Novel casting mould structure for car brake disc

A technology of casting models and brake discs, which is applied in the field of auto parts, can solve problems such as low production efficiency, brake disc fracture under force, and poor safety in the braking process, so as to achieve high productivity, improve impact toughness, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

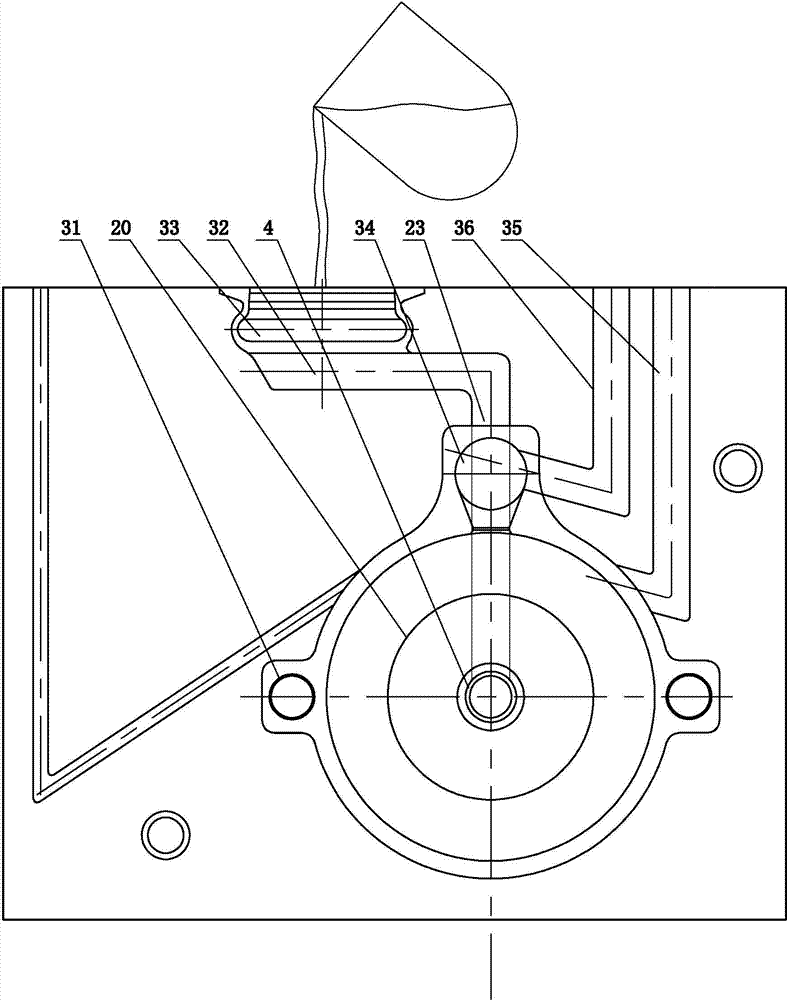

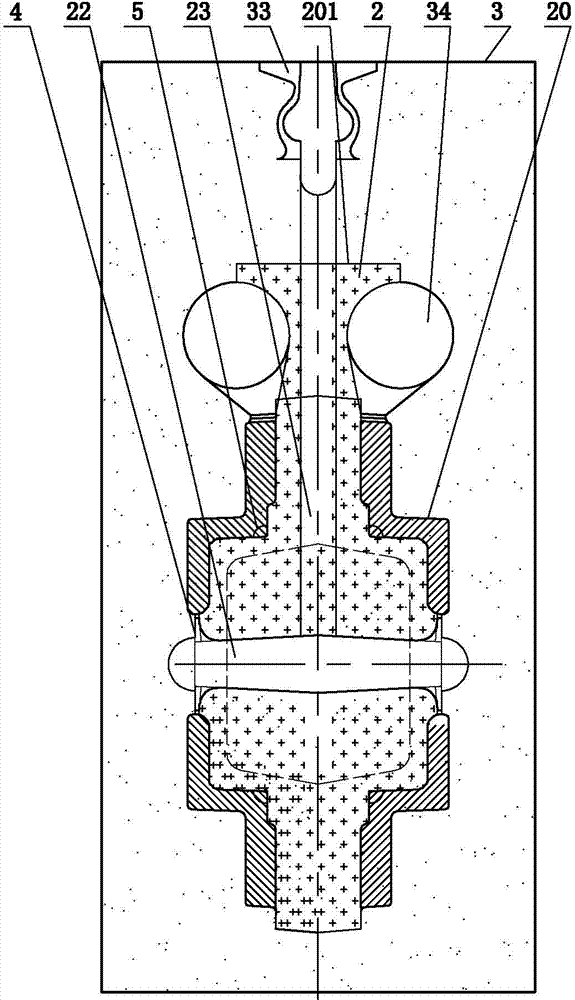

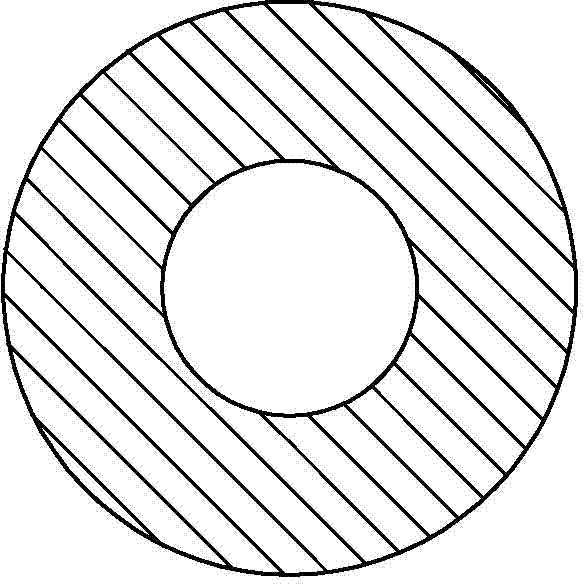

[0021] figure 1 is the structural diagram of sand core molding, figure 2 is a schematic diagram of the sand core, image 3 is the structural diagram of the rear brake disc, Figure 4 is a schematic diagram of the cold iron structure, Figure 5 is the schematic diagram of the microalloy vanishing ring, Image 6 It is a schematic diagram of a sand molding machine.

[0022] Such as Image 6 As shown, the working process of the sand molding machine 1 is to send the molding sand 12 into the sand bucket 11 of the sand molding machine 1 (the existing ordinary molding machines can be made, and the molding machine production line can continuously produce sand molds in large quantities, and the production efficiency is very high). Blow the molding sand 12 in the sand bucket 11 into the molding chamber 13, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com