Flow meter housing casting piece

A flowmeter and shell technology, which is applied in the directions of casting molds, casting mold components, casting molding equipment, etc., can solve the problems of poor quality of flowmeter shell castings, and achieve the effect of improving product quality and avoiding shrinkage defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

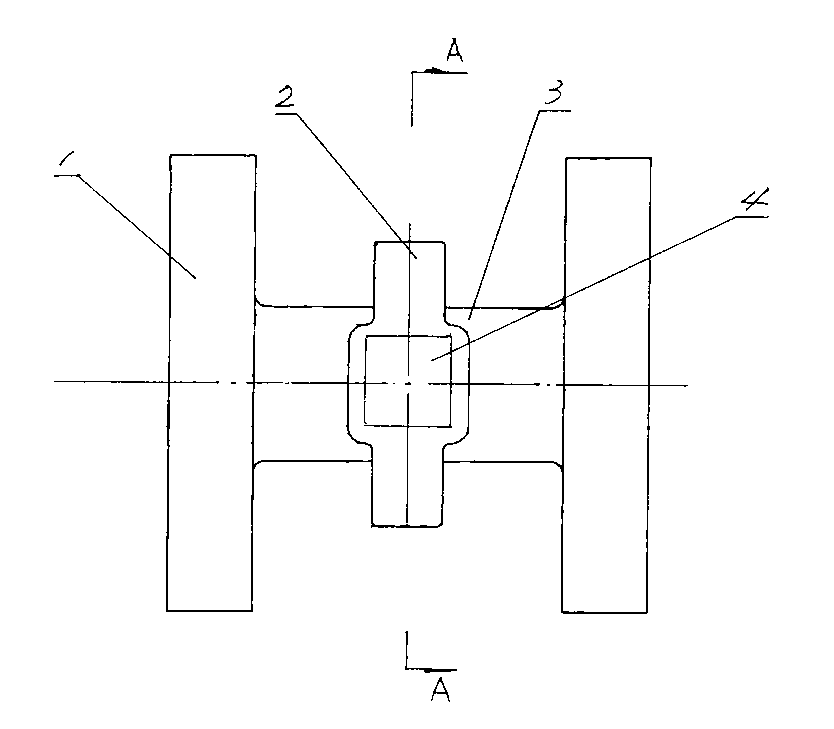

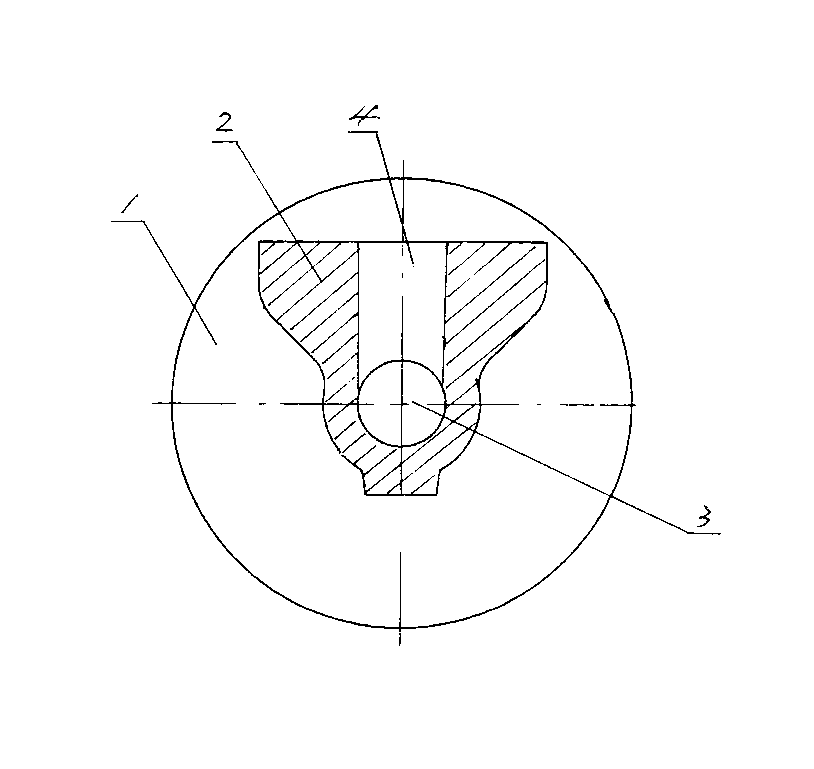

[0010] Such as figure 1 As shown, the casting of the flowmeter housing of the present invention includes a straight pipe 3, the two ends of the straight pipe 3 are cast with radial bosses 1, and the middle side of the straight pipe 3 is cast with a radial protrusion 2. During casting, a radial hole 4 for installing a flowmeter sensor is reserved on the radial projection 2 , and the radial hole 4 communicates with the inner cavity of the straight pipe 3 . Compared with the flowmeter casing castings in the background art, not only does it not need to process the sensor installation hole for installing the flowmeter after casting, which improves the processing efficiency, but also avoids the occurrence of shrinkage and porosity defects, so that the product quality is greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com