Method for improving internal quality of high manganese steel frog and lowering production cost

A technology of internal quality and production cost, applied in the field of technology, can solve the problems of waste of resources, non-recyclable riser feeding channel, etc., and achieve the effects of energy saving, high appearance quality and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

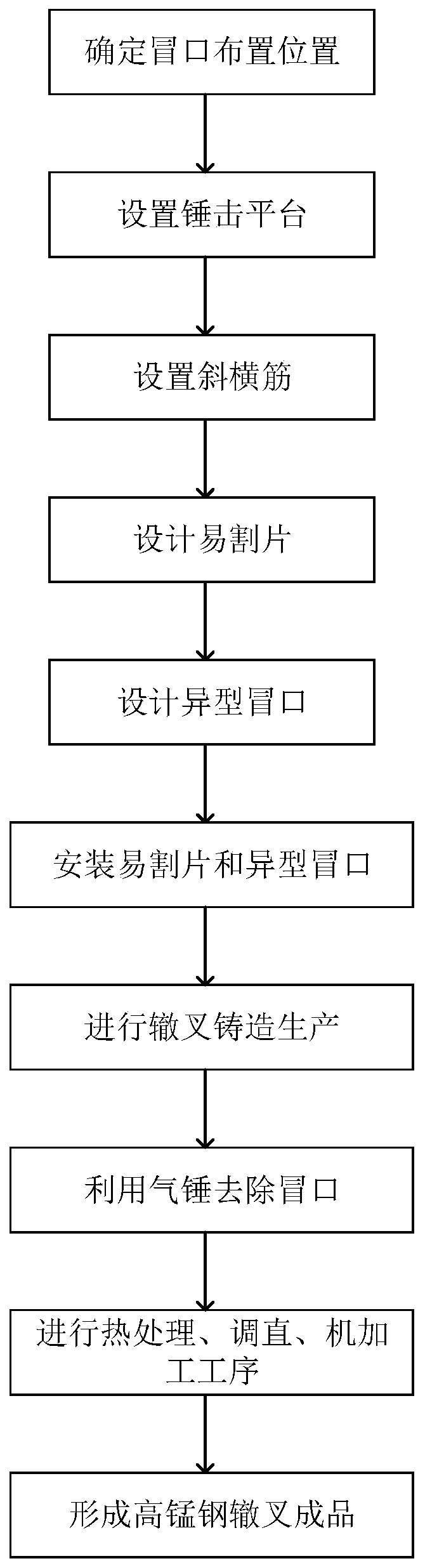

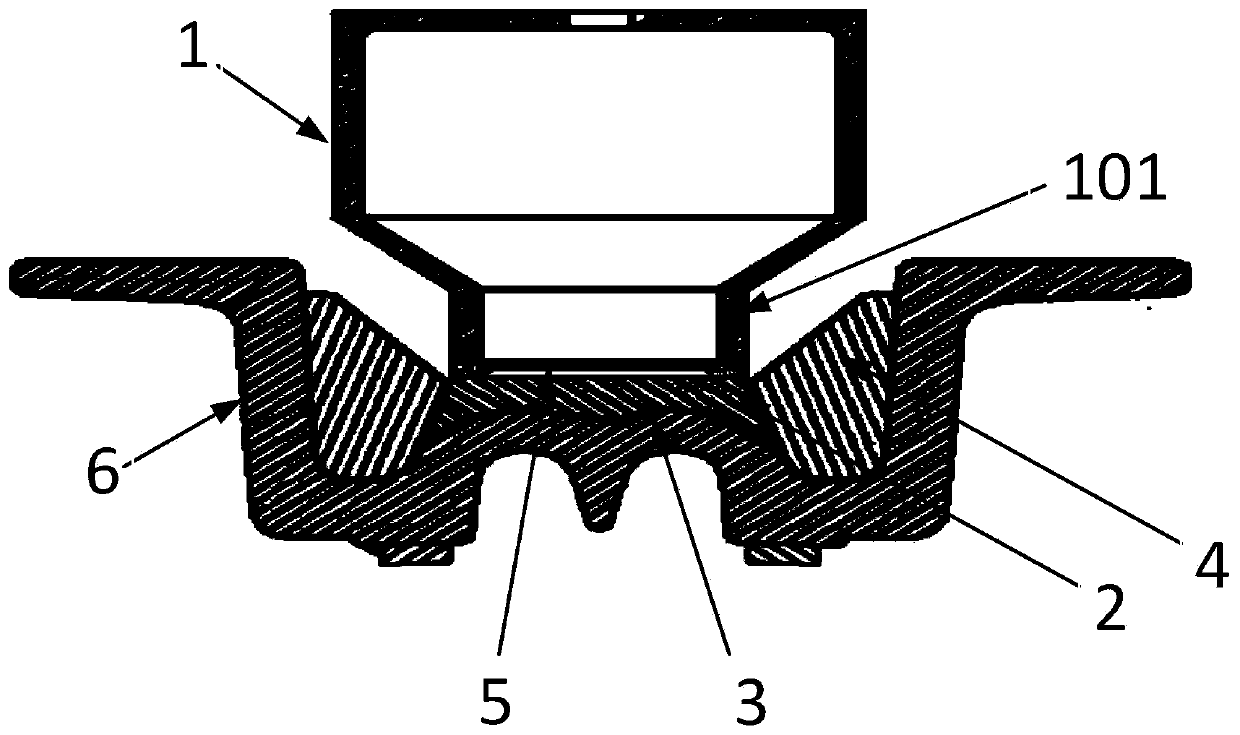

[0052] Such as Figure 1~4 Shown, in order to produce high manganese steel frog 60-12VGA, adopt 60kg / m speed-up high manganese steel frog, adopt V method molding high-density process to produce, adopt the method of the present invention to optimize below it:

[0053] Step 1: Repair the 60-12VGA frog model 6, that is, cancel the casting process on the high manganese steel manufacturer's model, and reset it according to the patented method; determine the layout of the riser 1 according to the product structure and the occurrence of diseases Location.

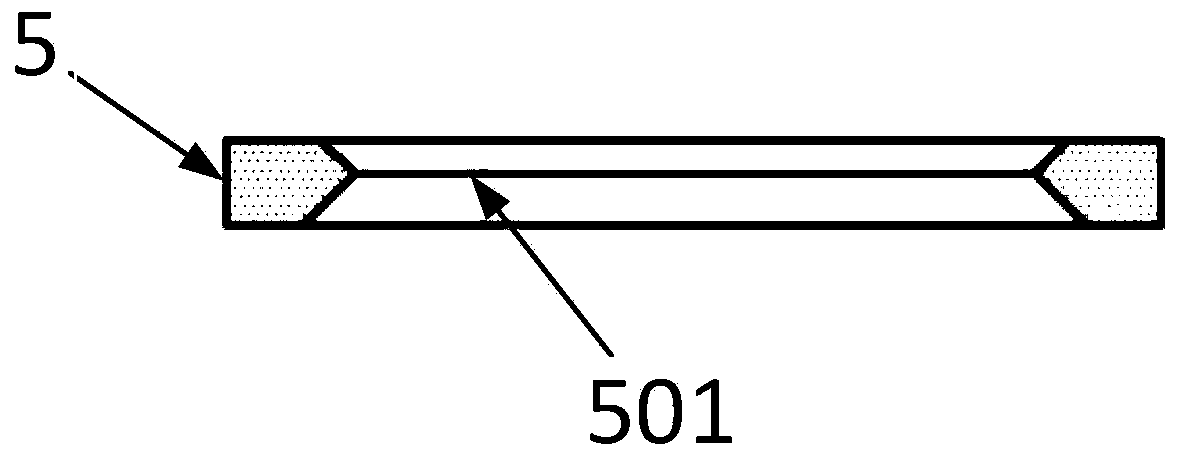

[0054] Step 2: Make the wooden hammering platform 2 with a height of 10mm, a diameter of φ105mm, and a slope of 1:20; set oblique transverse reinforcement 4 on both sides of the hammering platform 2, and the intersection of the oblique transverse reinforcement 4 and the frog model 6 rail wall is 30mm lower than the bottom plate, and The intersection of the hammering platform 2 is 5mm lower than the hammering platform, and the wid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com