Chain wheel seat casting system

A technology of casting system and sprocket seat, which is applied in the direction of casting mold, casting mold composition, casting molding equipment, etc., and can solve the problems of sprocket seat shrinkage and loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

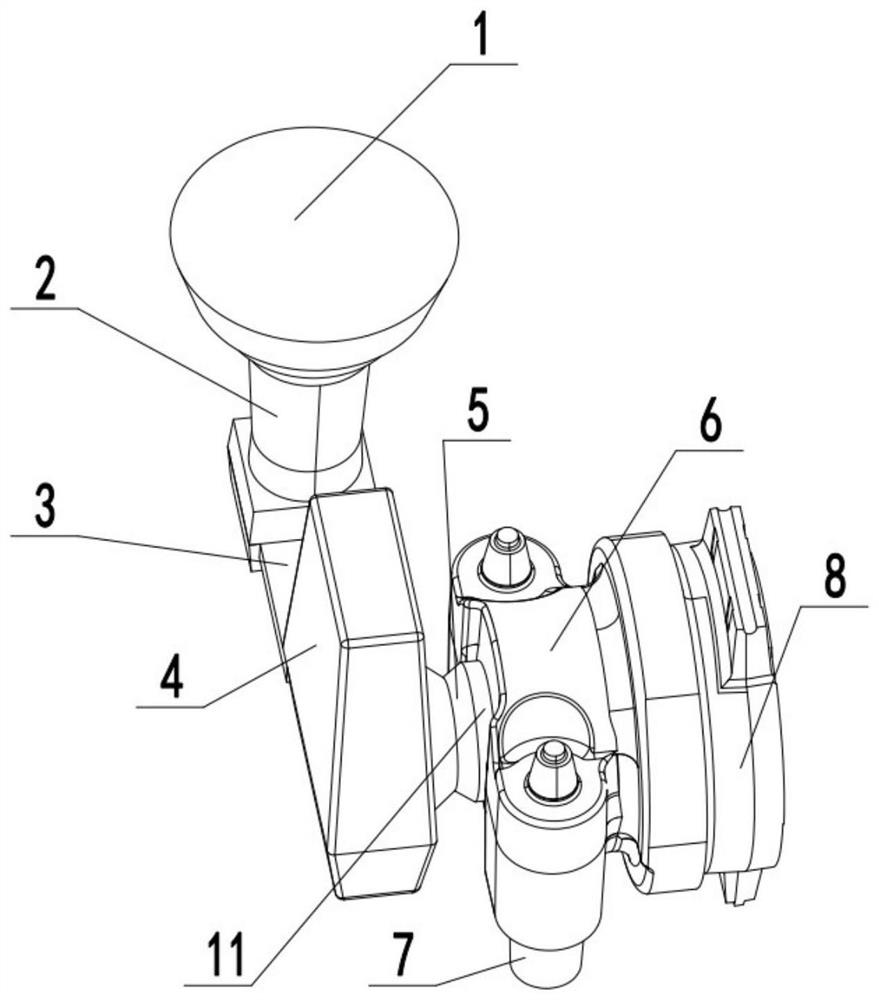

[0031] Please refer to figure 1 , Figure 4 , Figure 5 and Image 6 , a sprocket seat casting system, including a connected sprue cup 1, a sprue 2 and a runner 3, the sprue cup 1 is conical with a wide top and a narrow bottom, and the sprue 2 is a cylinder Body shape, the cross-section of the runner 3 is trapezoidal, the runner 3 extends between the sprue 2 and the dark riser 4, and the end of the runner 3 is provided with a dark riser 4 , the dark riser 4 communicates with the inner runner 5 at 90°, the inner runner 5 communicates with the casting cavity of the sprocket seat 6, and the joint between the inner runner 5 and the casting cavity It is the center hole 6-1 of the sprocket seat 6, and the height of the sprue cup 1 is greater than the height of the casting cavity, so as to ensure that the molten iron can smoothly fill the cavity. The dark riser 4 is a trapezoid with a narrow top and a wide bottom. At least one dark riser 4 is provided, and the inner runner 5 com...

Embodiment 2

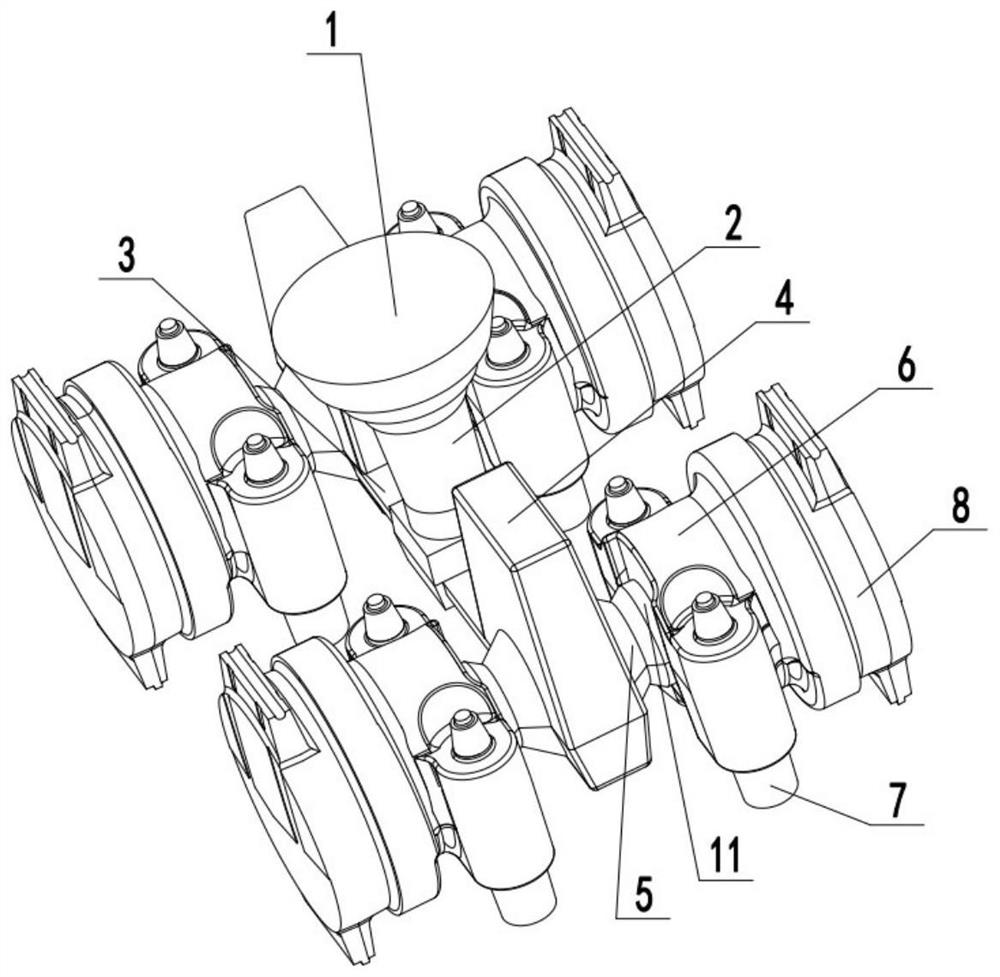

[0038] Please refer to figure 2 and image 3 , The difference from Example 1 is the number of dark risers 4, and the rest are the same as Example 1.

[0039] The sprue cup 1 is provided with one, and the runner 3 and the dark riser 4 are provided with two, and the two dark risers 4 and the runner 3 are arranged symmetrically on the side of the sprue cup 1 On both sides, both sides of the hidden riser 4 are provided with ingates 5, so the casting of four sprocket seats 6 can be completed in one casting, which greatly improves the casting efficiency.

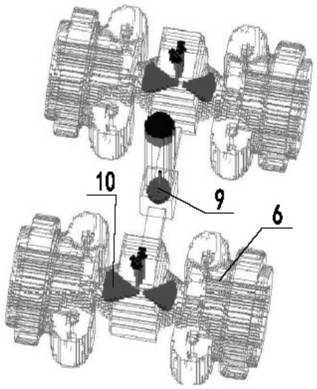

[0040] Please refer to image 3 After the design of the casting system is completed, the cooling process of the molten iron in the entire casting system is analyzed through CAE. There are only two shrinkage porosity in the entire casting system, which are shrinkage porosity 9 in the sprue and shrinkage porosity 10 in the inner runner. The pine is located outside the sprocket seat 6 , so the cast sprocket seat 6 has no shrinkag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com