Method for casting ductile iron casting of air-conditioning compressor

A technology for air-conditioning compressors and ductile iron, which is applied to casting molding equipment, casting molds, and casting mold components. The effect of slag defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

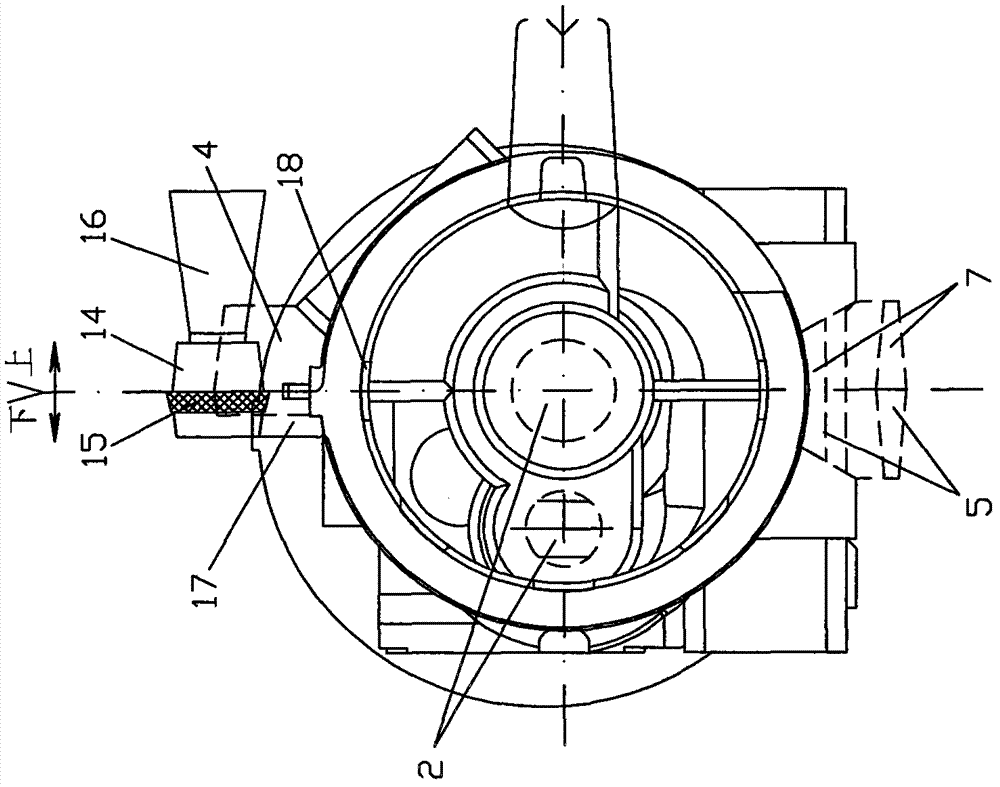

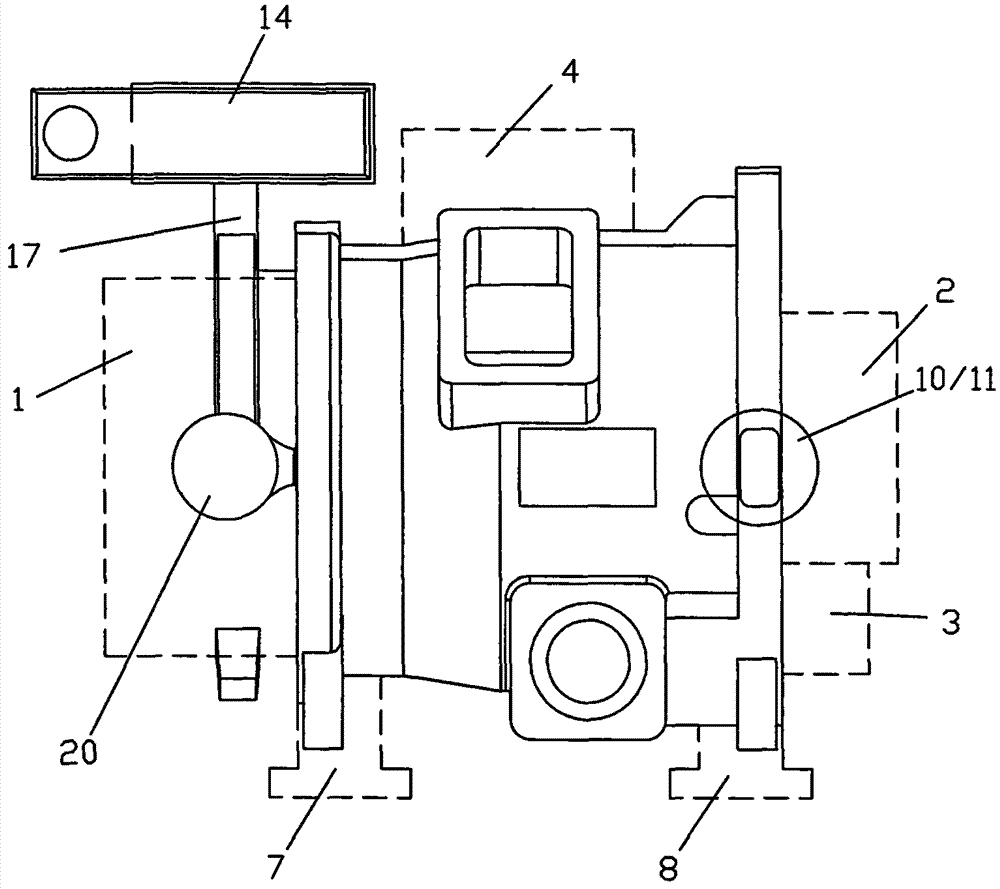

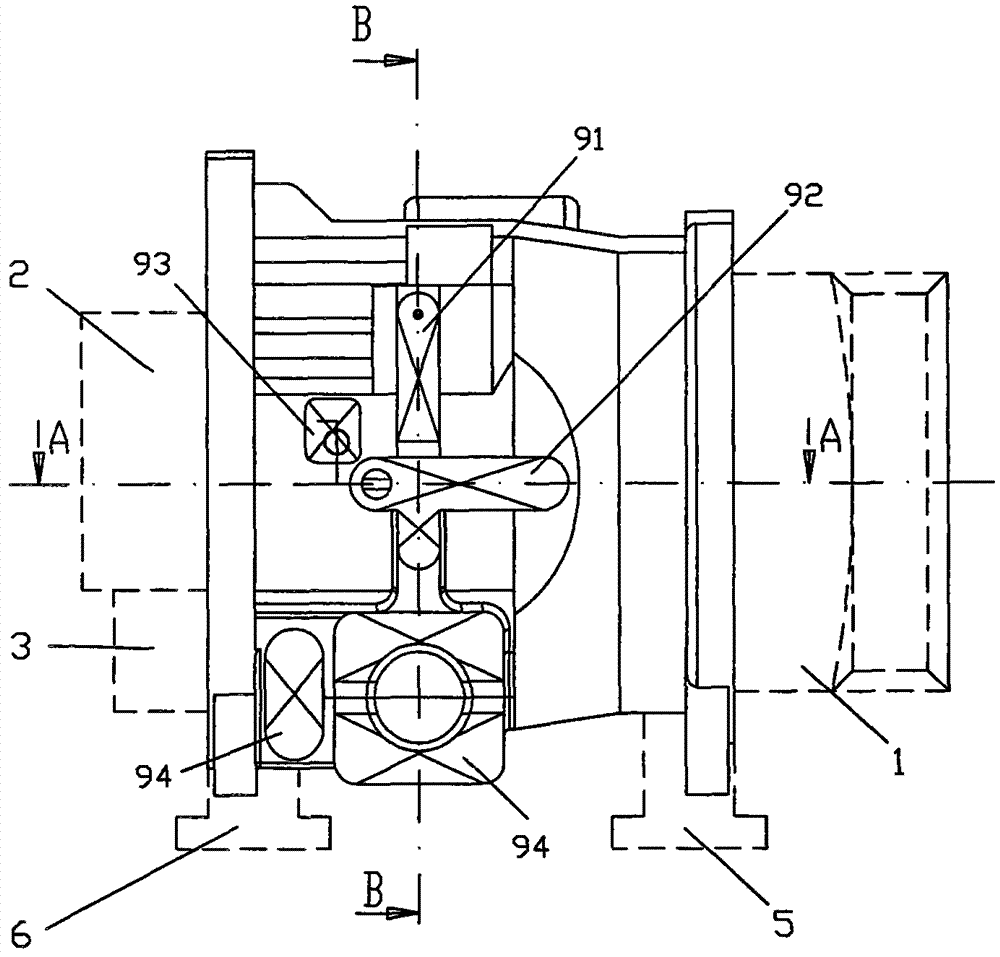

[0035] see Figure 1 to Figure 6 , the casting method of air conditioner compressor ductile iron body casting of the present invention, comprises the steps:

[0036] 1) Sand mixing, molding and core making

[0037] Air-conditioning and air-conditioning compressor ductile iron body castings use an automatic sand mixer to mix furan resin self-setting sand and then shape and manufacture the first to eighth sand cores 1 to 8.

[0038] Before molding, place 11 kinds of cold iron 9 (91~911) on the lower mold plate as required, and put sand for molding, place heat preservation riser 10 and exhaust piece 11 at the specified position of the upper mold, and then carry out sand filling, compaction, lifting Modeling, repairing, and brushing paint and drying the surface; then manufacturing the first to eighth sand cores 1 to 8, brushing paint and drying the surface and placing them for later use, among which the first sand core 1 and the second sand core are manufactured When the sand co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com