Boring rod feeding-in protection device

A technology of protection device and boring bar, applied in feeding device, maintenance and safety accessories, parts of boring machine/drilling machine, etc., can solve problems such as low action accuracy, simple structure, and boring bar damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

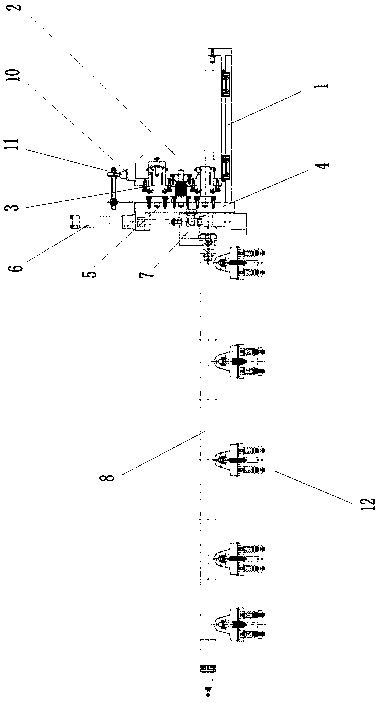

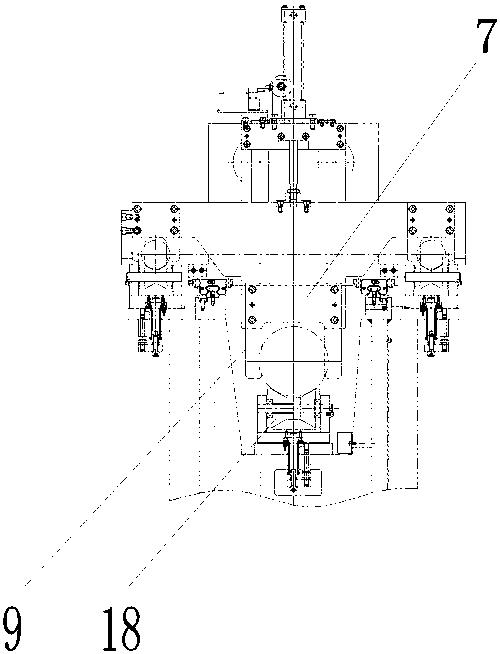

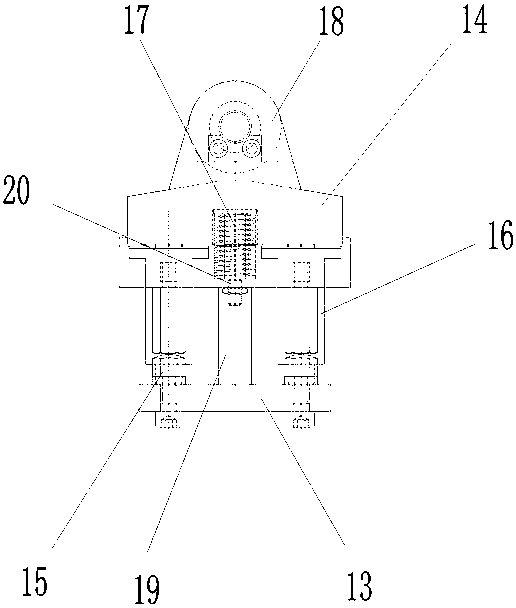

[0012] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 , figure 2 , image 3 Shown: a boring bar feeding protection device, including a slideway 1, a slide body 2 is slidably connected to the slideway 1, and two guide sleeves are symmetrically arranged on the slide body 2, and the inside of the guide sleeve A guide post 3 is slidably connected, and the two guide posts 3 are connected to the connecting plate 4 at the same time, and a spring 5 is also provided between the connecting plate 4 and the slider body 2, and a connecting plate 4 is provided on the top of the connecting plate 4. Cylinder 6, the working end of the connecting cylinder 6 is provided with a connecting terminal 7, the connecting terminal 7 is provided with a slot 9 matching the tail end of the boring bar 8, and the top of the slide body 2 is provided with There is a switch stopper 10, and a proximity switch 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com