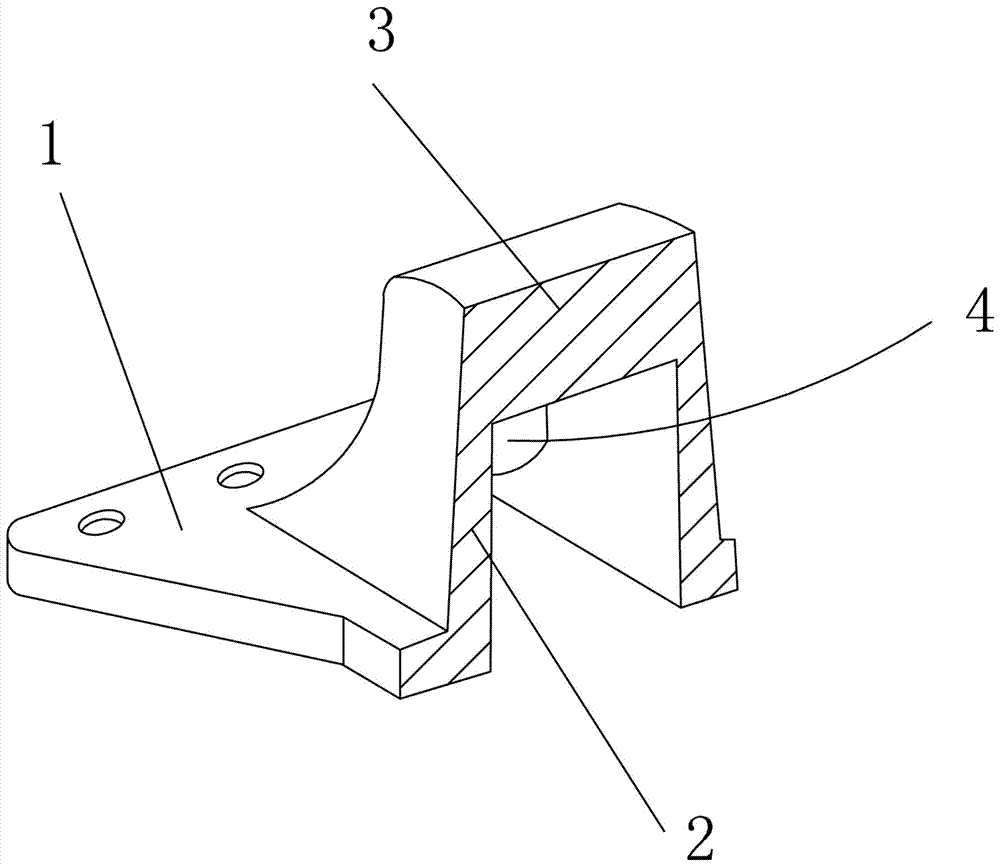

InactiveCN103691916AReduce labor intensitySolve shrinkage defectsFoundry mouldsFoundry coresAlloyMaterials science

The invention discloses a casting method for protecting a thin-wall casting from local isolated hot spot shrinkage. The casting method comprises the steps of manufacturing a sand core; manufacturing a corresponding densener die; utilizing the densener die to obtain an aluminum alloy densener; enabling the aluminum alloy densener to adhere to a corresponding isolated hot spot part of the sand core; manufacturing molten aluminum; placing the sand core in a cavity of a thin-wall casting die; pouring the molten aluminum into the cavity of the thin-wall casting die, and forming a casting by cooling; and performing operation of removing the sand core and a casting head to obtain the finished product thin-wall casting. The hot spot part is subject to chilling through the densener, so that the hot spot first is solidified, and the shortcoming of shrinkage is overcome.

Owner:SHANGHAI AISHIDA AUTOMOTIVE COMPONENTS

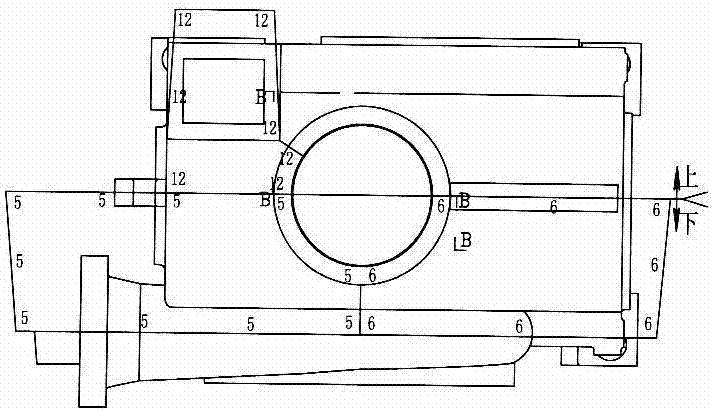

Casting process for heavy-section workbench

InactiveCN102416437AReduce manufacturing costShorten the production cycleFoundry mouldsFoundry coresAlloyHardness

The invention relates to a casting process, in particular to a casting process for a heavy-section workbench. The casting process is characterized by comprising the following steps of: manufacturing a mold; molding; making a core; assembling the mold; casting: casting a downsprue sectional area, a cross gate sectional area and an in-gate sectional area in the ratio 1: (1.8-2.2):(0.7-0.9) by adopting a fully-enclosed casting system; and performing shakeout cleaning. In the casting process, a method for placing direct-cooled iron chill is adopted under the condition of not increasing the alloy adding amount, and a fully-enclosed casting system is adopted, so that the problems of hardness, shrinkage porosity and surface quality of a table-board can be solved, and the yield of castings can be increased simultaneously without increasing the cost.

Owner:NINGXIA KOCEL GRP CO LTD +1

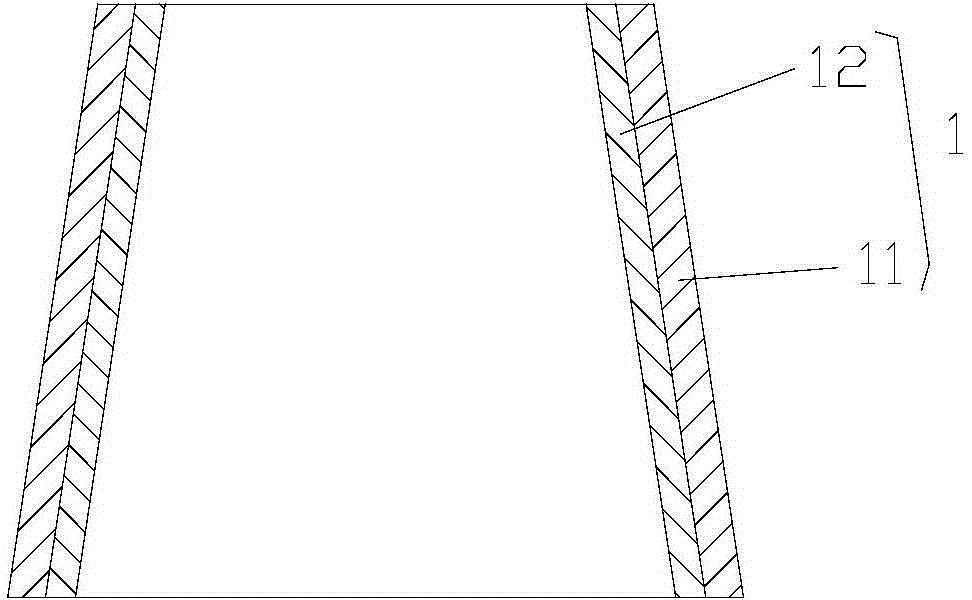

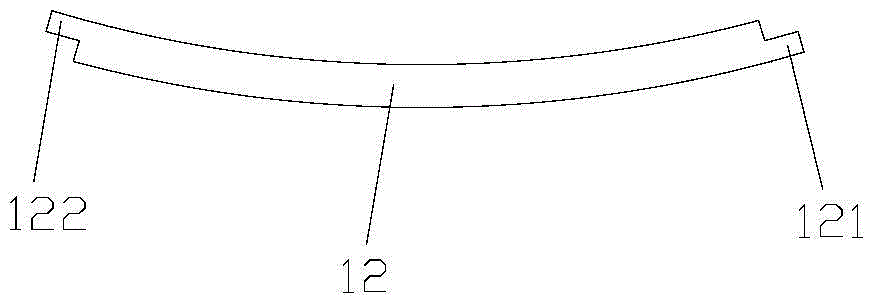

Insulating riser and manufacture method thereof

The invention discloses an insulating riser, comprising a hollow riser body. The hollow riser body comprises an insulating layer and a plurality of heating sheets, the plurality of heating sheets are peripherally bonded to the inner wall of the insulating layer, the heating sheets are tightly attached to one another, the outer side of the heating sheets mates with the inner side of the insulating layer, and the heating sheets are connected with the insulating layer through a locking device located outside the insulating layer; the heating sheets are made from, according to parts by weight: 30-50 parts of hollow microspheres, 10-20 parts of aluminum powder, 5-15 parts of ferric oxide, 20-40 parts of magnesium powder, 40-60 parts of charcoal powder, 5-15 parts of potassium permanganate, and a suitable amount of bonding agent and water, wherein the bonding agent is sodium silicate. The invention also discloses a manufacture method of the insulating riser, overcoming looseness and shrinkage defects of light alloy sand castings, improving compactness of castings, saving energy and reducing consumption, and reducing production cost.

Owner:JIANGSU KASI MEITE CASTING TECH

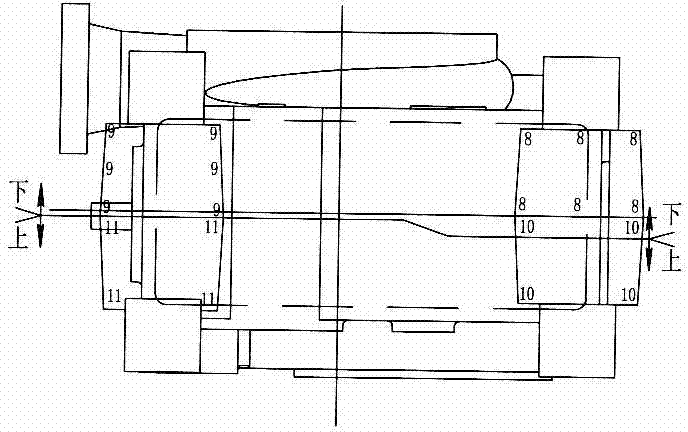

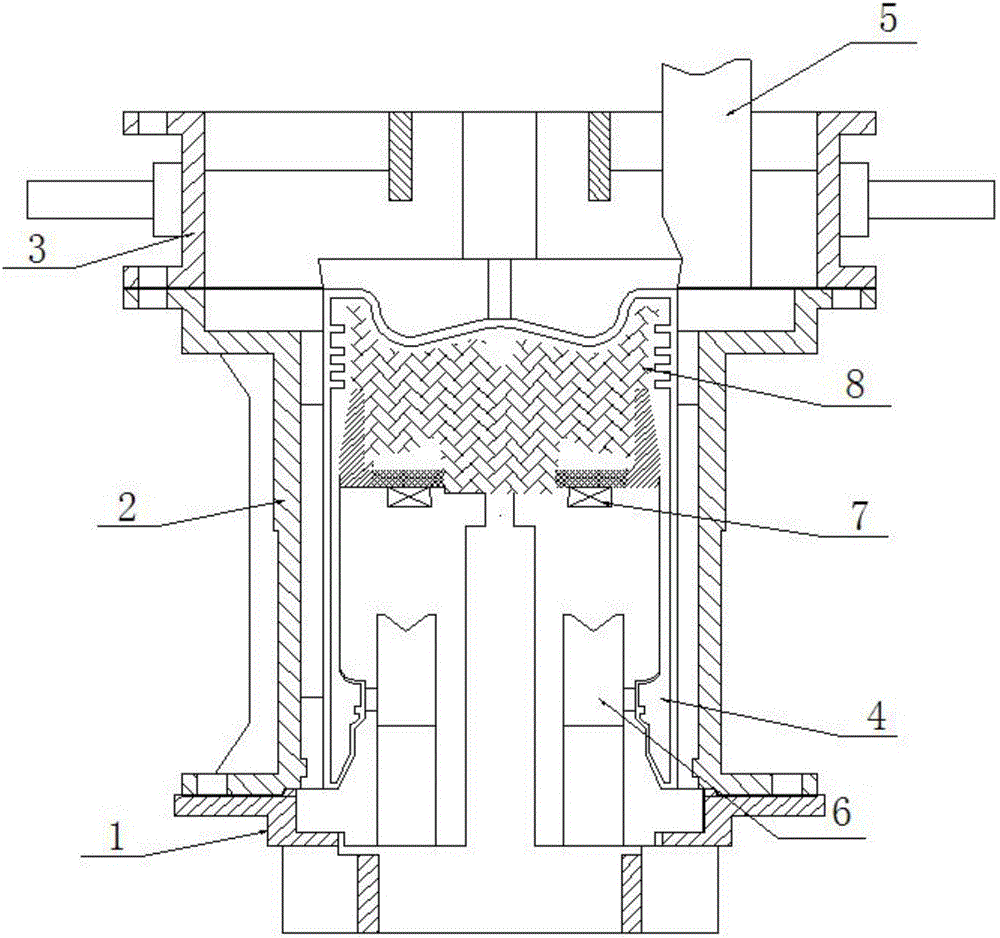

Casting method of body casting of centrifugal air compressor

ActiveCN102451904APrevent movementGuaranteed dimensional accuracyFoundry mouldsFoundry coresHardnessCasting defect

The invention discloses a casting method of a body casting of a centrifugal air compressor. The method comprises the following steps of: sand mulling, moulding, core making, mould assembly, furnace burden melting, iron discharge incubation, pouring, cooling, box opening, casting cleaning and product quality inspection. In the invention, multiple sand cores are designed to form a whole casting, and the pouring of the whole casting is finished by adopting a mode of dispersing the pouring with multiple sheet-type ingates. The mechanical performance of the casting meets that the tensile strength is greater than or equal to 250Mpa and the body hardness is 170-230HBS. The product does not have any internal casting defect.

Owner:上海华新合金有限公司

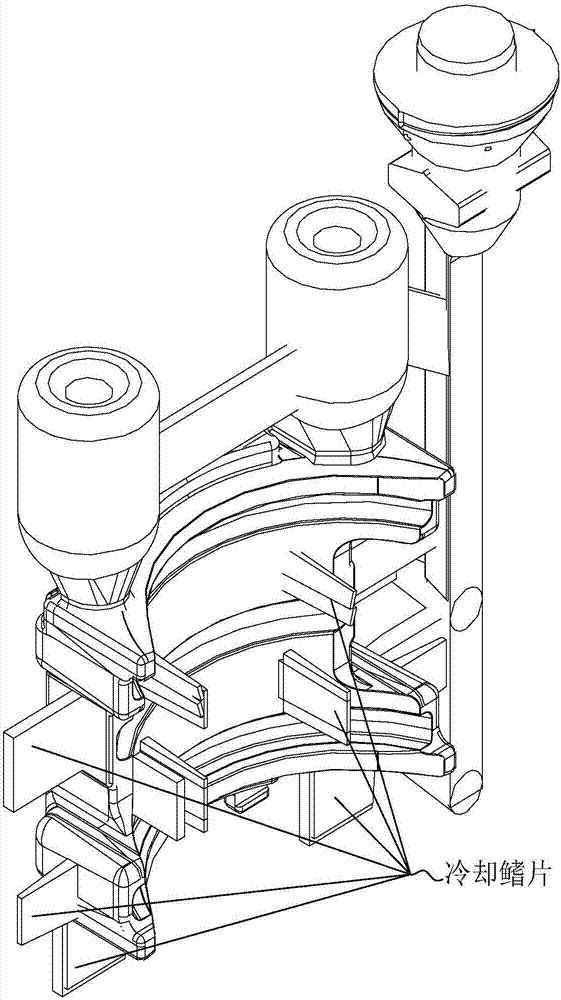

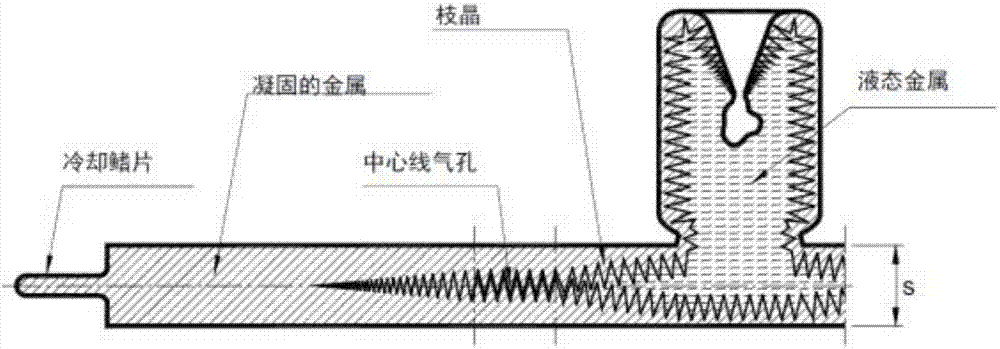

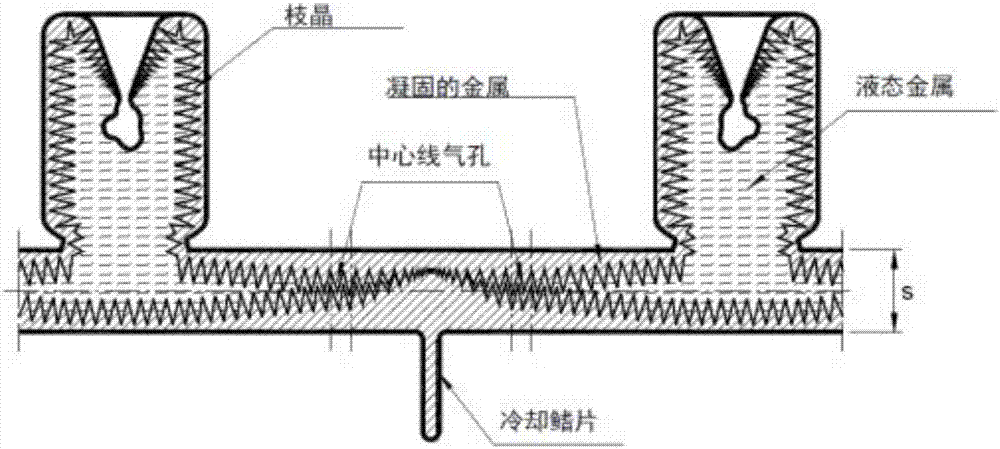

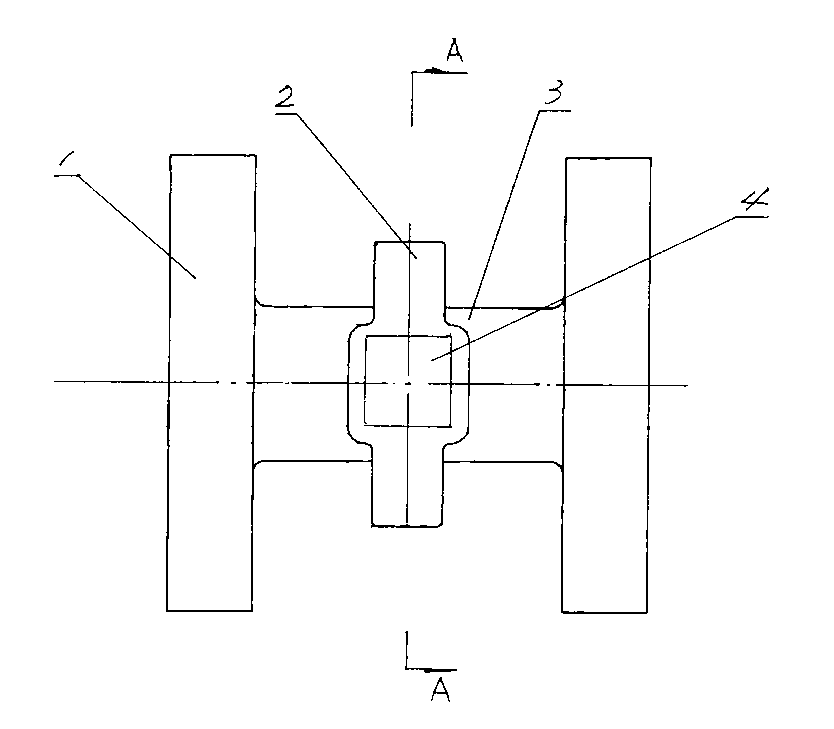

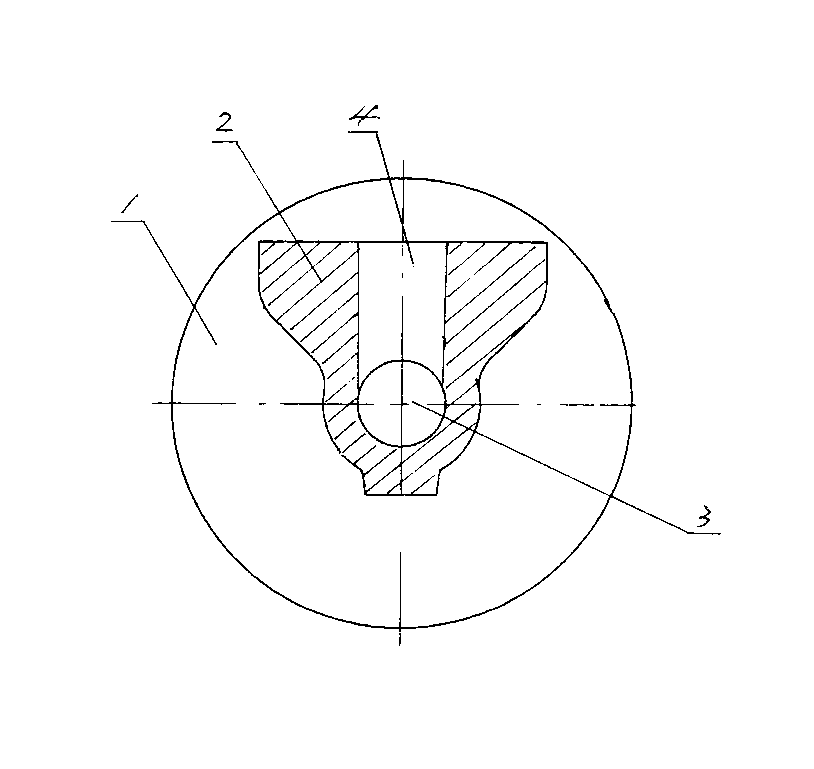

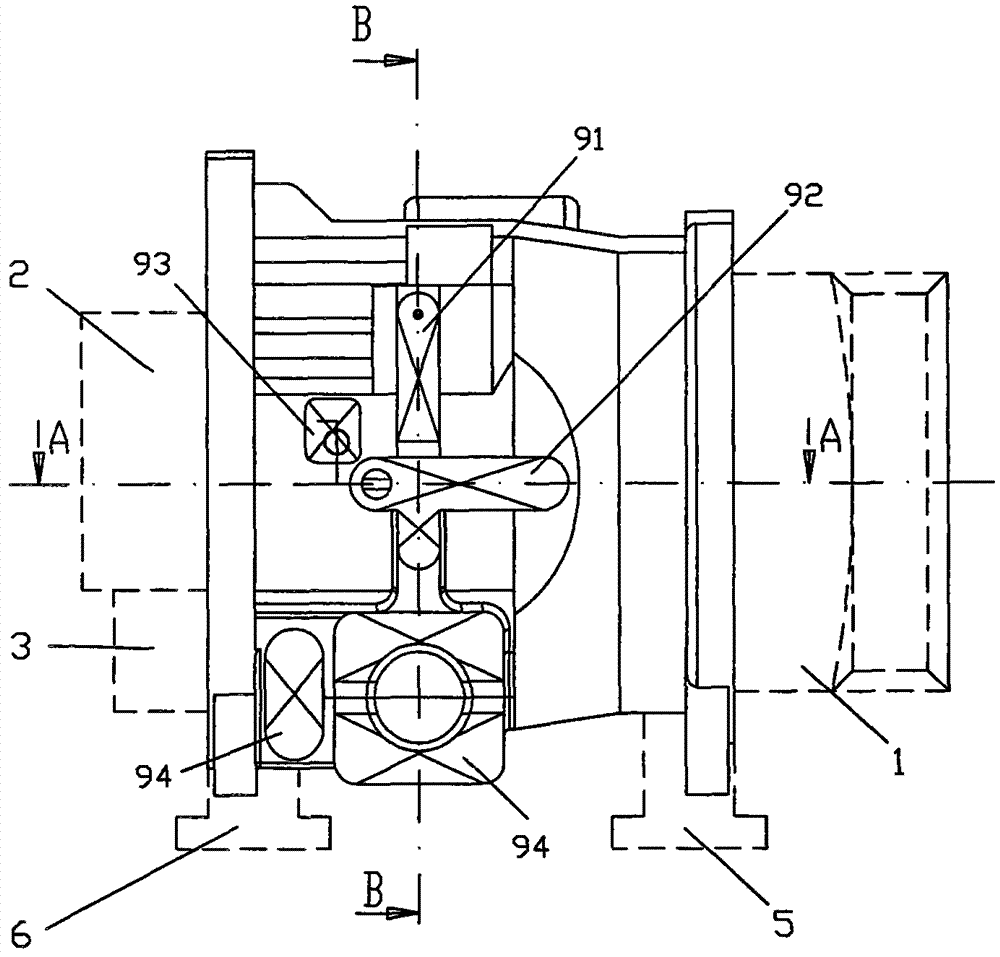

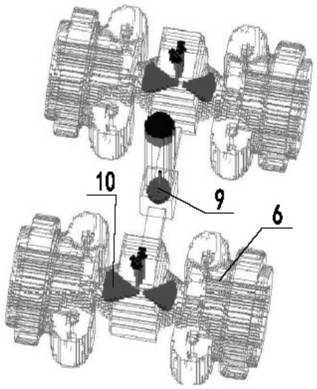

Vertical parting casting method for overcoming shrinkage defect of castings through cooling fins

InactiveCN106862488AAvoid Casting DefectsNo defectFoundry mouldsFoundry coresAfter treatmentCasting defect

The invention belongs to the field of casting techniques of rolling bearing adjusters and particularly relates to a vertical parting casting method for overcoming the shrinkage defect of castings through cooling fins. The major steps of the method specifically include additional arrangement of the cooling fins to a die, detailed setting of the die and the cooling fins, pouring of the castings and after-treatment. According to the method, a cooling plate is replaced with the cooling fins, so that the casting technique with molten iron being solidified sequentially is achieved, and casting defects are overcome. Through the vertical molding line, the effect that the castings have no defects inside is ensured while the product performance is ensured and the production efficiency is not affected. As the cooling fins replace chilling blocks, the shrinkage defect is effectively overcome by producing the castings through vertical parting, the molding efficiency is improved, and the production cost is reduced.

Owner:山东汇金股份有限公司

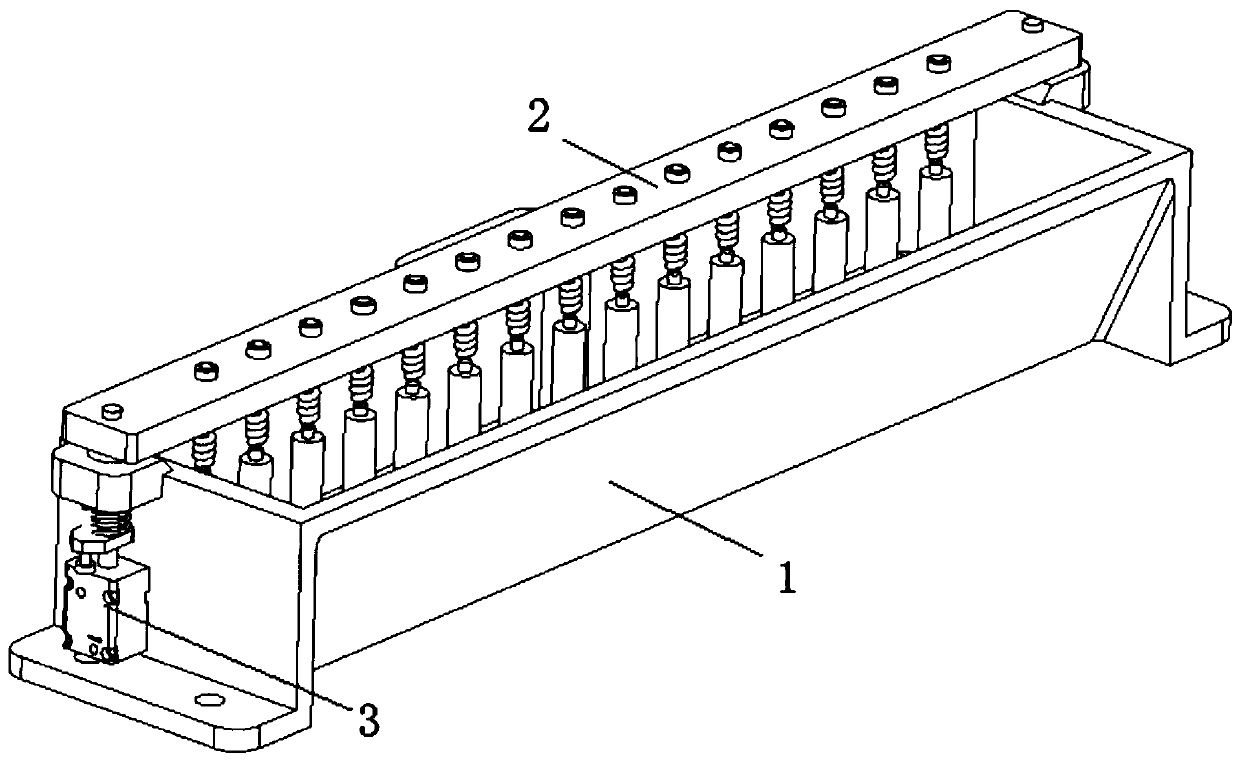

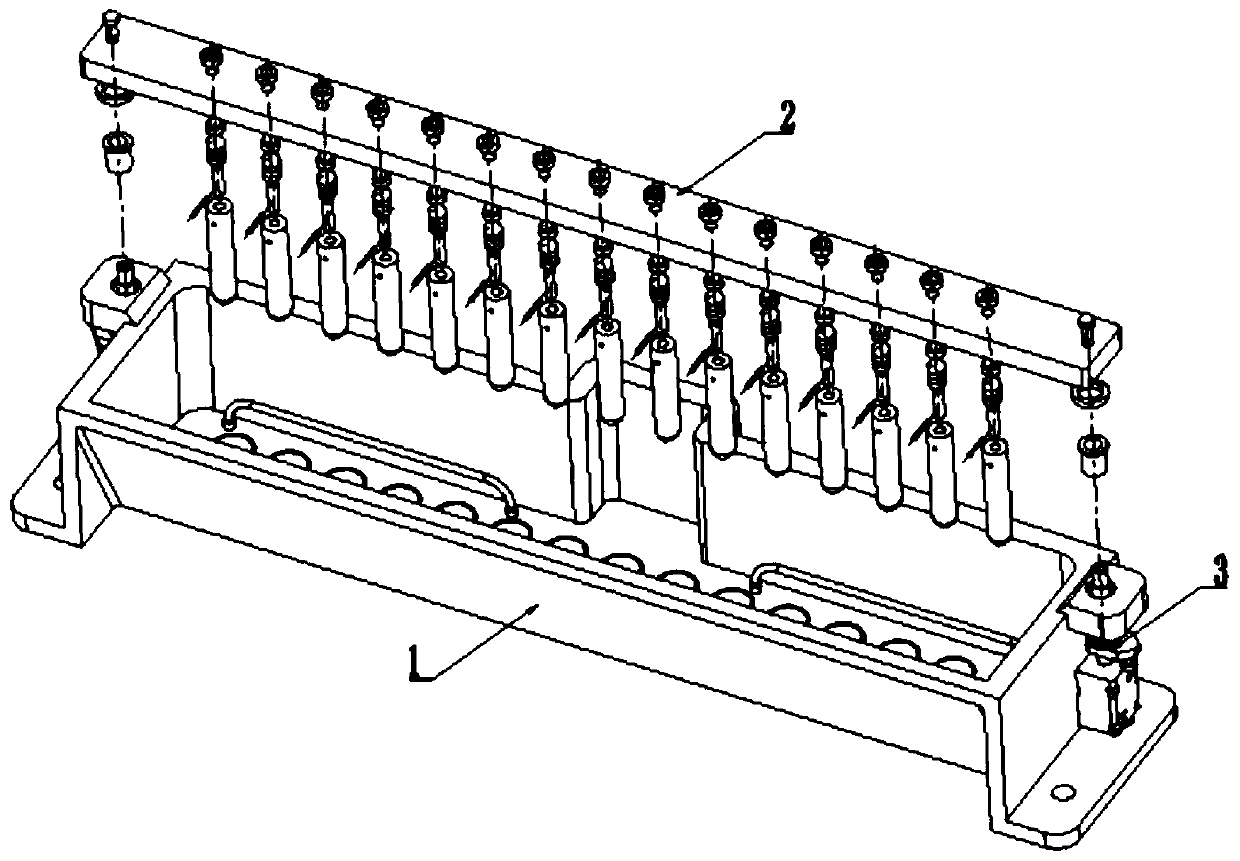

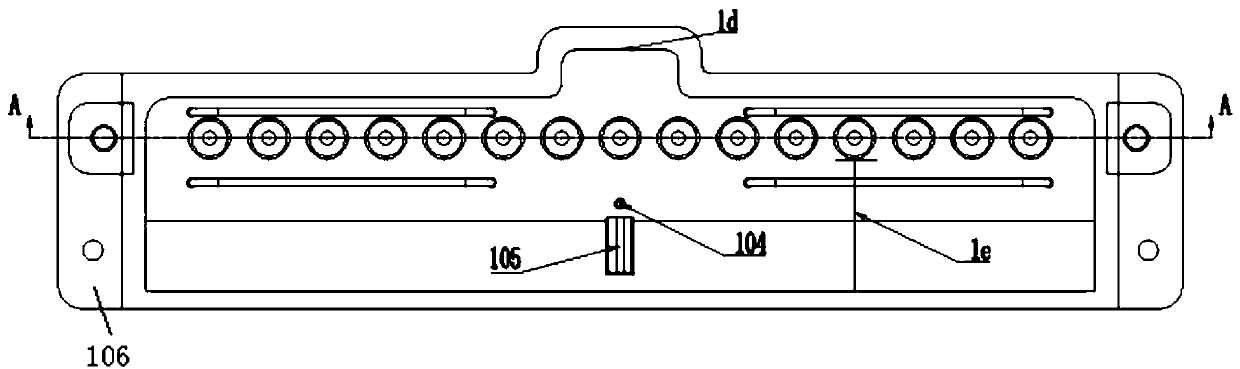

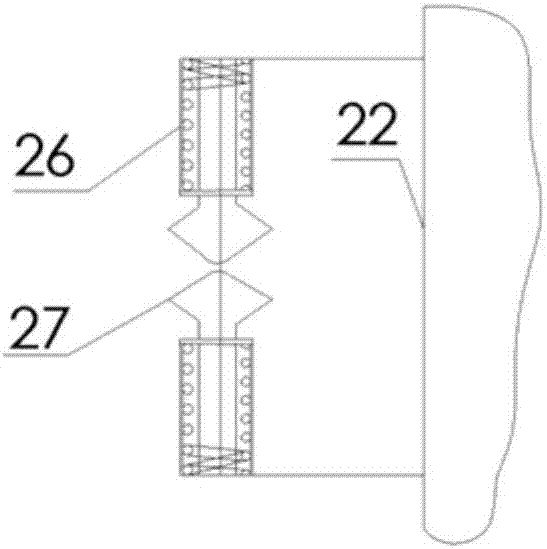

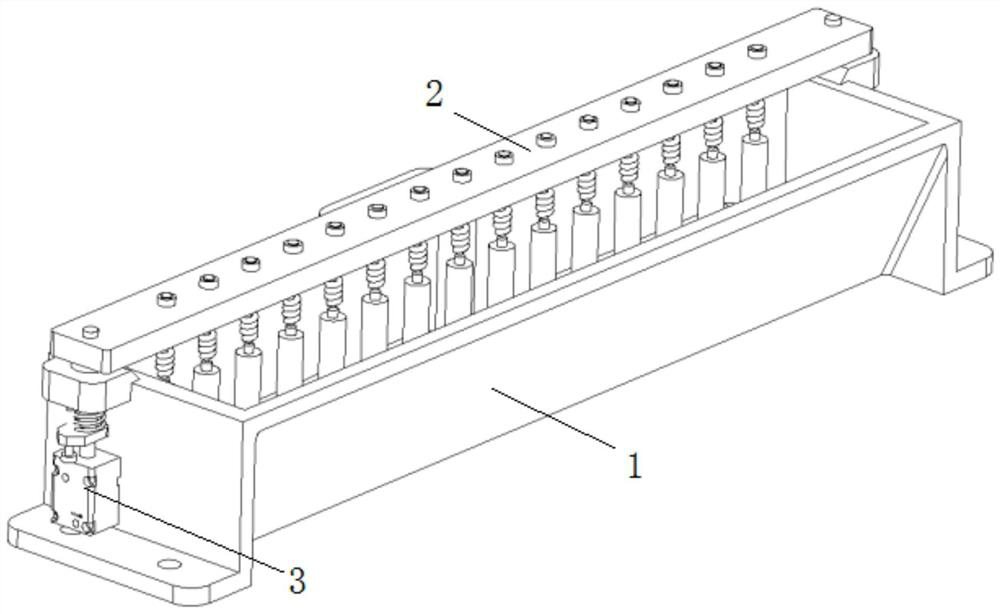

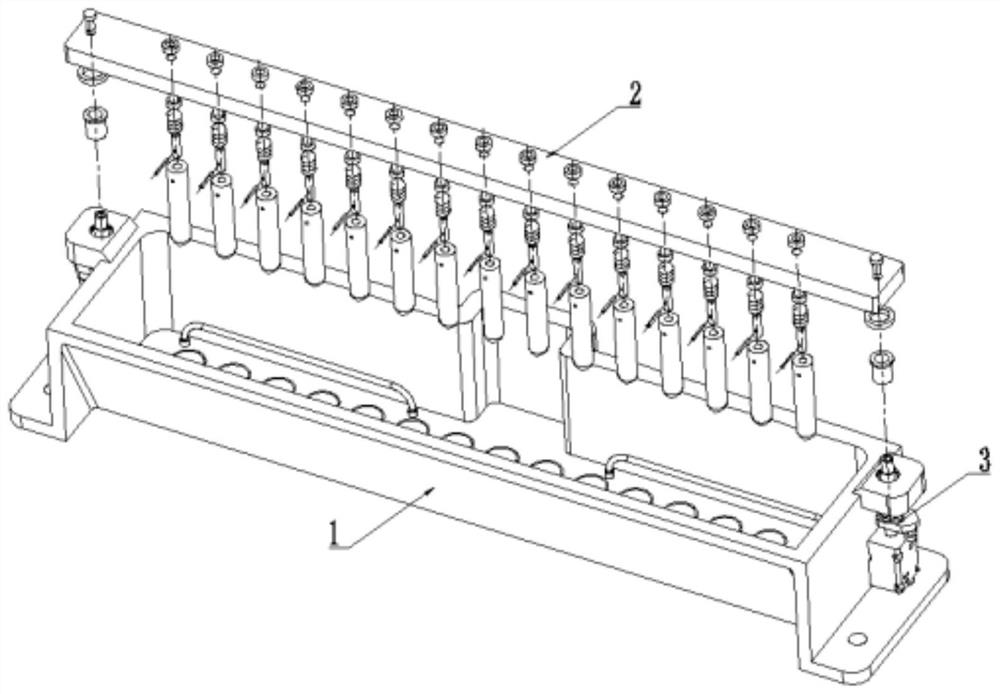

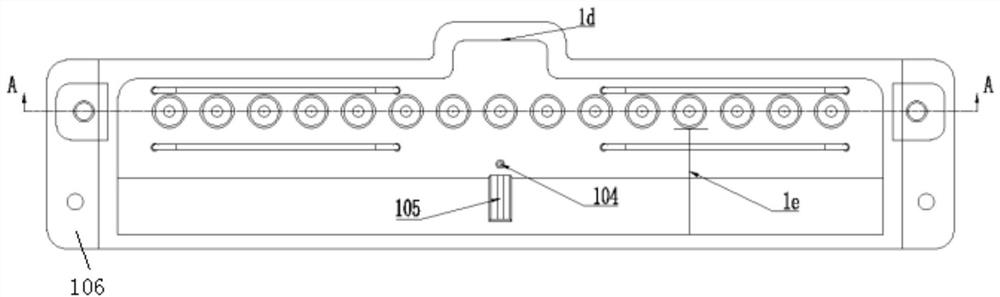

Quantitative bottom pouring device used for molten tableting

ActiveCN110026534AImprove production safetyModerate pouring speedMolten metal supplying equipmentsIngot casting plantsTundishEngineering

The invention relates to a quantitative bottom pouring device used for molten tableting. The device comprises a pouring ladle assembly, a plunger assembly and ejecting and resetting assemblies; the ejecting and resetting assemblies are arranged on the two sides of the pouring ladle assembly, the plunger assembly is arranged above the pouring ladle assembly through the ejecting and resetting assemblies, the ejecting and resetting assemblies are in drive connection with the plunger assembly, the pouring ladle assembly comprises a tundish, and multiple runners are arranged on the bottoms of the tundish. The plunger assembly comprises multiple plungers corresponding to the runners, when the ejecting and resetting assemblies drive the plungers to be ejected, the gaps between the plungers and the runners are opened, molten metal in the tundish is casted, and when the ejecting and resetting assemblies drive the plungers to be reset, the gaps between the plungers and the runners are closed, and the molten metal in the tundish is stopped from casting. Production safety, casting ingot quality and the production efficiency of molten tableting are improved.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

Control method for increasing the number of graphite nodules in solid solution strengthened ferritic ductile iron with thick and large section

ActiveCN109402491BEnsure consistencyStable and reliable gating systemProcess efficiency improvementPerformance indexDuctile iron

The invention discloses a control method for increasing the number of graphite nodules by solid solution strengthening ferrite nodular cast iron with a thick and large cross section, which comprises the following steps: selecting materials: 50-70 percent of pig iron and 30-50 percent of scrap steel; smelting: adding the materials into an electric furnace for smelting, wherein the tapping temperature of the molten iron is 1420-1450 DEG C; spheroidizing: adding a spheroidizing agent, adding a covering agent on the spheroidizing agent, and then spheroidizing, wherein the spheroidizing temperatureis 1420-1450 DEG C; inoculating: adding a silicon-aluminum-calcium-barium type inoculant during a primary inoculation, and respectively adding the inoculant on the surface of the covering agent and the other side of a ladle dam before tapping, wherein the distribution proportion is 50 percent; adding a trace amount of alloy Sb along with the flow of the molten iron during casting, wherein the adding amount of the alloy Sb is 0.003-0.005% of the total amount of the molten iron, molding, casting and cooling: ensuring that the casting opening temperature is controlled to be <= 300 DEG C, and thecasting is obtained by air cooling after the casting is opened. The control method has the advantages of obtaining higher number of the graphite nodules, ensuring a metallographic structure and goodconsistency of performance indexes, thereby improving the quality of the castings and prolonging the service life.

Owner:宁波日星铸业有限公司

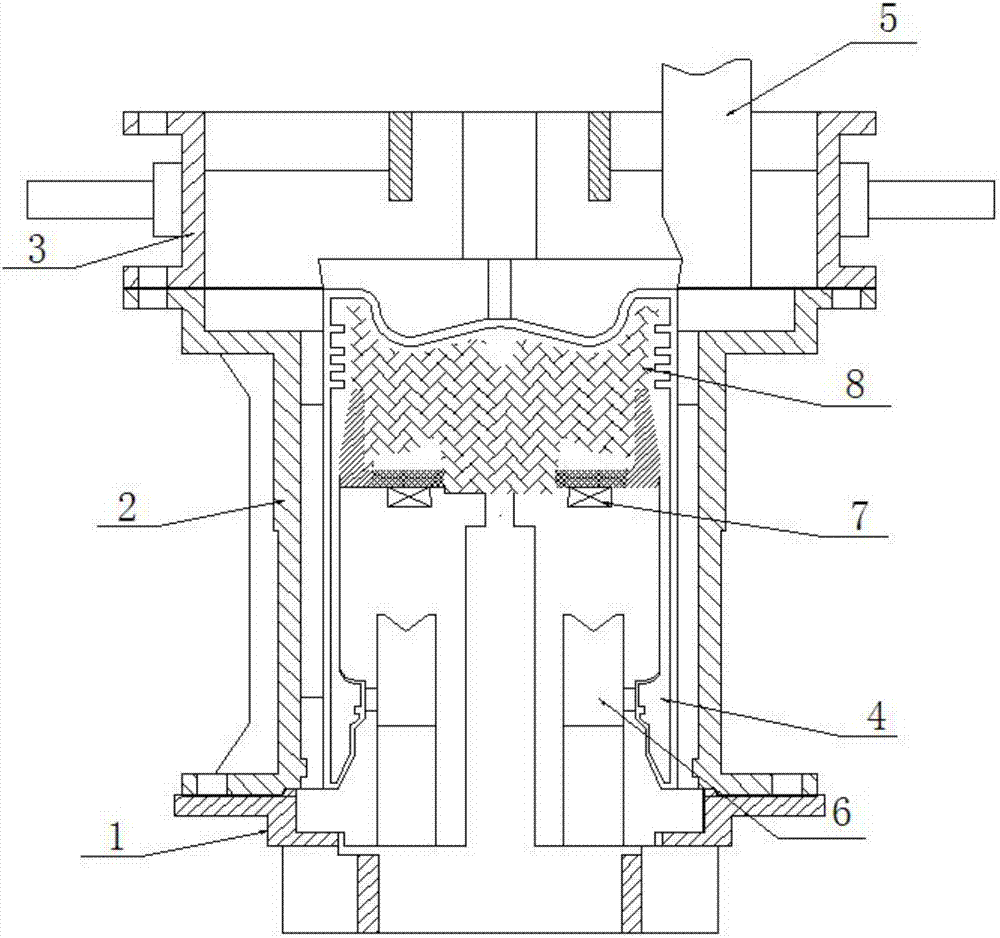

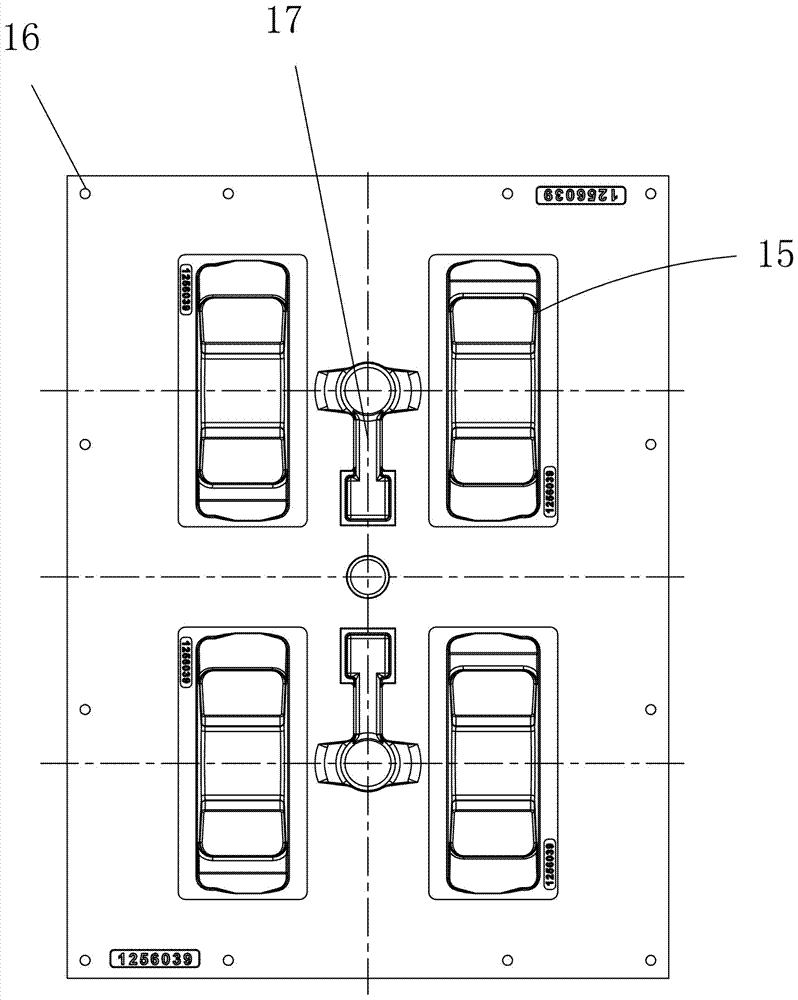

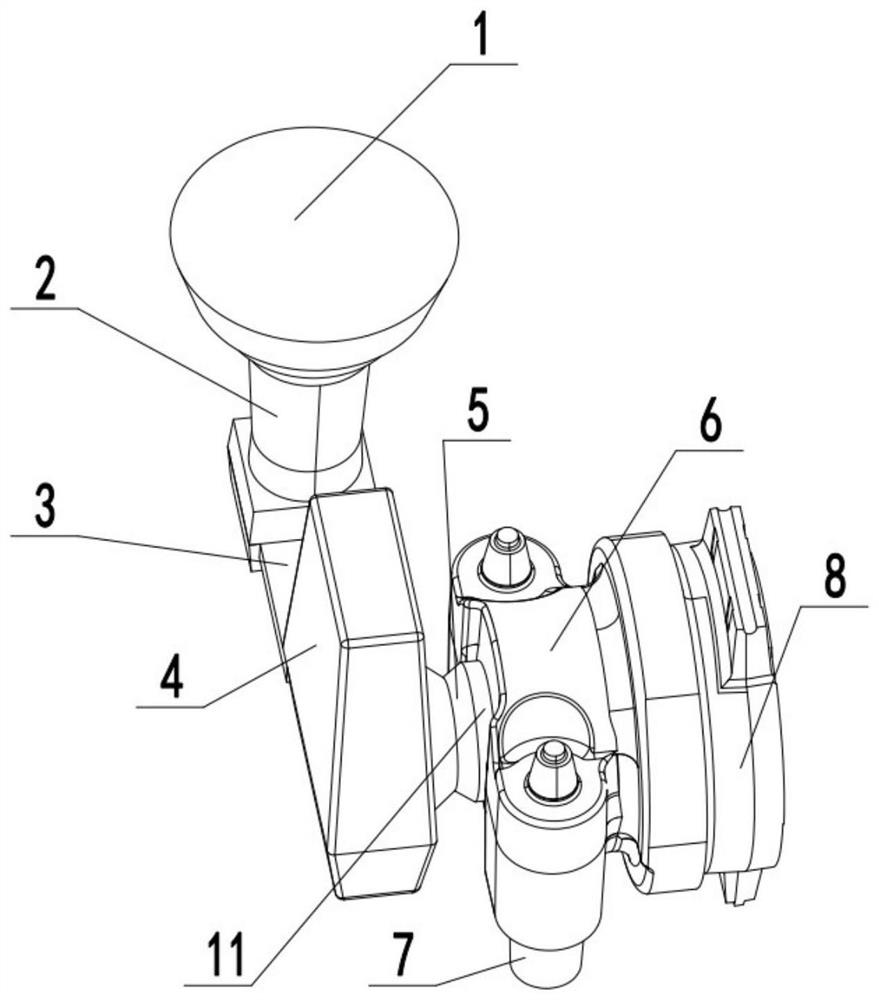

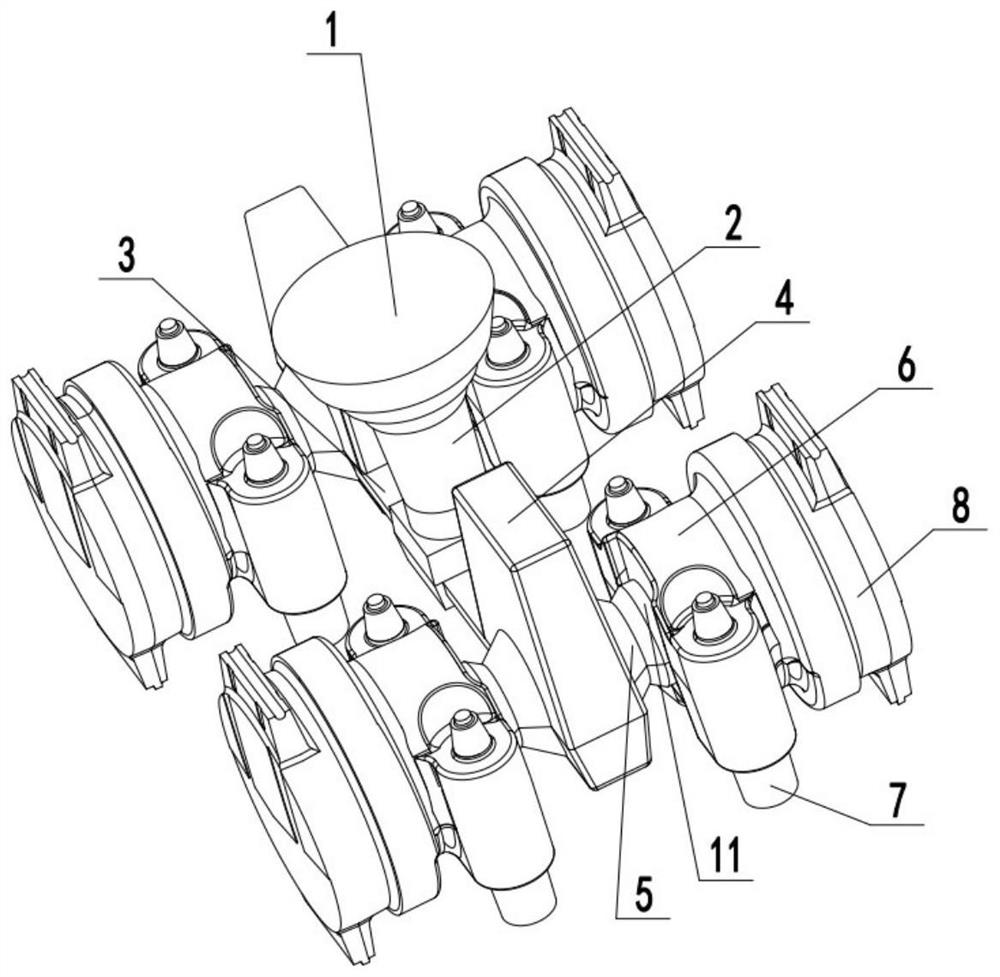

Production technology of low-alloy high-strength cast iron piston

ActiveCN105772630AAvoid problemsSolve shrinkage defectsFoundry mouldsFoundry coresCombustion chamberHigh intensity

The invention provides a production technology of a low-alloy high-strength cast iron piston. An adopted production tool sequentially comprises a bottom box, a middle box and a cover box from bottom to top, and an internal cavity is defined by the bottom box, the middle box and the cover box; a piston casting is placed in the internal cavity, one end of a combustion chamber of the piston casting is upward, a top riser is formed in the cover box, and the position of the top riser corresponds to an outer ring groove of the piston casting; blind risers are formed in a skirt inner ring groove of the piston casting; blind chilling blocks are arranged at an inner platform of the piston casting; and a plurality of air outlets are formed inside an oil cavity even core of the piston casting. According to the production technology of the low-alloy high-strength cast iron piston, gas in the forging process of the oil cavity even core is led out, air holes are prevented from appearing in the outer circle of the piston, the riser and the blind risers are added, the shrinkage defect of the ring groove portion is avoided, accelerated cooling is adopted in the local part, and a metallographic phase and the hardness of a wall thickness portion can meet the standard.

Owner:JIANGSU YUANFANG POWER TECH CO LTD

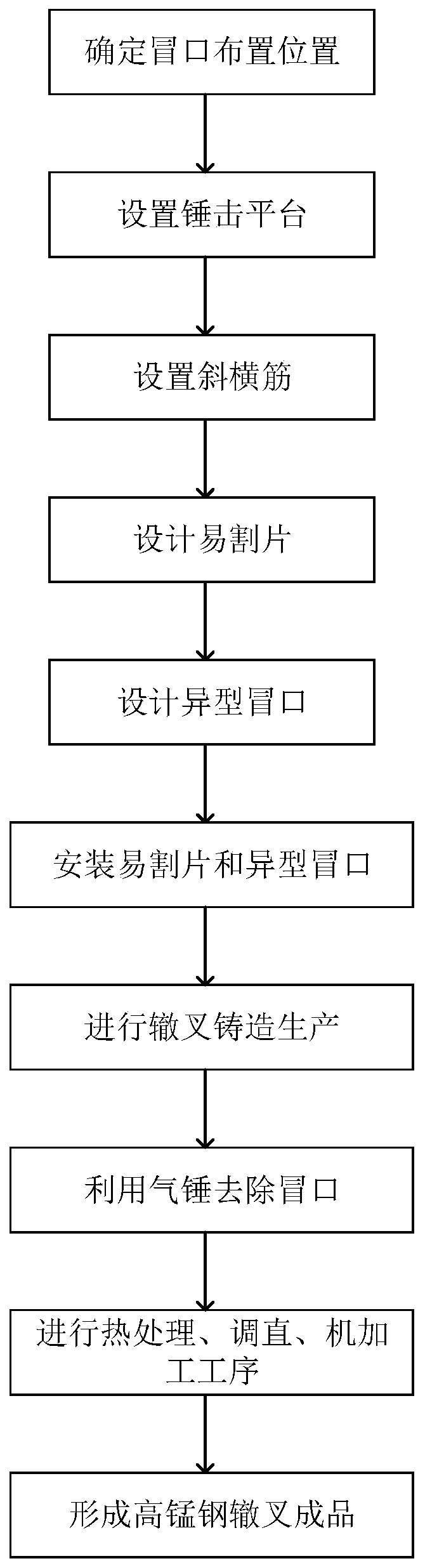

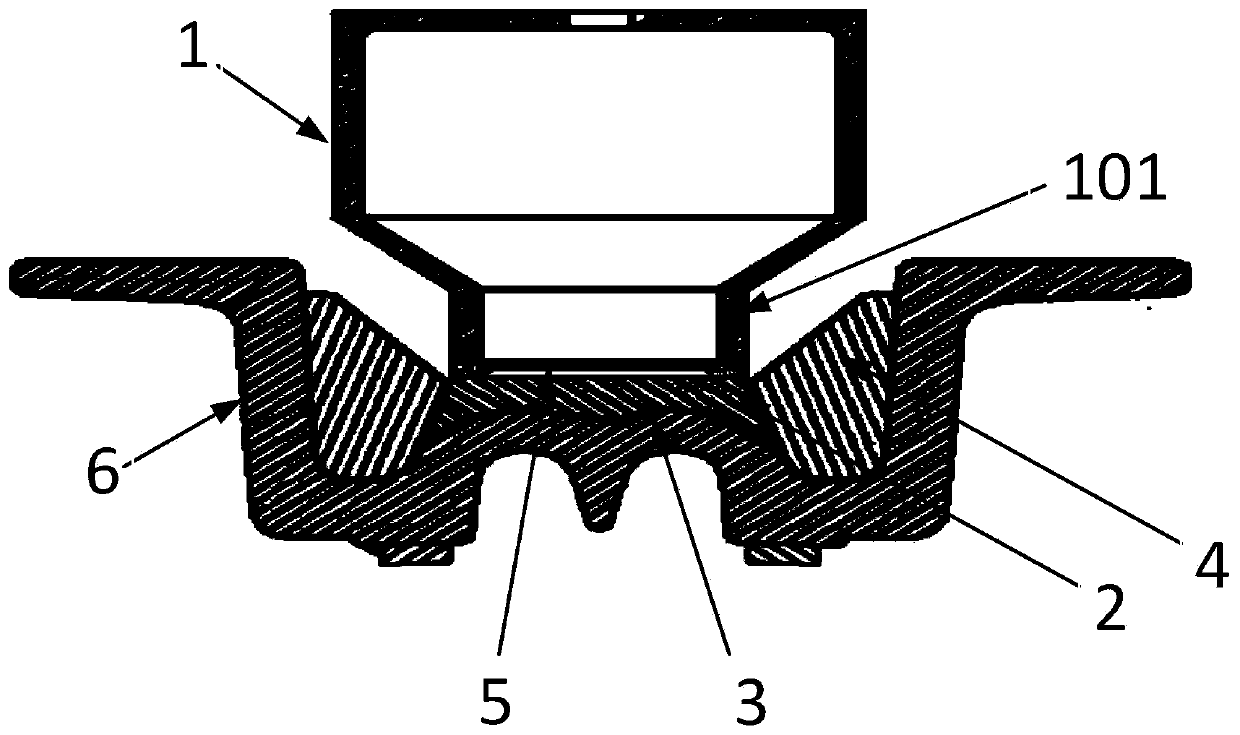

Method for improving internal quality of high manganese steel frog and lowering production cost

ActiveCN111515341AImprove internal qualityExtended service lifeFoundry mouldsFurnace typesCrazingPhysical chemistry

The invention discloses a method for improving the internal quality of a high manganese steel frog and lowering the production cost, and relates to the procedures of model forming, modeling and removal of risers. Innovative special-shaped risers, easy-to-cut pieces, frog structures, repairing and attaching forms and riser removal methods are put forward, and the traditional process of removing risers through a hot-cutting method, namely the method of conducting melting through burning, and high-temperature heat release of sharp gas (acetylene) is omitted, so that the energy is saved, and environmental pollution is avoided; and moreover, the situation that the high manganese steel frog has high cross-section appearance quality after being hammered, then a high stress area is formed due to local uneven heating of the hot risers to the frog rail wall, and then hot cracks are generated in the rail wall, and cause scrapping due to centralized release of heat in a finally-solidified organization part of a casting can be essentially avoided. At the same time, the repairing and attaching of the riser feeding channel is added, the modulus of the feeding channel is increased, the feeding effect of the risers is improved by more than 500%, the internal density of the high manganese steel frog is increased, the generation of shrinkage porosity defects is avoided, and the quality bottleneckof the traditional casting process is overcome. According to the method, the feeding channel can also be recycled for repeat use, so that the cost is lowered.

Owner:CHINA RAILWAY MATERIALS TECH

Production process of a low-alloy high-strength cast iron piston

ActiveCN105772630BAvoid problemsSolve shrinkage defectsFoundry mouldsFoundry coresCombustion chamberHigh intensity

Owner:JIANGSU YUANFANG POWER TECH CO LTD

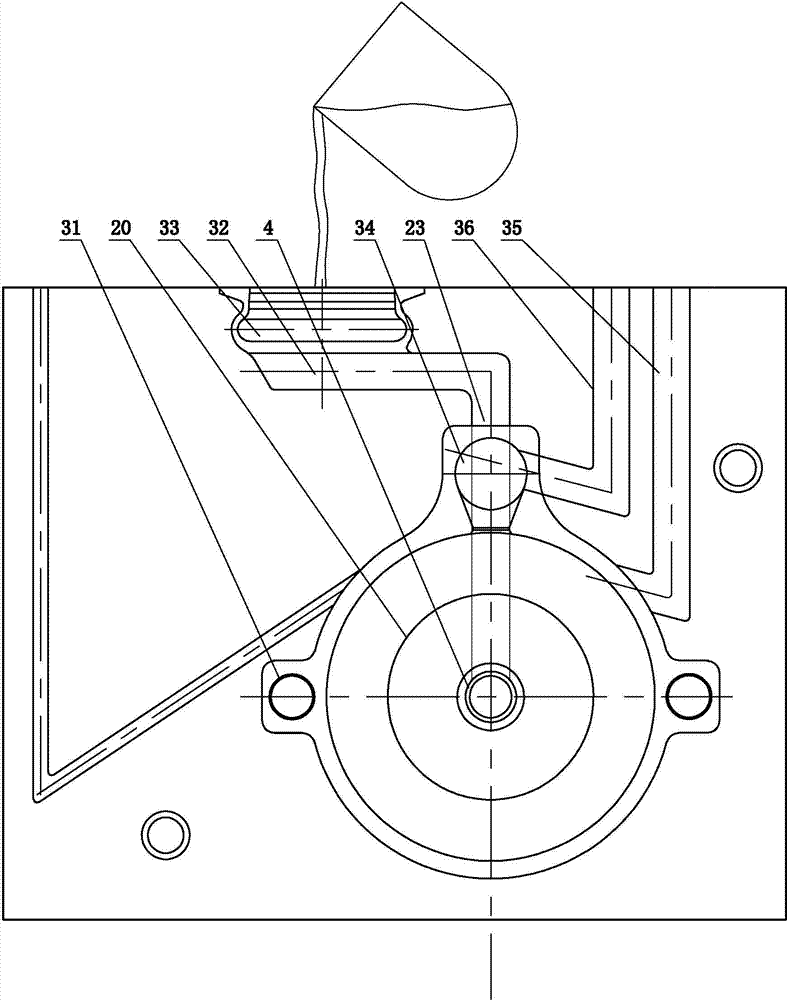

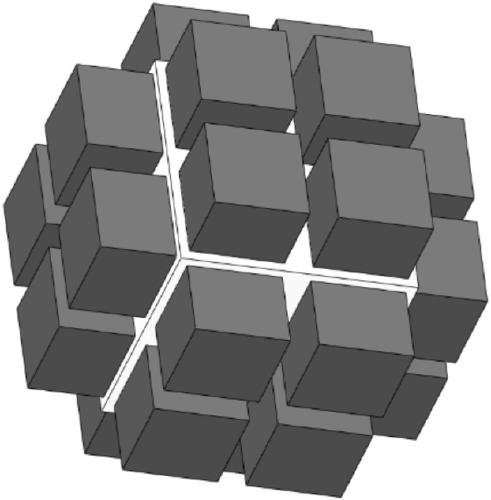

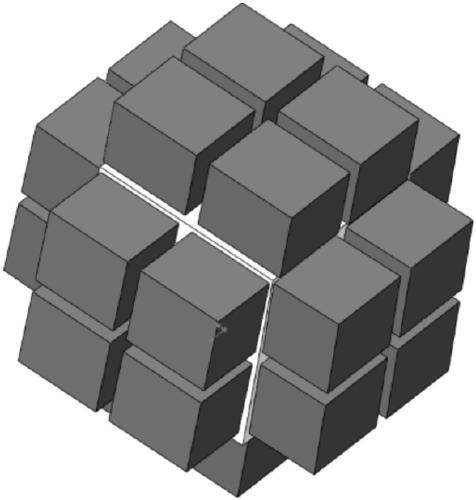

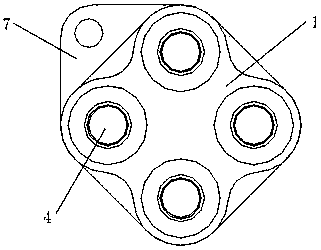

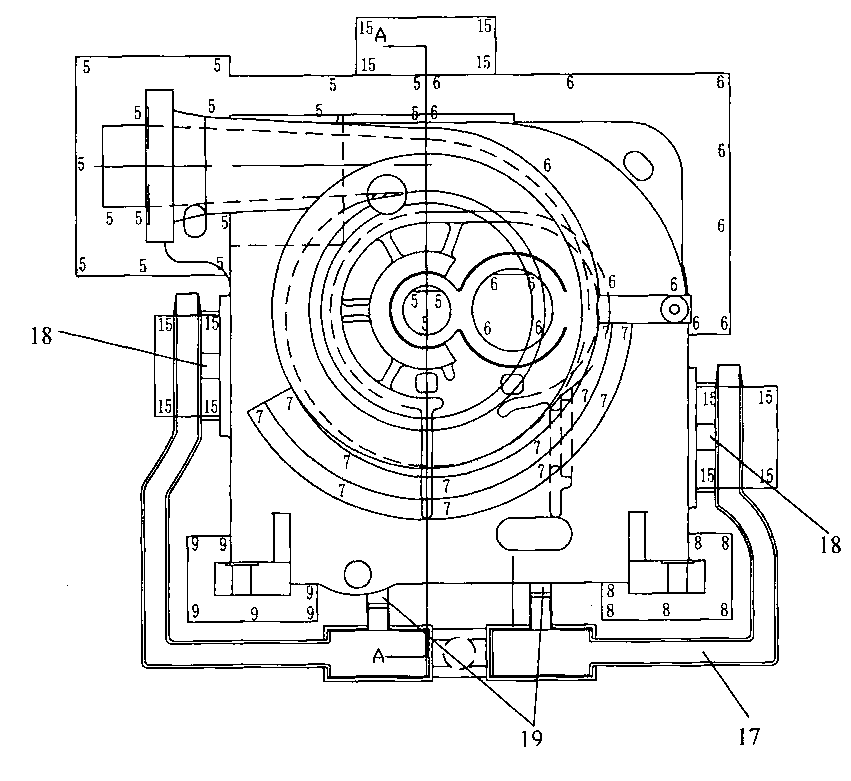

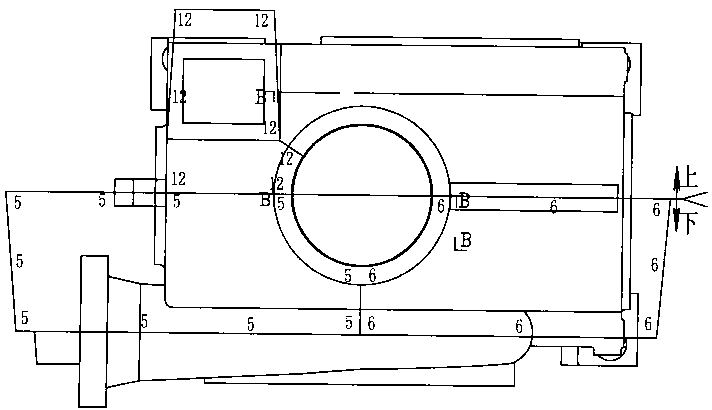

Multi-rubber rotary body casting, multi-rubber rotary body and casting mold for casting multi-rubber rotary body casting

PendingCN110479966ASolve shrinkage defectsGuaranteed runner hole sizeFoundry mouldsFoundry coresCasting moldMaterials science

The invention relates to a multi-rubber rotary body casting. The multi-rubber rotary body casting comprises a base and a matrix. The base is in a cube shape. The matrix is in a two-step columnar shape. The second step of the matrix is connected with one end face of the base. Four oil outlets are evenly arranged on the second step of the matrix by a circle, and the four oil outlets are distributedin a staggered manner in the axial direction of the matrix. Four oil inlets are evenly arranged on the other end face of the base. The oil inlets and the oil outlets are in one-to-one correspondence and are connected through runner holes formed in the rotary body casting. Design is reasonable, the structure is simple, the defect of shrinkage porosity of the casting is overcome, and meanwhile the size of each runner hole in the rotary body casting can be guaranteed.

Owner:南通华东油压科技有限公司

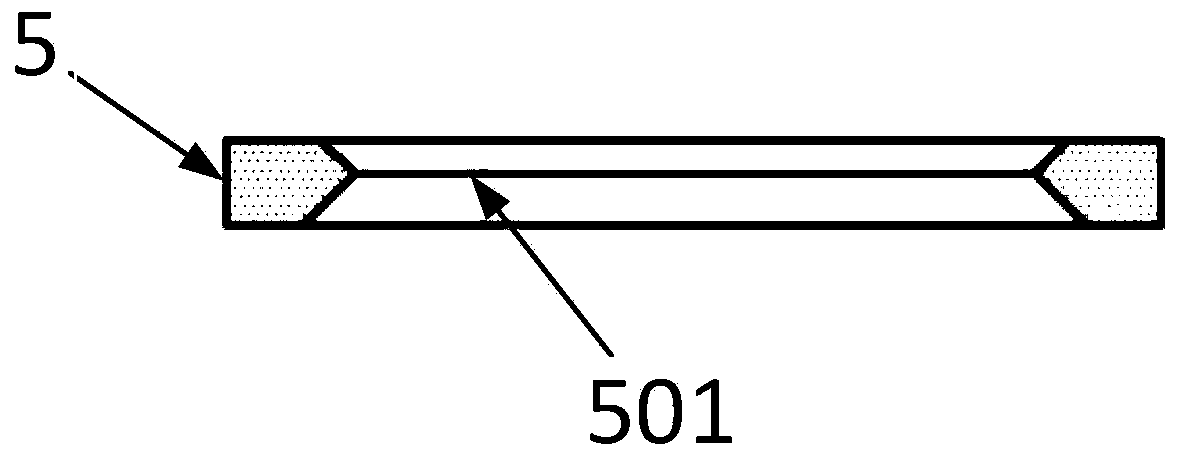

Flow meter housing casting piece

InactiveCN102699283ASolve shrinkage defectsImprove product qualityFoundry mouldsFoundry coresEngineering

The invention relates to a flow meter housing casting piece, in particular to a housing casting piece of a flow meter. The flow meter housing casting piece comprises a straight pipe, and is characterized in that radial bosses are formed at the both ends of the straight pipe; a radial hole for mounting a sensor is reserved in the middle of the straight pipe; a radial embossment is processed on one side in the middle of the straight pipe; and the radial hole is cast on the radial embossment. The flow meter housing casting piece is better in quality.

Owner:WUXI UNIVERSAL PRECISION CASTING

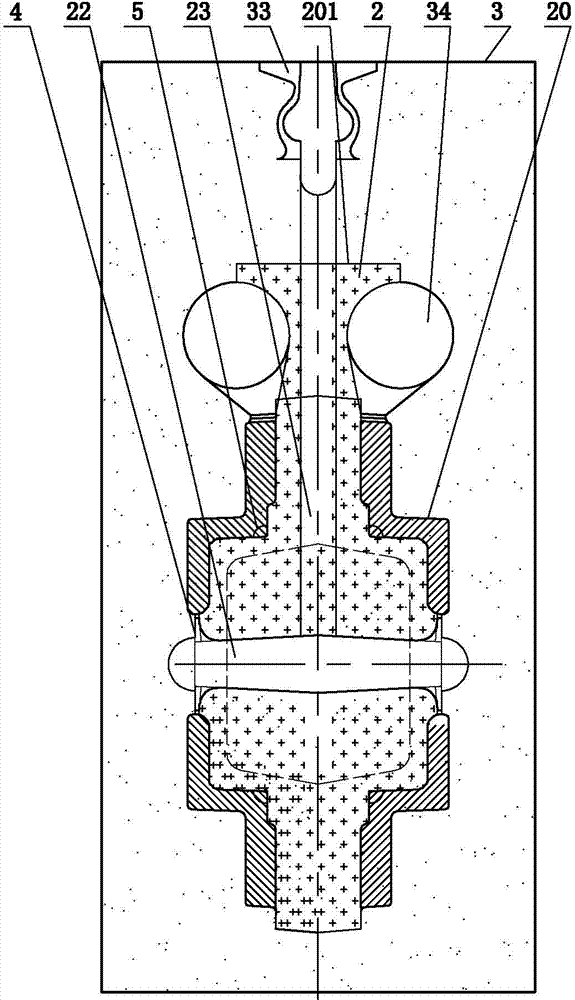

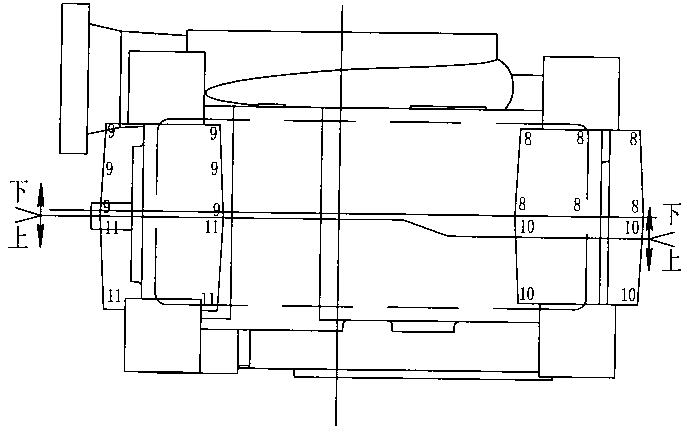

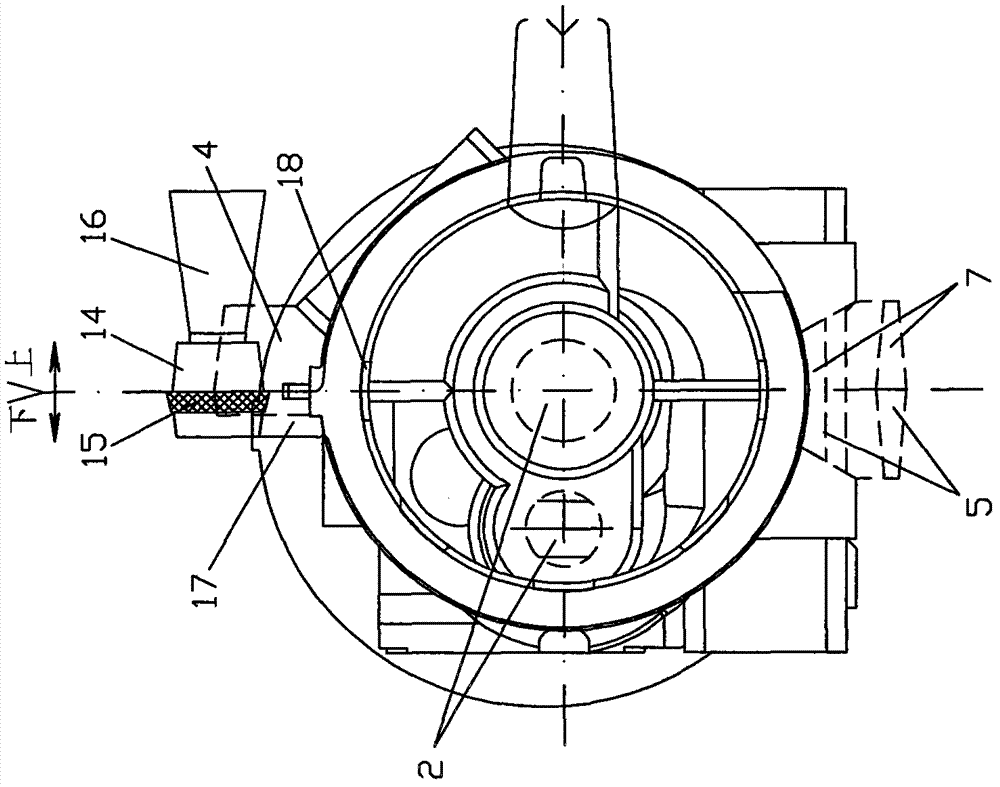

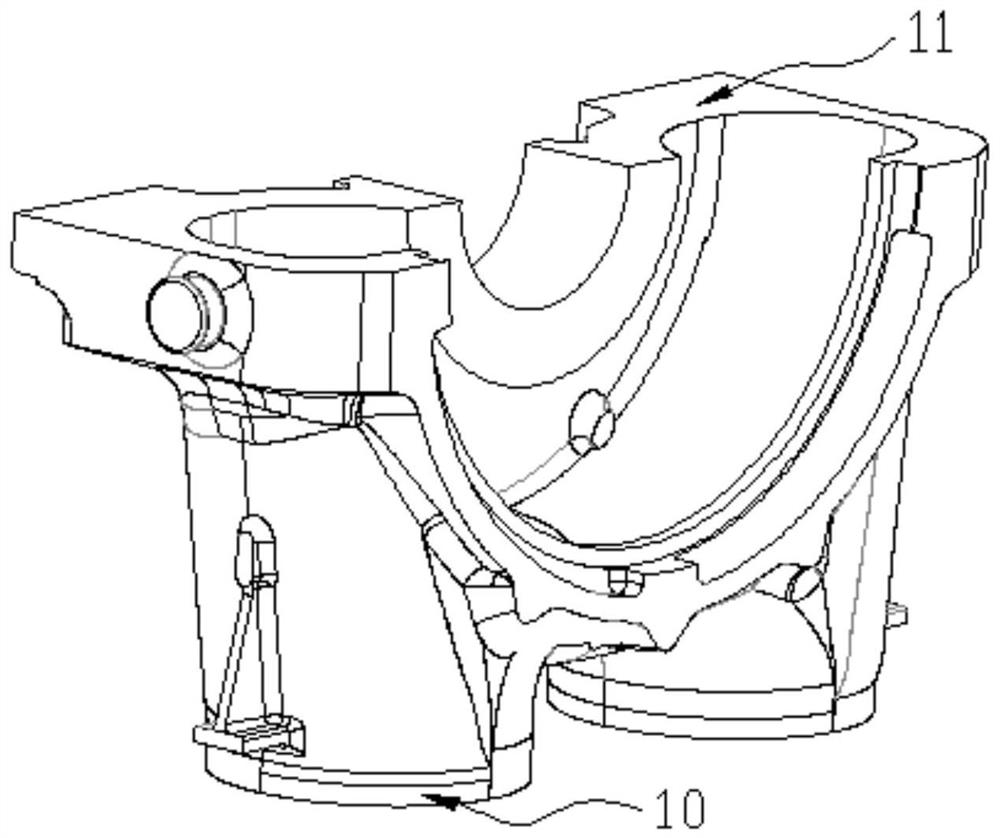

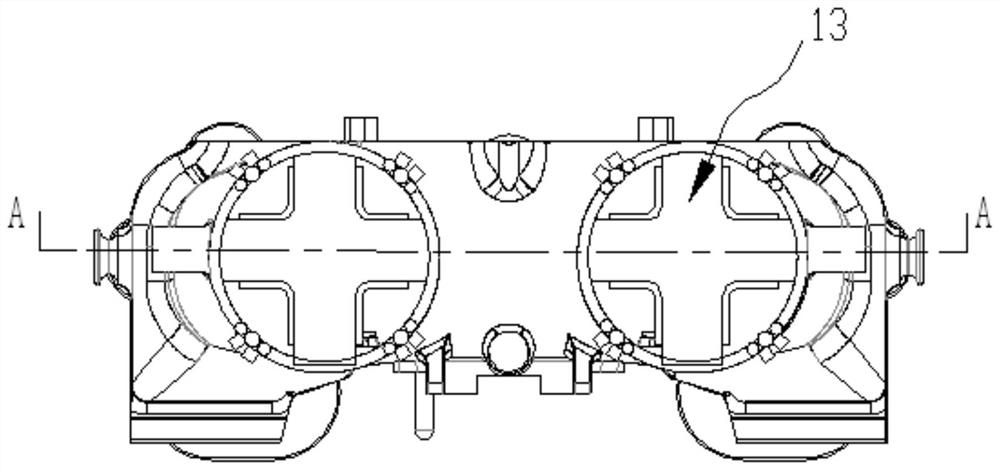

Casting method of body casting of centrifugal air compressor

ActiveCN102451904BEffective dispersionSolve shrinkage defectsFoundry mouldsFoundry coresAir compressorCasting defect

The invention discloses a casting method of a body casting of a centrifugal air compressor. The method comprises the following steps of: sand mulling, moulding, core making, mould assembly, furnace burden melting, iron discharge incubation, pouring, cooling, box opening, casting cleaning and product quality inspection. In the invention, multiple sand cores are designed to form a whole casting, and the pouring of the whole casting is finished by adopting a mode of dispersing the pouring with multiple sheet-type ingates. The mechanical performance of the casting meets that the tensile strength is greater than or equal to 250MPa and the body hardness is 170-230HBS. The product does not have any internal casting defect.

Owner:上海华新合金有限公司

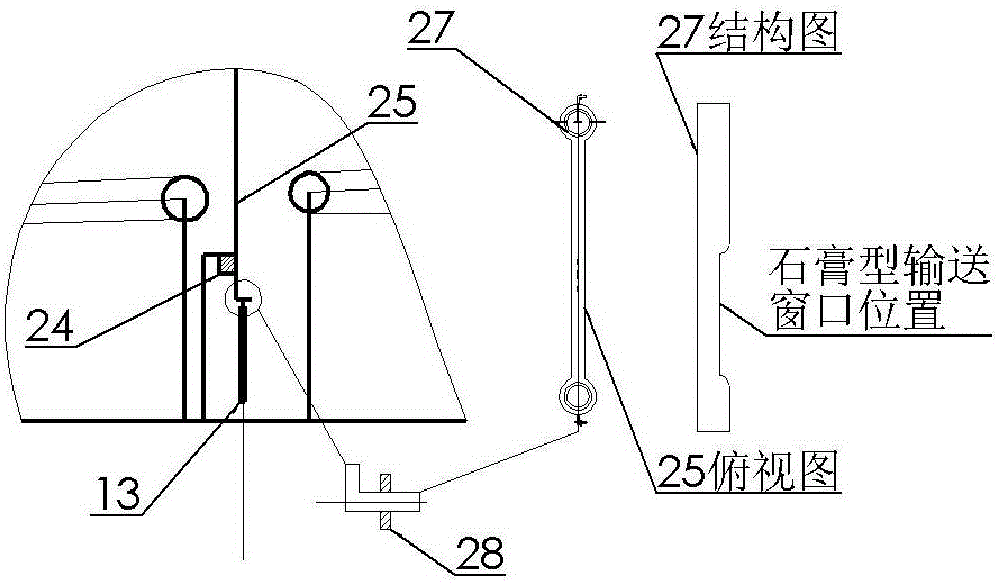

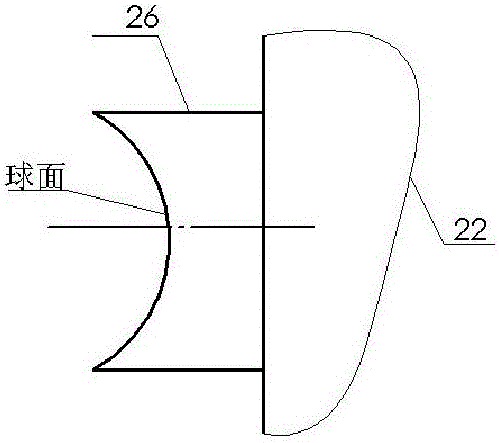

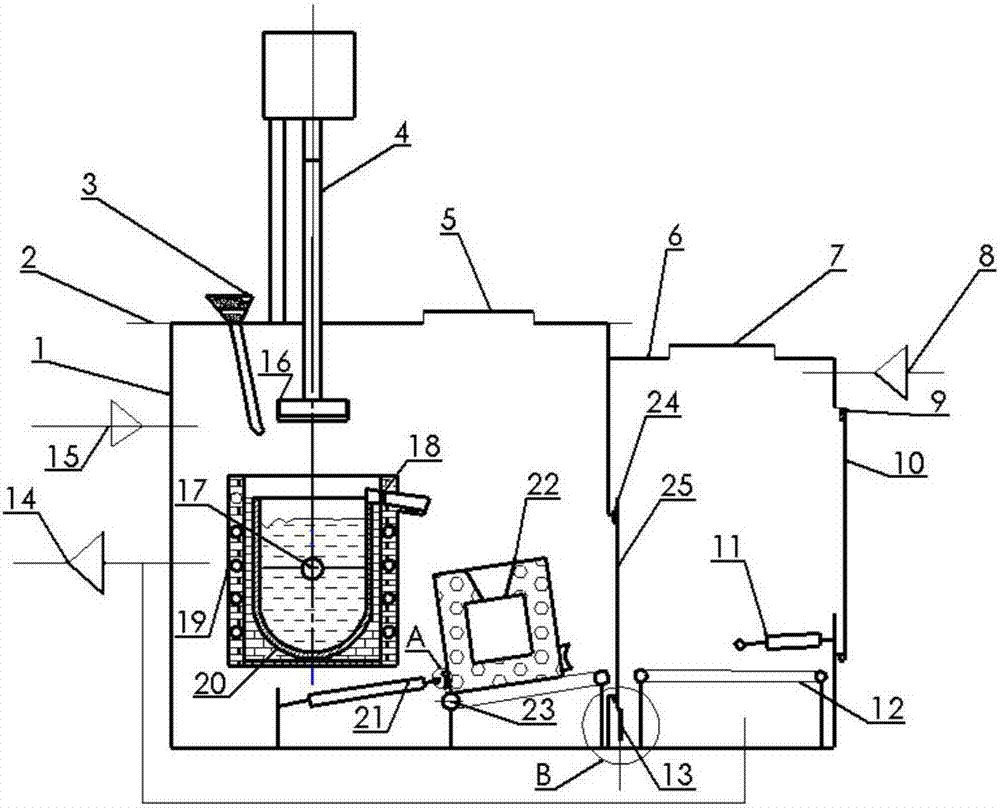

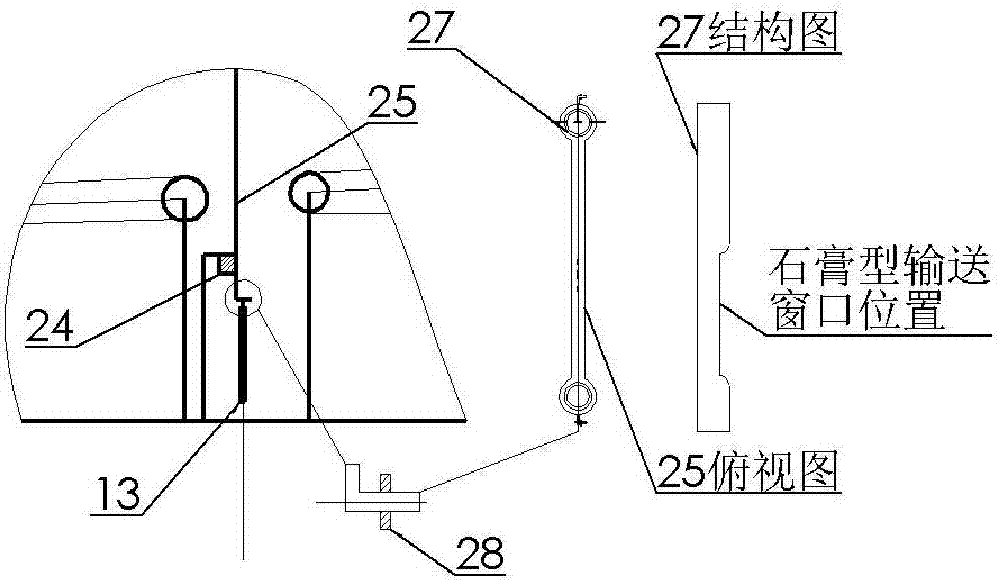

An integrated forming equipment and method for thin-walled parts of aluminum matrix composite materials

The invention relates to an integrated forming device and method for aluminum matrix composite thin-walled pieces. The device comprises a preparing-pouring tank (1) and a pressurization tank (6), wherein the preparing-pouring tank (1) and the pressurization tank (6) are used for preparing aluminum matrix composites. The preparing-pouring tank can be vacuumized through a vacuumizing device. The pressurization tank can be pressurized through a pressurization device. A gypsum mold can enter the preparing-pouring tank from the pressurization tank through a conveying window to conduct pouring. The stable-quality and integrally-formed aluminum matrix composite complex thin-walled pieces are obtained through the method of preparing and pouring the aluminum matrix composites under the vacuum condition and conducting solidification at high pressure. The interiors of the obtained castings are free of defects such as slag inclusion, shrinkage porosity and pores, and the castings are compact in structure, good in performance and capable of meeting production requirements. The device is easy to popularize, suitable for producing the aluminum alloy composite complex thin-walled pieces on a small scale and high in casting yield.

Owner:HENAN POLYTECHNIC UNIV

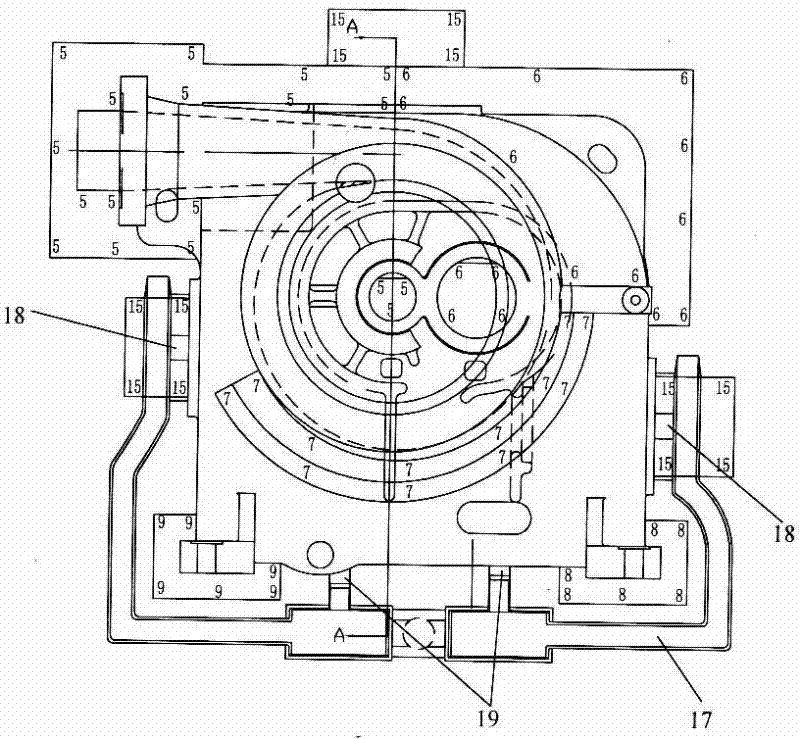

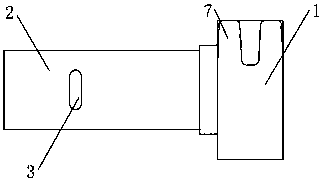

Method for casting ductile iron casting of air-conditioning compressor

ActiveCN102371345BShort processAvoid slag inclusion defectsFoundry mouldsFoundry coresHardnessCasting defect

A method for casting a ductile iron casting of an air-conditioning compressor comprises the following steps of: sand mixing, moulding, core manufacturing, mold assembling, furnace charge melting, tapping spheroidization and inoculation treatment, casting, cooling, unpacking, casting cleaning and product quality inspection. A unilateral flange dispersed casting technology is adopted in process design, and external chill is disposed on several thicker positions of the casting. The casting needs to satisfy the following mechanical properties: the tensile strength is larger than or equal to 450MPa, the yield strength is larger than or equal to 310MPa, the elongation percentage is larger than or equal to 10% and the hardness is within 160-210HBS. There exist no casting defects within products.

Owner:上海华新合金有限公司

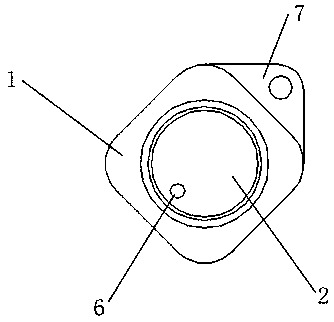

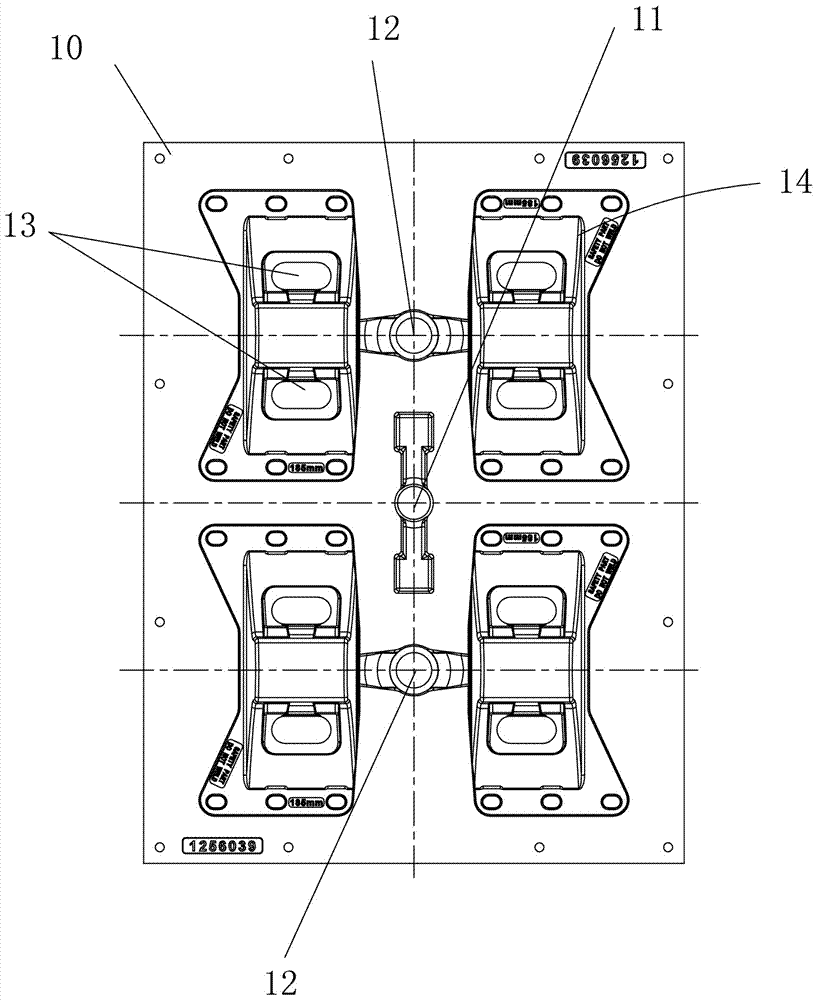

Height Limit Feeding Technology of Support Seat

ActiveCN104550746BGuaranteed dimensional accuracyGuaranteed tightFoundry mouldsFoundry coresInlet channelEngineering

The invention discloses a height-limit feeding head structure for a bearing seat. A casting sand core of the bearing seat is in a one-template and four-piece layout structure. Two first dead heads and a plurality of second dead heads are arranged, and the first dead heads are arranged between sand core cavities of two adjacent bearing seats, so that a ductile iron liquid flows into a water inlet channel through a sprue gate, and then flows into the cavities of the four bearing seats through the water inlet channel; the first dead heads perform feeding on bottom plates of the bearing seats, and the second dead heads are arranged in windows of the bearing seat cavities and perform the feeding on the tops of the bearing seats. Through the scientific selection, according to the structural characteristics of parts that the top is thick and large and the bottom is thin-walled and is not processed, the feeding heads at the top are arranged in the windows at two oblique sides, accordingly, the amount of the feeding liquid can be effectively ensured, the shrinkage porosity defect can be prevented; the densification of a microstructure is ensured and further the dimensional accuracy of castings is ensured.

Owner:GUANGDONG FUHUA CASTING

A Quantitative Bottom Injection Device for Melting Ingot Making

ActiveCN110026534BImprove production safetyImprove quality and efficiencyMolten metal supplying equipmentsIngot casting plantsEngineeringIngot

The invention relates to a quantitative bottom injection device for melting ingots, which includes a ladle assembly, a plunger assembly and a ejection reset assembly, the ejection reset assembly is arranged on both sides of the ladle assembly, and the column The plug assembly is arranged above the ladle assembly through the ejection reset assembly, and the ejection reset assembly is drivingly connected with the plunger assembly; the ladle assembly includes a tundish, and the bottom of the tundish is set There are several flow passages; the plunger assembly includes several plungers corresponding to the flow passages; when the ejection reset assembly drives the plunger out, the gap between the plunger and the flow passage Open, the molten metal in the tundish is poured; when the ejector reset component drives the plunger to reset, the gap between the plunger and the flow channel is closed, and the molten metal in the tundish stops pouring. The invention improves the production safety, ingot quality and production efficiency of molten ingot making.

Owner:SHANGHAI INST OF TECH

An integrated preparation and forming equipment for magnesium alloy thin-walled parts

The invention relates to an integrated preparing and forming device for magnesium alloy thin-walled pieces. The forming device comprises a smelting-pouring tank and a protective atmosphere solidification tank, wherein the smelting-pouring tank and the protective atmosphere solidification tank are used for preparing a magnesium alloy. The smelting-pouring tank and the protective atmosphere solidification tank are both connected with a vacuumizing device and a protective gas injection device. By means of the integrated preparing and forming device, the magnesium alloy can be smelted under the vacuum condition, preparation is completed and pouring is conducted under the condition that the protective gas is injected, and pressurized solidification is conducted under the condition that the protective gas is injected in the protective atmosphere solidification tank. The integrated preparing and forming device is suitable for producing complex and thin-walled magnesium alloy castings, the production safety is high, the surfaces of the castings are free of oxidation defects, internal defects such as slag inclusion, shrinkage porosity and cold shut are basically solved, the structure is compact, performance is good, production requirements are met, the integrated preparing and forming device is easy to popularize, and the yield of the castings is high.

Owner:HENAN POLYTECHNIC UNIV

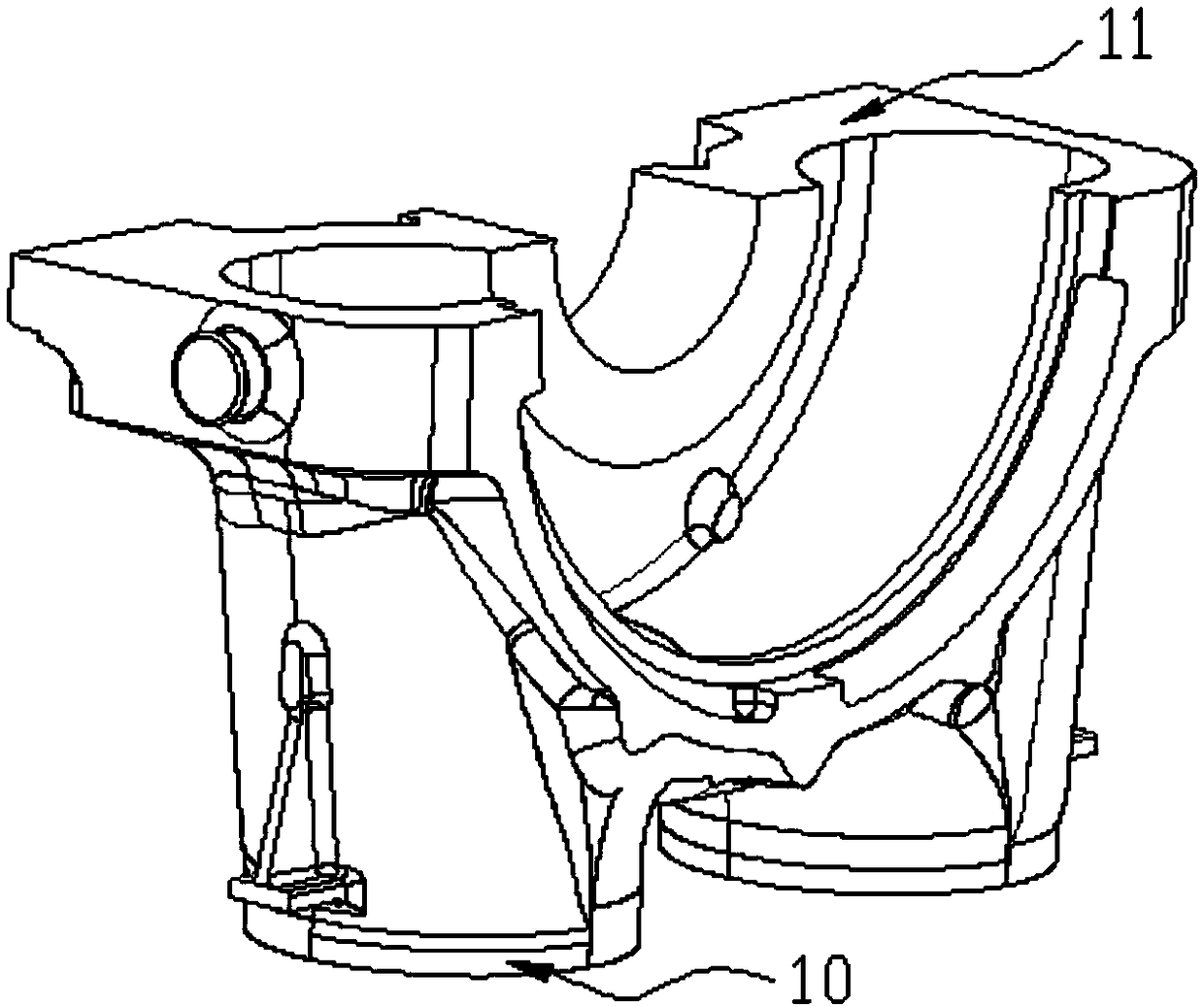

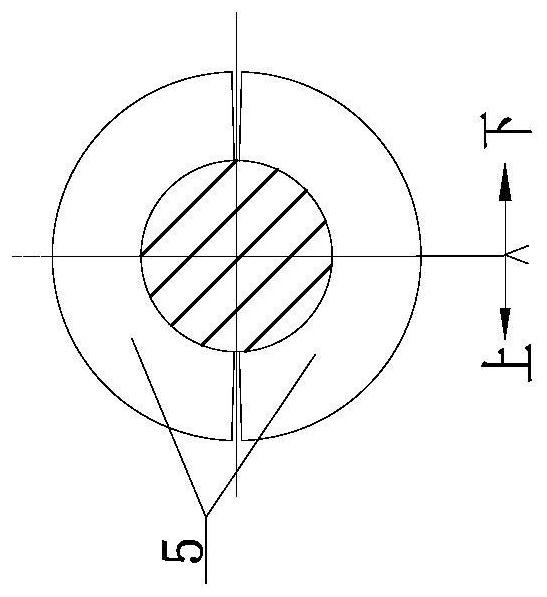

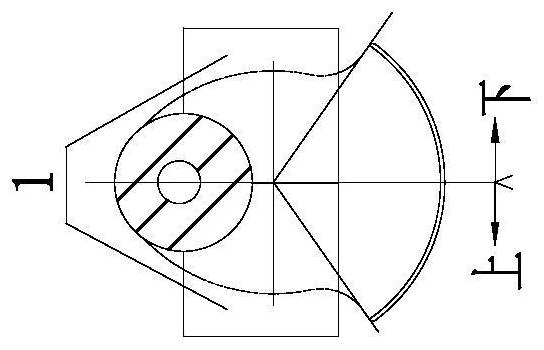

Chain wheel seat casting system

PendingCN113600757AEasy end connectionQuality improvementFoundry mouldsFoundry coresPolishingEngineering

The invention relates to the technical field of engineering machinery, in particular to a chain wheel seat casting system. The system comprises a pouring cup, a straight pouring gate and a transverse pouring gate which are communicated, a blind riser is arranged at the end of the transverse pouring gate and communicated with an inner pouring gate in a 90-degree angle, the inner pouring gate is communicated with a casting cavity of a chain wheel seat, and the joint of the inner pouring gate and the casting cavity is a center hole of the chain wheel seat. The inner pouring gate is in contact with the casting cavity at the center hole of the chain wheel seat, so that the inner pouring gate can be connected with the structure of the chain wheel seat in a 360-degree range, molten iron is ensured to be quickly injected into an upper cavity and a lower cavity of the casting cavity, sequential solidification is realized, the phenomenon of shrinkage porosity is avoided, and meanwhile, the separation part of the inner pouring gate and the cast chain wheel seat is positioned at the center hole, so that a casting head formed through separation can be removed in a drilling manner or a trepanning drilling manner, the trace of the casting head formed on the chain wheel seat is avoided, the quality of the chain wheel seat is improved, meanwhile, damage caused by manual polishing of the casting head is avoided, and the machining efficiency is improved.

Owner:LAIZHOU HONGYUAN BENCH VICE MFR

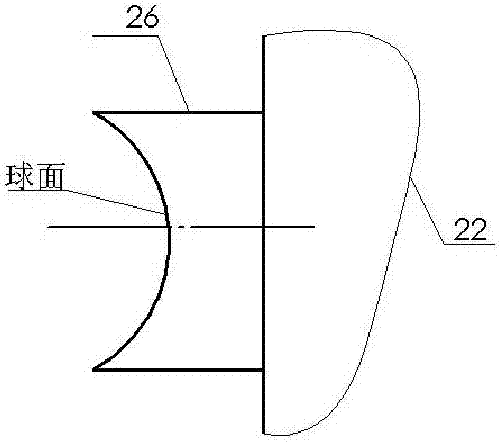

Casting Method to Prevent Shrinkage Porosity of Ductile Iron Crankshaft

The invention is mainly applied in the technical field of casting of nodular cast iron crankshaft castings of marine diesel engines and particularly relates to a casting method preventing a shrinkagedefect of a nodular cast iron crankshaft. The following steps that (firstly), process design of a cast model and design of a mold bottom plate and a sand box are completed; (secondly) a temperature field during box erecting of a casting is calculated, and hot section portions are determined; (thirdly) chilling blocks are designed at the positions of the hot section portions; (fourthly) riser design is performed, specifically, a spherical riser is arranged at the crankshaft free end to be used for feeding of the free end, and the riser is required to be provided with gas outflow holes; (fifthly) crankshaft, chilling block mold and tool manufacturing and installing are completed; (sixthly) a modeling procedure is completed; and (seventhly) casting and box erecting are performed are adopted.According to the method, the hot section positions are determined, the different chilling blocks are adopted on different portions to be matched according to the structure so that generated defects can be reduced, meanwhile, the riser, the chilling blocks and a manner that box erecting and casting are combined are adopted at the same time to solve the shrinkage defect, the effect is obvious, the production quality is improved, and cost is lowered.

Owner:ZICHAI POWER CO LTD

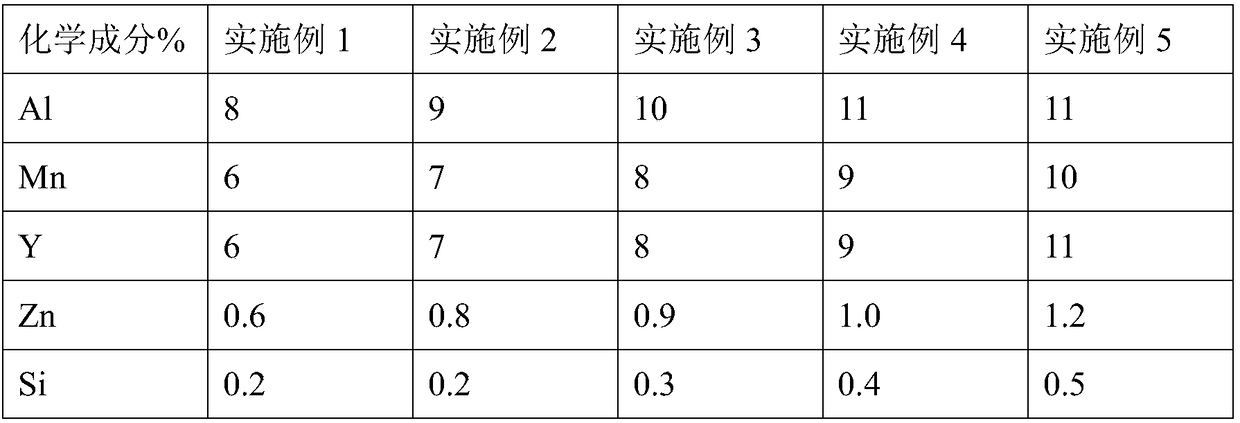

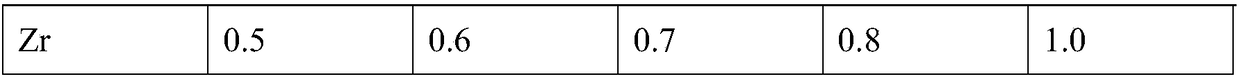

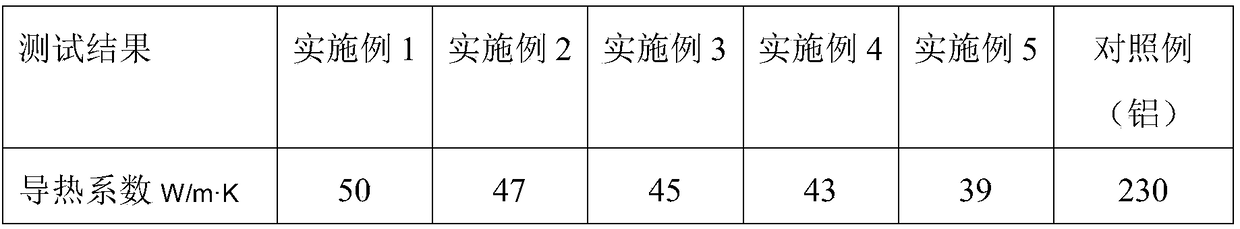

Thermal insulation metal material

InactiveCN108859303ALow melting pointImprove liquidityLaminationLamination apparatusThermal insulationChemical Ingredients

The invention relates to the field of metal alloy materials and specifically relates to a thermal insulation metal material. The thermal insulation metal material is prepared from a metal material anda thermal insulation material, wherein the metal material is prepared from the following chemical components in percentage by weight: 8-11% of Al, 6-10% of Mn, 6-11% of Y, 0.6-1.2% of Zn, 0.2-0.5% ofSi, 0.5-1% of Zr and the balance of Mg. A thermal insulation material strip penetrates through the middle of the metal material, and the metal material is cut to form a broken bridge. The preparationmethod of the thermal insulation metal material provided by the invention comprises the following steps: melting a magnesium alloy prepared from Mg, Al, Zn, Si and the like into liquid under protection of a solvent covering agent; adding Y, Zr and Mn and stirring; heating to 760-820 DEG C; injecting the liquid-state thermal insulation material into an alloy type thermal insulation slot, and solidifying; combining the two separate parts of the magnesium alloy by the thermal insulation material; finally, refining at 680-730 DEG C, and performing certain standing inoculation before casting moulding. The thermal insulation metal material has the functions of insulating heat and cold. Moreover, the thermal insulation metal material also has good thermal insulation property and sound insulationproperty.

Owner:四川大阳实业发展有限公司

A Casting Method for Preventing Nozzle Defects of Cylinder Castings

ActiveCN109128046BPrevent inflowSolve the problem that the gate cannot be set when the wall thickness is thinFoundry mouldsFoundry coresEngineeringCasting defect

The invention belongs to the field of casting and mainly relates to a casting method capable of preventing defects of an air cylinder casting pipe orifice. When the pipe orifice part is casted in theprior art, one loop of cold iron is adopted, and the casting defects such as shrinkage porosity and slag inclusion exist among the cold iron through RT ray detection; in consideration of the above problem, the invention provides a casting method capable of preventing casting defects for an air cylinder casting pipe orifice part. The casting method comprises: a casting process scheme of placing theair cylinder casting with the upward combined surface and the downward pipe orifice is selected, a crossed riser neck is arranged at the radial part of the air cylinder casting pipe orifice, a blindriser is arranged at the middle position of the crossed riser neck, and partitioned cold iron is arranged on the end face part of a crossed riser neck feeding superposed area of the air cylinder casting pipe orifice, so that the casting defects such as shrinkage porosity, slag inclusion and crack on the air cylinder casting pipe orifice part are effectively avoided, the quality of the air cylindercasting is improved, and the standard requirement for the RT ray detection first level of the air cylinder casting pipe orifice part is met.

Owner:KOCEL STEEL

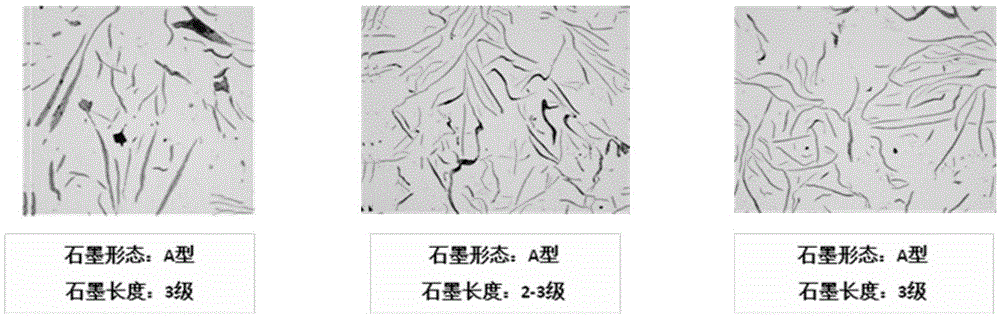

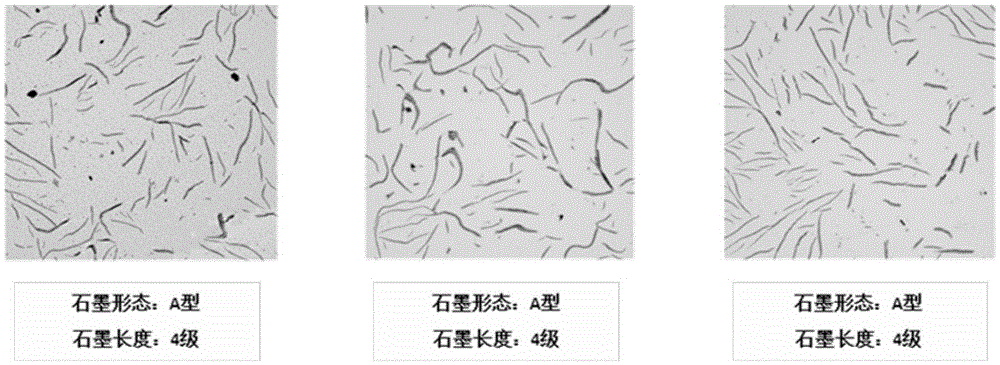

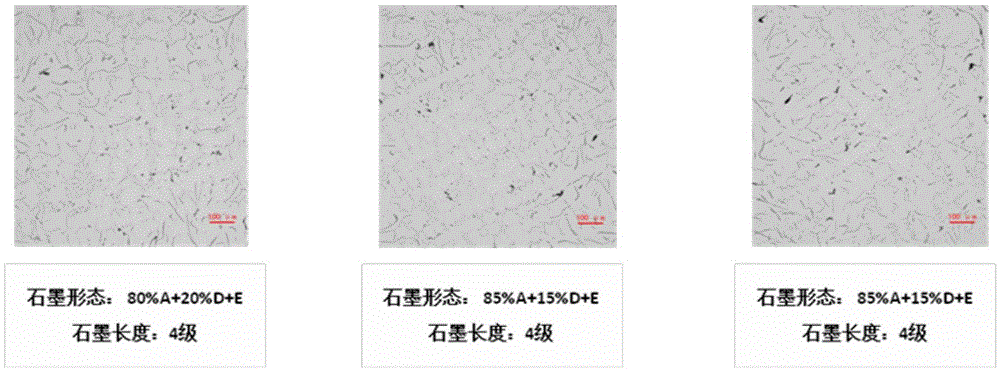

A method for improving graphite grade of thick and large section gray cast iron

ActiveCN104263888BPoor shapeLow length gradeProcess efficiency improvementMechanical propertyCooling methods

The invention relates to a method for improving grade of gray cast iron graphite and in particular relates to a method for improving grade of thick section gray cast iron graphite. The method comprises the following steps: selecting thick section castings, selecting cooling modes, proportioning materials, selecting the components, performing modification treatment, detecting the castings, analyzing the test results and obtaining the metallograph. According to the method provided by the invention, cooling of the casting is accelerated by utilizing high heat conductivity coefficient and heat storage coefficient of chrome ore, and the aim of improving the form / grade of the gray cast iron graphite is achieved, so that the mechanical properties of the castings are improved.

Owner:KOCEL EQUIP

A precision casting method for the rear cover of a spiral supercharged diffuser

ActiveCN104399887BSolve the problem of dimensional accuracy deviationImprove pass rateFoundry mouldsFoundry coresWaxSlurry

The invention discloses a precision casting method of the back cover of a spiral supercharging diffuser. The casting method comprises steps of wax member preparation, assembling, slurry dipping and shell manufacturing, de-waxing, burning, casting, shell breaking, and cleaning. In the wax member preparation step, a cold wax core is manufactured through a cold wax core mould, then the cold wax core is allowed to stand still, and after the standing time is longer than four hours, the cold wax core is placed into a diffuser back cover mould to assemble a wax member. In the assembling step, the assembled wax member is trimmed and then adhered, and a casting system with a cast gate, a runner, and a sink head is combined with the wax member. In the slurry dipping and shell manufacturing step, after the wax member and the casting system are combined to form an assembled member, slurry is painted on the periphery of the assembled member. The tendencies of shrinkage hole and shrinkage porosity in the casting are reduced by the provided method, and the qualified rate of the casting is improved therefor.

Owner:BAODING FENGFAN PRECISION CASTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com